Microfluidic chip for capillary electrophoresis separation and chemiluminescence detection

A technology of chemiluminescence detection and capillary electrophoresis, which is applied in the field of micro-total analysis system, can solve the problems that affect the stability of electrophoretic separation and the reproducibility of results, the chemiluminescence detection method has not been widely used, and the analysis speed is slow. Lightweight, improved detection sensitivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

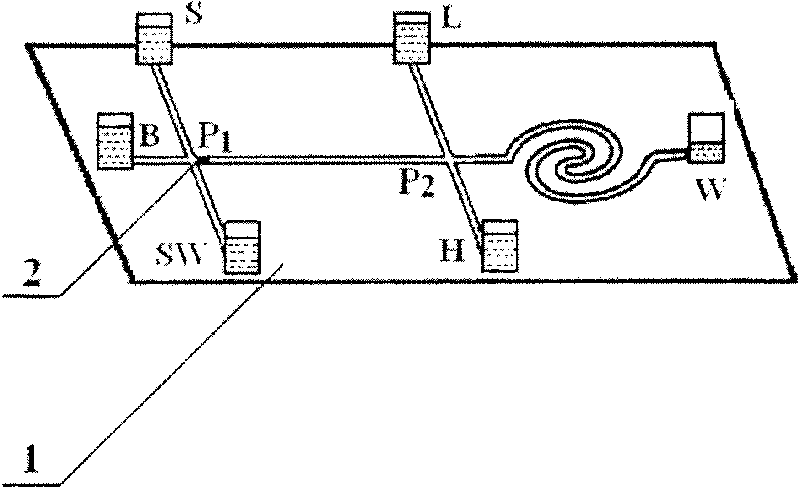

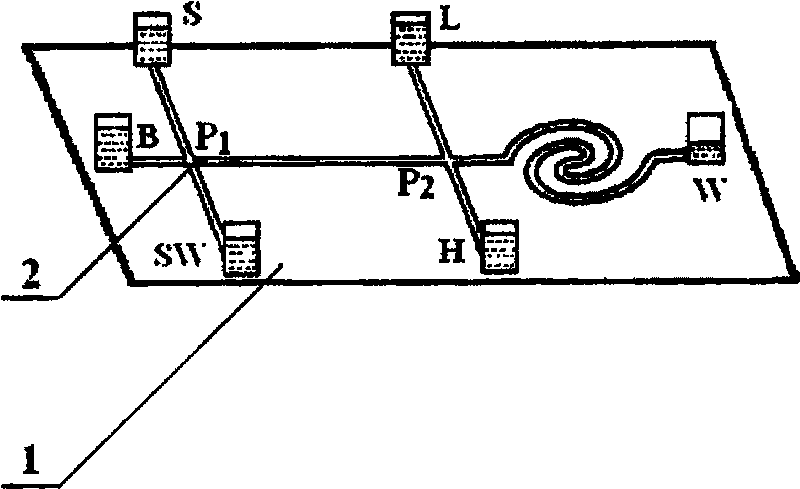

[0018] A microfluidic analysis chip integrating chip capillary electrophoresis separation and chemiluminescence detection. The chip is composed of a sample injection channel, a separation channel, a detection channel and a sheath flow channel. The sampling channel intersects with the separation channel, the terminal of the separation channel is connected with the starting point of the detection channel, and the sheath flow channel for passing the chemiluminescent reagent is also connected here as a branch pipe. The separation channel between the injection channel and the detection channel is an effective separation channel. Fabricate microporous plugs in active separation channels. The sample to be analyzed can enter the separation channel for electrophoretic separation driven by electroosmotic flow; while the luminescence reagent driven by pressure difference will not flow back into the separation channel.

[0019] see figure 1 , the microfluidic chip 1 has a buffer solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com