Combination method for hydrocracking of coal tar whole-fraction suspended bed and hydro-upgrading of fixed bed

A hydrocracking and hydro-upgrading technology, which is applied in hydroprocessing process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problem of low utilization rate of coal tar, incomplete utilization of coal tar, reduction of catalyst activity and service life, etc. problems, to achieve the effect of large promotion and application prospects, good product properties, and less coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of oil-soluble metal catalyst:

[0032] Get 10g molybdenum metal mass fraction and be 3.0% molybdenum naphthenate and 10g nickel metal mass fraction be the nickel naphthenate of 7.0%, mix and make oil-soluble liquid catalyst, the total mass of molybdenum metal and nickel metal accounts for catalyst mass in this catalyst of 5.0%.

[0033] (2) The preparation method of vulcanizing agent is:

[0034] Just take 2g elemental sulfur.

[0035] (3) the preparation method of coke inhibitor is:

[0036] Take 3g of cetyltrimethylammonium bromide and 2g of oleic acid, and mix them to obtain a coke inhibitor.

[0037] (4) The prepared oil-soluble liquid catalyst, vulcanizing agent and coke inhibitor are directly mixed.

[0038] Under the condition of 50-80°C, directly mix the oil-soluble metal catalyst, vulcanizing agent and coke suppressor to obtain the soluble compounding agent.

[0039] The mass ratio of the total metal mass, sulfur element mass and coke inhibi...

Embodiment 2

[0041] (1) Preparation of oil-soluble metal catalyst:

[0042] Get 10g molybdenum metal mass fraction and be 3.0% molybdenum naphthenate and 10g nickel metal mass fraction be the nickel naphthenate of 7.0%, 5g cobalt metal mass fraction 4%, mix and make oil-soluble liquid catalyst, in this catalyst, molybdenum metal The total mass of nickel metal and cobalt metal accounts for 4.2% of the mass of the catalyst.

[0043] (2) The preparation method of vulcanizing agent is:

[0044] Just take 5g elemental sulfur.

[0045] (3) the preparation method of coke inhibitor is:

[0046] Take 3g of sodium dodecyl sulfonate, 2g of oleic acid and 2g of coco fatty amine, and mix them to obtain a coke inhibitor.

[0047] (4) The prepared oil-soluble liquid catalyst, vulcanizing agent and coke inhibitor are directly mixed.

[0048] Under the condition of 50-80°C, directly mix the oil-soluble metal catalyst, vulcanizing agent and coke suppressor to obtain the soluble compounding agent.

[00...

Embodiment 3

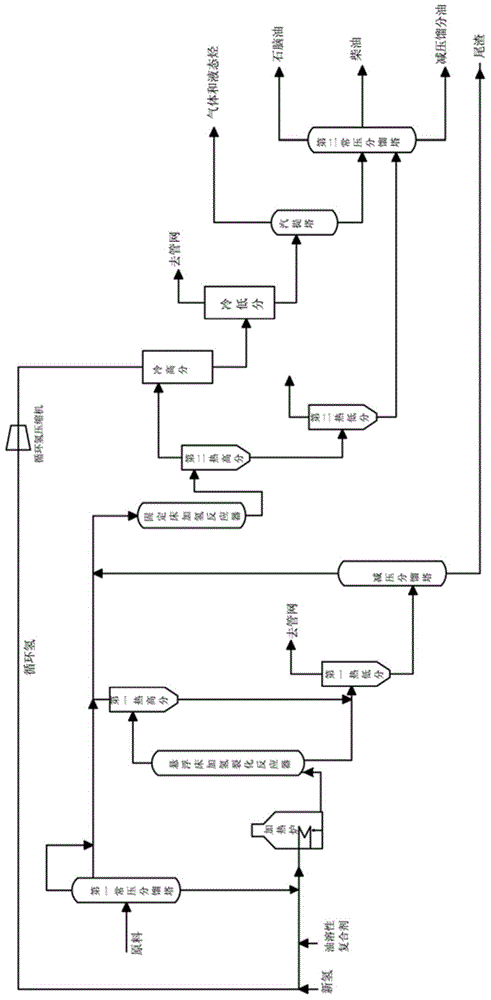

[0052] Such as figure 1 Shown, a kind of coal tar full-fraction suspension bed hydrocracking and fixed bed hydrogenation upgrading combined method, comprises the following steps:

[0053] (1) The raw material is carried out atmospheric shunt through the first atmospheric fractionation tower, obtains naphtha fraction, diesel oil fraction and atmospheric residue, and the oil-soluble composite agent prepared by atmospheric residue and embodiment 1 passes through multi-stage buffer tank Mixing with a multi-stage static mixer, this mixing method can ensure that a small amount of compounding agent is evenly dispersed in a large amount of raw materials. The mixture is then mixed with fresh hydrogen and circulating hydrogen and enters the heating furnace. After being heated by the heating furnace to 425-455°C, it enters the suspension bed hydrocracking reactor from the bottom. Under the conditions of reaction pressure 10-20MPa and reaction temperature 420-450°C carry out hydrocrackin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com