Protective agent of coal tar hydrogenation catalyst and preparation method of protective agent

A hydrogenation catalyst and coal tar technology, which is applied in the direction of catalyst protection, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of cumbersome process, achieve simple process, improve demetallization activity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

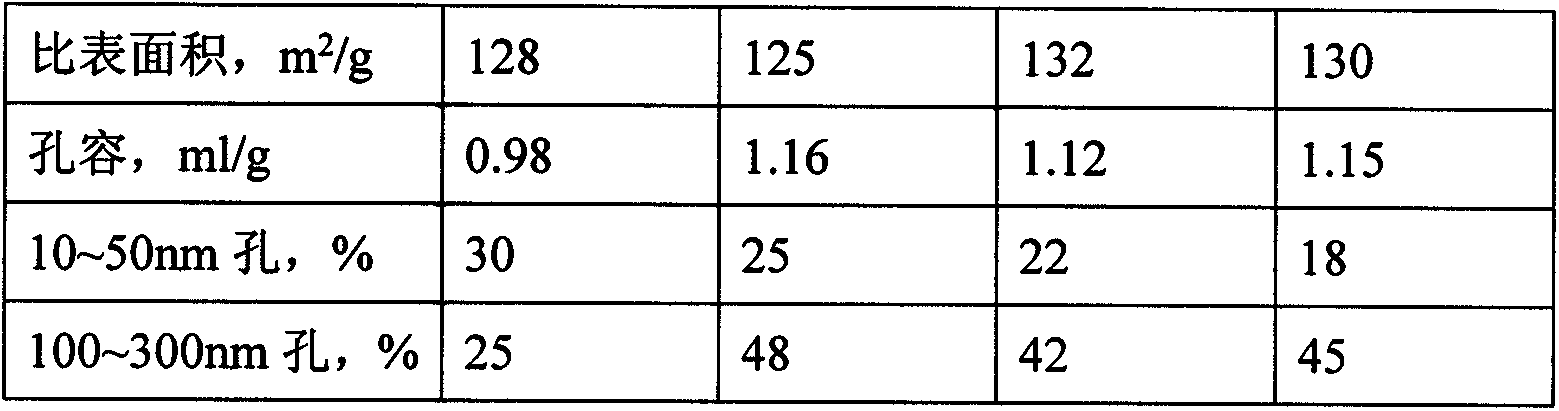

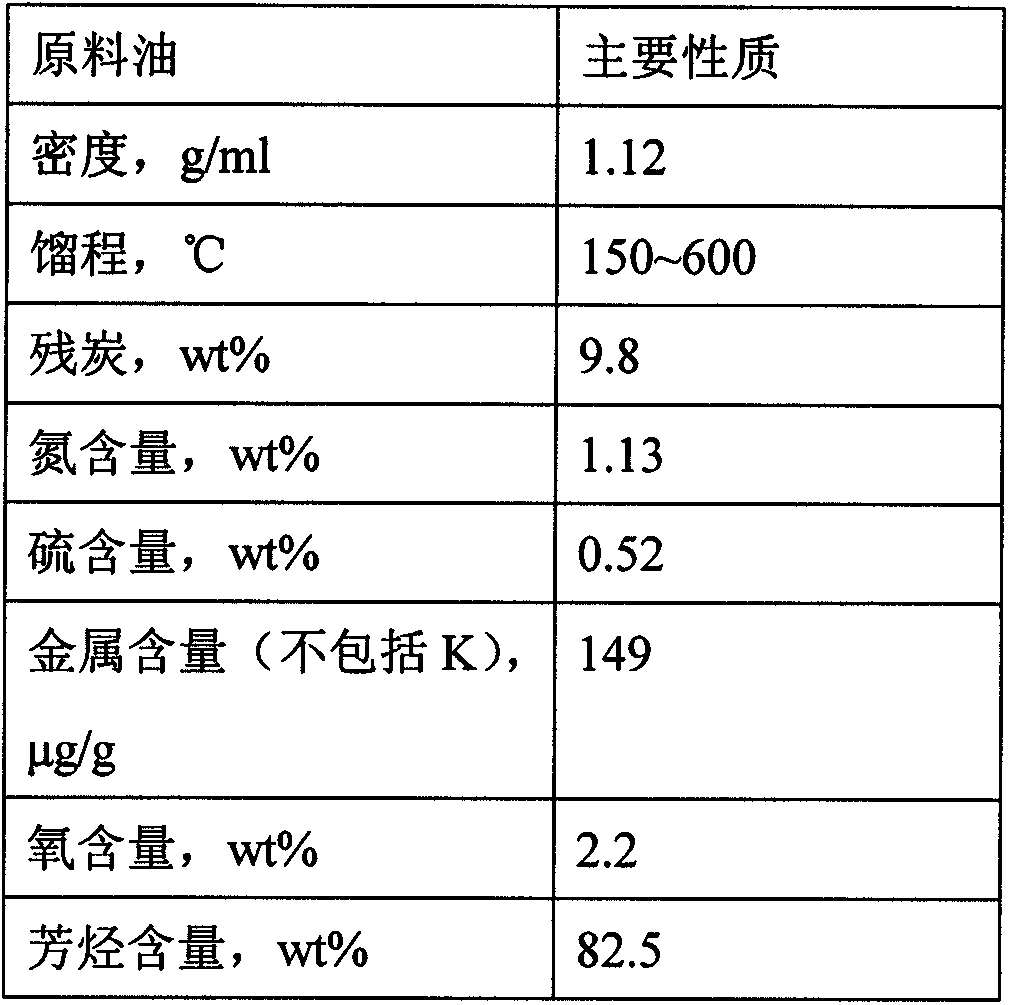

Embodiment 1

[0027] Take the calculated amount of pseudo-boehmite and zirconium nitrate and mix evenly, add nitric acid accounting for 1% of the total solid mass, 1% of activated carbon with a particle size of 600 mesh, 10% of polystyrene balls with a particle size of 100 mesh, and 1% of cinnamon Powder, and a small amount of water, kneaded evenly and extruded into a four-leaf clover shape, the molded carrier was dried in an oven at 120°C for 8 hours, and baked in a muffle furnace at 800°C for 8 hours to obtain the protective agent carrier of the present invention.

[0028] Take the calculated amount of ammonium molybdate, ammonium tungstate, phosphoric acid, and potassium nitrate to make a solution, impregnate the carrier prepared above for 4 hours, dry in an oven at 120°C for 12 hours, and roast in a muffle furnace at 500°C for 6 hours to obtain the final Protective agent C1 for coal tar hydrogenation catalyst.

Embodiment 2

[0030] Take the calculated amount of pseudo-boehmite and zirconium nitrate and mix evenly, add nitric acid accounting for 1% of the total solid mass, 1% of activated carbon with a particle size of 600 mesh, 25% of polystyrene balls with a particle size of 100 mesh, and 1% of the Powder, and a small amount of water, kneaded evenly and extruded into a four-leaf clover shape, the molded carrier was dried in an oven at 120°C for 8 hours, and baked in a muffle furnace at 800°C for 8 hours to obtain the protective agent carrier of the present invention.

[0031] Take the calculated amount of ammonium molybdate, ammonium tungstate, phosphoric acid, and potassium carbonate to form a solution, impregnate the carrier prepared above for 6 hours, dry it in an oven at 120°C for 12 hours, and roast it in a muffle furnace at 500°C for 6 hours to obtain the final Protective agent C2 for coal tar hydrogenation catalyst.

Embodiment 3

[0033] Take the calculated amount of pseudo-boehmite and zirconia and mix evenly, add nitric acid accounting for 1% of the total solid mass, 3% of activated carbon with a particle diameter of 500 mesh, 25% of polymethylmethacrylate microspheres with a particle diameter of 100 mesh, 1 % of scallop powder, and a small amount of water, knead evenly and extrude into the shape of a four-leaf clover. The formed carrier is dried in an oven at 120°C for 8 hours, and roasted in a muffle furnace at 800°C for 8 hours to obtain the protection of the present invention. agent carrier.

[0034] Take the calculated amount of ammonium molybdate, nickel nitrate, ammonium dihydrogen phosphate, and potassium nitrate to form a solution, impregnate the carrier prepared above for 4 hours, dry it in an oven at 120°C for 12 hours, and bake it in a muffle furnace at 500°C for 6 hours. Obtain the protective agent C3 of the final coal tar hydrogenation catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com