Processes for catalytic conversion of lignin to liquid bio-fuels

A biofuel and lignin technology, applied in the field of product conversion, can solve problems such as easy blockage, excessive catalyst coking, and reduced process reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

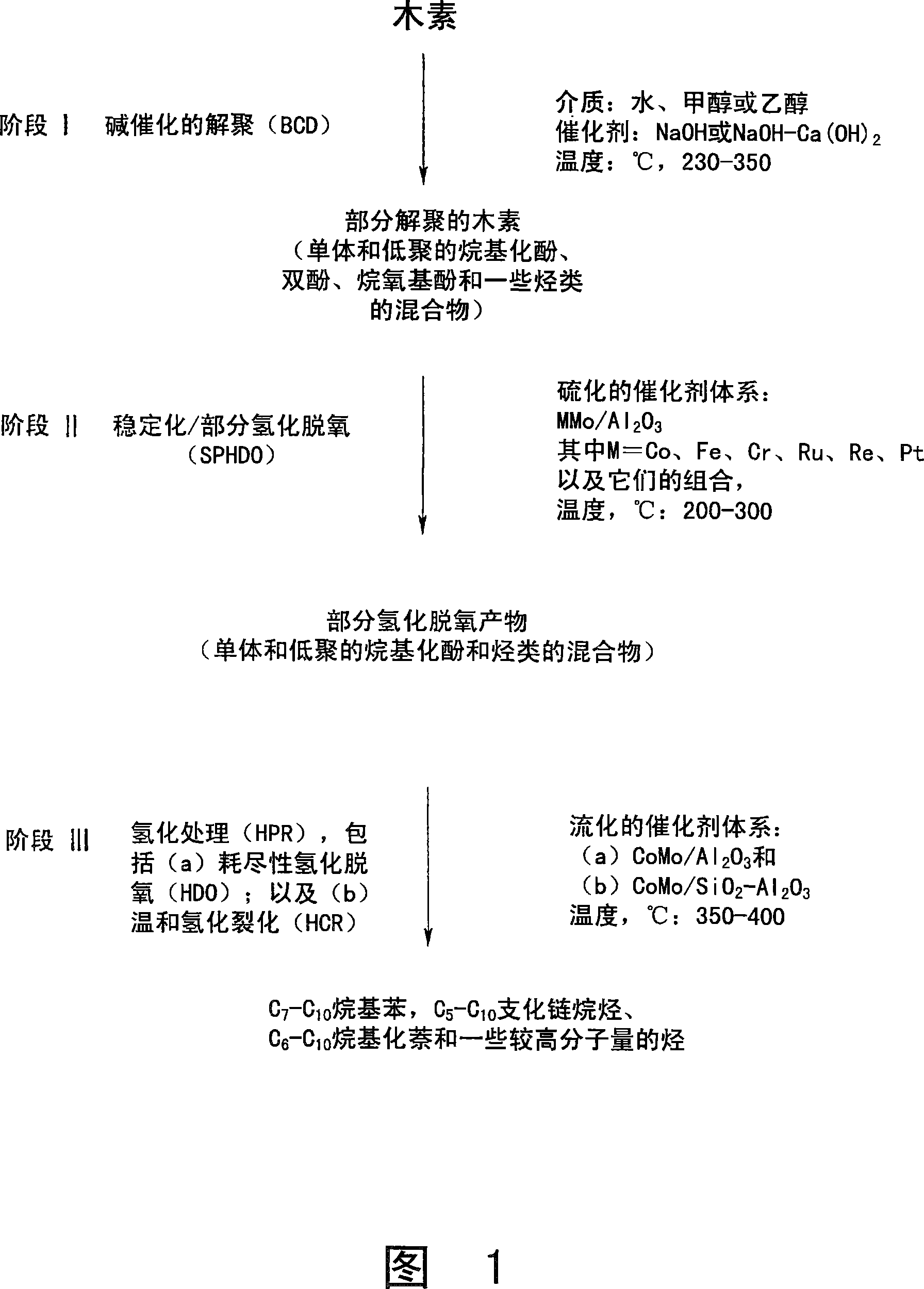

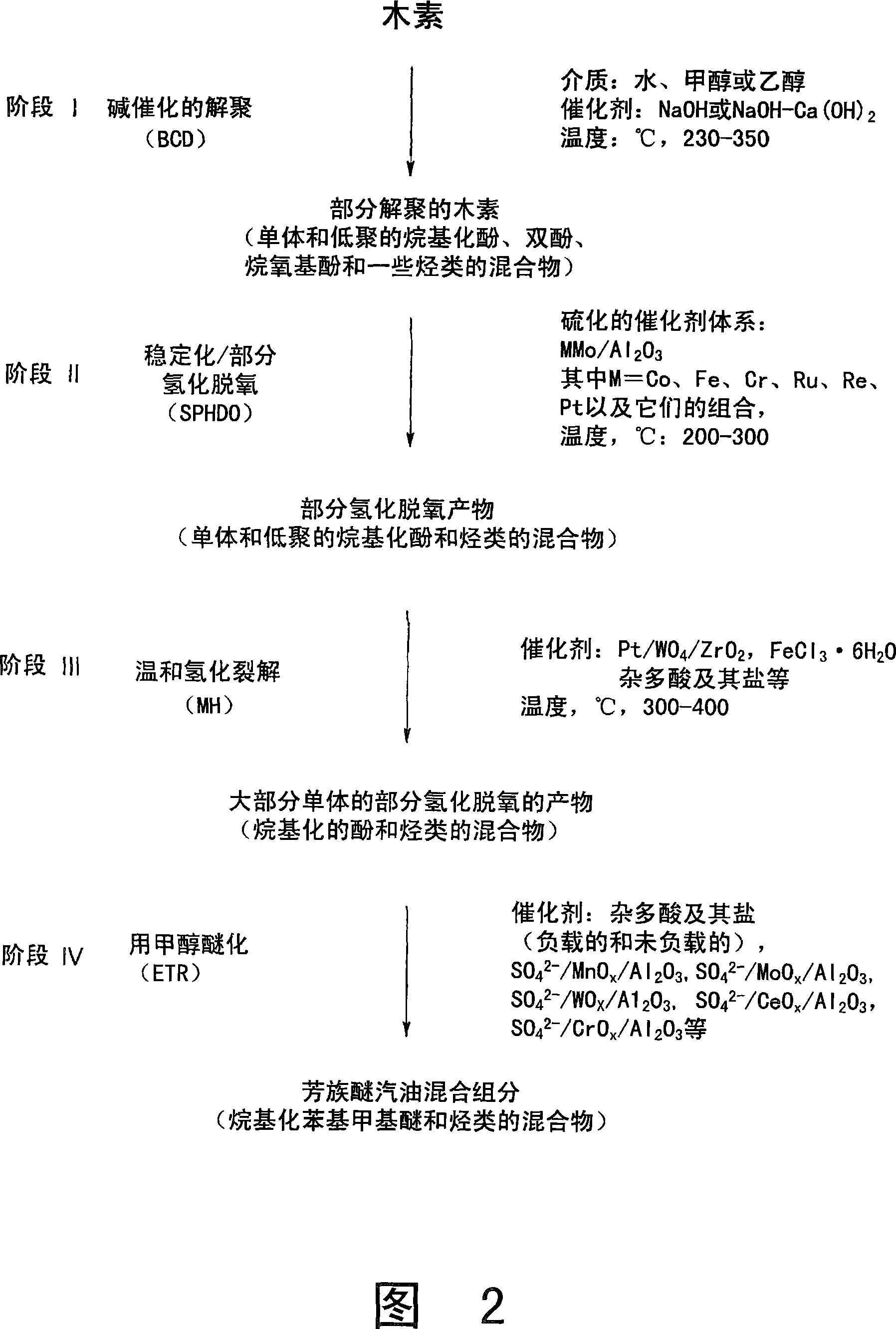

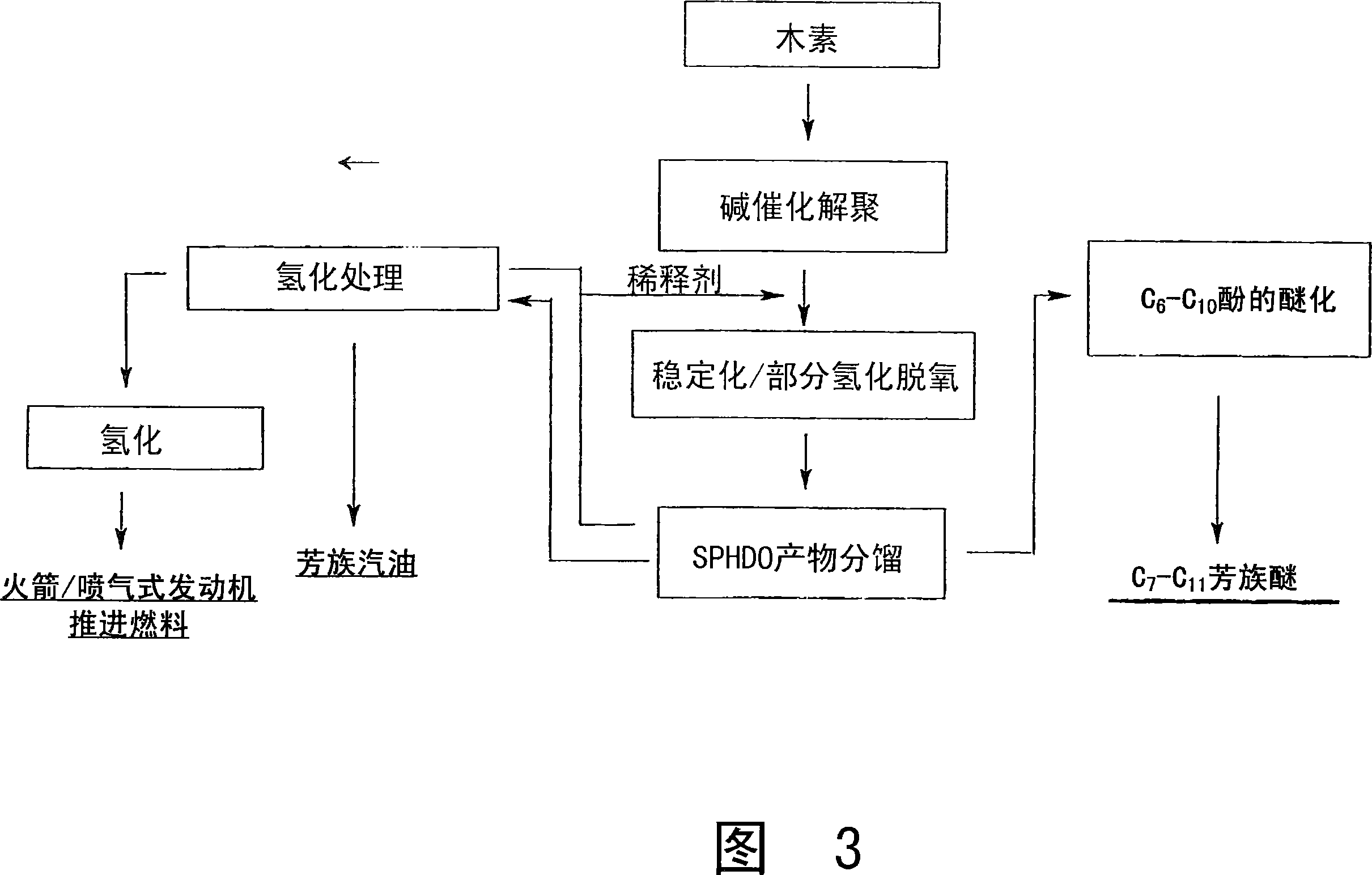

Method used

Image

Examples

Embodiment Construction

[0029] Detailed description of the preferred embodiment

[0030] Before specific embodiments of the present invention are disclosed and described, it is to be understood that this invention is not limited to the particular methodology and materials disclosed herein as such methods and materials may vary to some extent. It should also be understood that the terminology used herein is for describing particular embodiments only and is not intended to be limiting, the scope of the present invention being defined only by the appended claims and their equivalents.

[0031] In describing and claiming the present invention, the following terms are used.

[0032] The singular forms "a", "an" and "this / the / this" include plural forms unless the context clearly dictates otherwise. Thus, for example, reference to "a step" includes one or more of such steps.

[0033] As used herein, "reaction" includes single-step reactions and multi-step reactions, which may be direct reactions from reacta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com