Method for preparing multiwalled carbon nanotube through microwave enhanced fast pyrolysis of biomass and/or carbonaceous organic waste

A technology of multi-walled carbon nanotubes and organic wastes, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, which can solve the problem that catalysts cannot be reused, unfavorable for carbon nanotube modification, and increasing complexity. degree and other problems, to achieve the effect of reducing the preparation cost, increasing the yield and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

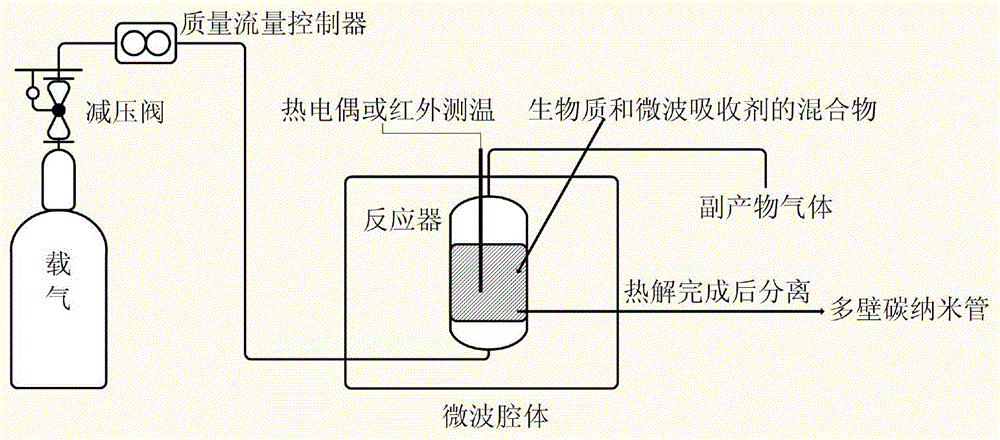

Method used

Image

Examples

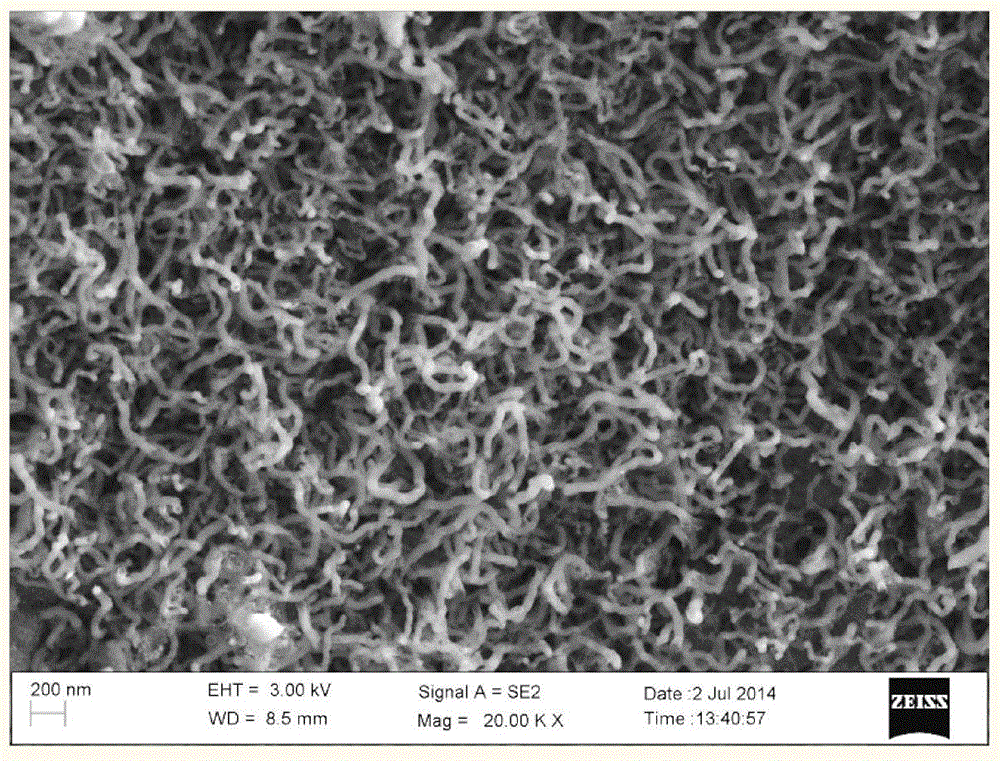

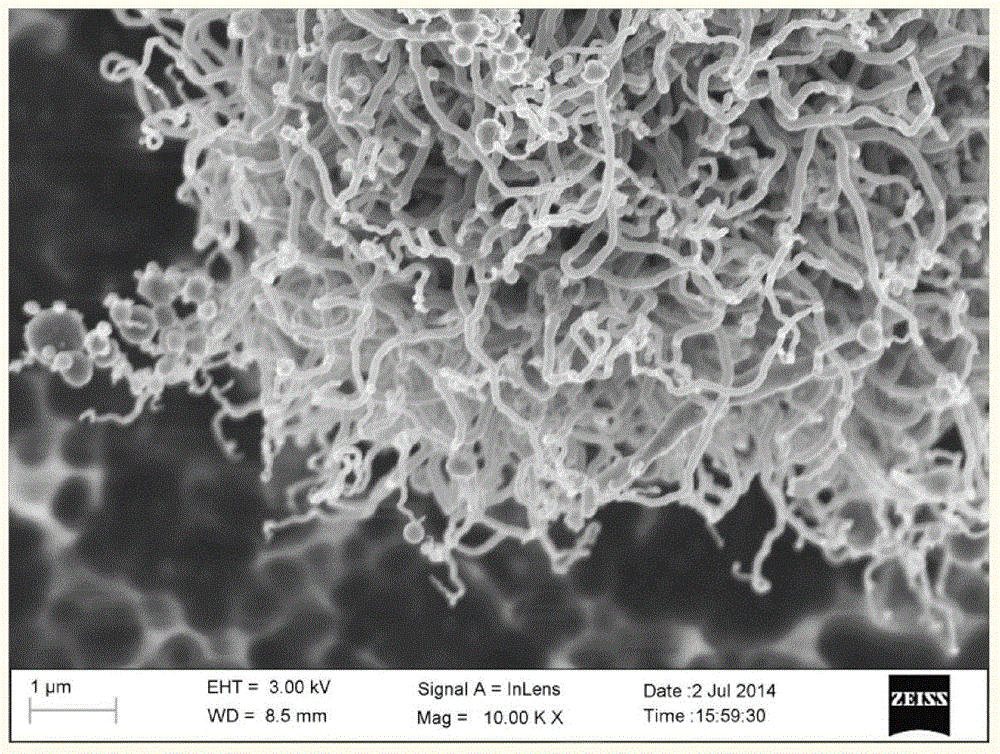

Embodiment 1

[0037] After uniformly mixing 500g of dry eucalyptus powder and 500g of microwave absorber CuO (in a microwave electromagnetic field, a heating rate of 161.9°C / min can be achieved), add a closed and N 2 Carrier gas in the quartz reactor, and then place the entire quartz reactor in a 3kw / 2450MHz multimode microwave cavity; adjust N 2 The flow rate (1L / min) was purged for 30 minutes to ensure that there was no oxygen in the reactor; turn on the microwave, set the reaction temperature to 800°C in temperature control mode, and adjust the microwave input power to 2kw to keep the reaction temperature in the reactor constant at 800°C ℃, pyrolysis for 20 minutes, so that the eucalyptus powder is fully decomposed; turn off the microwave, and after the reactor is naturally cooled to room temperature, turn off the N 2 , take out the mixture of eucalyptus pyrolysis residual charcoal and microwave absorber; according to the density difference of eucalyptus pyrolysis residual charcoal and C...

Embodiment 2

[0039] Mix 50g dry pine wood particles with 500g microwave absorber Fe 3 o 4 (A heating rate of 457.5°C / min can be achieved in a microwave electromagnetic field) After uniform mixing, put it into a sealed quartz reactor with Ar carrier gas, and then place the entire quartz reactor in a 3kw / 2450MHz multimode microwave cavity; Adjust the Ar flow rate to 200ml / min, and purge for 30 minutes to ensure that there is no oxygen in the reactor; turn on the microwave, use the temperature control mode to set the reaction temperature to 1000°C, and adjust the microwave power input to 3kw to make the reaction temperature in the reactor Keep at 1000°C, pyrolyze for 2 minutes to fully decompose the eucalyptus powder; turn off the microwave, and after the reactor cools down to room temperature naturally, turn off the Ar, take out the mixture of eucalyptus pyrolysis residual charcoal and microwave absorbent; according to the eucalyptus thermal Residual charcoal and Fe 3 o 4 The densities ar...

Embodiment 3

[0041] 50g dry beech wood powder (particle size600 microns, which can achieve a heating rate of 232.3°C / min in a microwave electromagnetic field) were evenly mixed and then added into a sealed and ventilated He carried the gas in the quartz reactor, and then placed the entire quartz reactor in a 10kw / 2450MHz single-mode microwave cavity; adjusted the He flow rate to 500ml / min, and purged for 10 minutes to ensure that there was no oxygen in the reactor; turned on the microwave , use the temperature control mode to set the reaction temperature to 600°C, adjust the microwave power input power to 10kw, keep the reaction temperature in the reactor constant at 600°C, and pyrolyze for 1 minute to fully decompose the beech wood powder; turn off the microwave and wait for the reactor to After naturally cooling to room temperature, close the He, and take out the mixture of beech wood pyrolysis residual carbon and Co powder; Powder particle size>600 microns), sieve and separate to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com