Method and device for utilizing high value through pyrolysis and gasification of coal

A technology for pyrolysis gas and coal gasification, which is used in the gasification of granular/powdered fuels, mitigation of combined combustion, and the manufacture of combustible gases. Coal C, H structure resources and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

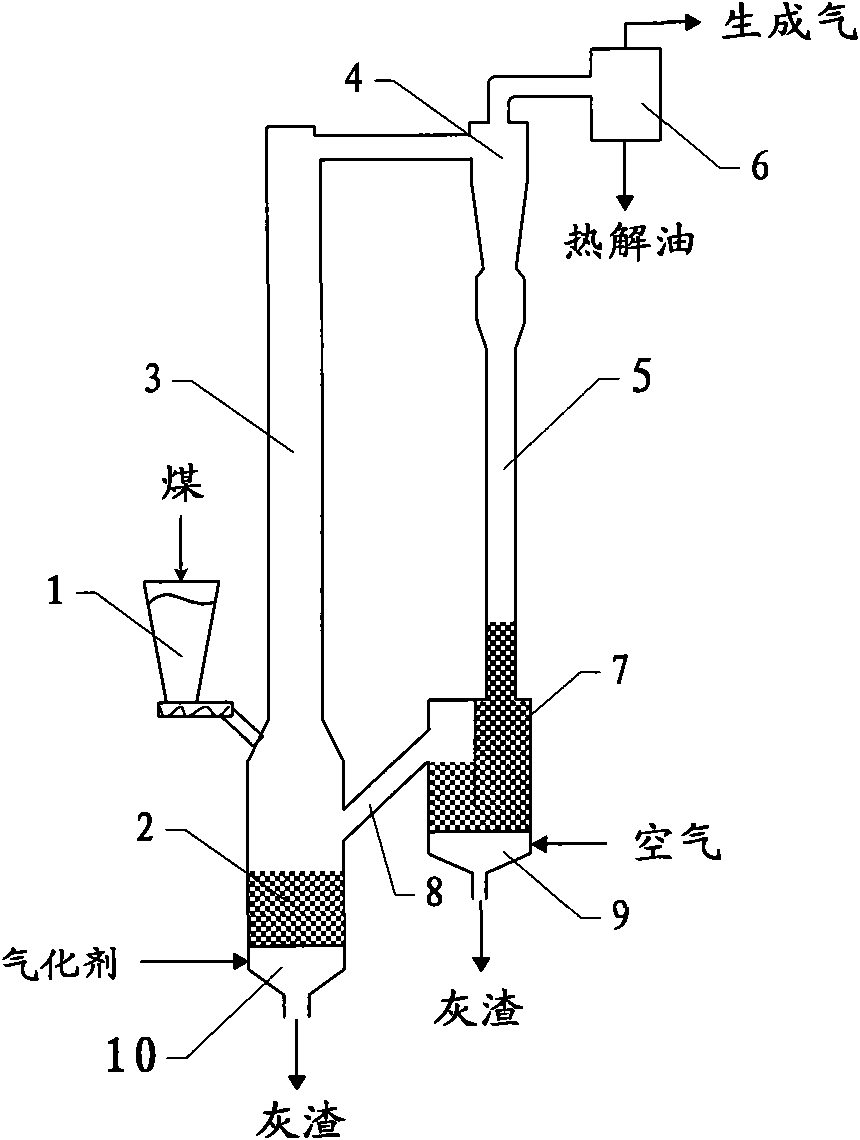

[0083] The dilute-phase conveying bed and dense-phase fluidized bed in this embodiment are a coal pyrolysis gasification process system coupled up and down, such as figure 1 As shown, it includes: feed system 1, dense-phase fluidized bed 2, dilute-phase conveying bed 3, separation equipment (cyclone separator 4 and pyrolysis oil separator 6), return valve 7 and down riser 5.

[0084] In this process flow, the raw coal is fed from the lower part of the dilute-phase conveying bed 3 through the first feeding system 1, and the large-sized coal with a particle size of 3-25 mm in the raw coal enters the dense phase below the dilute-phase conveying bed 3 downwards. In the fluidized bed 2, partial combustion and gasification occurs under the action of one or more gases of air, oxygen, water vapor, oxygen-containing carbon dioxide and methane fed into the dense-phase fluidized bed air chamber 10, relying on Part of the heat generated by coal combustion is gasified in the range of 500-1...

Embodiment 2

[0086] The dilute-phase conveying bed and the dense-phase fluidized bed in this embodiment are coal pyrolysis and gasification process systems coupled left and right, such as figure 2 Shown, comprise: feed system (the first feed system 1 and the second feed system 17), dense-phase fluidized bed 2, dilute-phase conveying bed 3, separation equipment (cyclone separator 4 and heat produced during low temperature Oil separation separator 6), distribution valve 13 and down riser 5.

[0087] In this process flow, the raw coal is fed into the dense-phase fluidized bed 2 through the first feed system 1, and the hot ash and / or The incompletely gasified semi-coke is mixed and fluidized and heated, and pyrolyzed in the temperature range of 300-1100°C, and the pyrolysis gas products (including pyrolysis gas and pyrolysis oil (pyrolysis temperature lower than 800°C) will be produced)) from the upper part of the dense-phase fluidized bed 2 into the pyrolysis oil separator 6 to be separated...

Embodiment 3

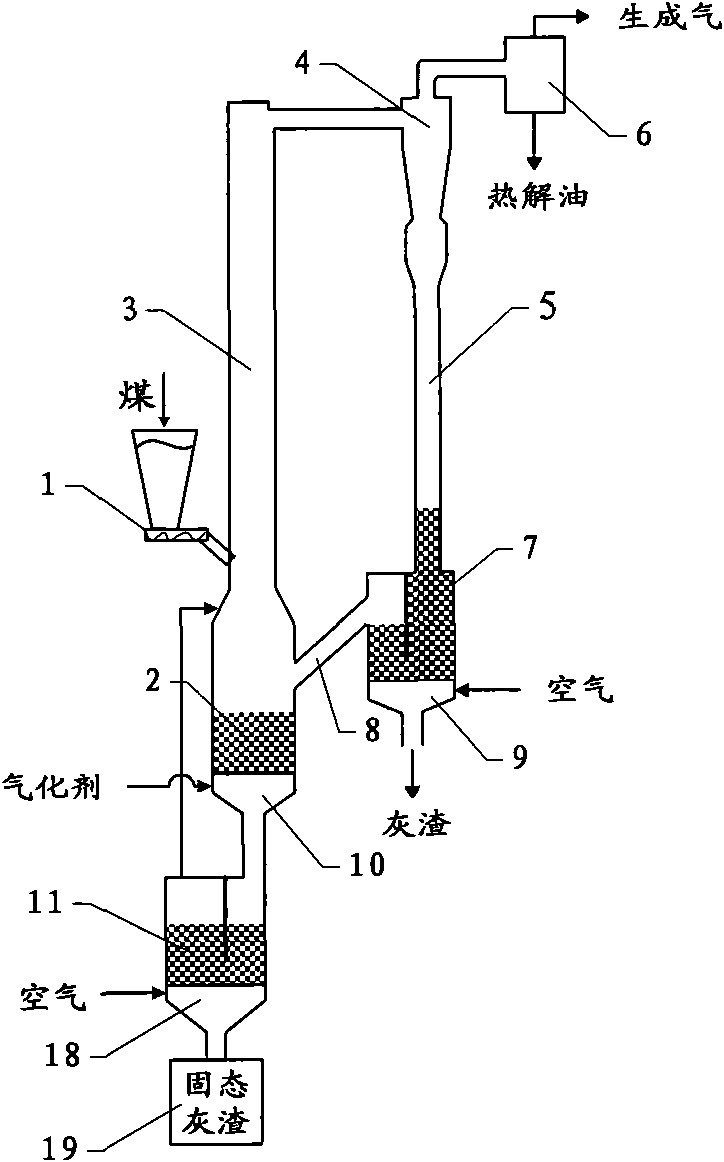

[0091] In this embodiment, a coal pyrolysis gasification process system that uses a dilute-phase conveying bed that further burns out ash and a dense-phase fluidized bed is coupled up and down, such as image 3 As shown, it includes: feed system 1, dense-phase fluidized bed 2, dilute-phase conveying bed 3, separation equipment (cyclone separator 4 and pyrolysis oil separator 6), return valve 7, down riser 5, ash The slag burns out the fluidized bed 11 and the solid slag removal device 20 .

[0092] In this process flow, the raw coal is fed from the lower part of the dilute-phase conveying bed 3 through the first feeding system 1, and the large-sized coal with a particle size of 3-25 mm in the raw coal enters the dense phase below the dilute-phase conveying bed 3 downwards. In the fluidized bed 2, partial combustion and gasification occurs under the action of one or more gases of air, oxygen, water vapor, oxygen-containing carbon dioxide and methane fed into the dense-phase flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com