Chain type ultrasonic full-automatic cleaning device for stainless steel tableware

A fully automatic cleaning and ultrasonic technology, applied to cleaning equipment, tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, etc., can solve the problems of failing to meet disinfection requirements, lower cleaning efficiency, and poor cleaning quality and other issues to achieve the effect of simplifying equipment, saving energy, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

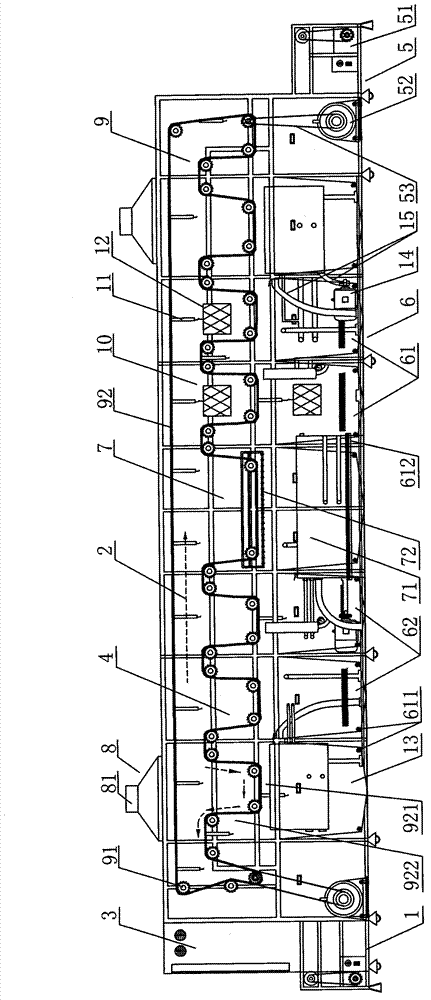

[0016] Such as figure 1 As shown, a chain-type ultrasonic automatic cleaning equipment includes a base 1 and a cleaning production line 2 arranged on the base 1. The cleaning production line 2 includes an electric control part 3, a conveying mechanism 4, a power mechanism 5, an ultrasonic cleaning part 6, The spraying part 7 and the drying part 8, the power mechanism 5 and the conveying mechanism 4 are connected by transmission, and the ultrasonic cleaning part 6 is composed of an ultrasonic rough cleaning tank 61 and an ultrasonic fine cleaning tank 62 with a heating tube 611 and an ultrasonic vibrating plate 612 . The shower part 7 is composed of a shower chamber 71 and a shower pipe 72 arranged in the shower chamber 71 . The conveying mechanism 4 is composed of ultrasonic coarse cleaning tank 61 and ultrasonic fine cleaning tank 62, spray ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com