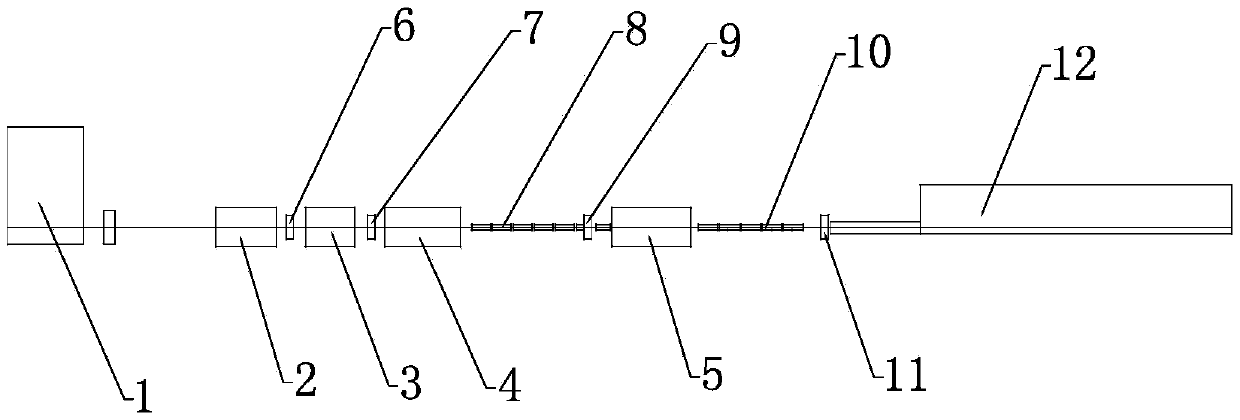

Low-temperature control rolling and splitting process method and device for ribbed steel bars

A ribbed steel bar, low temperature controlled rolling technology, applied in workpiece cooling devices, temperature control, manufacturing tools, etc., can solve problems that have not yet been disclosed, and achieve the effects of reducing economic and social benefits, stable production, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

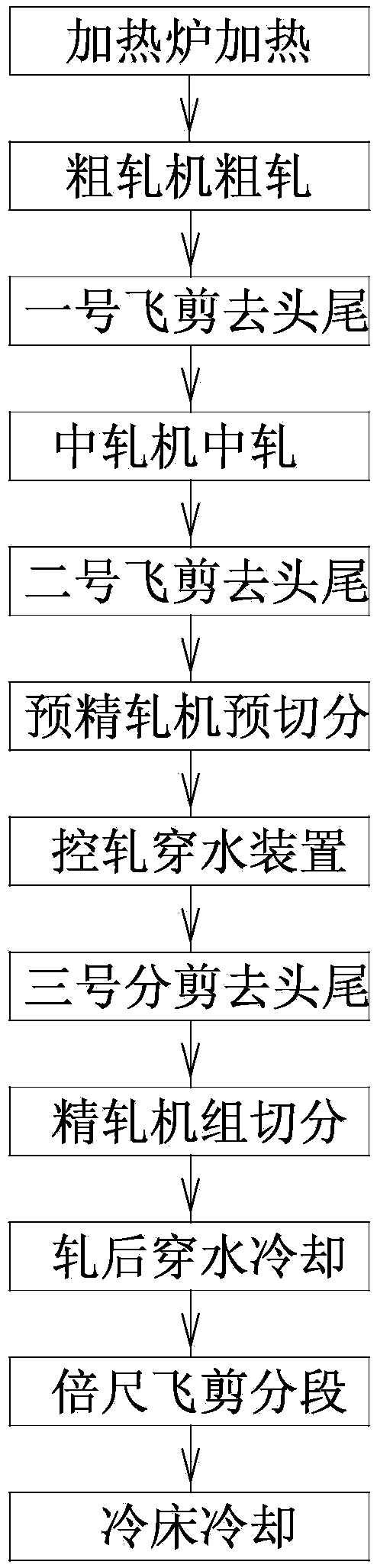

[0022] Such as figure 2 As shown, the Φ12 ribbed steel bar adopts the process method of five-segment low-temperature controlled rolling, and the following steps are taken:

[0023] (1) Select a square billet with a certain length of 165mm×165mm in height×width as a billet, and heat it to 960-1000°C in a heating furnace;

[0024] (2) Send the steel billet heated in step (1) into six rolling mills of the roughing rolling mill for rolling. into Φ71 round bars;

[0025] (3) The round bars rolled out in step (2) are sent to the 4th rolling mill of the middle rolling group for rolling after No. 1 flying shear head and tail. The pass system of the 4 middle rolling mills is ellipse-circle Hole-flat roll-flat roll, rolled into a rectangular bar with a size of 17.9±0.5mm×89±0.5mm;

[0026] (4) After the rectangular bar rolled in step (3) is cut head and tail by No. 2, it is sent to the 2 rolling mills of the pre-finishing rolling mill for pre-segmentation. The pass of the pre-finish...

Embodiment 2

[0032] Such as figure 2 As shown, the Φ18 ribbed steel bar adopts the process method of three-cut low-temperature controlled rolling, and the following steps are taken:

[0033] (1) Select a square billet with a certain length of 165mm×165mm in height×width as a billet, and heat it to 960-1000°C in a heating furnace;

[0034] (2) Send the steel billet heated in step (1) into six rolling mills of the roughing rolling mill for rolling. into Φ71 round bars;

[0035] (3) The round bar rolled out in step (2) is sent to the middle rolling mill for rolling with the 3rd rolling mill after the No. 1 flying shear head and tail. The pass system of the 3rd middle rolling mill is ellipse-circular Hole-flat roll, rolled into a rectangular bar with a size of 25.6±0.5×72±0.5mm;

[0036] (4) After the rectangular bar rolled in step (3) is cut head and tail by No. 2, it is sent to the 2 rolling mills of the pre-finishing rolling mill for pre-segmentation. The pass of the pre-finishing rolli...

Embodiment 3

[0042] Such as figure 2 As shown, the Φ25 ribbed steel bar adopts the process method of two-cut low-temperature controlled rolling, including the following steps:

[0043] (1) Select a square billet with a certain length of 165mm×165mm in height×width as a billet, and heat it to 960-1000°C in a heating furnace;

[0044] (2) Send the steel billet heated in step (1) into six rolling mills of the roughing rolling mill for rolling. into Φ71 round bars;

[0045](3) The round bar rolled out in step (2) is sent to the middle rolling mill for rolling with the 3rd rolling mill after the No. 1 flying shear head and tail. The pass system of the 3rd middle rolling mill is ellipse-circular Hole-flat roll, rolled into a rectangular bar with a size of 34.5±0.5mm×70±0.5mm;

[0046] (4) After the rectangular bar rolled in step (3) is cut head and tail by No. 2, it is sent to the 2 rolling mills of the pre-finishing rolling mill for pre-segmentation. The pass of the pre-finishing rolling mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com