A kind of measuring device and method of thin film thermoelectric performance parameters

A technology for measuring device and thermoelectric performance, which is applied in the direction of measuring device, measuring electrical variables, measuring resistance/reactance/impedance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

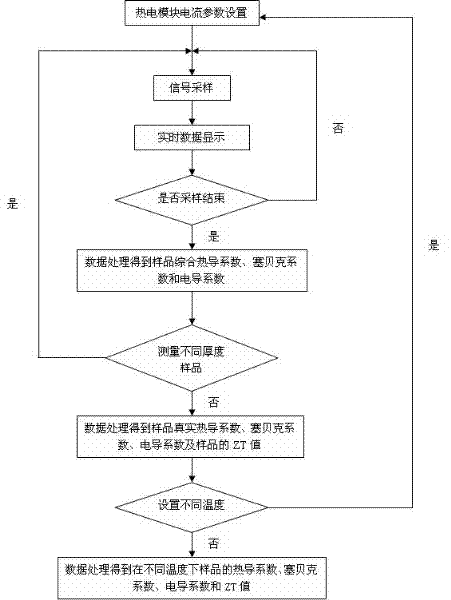

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

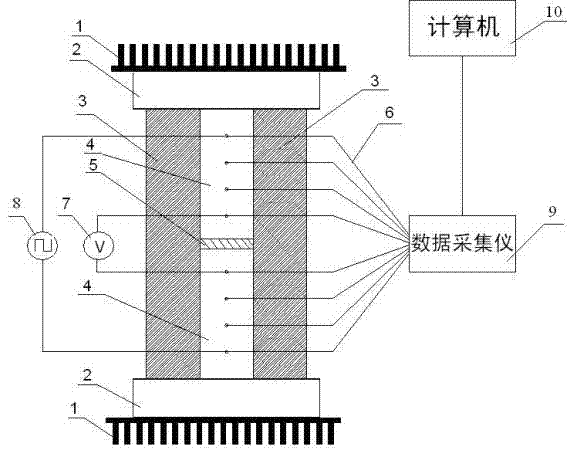

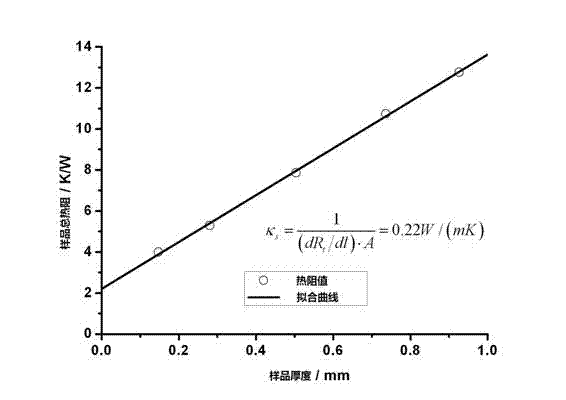

[0024] like figure 1 As shown, a device for measuring thermoelectric performance parameters of a thin film includes a heat sink 1, a thermoelectric module 2, a thermal insulation material 3, a metal round rod 4, a thermocouple wire 6, a voltmeter 7, a power supply 8, a data acquisition instrument 9 and a computer 10; the measuring device has an axisymmetric structure with respect to the film sample 5 to be measured, and the film sample 5 to be measured is sandwiched between two metal round rods 4, and the area of the film sample 5 to be measured is the same as that of the metal rod 4. The round rods 4 have the same cross-sectional area, and the film sample 5 to be tested and the metal round rod 4 are placed in a vacuum chamber or wrapped with a layer of heat insulating material to minimize heat loss; the two metal round rods 4 and the metal round rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Cross section diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com