Fast constant temperature microreactor

A micro-reactor and reactor technology, applied in the field of reactors, can solve the problems of long thermal equilibrium time, unfavorable miniaturization and micro-analysis, large consumption of heating and cooling, etc., achieve rapid temperature change and precise constant temperature control, and meet high-precision measurement Effect of usage requirements, high control precision and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

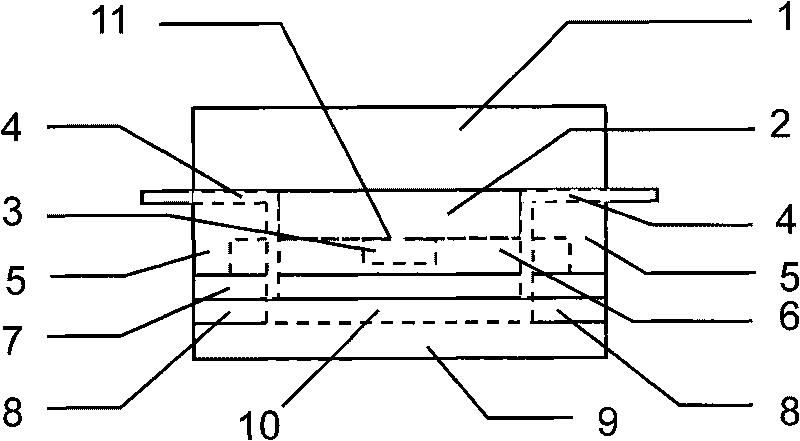

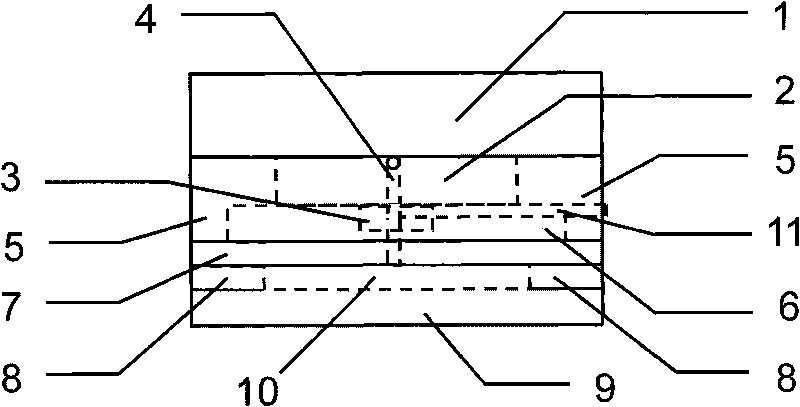

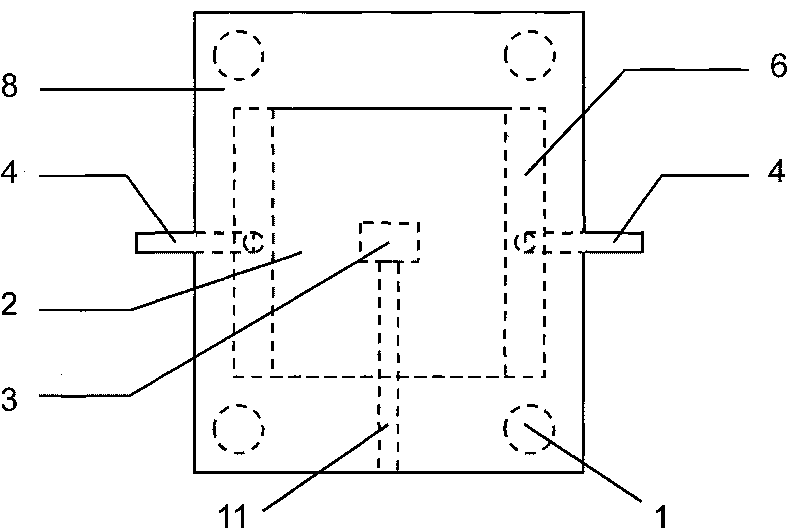

[0026] The structural schematic diagram of the fast constant temperature microreactor is as follows: figure 1 shown. The sample cell 10 is a closed cuboid space formed by an inert thin layer 7 with a thickness of 0.2mm, a sealing gasket 8 and an inert flat plate 9, and the size of the sample cell is 20mm×20mm×0.5mm. Glass is selected as the material for forming the inert thin layer, and silicone rubber PDMS sold by Dow Corning (Dow Corning) as the material for forming the sealing gasket is selected as Sylgard 184. During temperature control, the heat conduction block 6 is heated or refrigerated by the temperature control element 2 to provide a uniform temperature environment for the test solution in the sample cell 10 . Copper is selected as the material for the heat conduction block 6 , and a semiconductor heating and cooling chip sold by Qinhuangdao Fulianjing Electronics Co., Ltd., model number FPH1-1707NC, is selected as the temperature control element 2 .

[0027] The tem...

Embodiment 2

[0036] This embodiment is a fast constant temperature reactor using a microfluidic chip, and its structural schematic diagram is shown in Figure 4 and Figure 5 shown; Figure 4 for the side view, Figure 5 For top view. Among them, 13 is a microfluidic chip, 14 is a microchannel in the microfluidic chip, and the outlet and inlet of the channel communicate with the catheter respectively. The style of the microchannel is set according to actual needs and is not limited by this figure.

[0037] In this embodiment, the microfluidic chip 13 is used to replace the inert thin layer, sealing gasket and inert flat plate in Embodiment 1, and the microchannel area 14 in the microfluidic chip is used as the sample pool of the reactor. The microfluidic chip 13 is a glass microchannel chip, which is obtained through glass wet etching technology and heat sealing technology in this field. The specific operation steps are as follows: first, copy the desired channel pattern to the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com