Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about How to "Compensation for deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

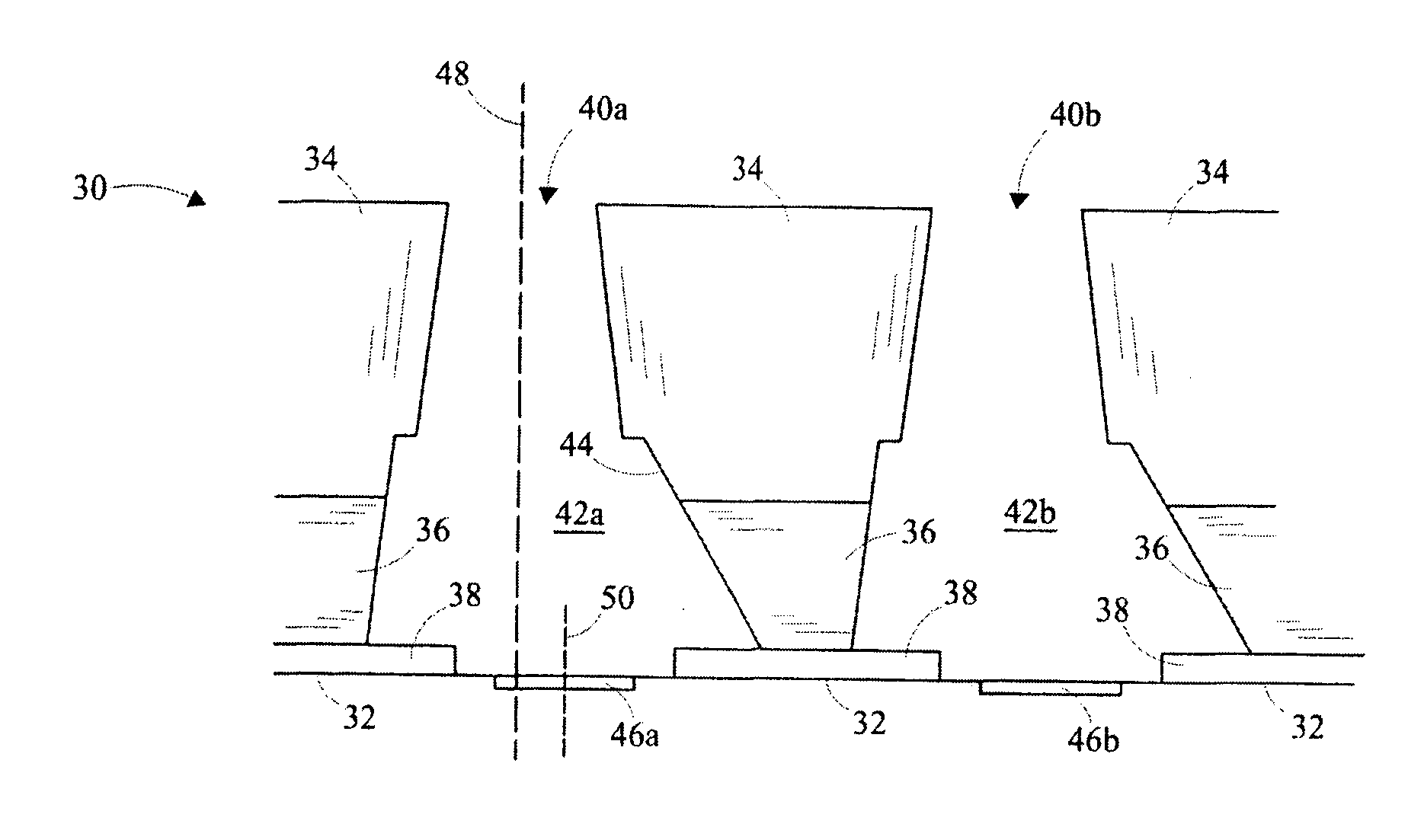

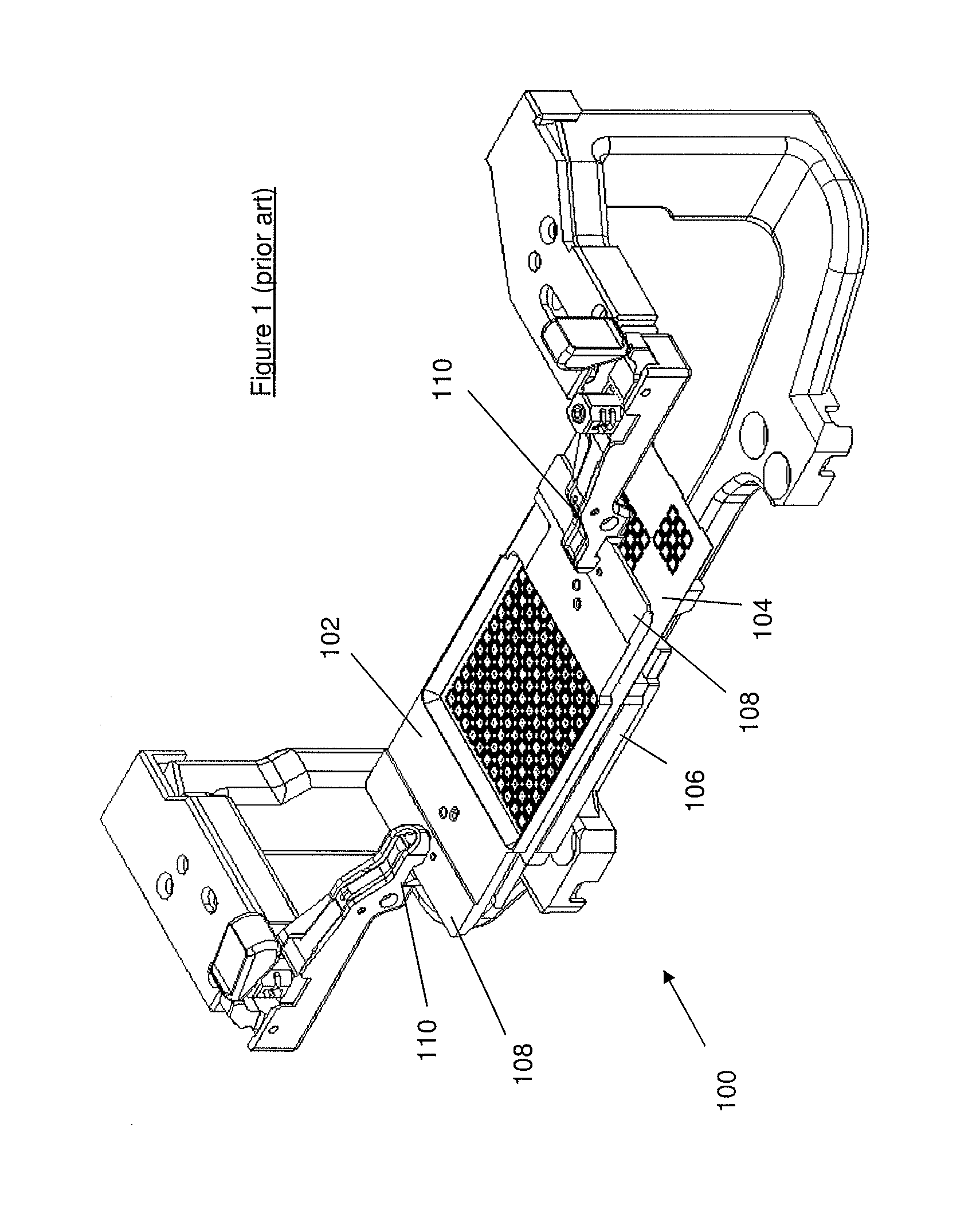

Nozzle plate for improved post-bonding symmetry

A nozzle plate for bonding to a chip for configuring a printhead of a printing device is disclosed. The chip comprises a plurality of energizing elements. The nozzle plate comprises a substrate layer, an adhesive layer and a plurality of nozzle holes perforated in the substrate layer and the adhesive layer. The each nozzle hole is capable of being associated with an energizing element of the plurality of energizing elements. The each nozzle hole comprises an asymmetric flow-feature configured by ablating at least a portion of a wall of the each nozzle hole prior to bonding the nozzle plate to the chip. The nozzle plate provides a substantially symmetrical flow-feature for the each nozzle hole on bonding to the chip.

Owner:SLINGSHOT PRINTING LLC

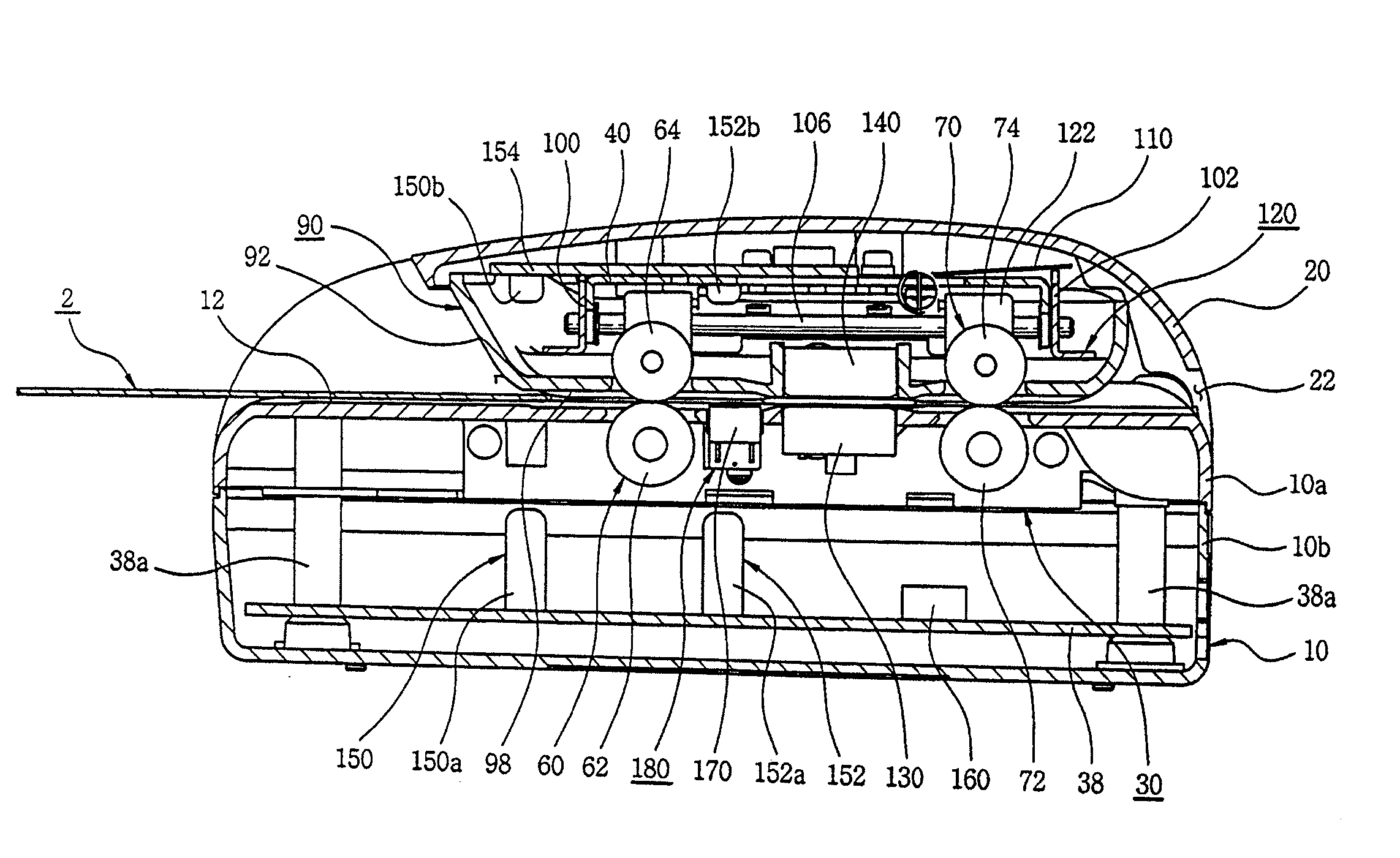

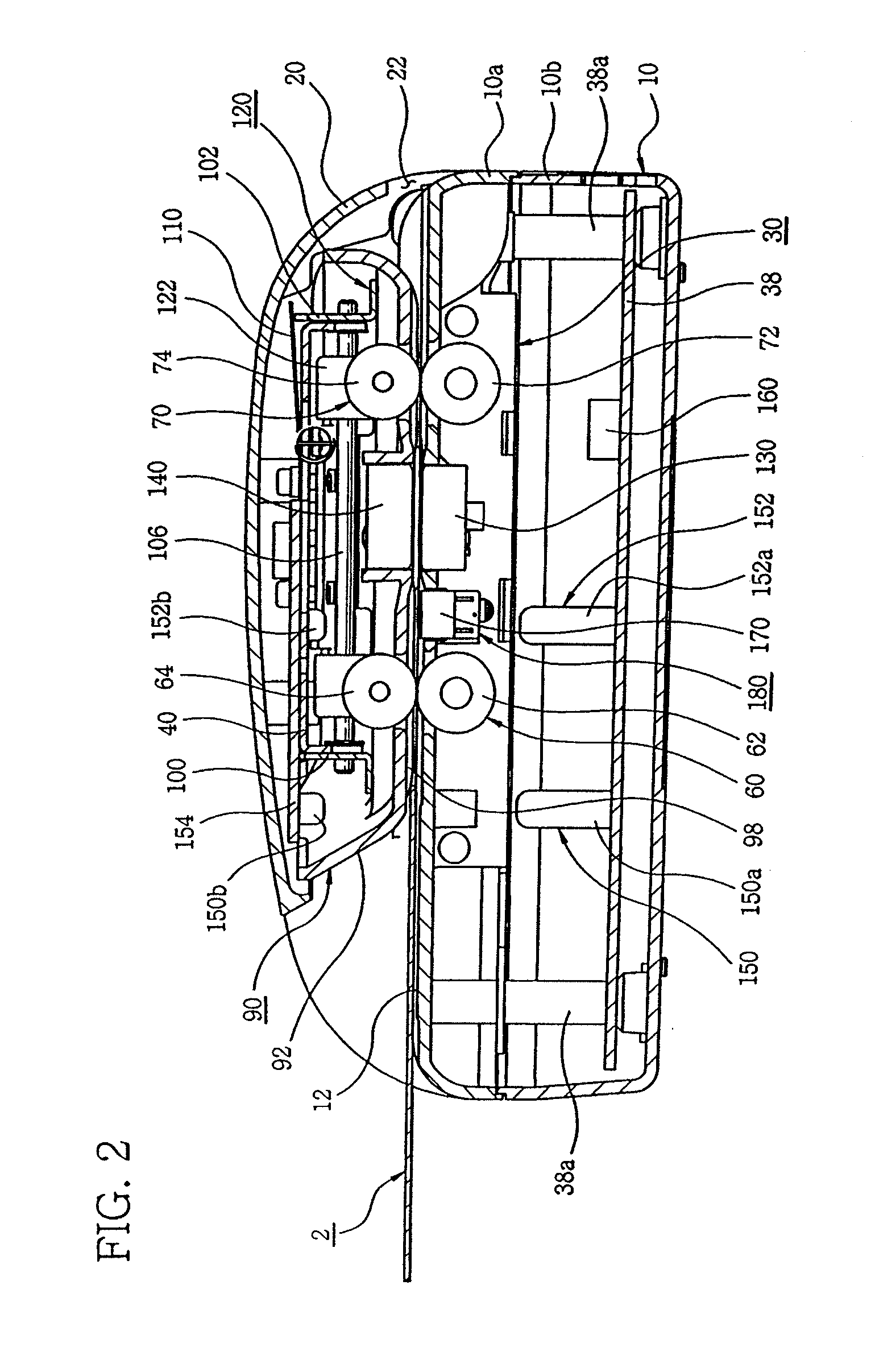

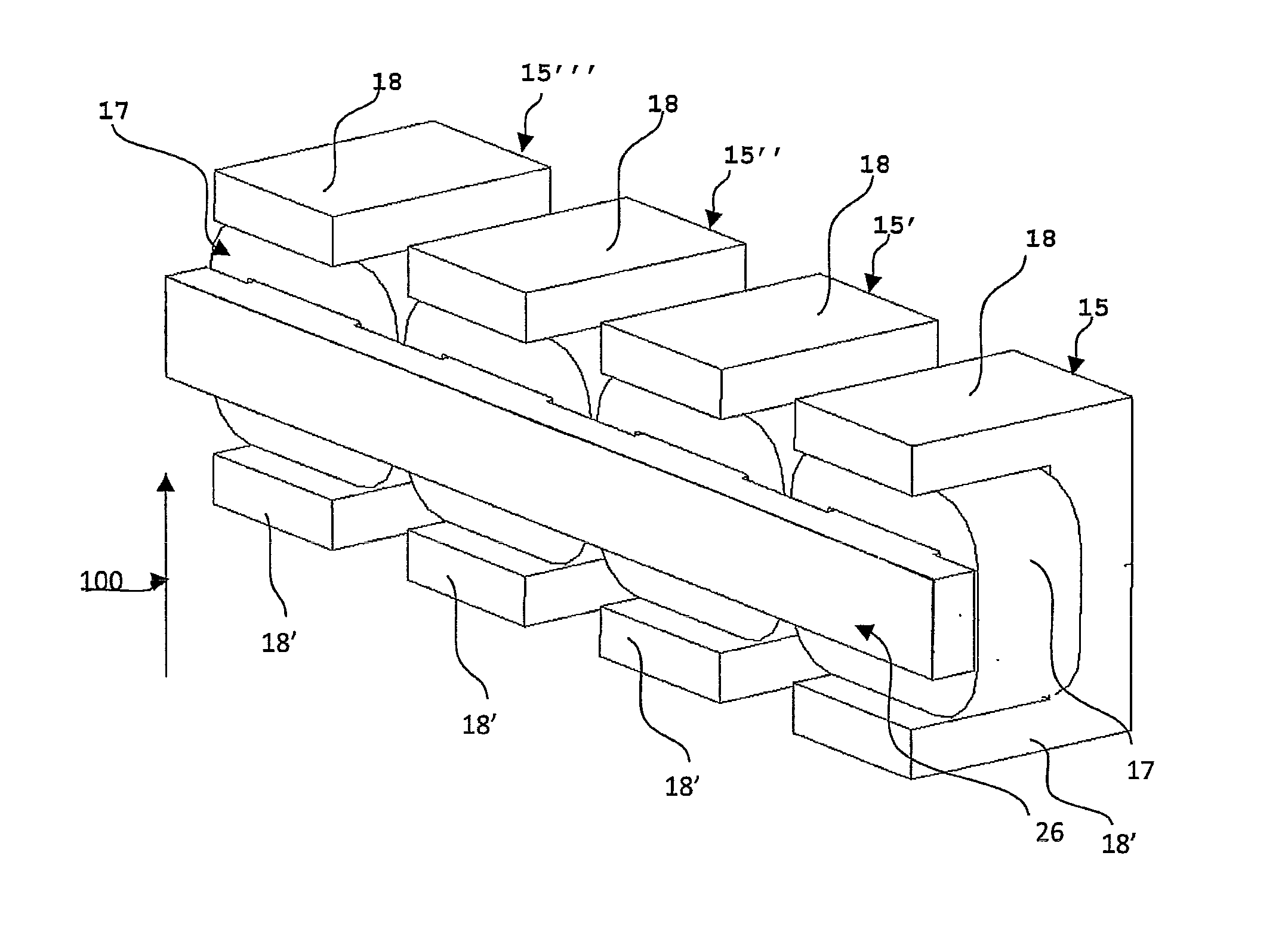

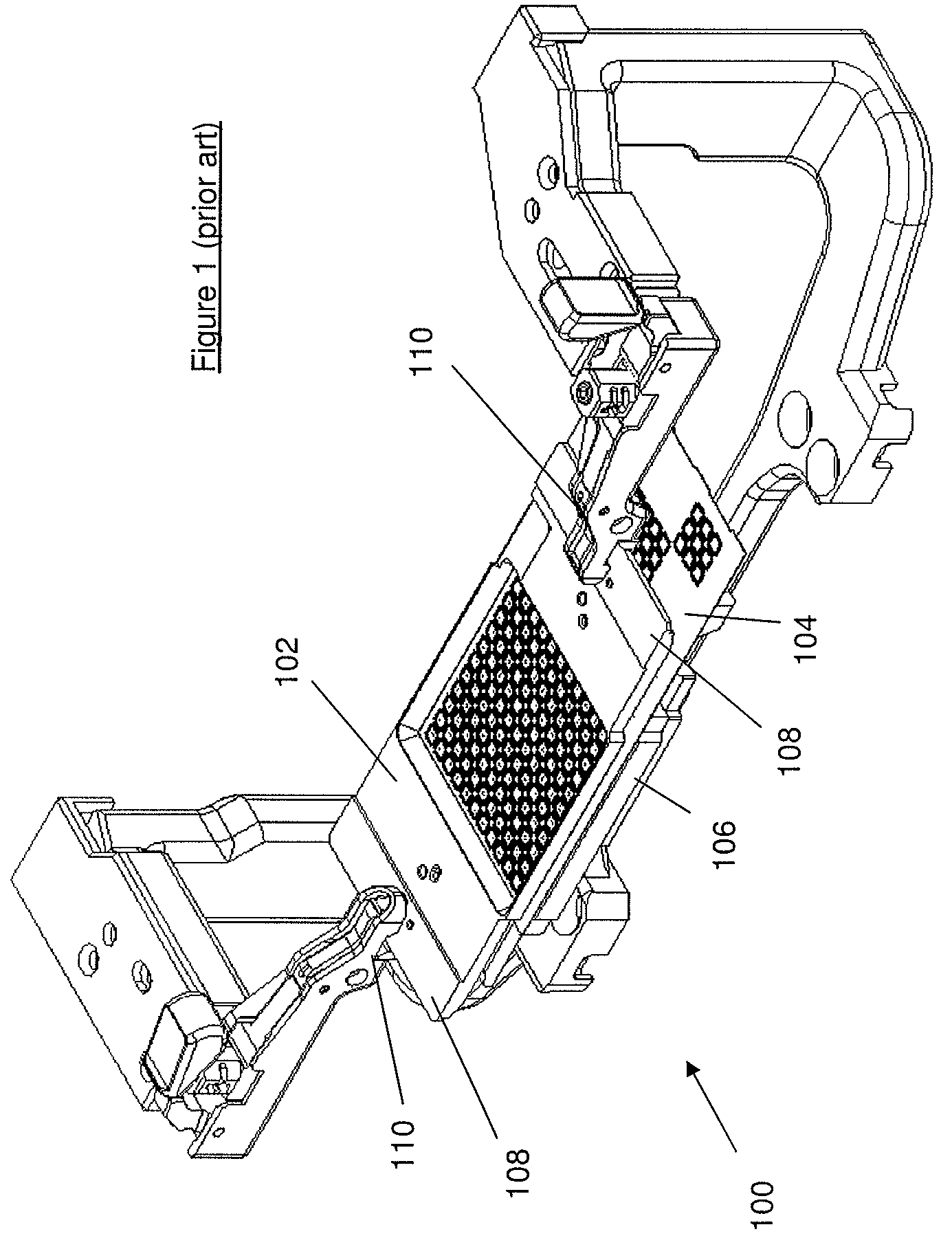

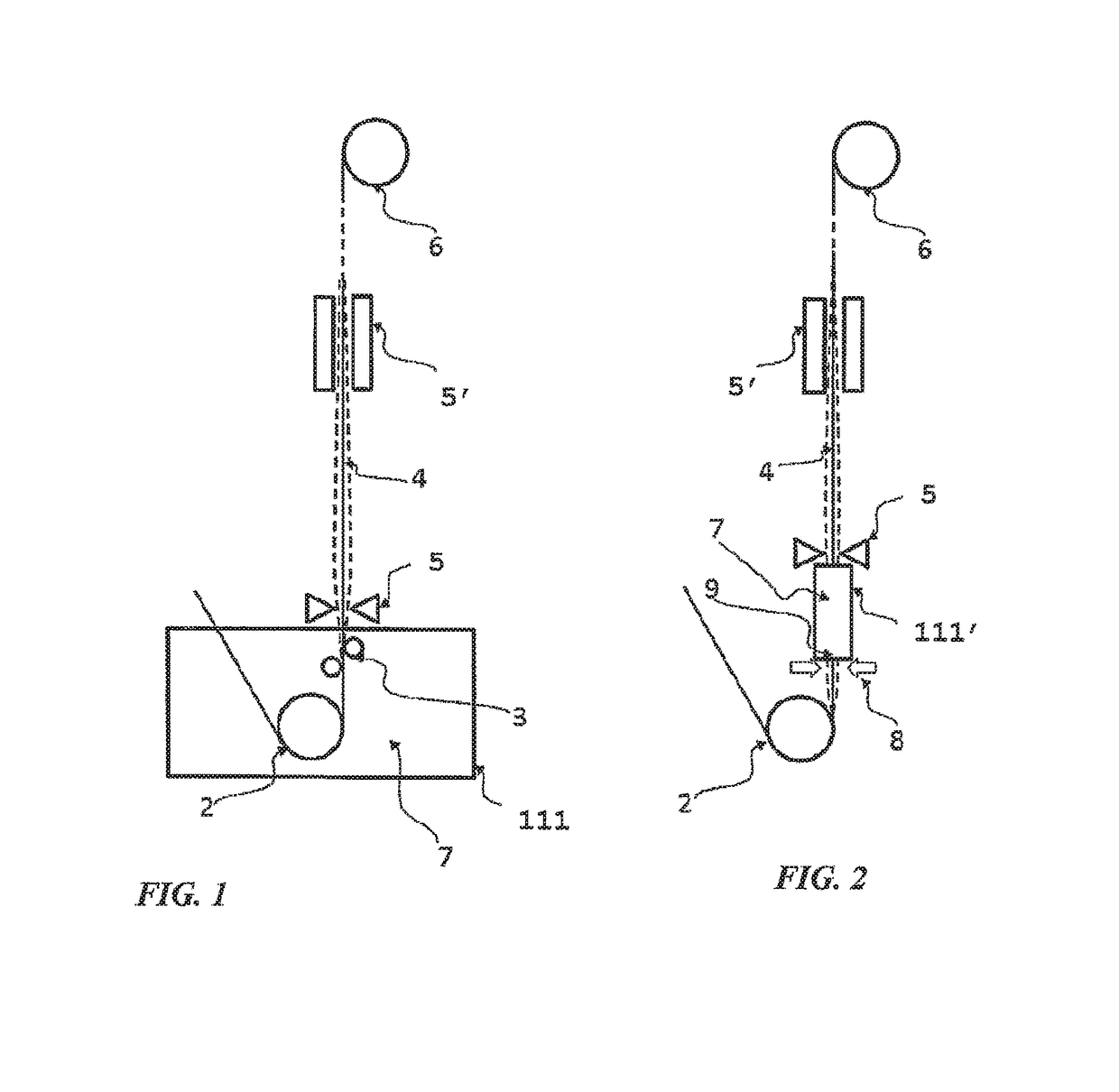

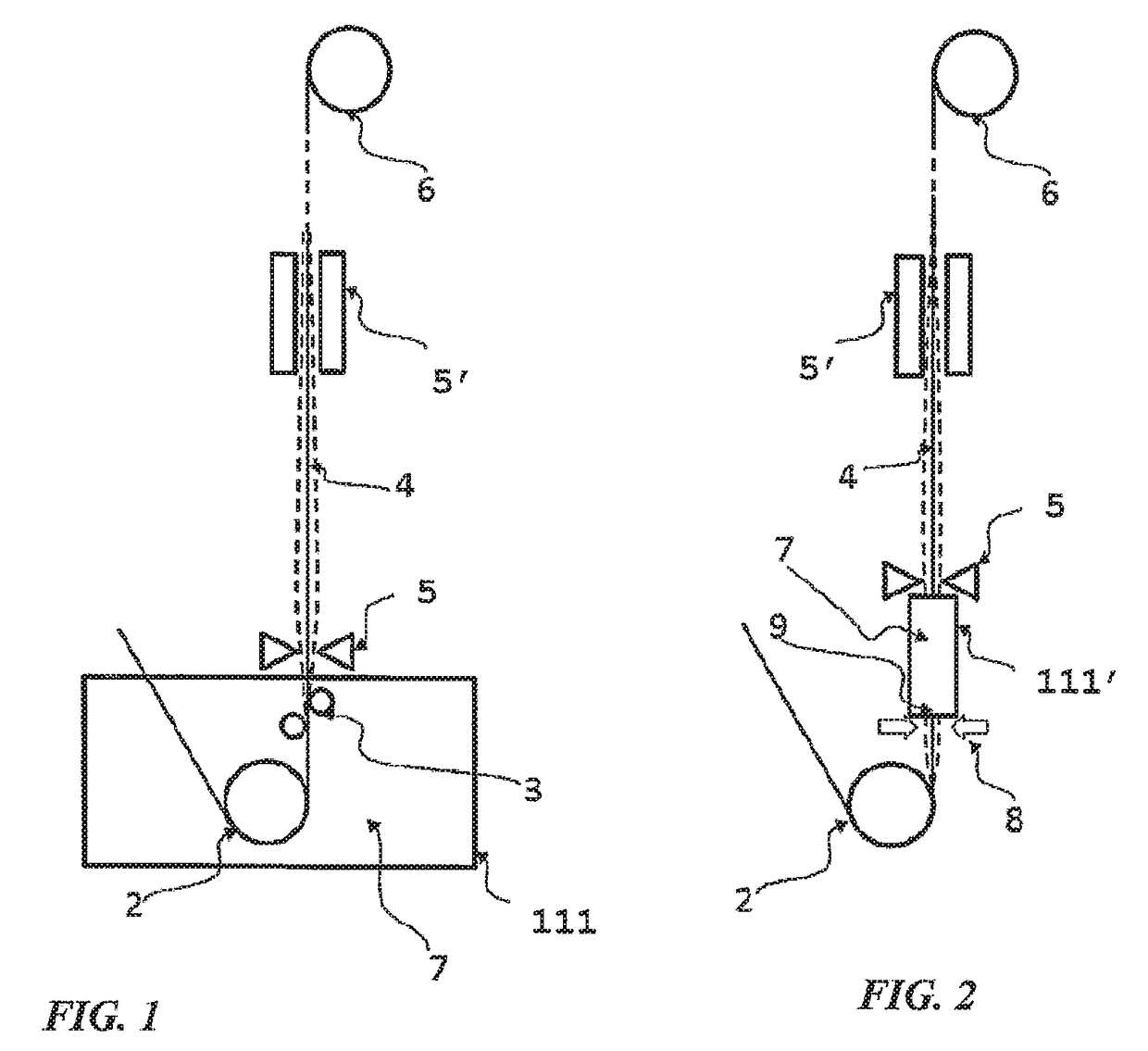

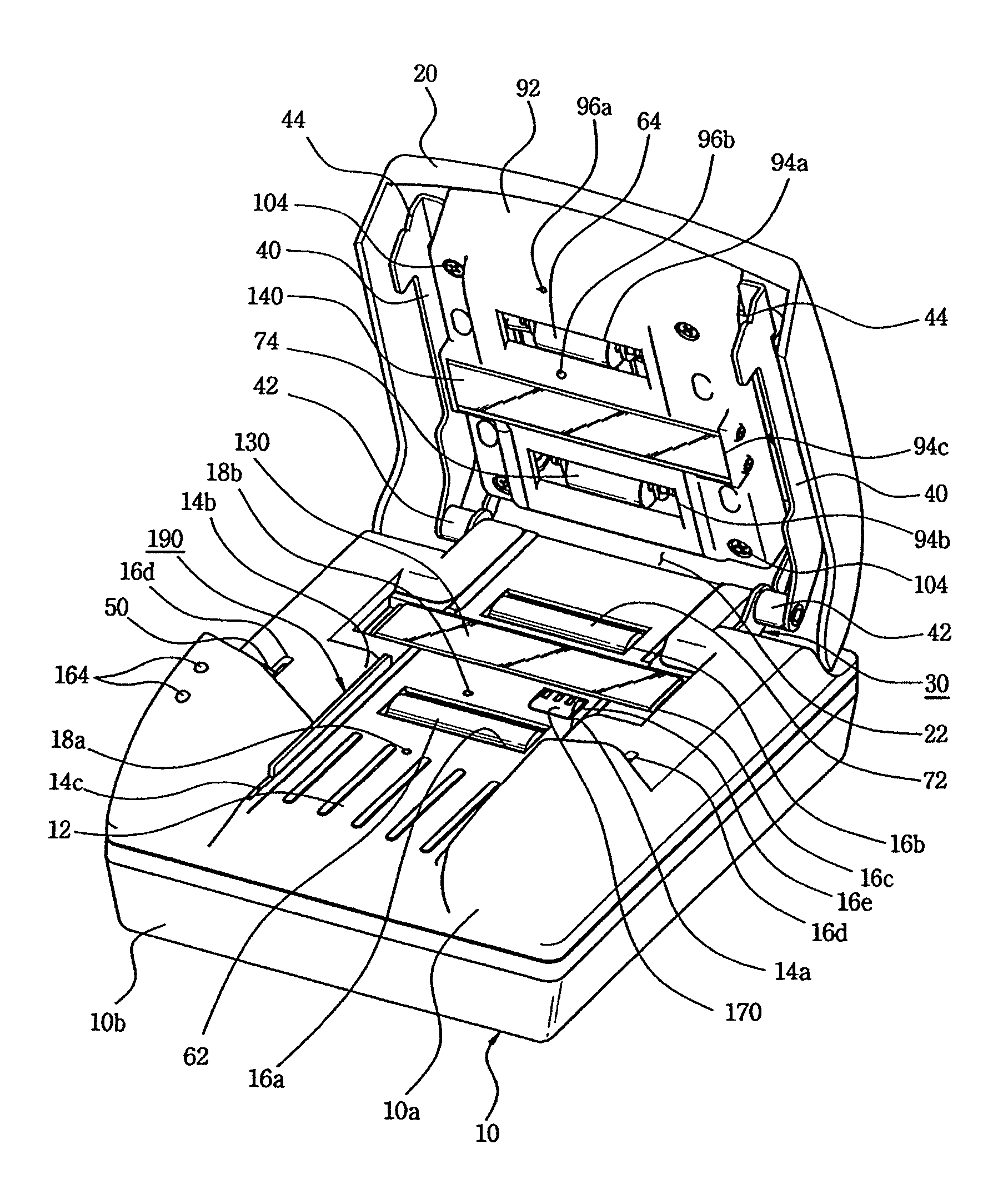

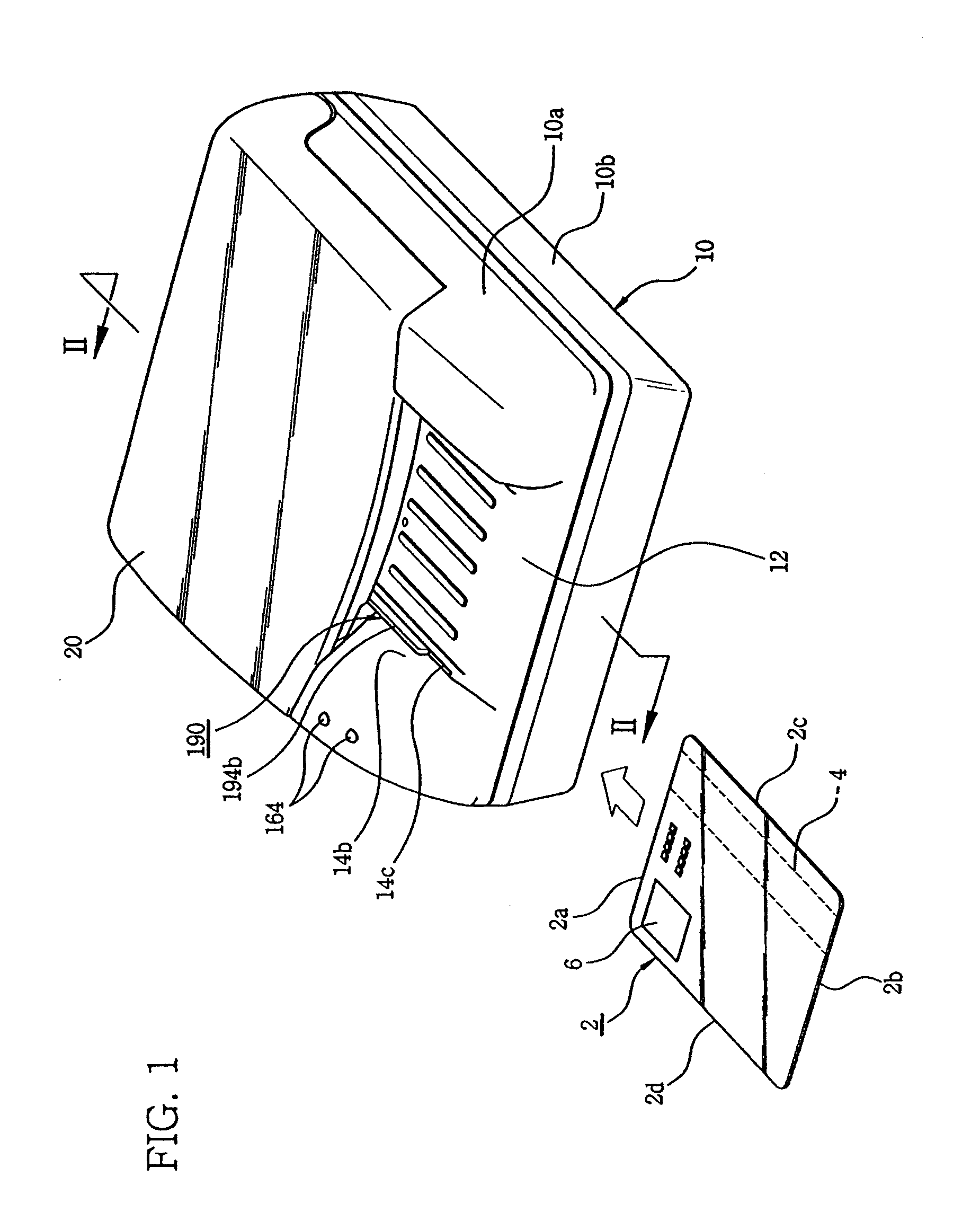

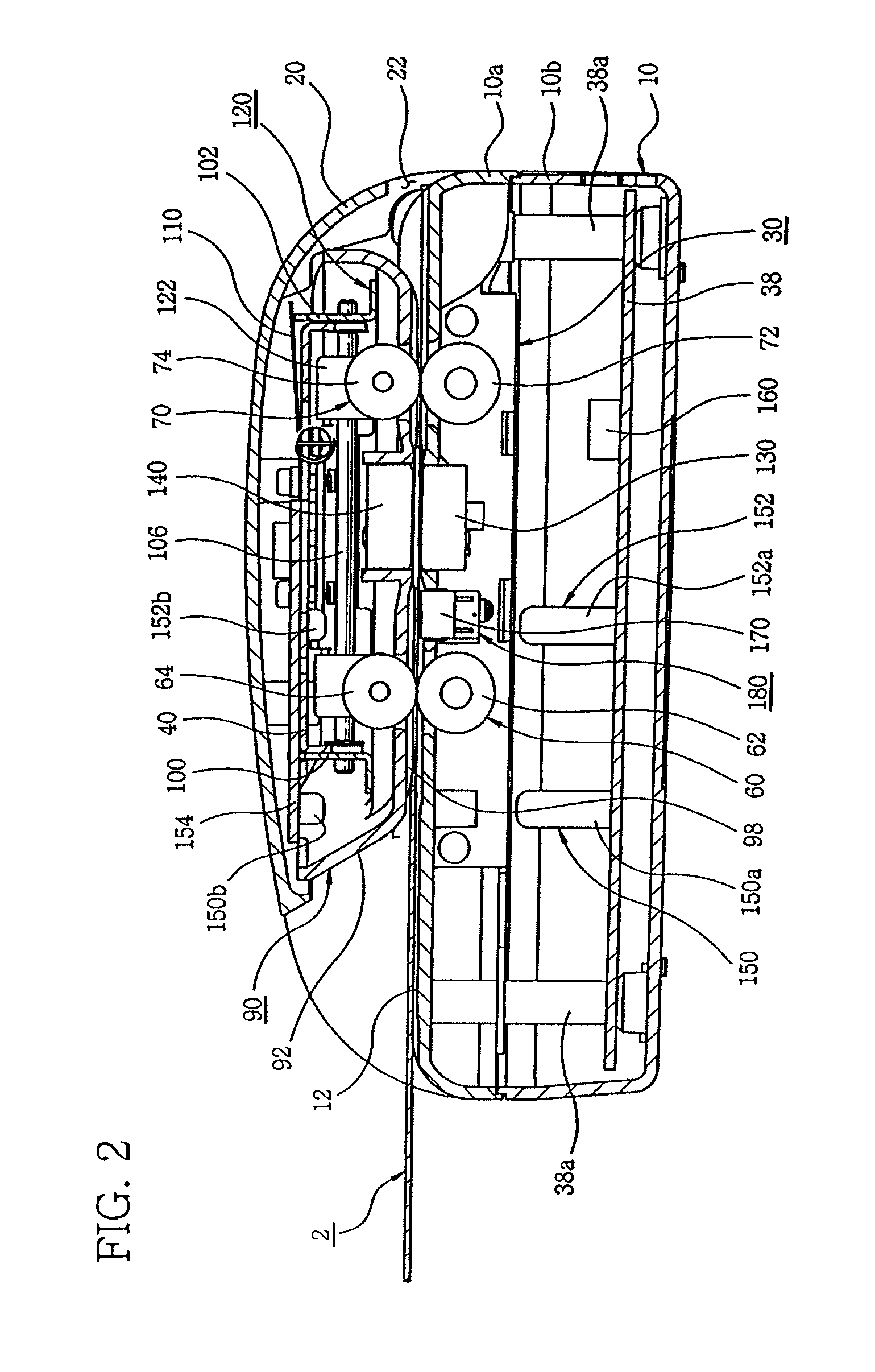

Double side image scanner

ActiveUS20060256391A1Improve image qualityImprove scanning accuracyElectrographic process apparatusTelevision systemsMechanical engineeringImage sensor

A double side image scanner includes a case having a medium guide track with a reference loading line, a main frame mounted inside the case, a first roll feed including a first feed roller mounted on a front side of the guide track and a first idle roller disposed above the first feed roller for cooperating with the first feed roller to load the medium, a second roll feed including a second feed roller mounted on a rear side of the guide track and a second idle roller disposed above the second feed roller for cooperating with the second feed roller to load the medium, a drive device for rotating the first feed roller and the second feed roller, first and second image sensors for scanning opposite surfaces of the medium to acquire image data, and a tracking device for biasing the medium toward the reference loading line.

Owner:WISECUBE

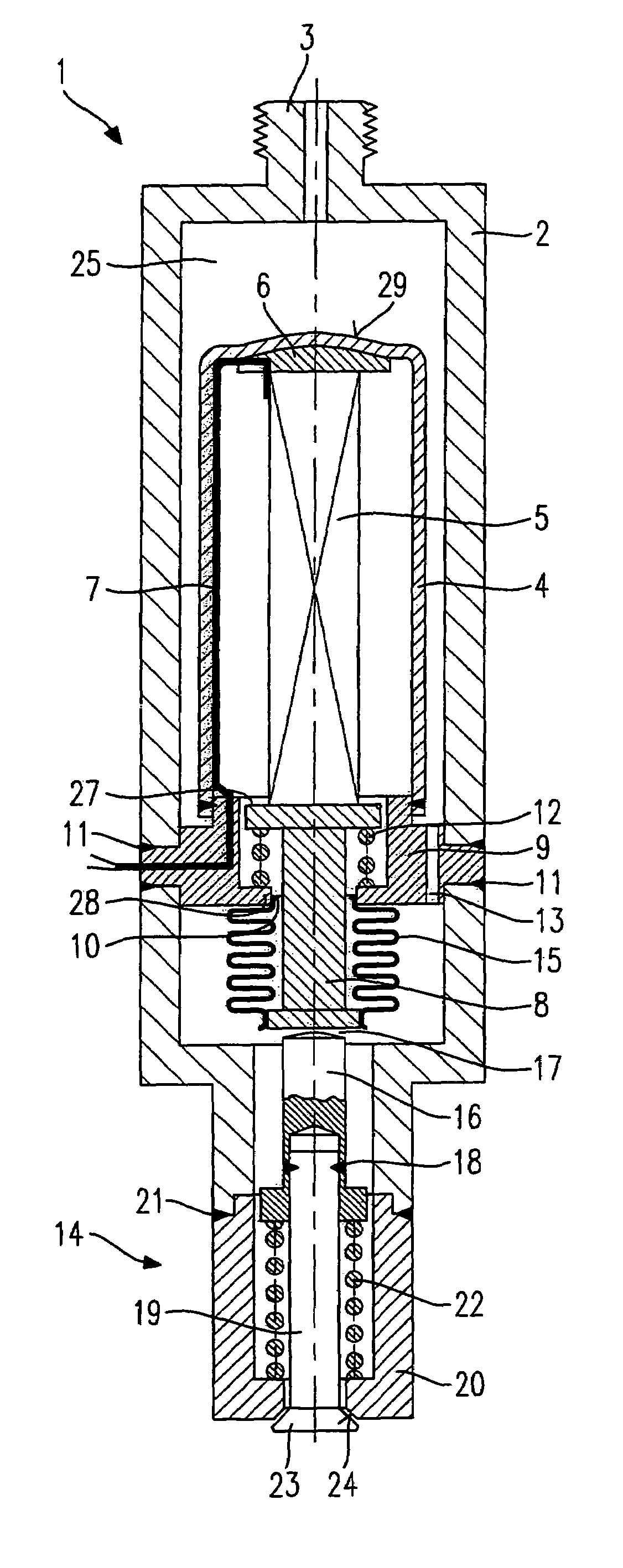

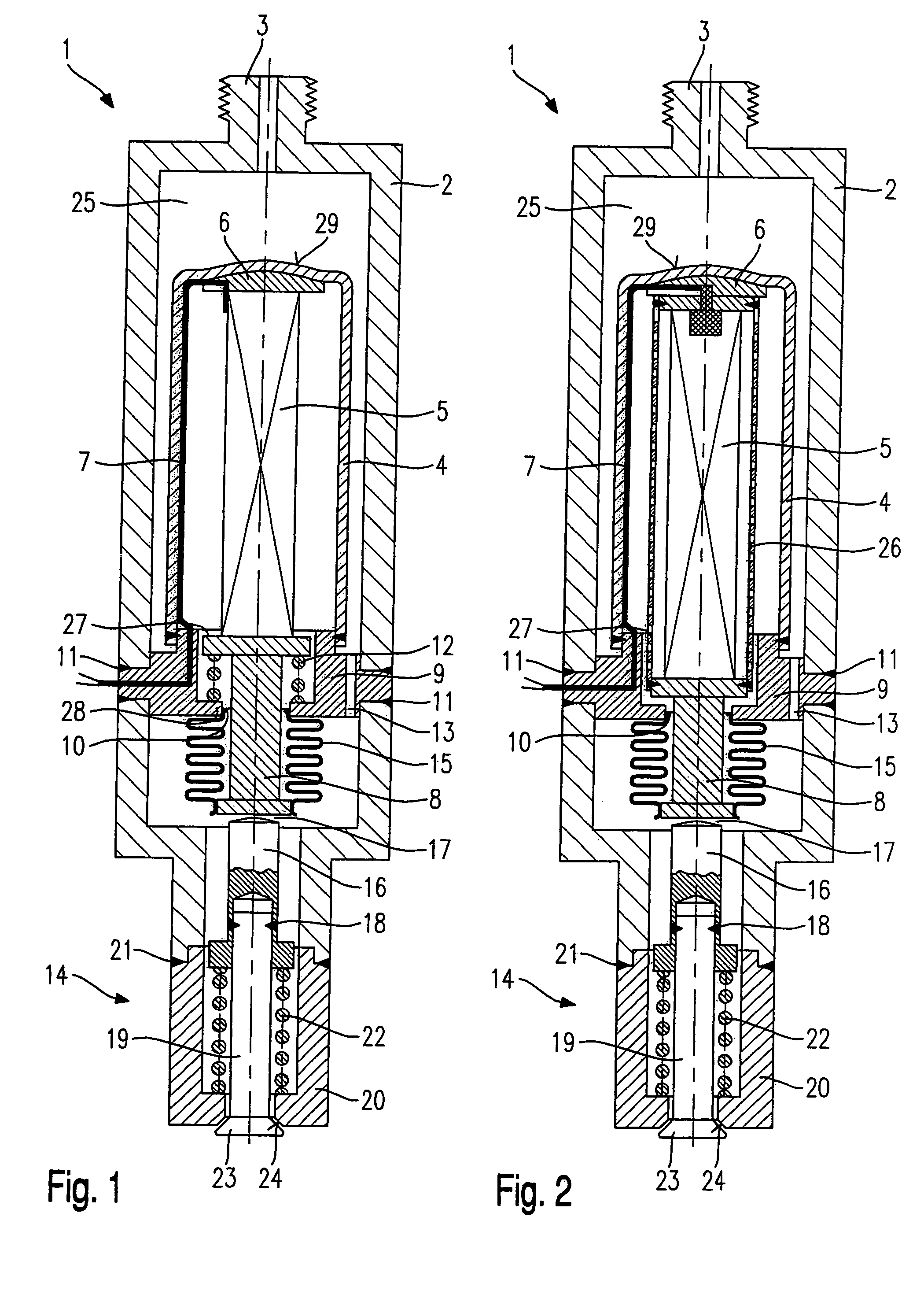

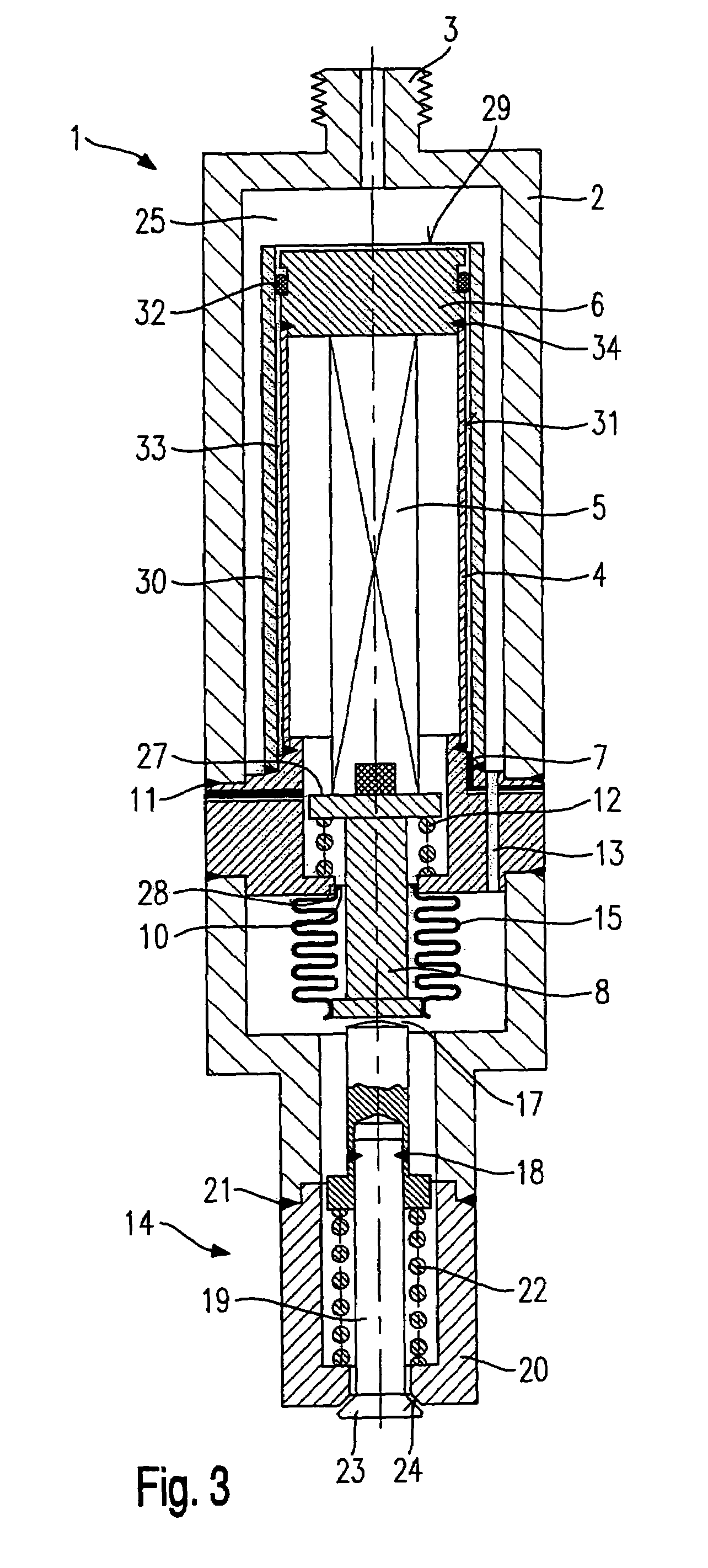

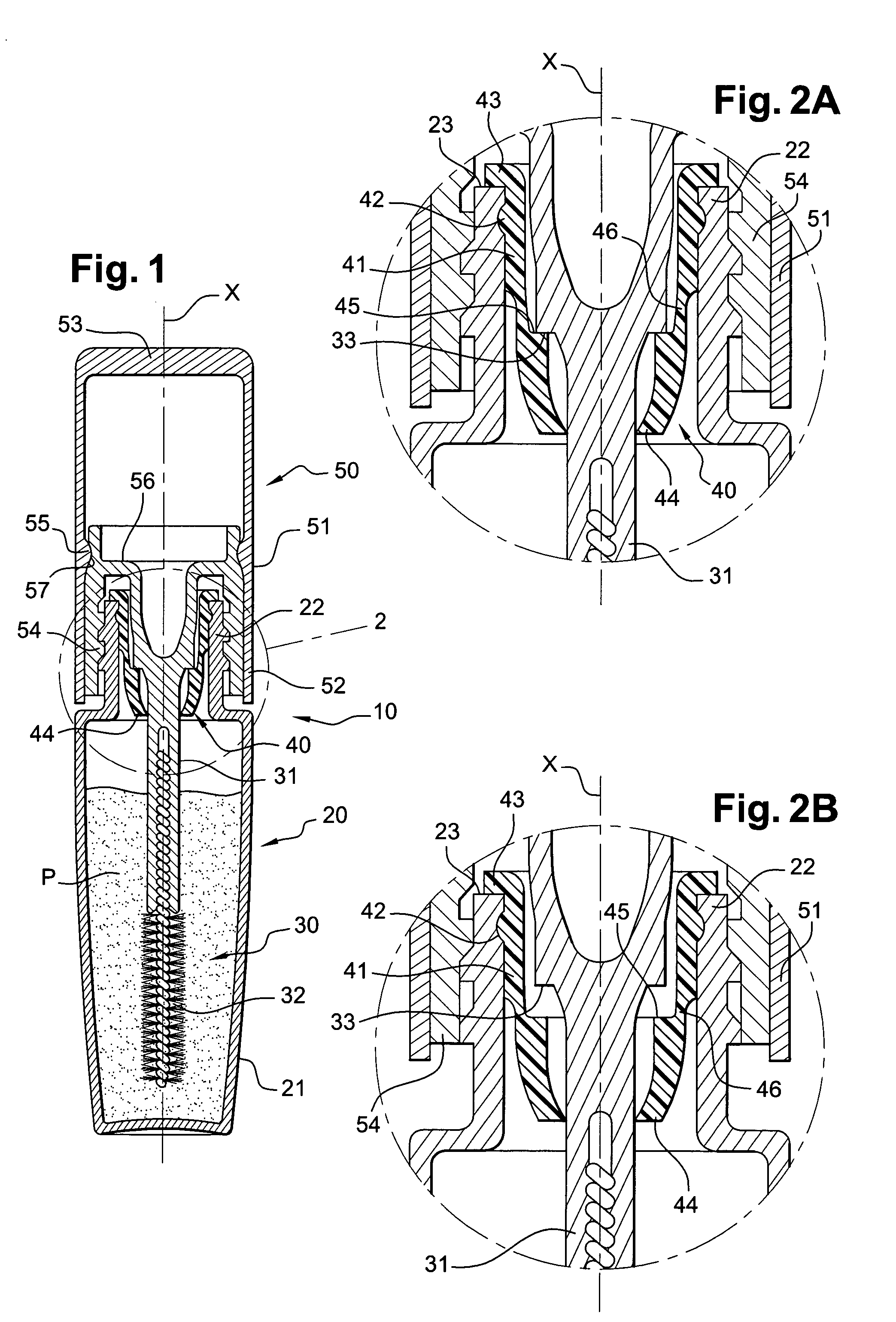

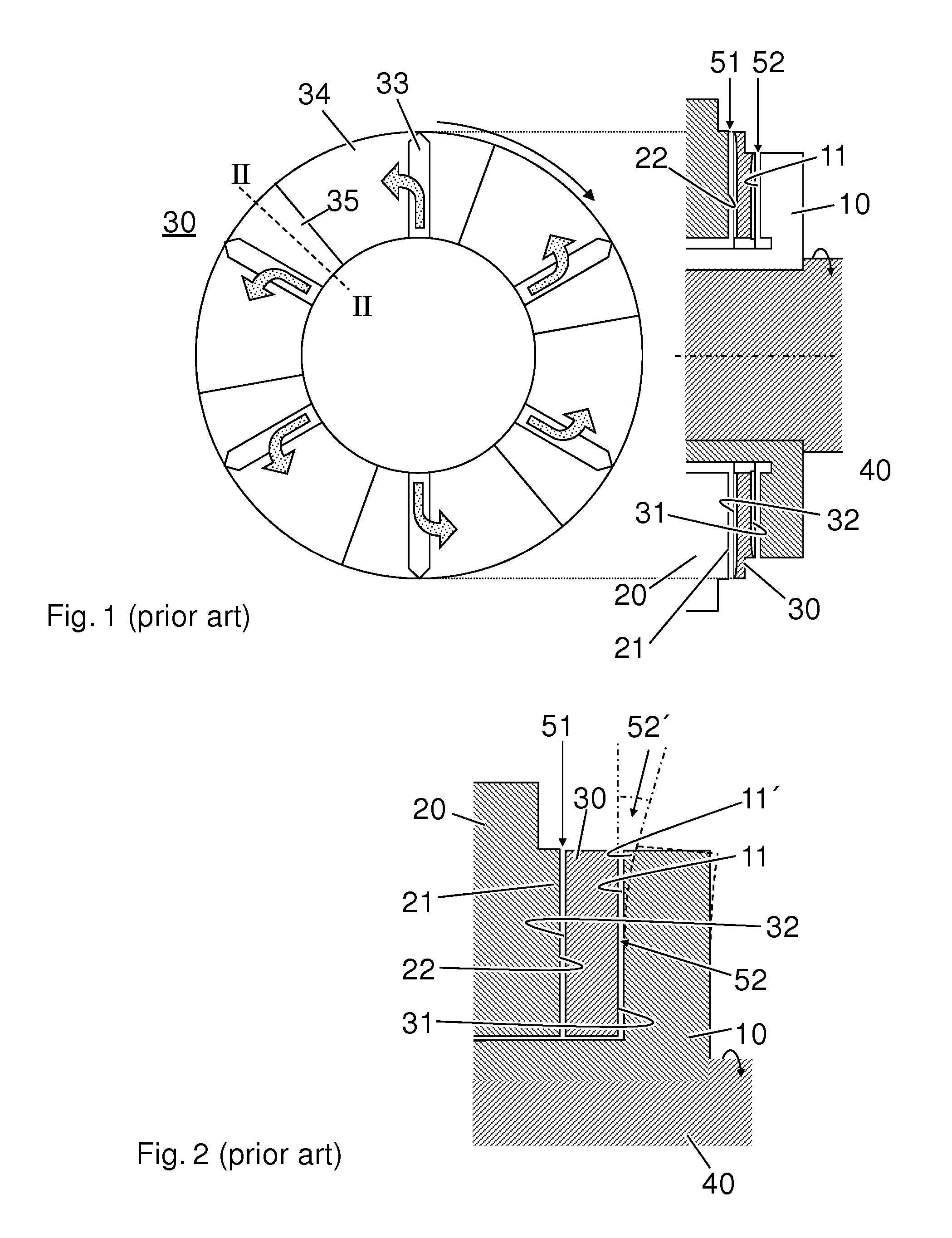

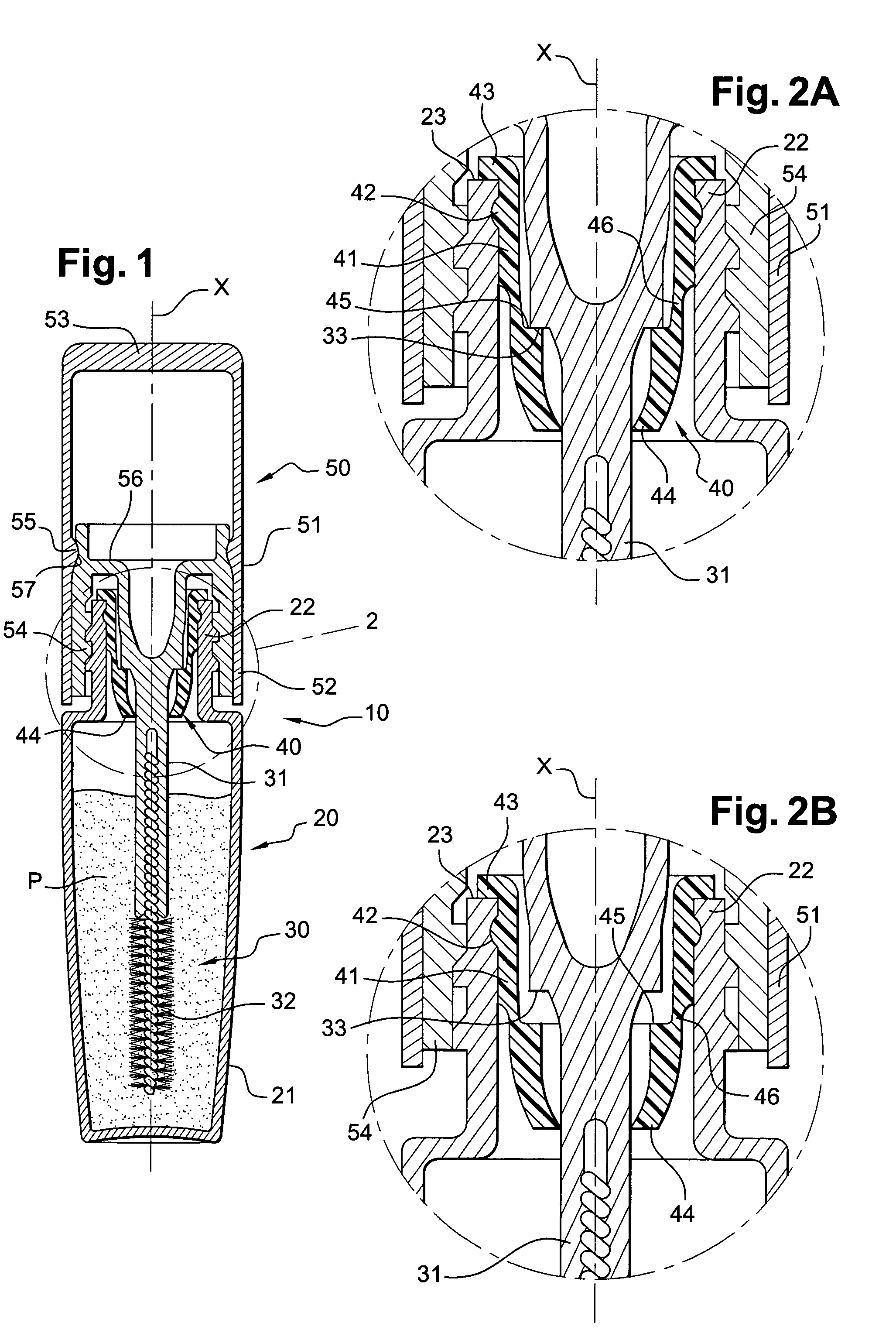

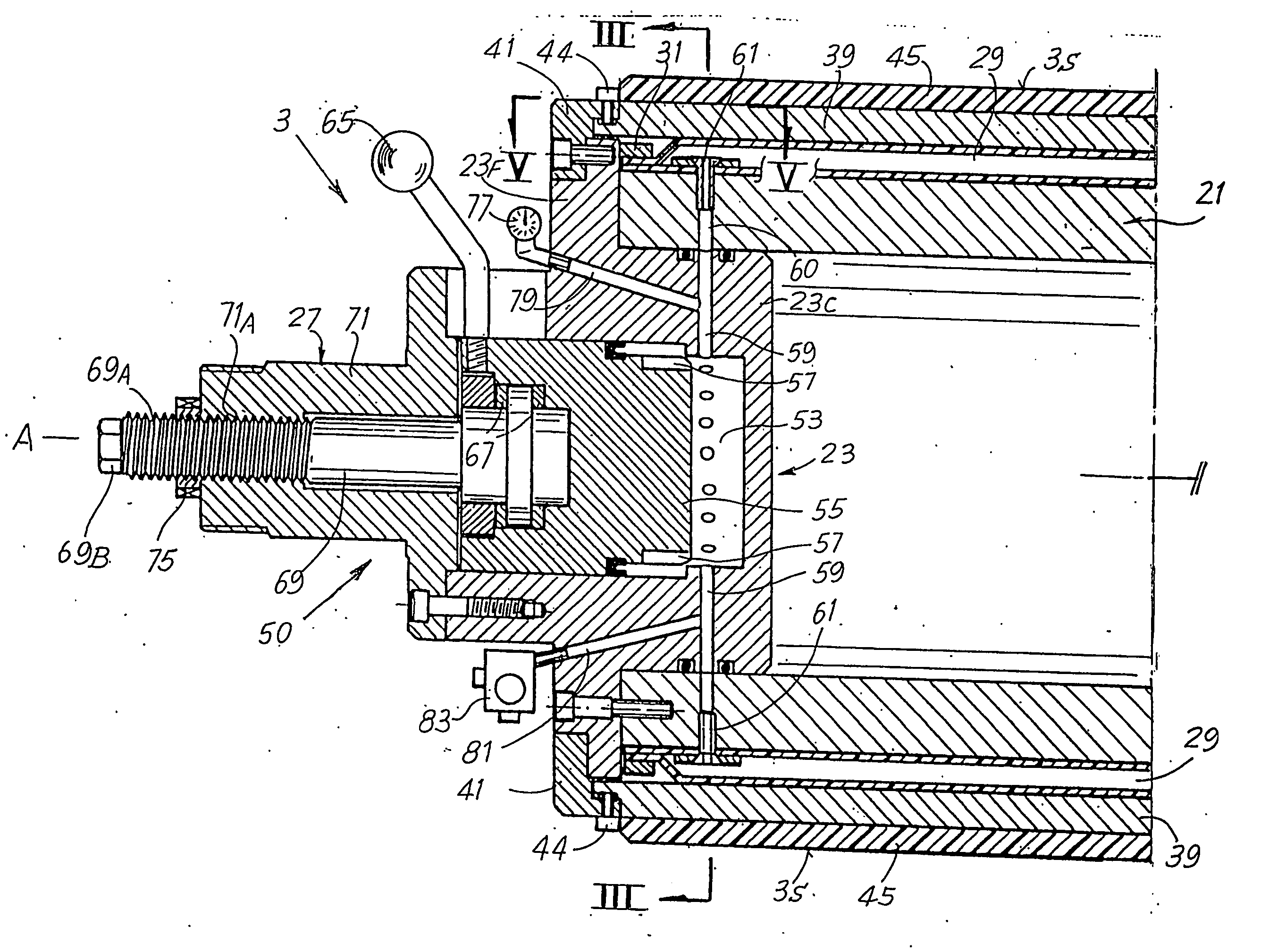

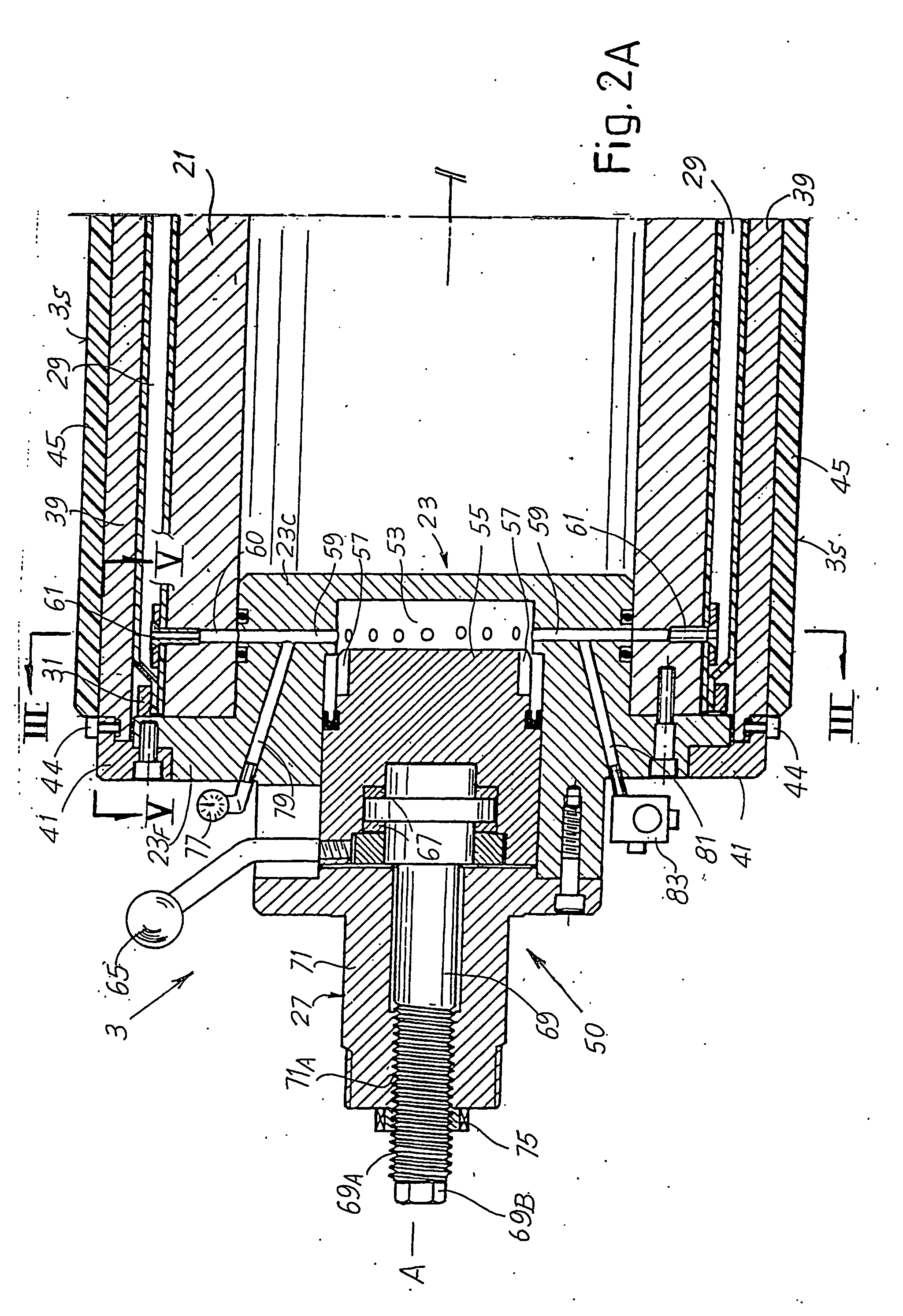

Fuel injector

InactiveUS7083114B2Reduce dependenceCompensation for deformationInternal combustion piston enginesMovable spraying apparatusCombustion chamberEngineering

Owner:ROBERT BOSCH GMBH

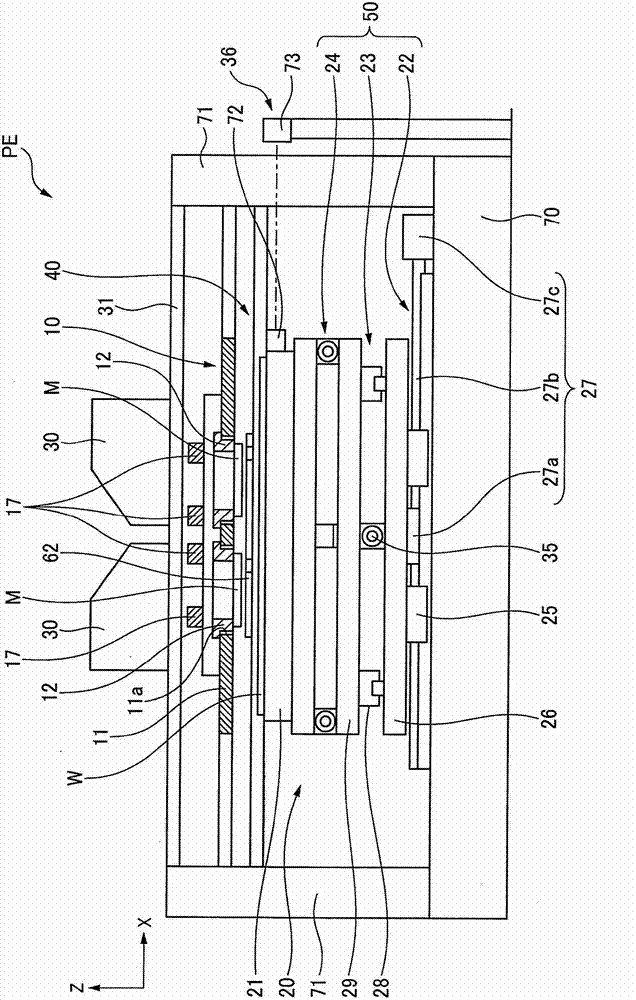

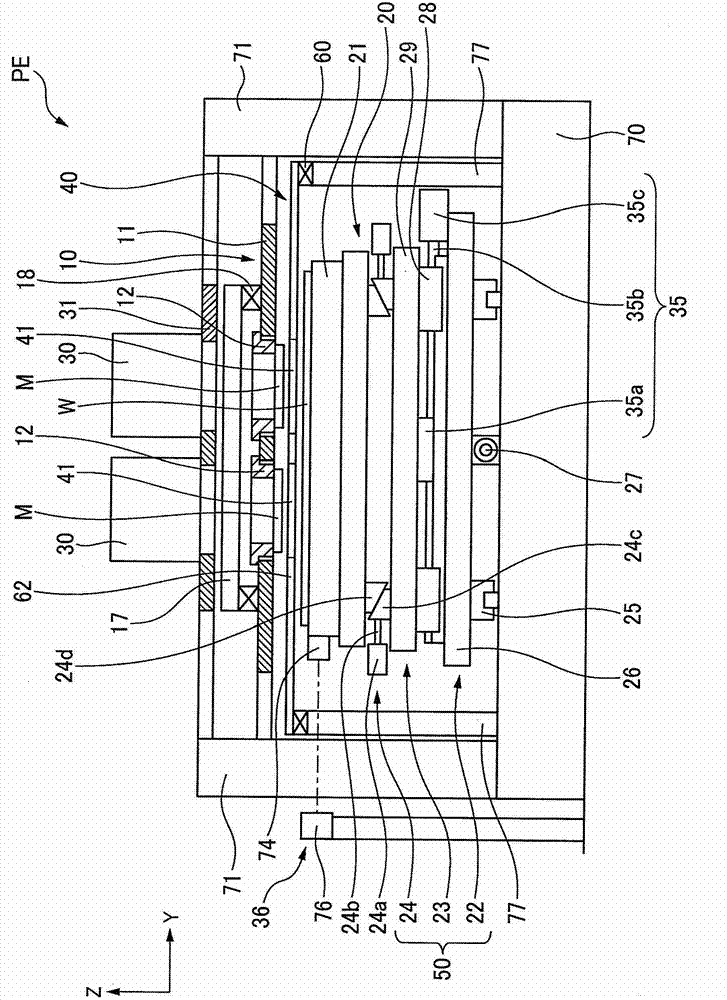

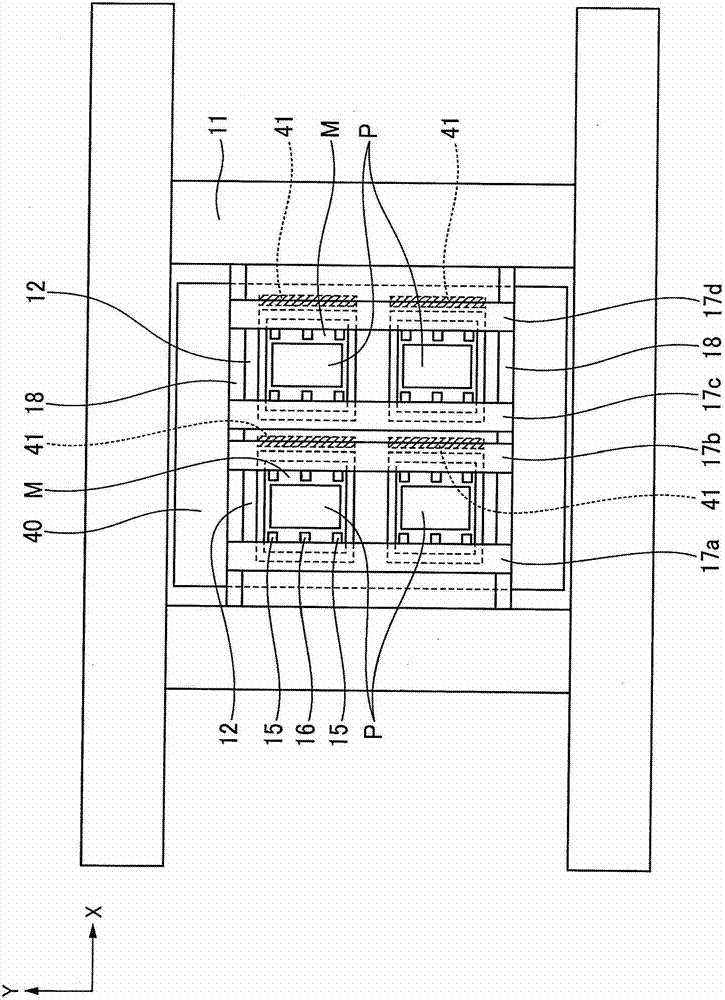

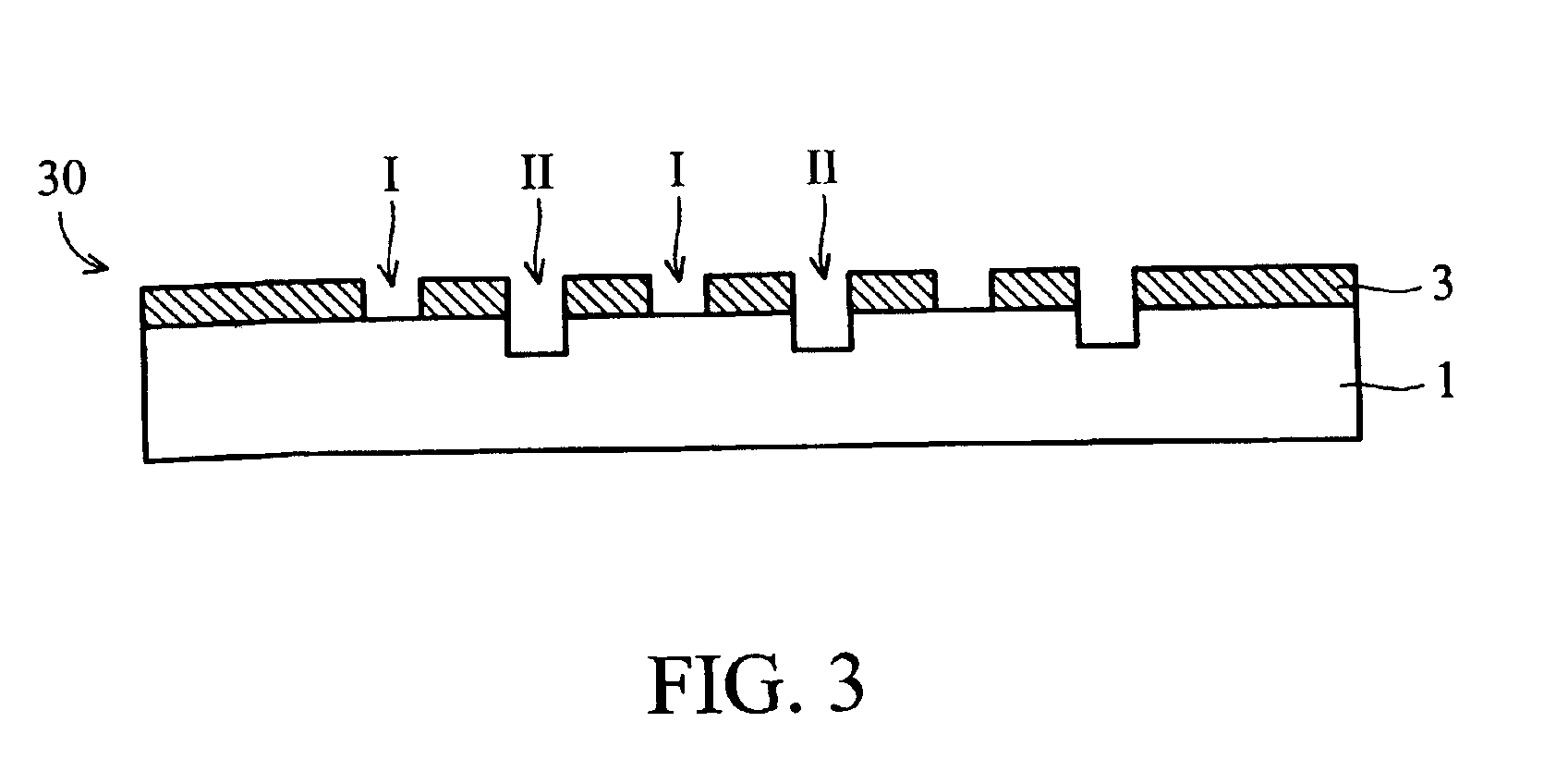

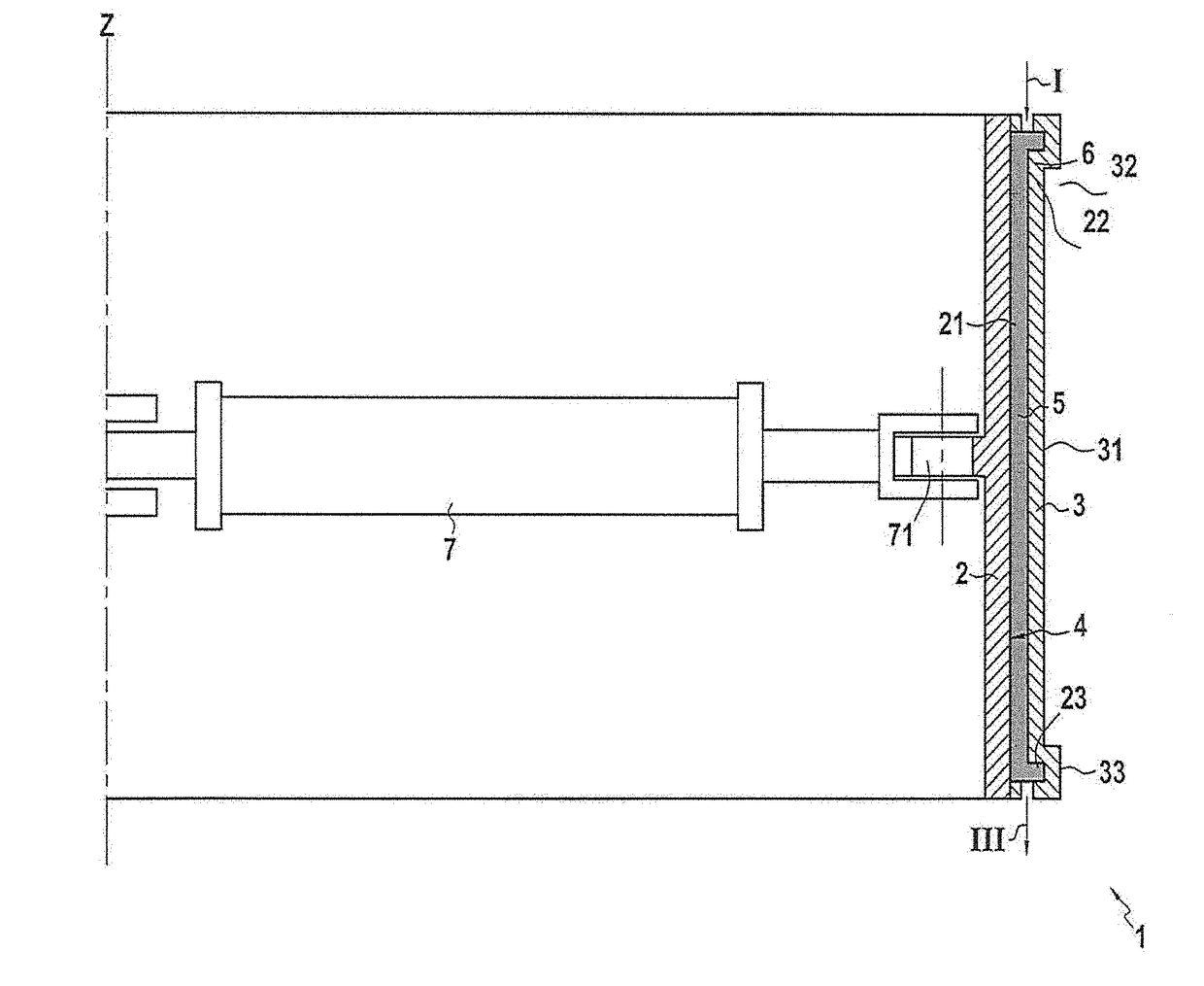

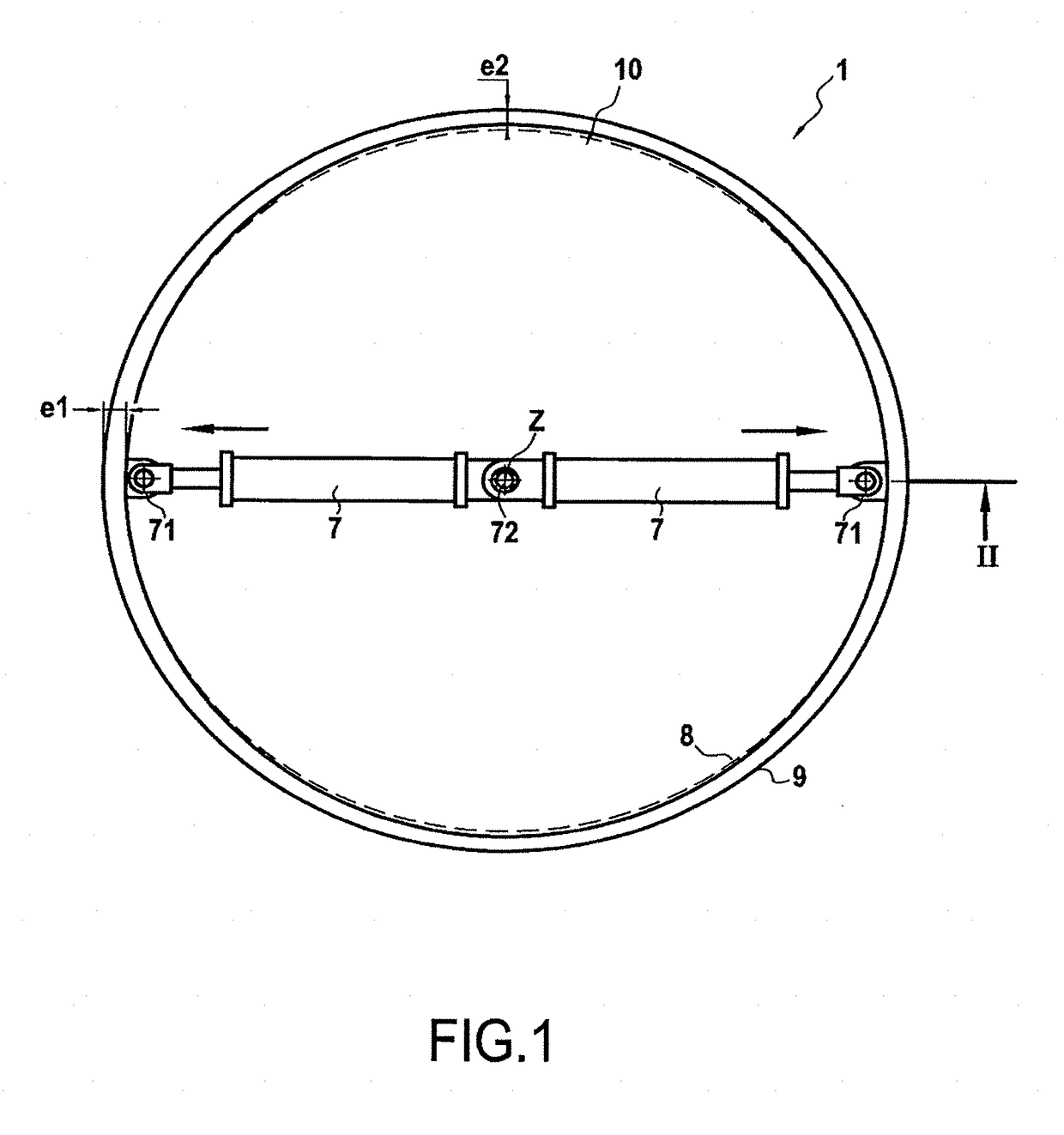

Exposure device and exposure method

InactiveCN102854753AHigh resolutionCompensation for deformationPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro lens arrayHigh resolution

The invention relates to an exposure device and an exposure method, capable of exposing and transferring a microfine exposure pattern on a substrate by using a micro lens array with high resolution at relatively short production takt interval. The exposure device of the invention comprises a mask loading platform (10); a substrate loading platform (20); an illuminating optical system (3) for irradiating lights for pattern exposure; a micro lens carrying plate (62), which has a micro lens array (41) that is formed by directional configuration of multiple micro lenses (42) on a plane and is extended in a linear manner along the Y direction, and is configured between a mask (M) and the substrate (W); and a micro lens driving mechanism (60) for enabling the micro lens carrying plate (62) to move along the X direction. When the micro lens carrying plate (62) moves along the X direction, lights for pattern exposure are irradiated to expose and transfer the mask pattern on the substrate (W) with the help of the micro lens (42).

Owner:NSK TECH

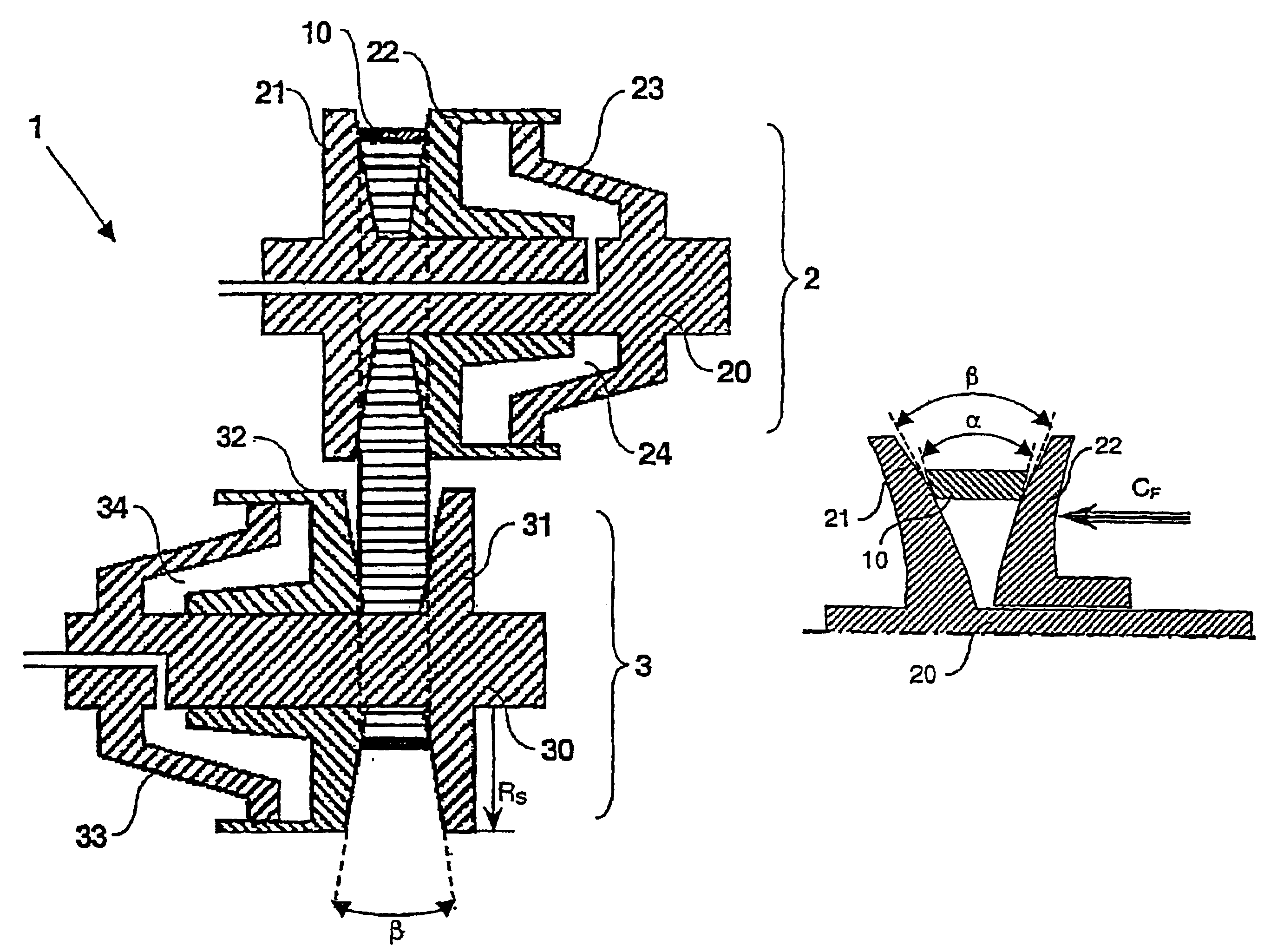

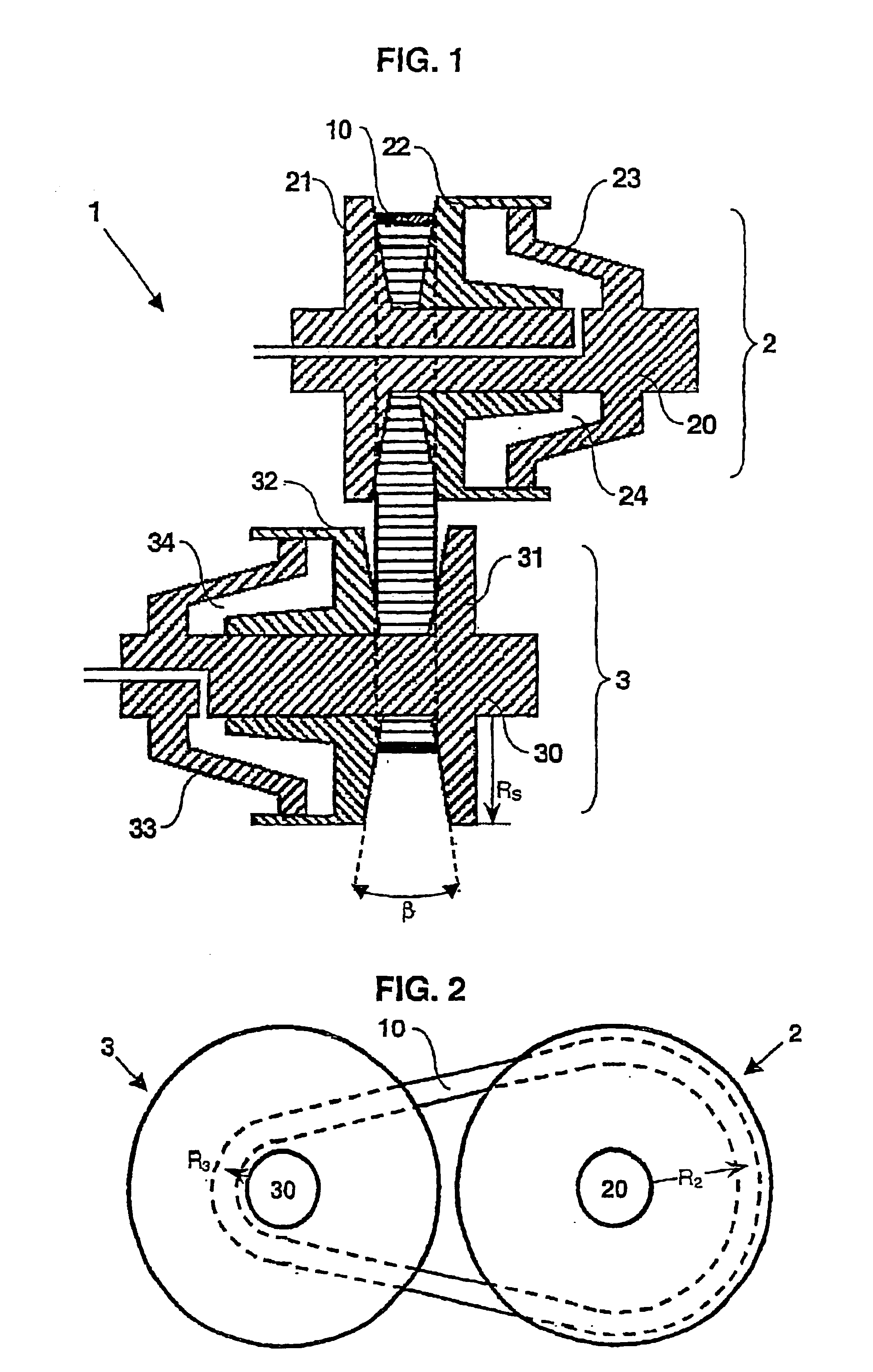

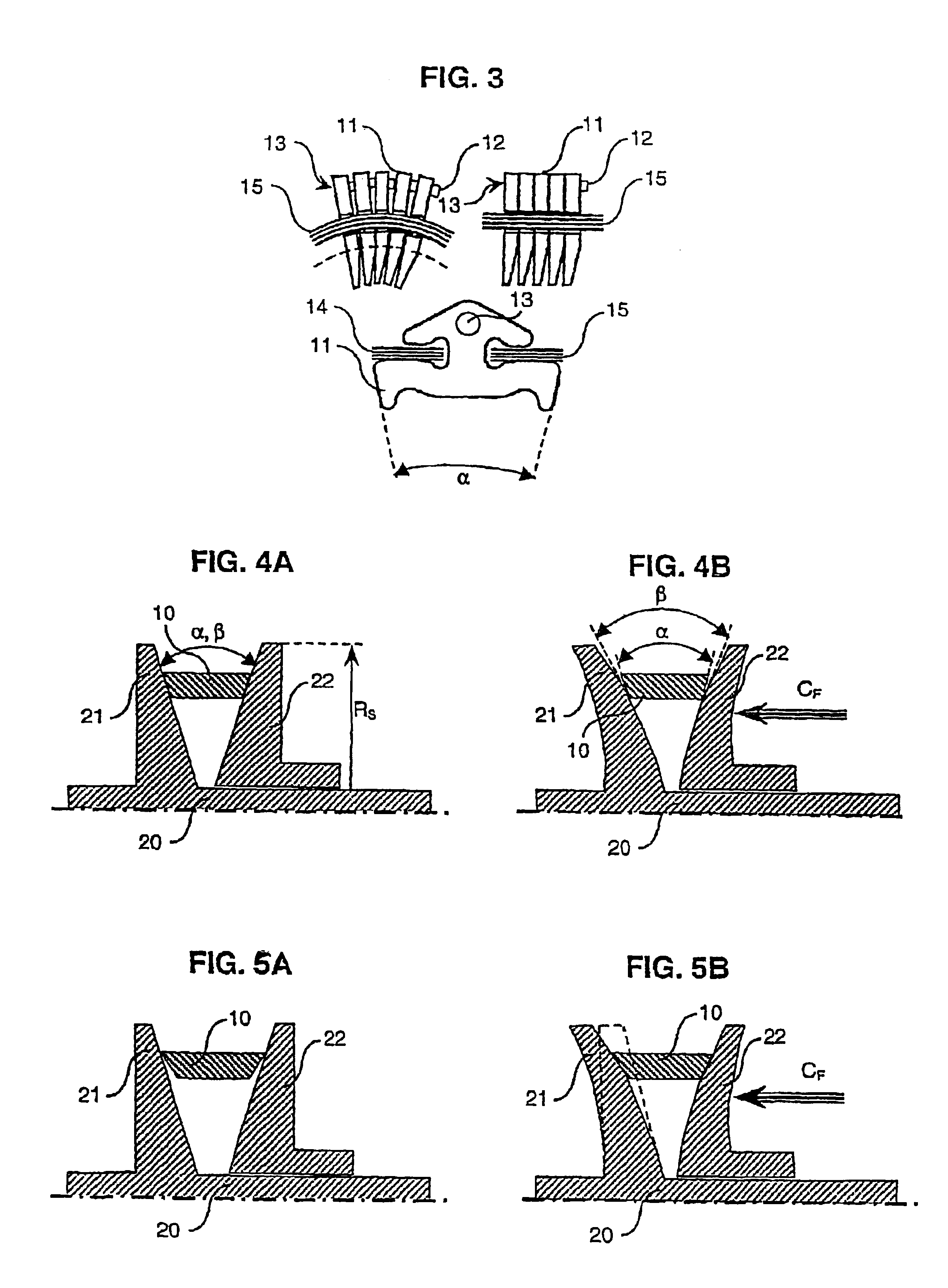

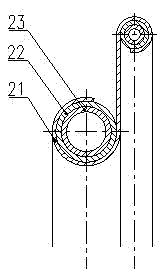

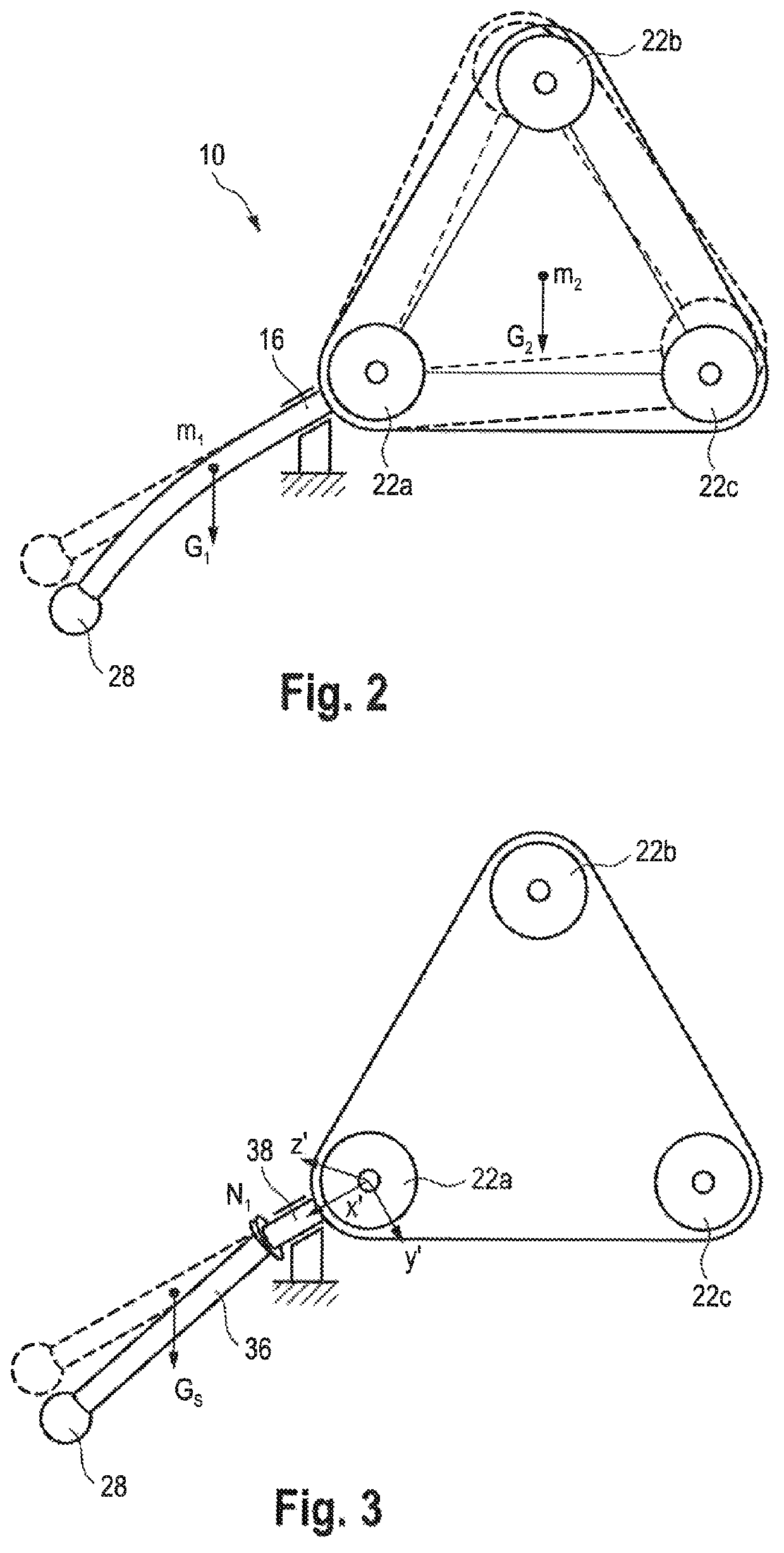

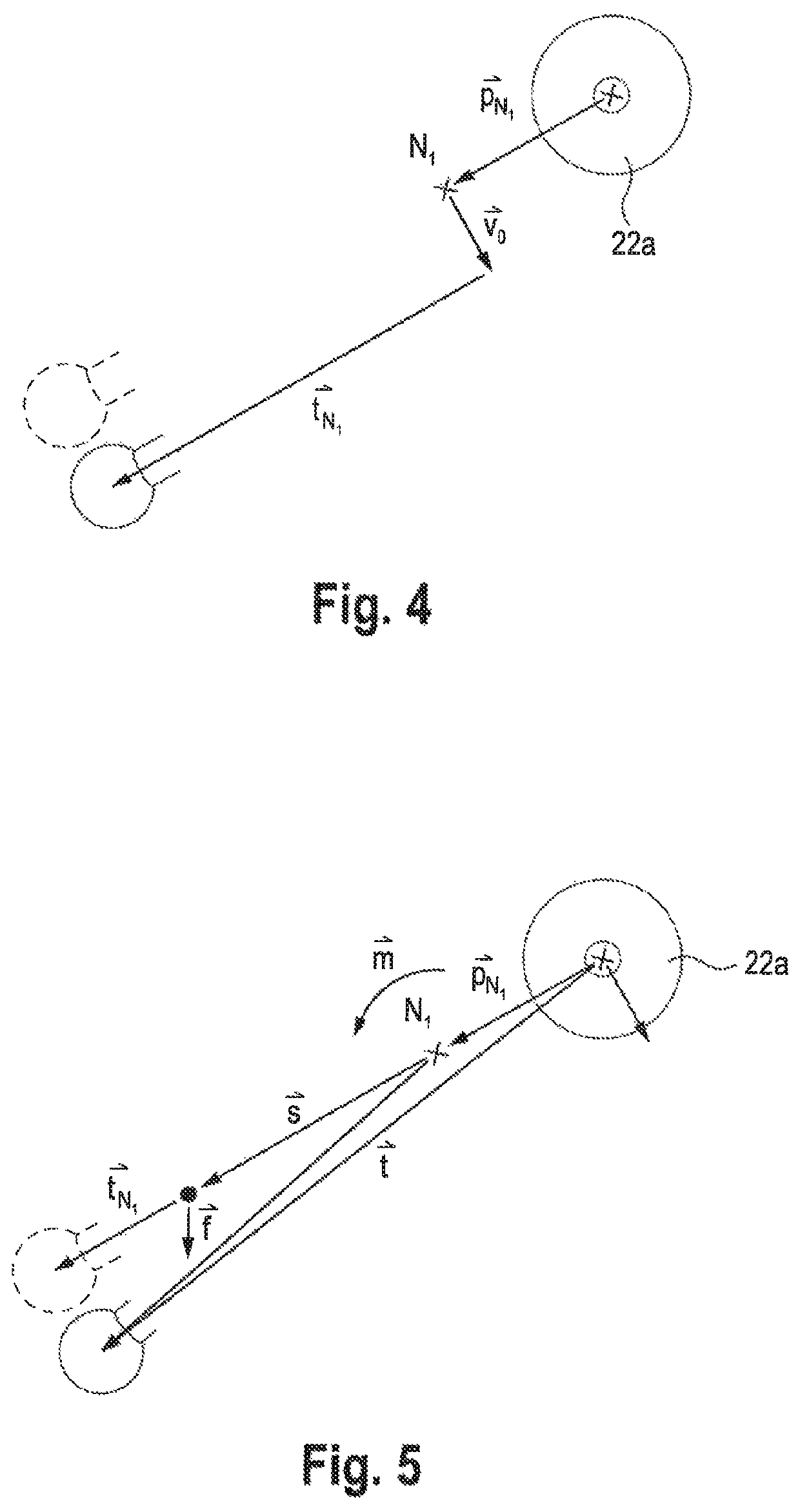

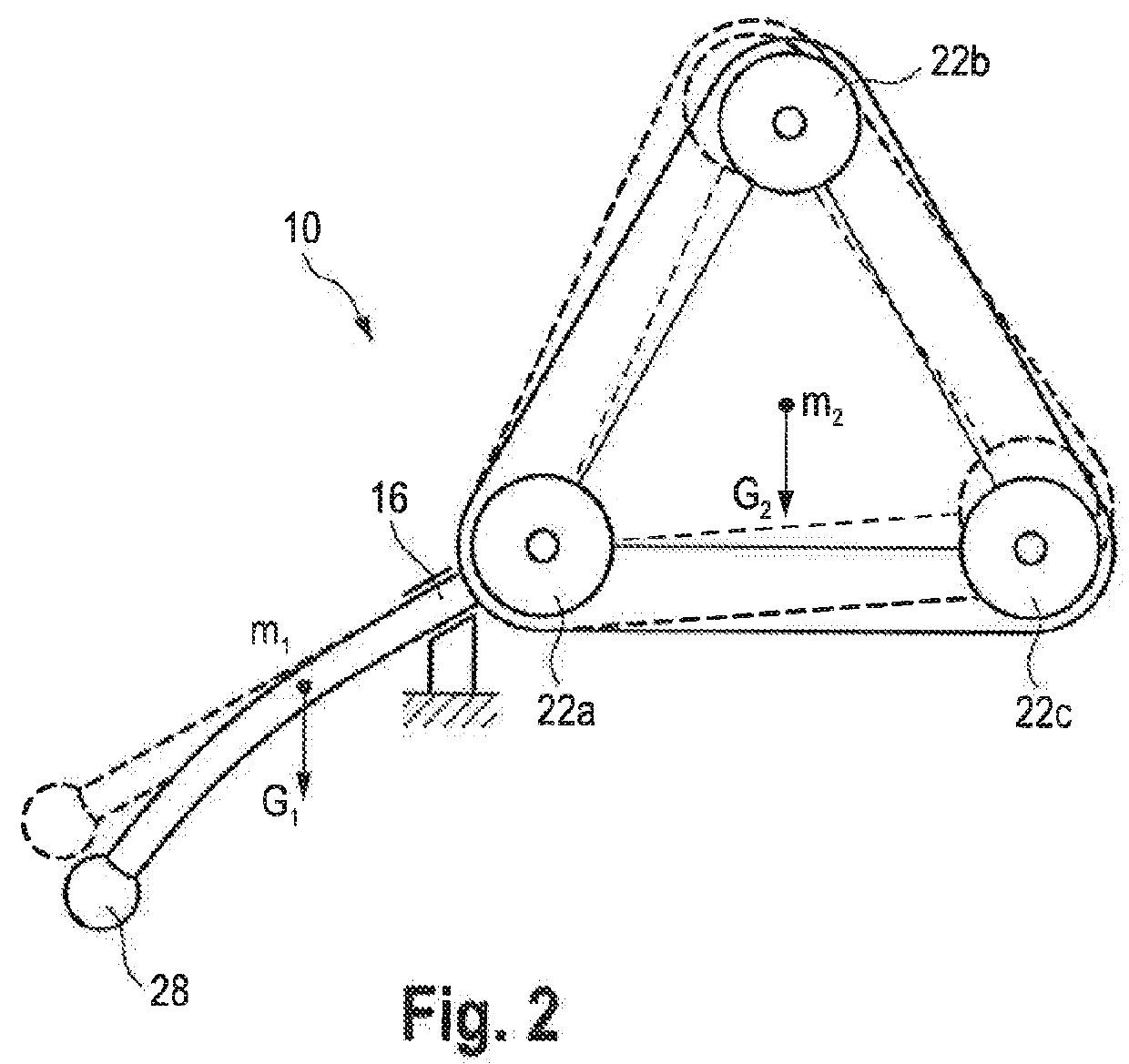

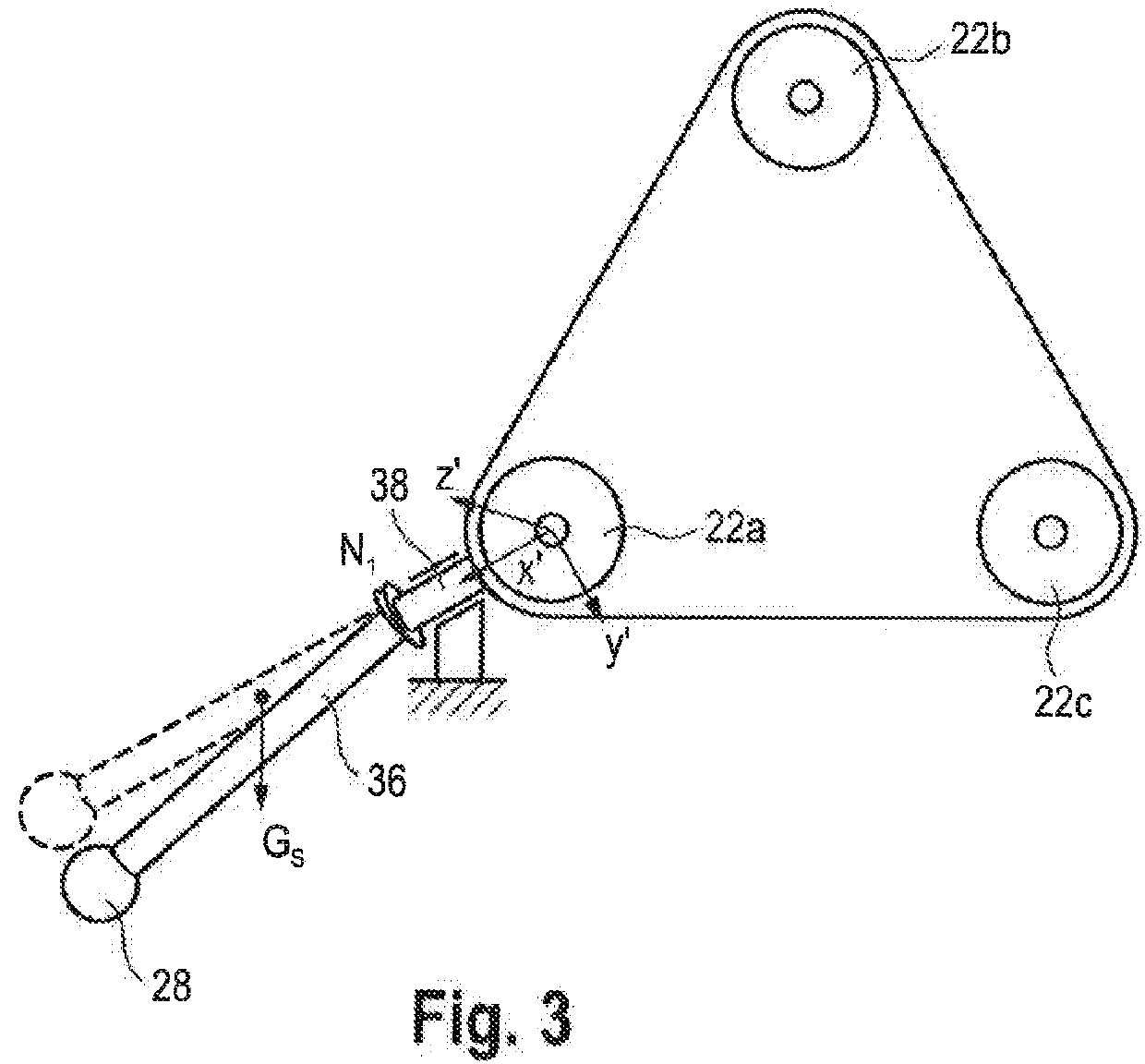

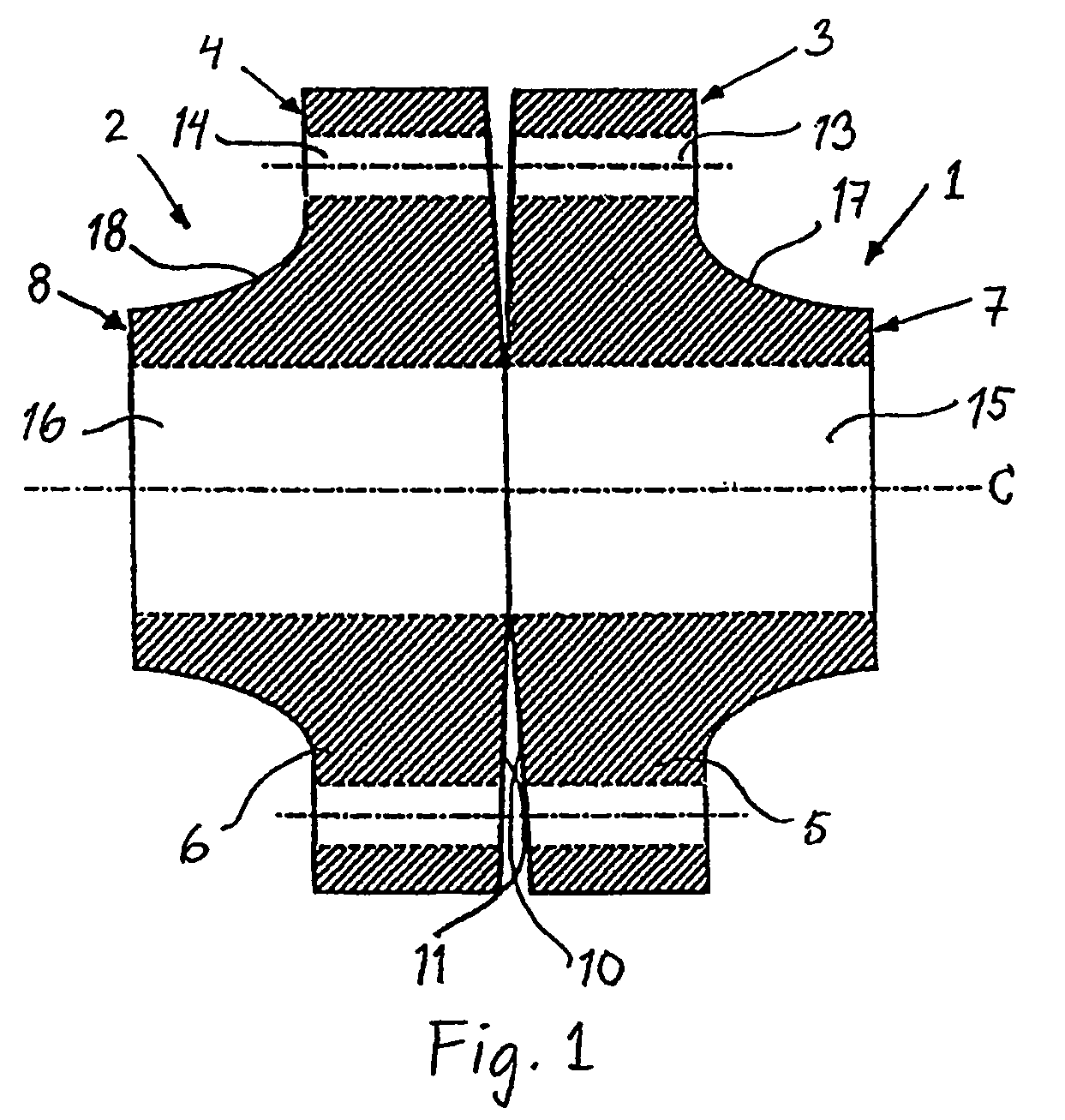

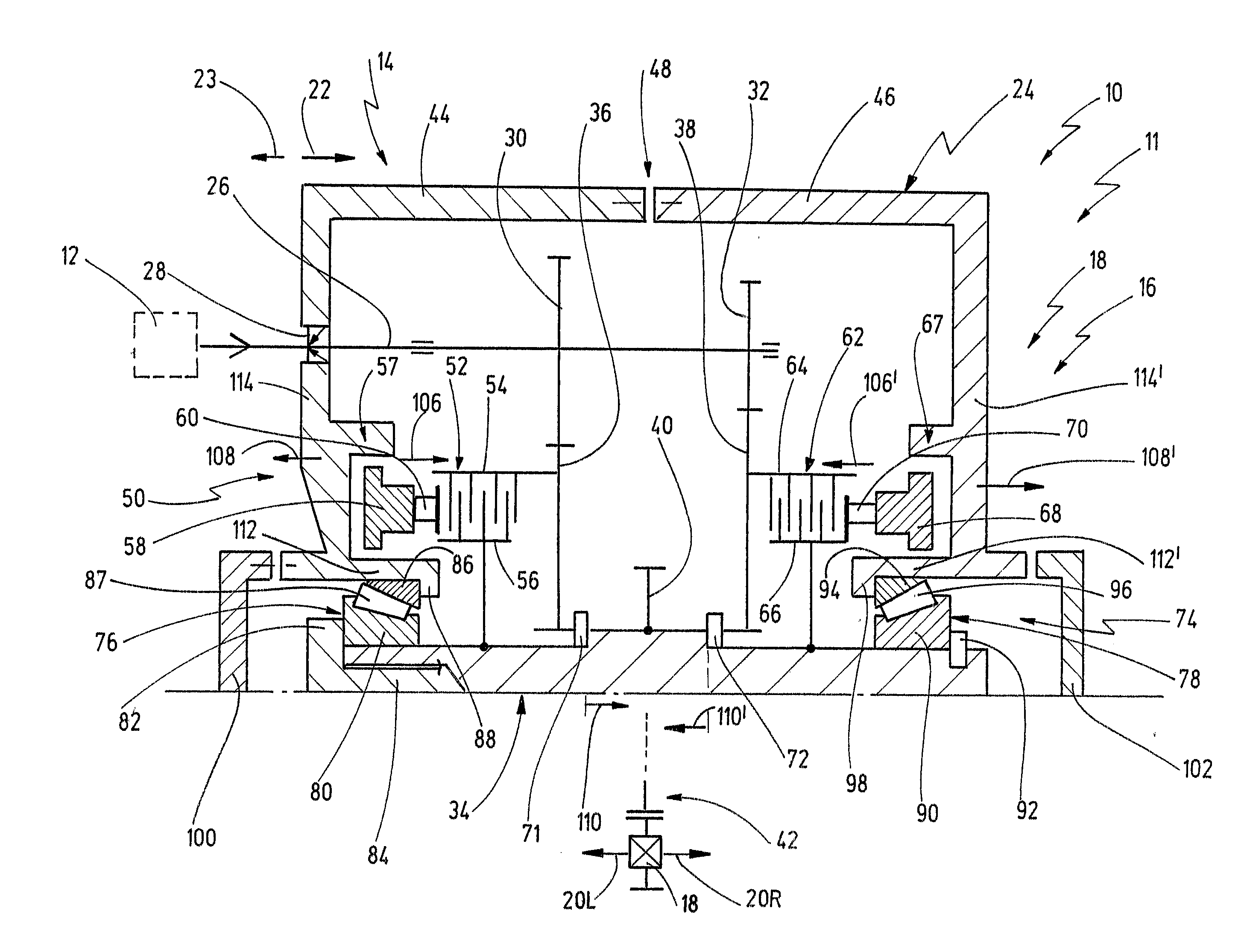

Continuously variable transmission, endless flexible belt for torque transmission and adjustable pulley

A continuously variable transmission, provided with two adjustable pulleys, each pulley comprising a pair of mutually displaceable essentially frusto-conical pulley sheaves having a radial dimension provided on a pulley shaft, each sheave having a sheave face, whereby the sheave faces of a pulley are mutually oriented at a pulley angle, and with an endless flexible belt for transmitting torque comprising two lateral side faces, which are mutually oriented at a belt angle (alpha) such that the flexible belt tapers radially inwardly and which are intended for interacting with the sheave faces of a pulley under the influence of a clamping force to be exerted on the flexible belt by the sheaves. The belt angle is marginally, but notionally, larger than the pulley angle (beta) of at least one pulley for at least a substantial part of the radial dimension of the pulley sheaves.

Owner:VAN DOORNES TRANSMISSIE BV

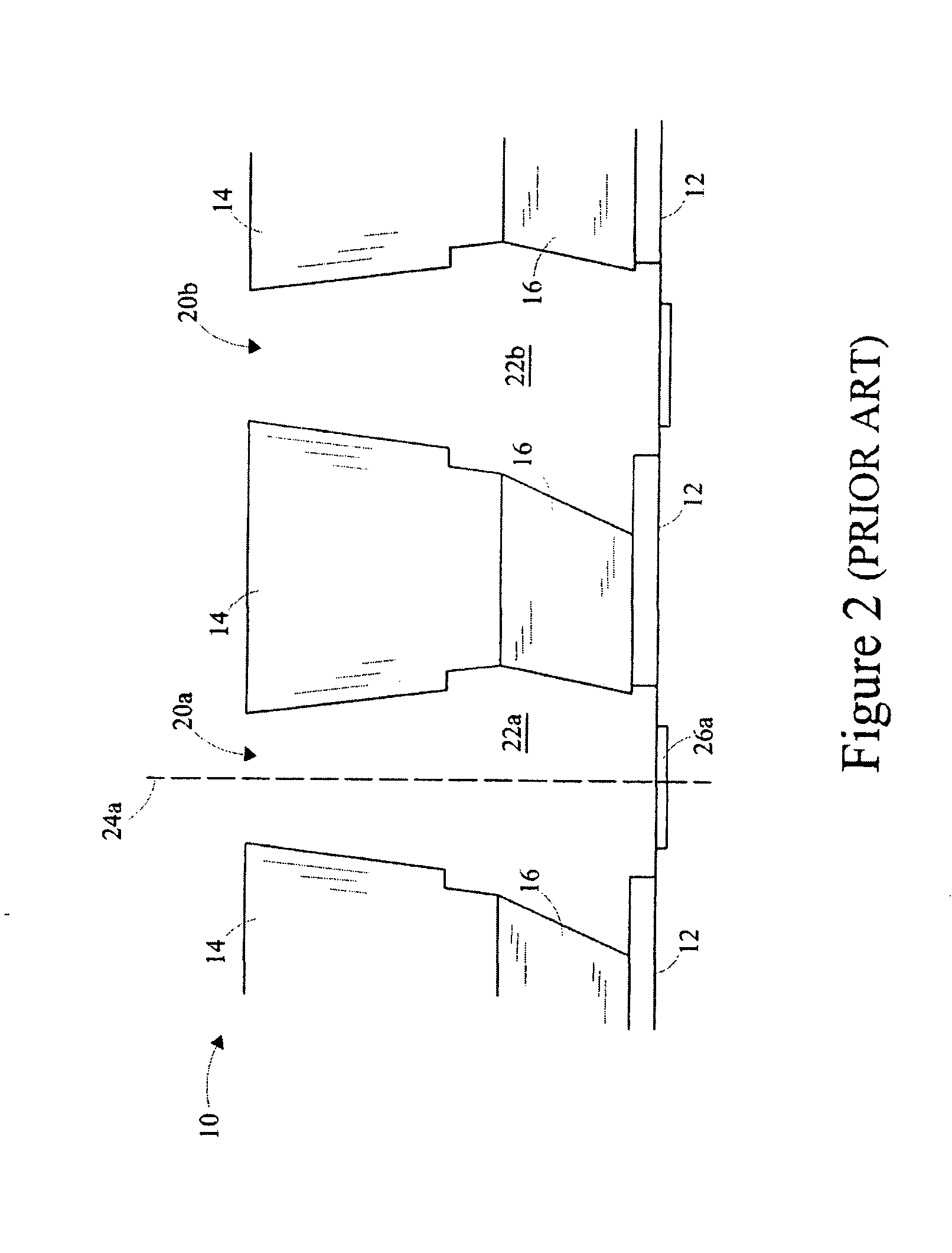

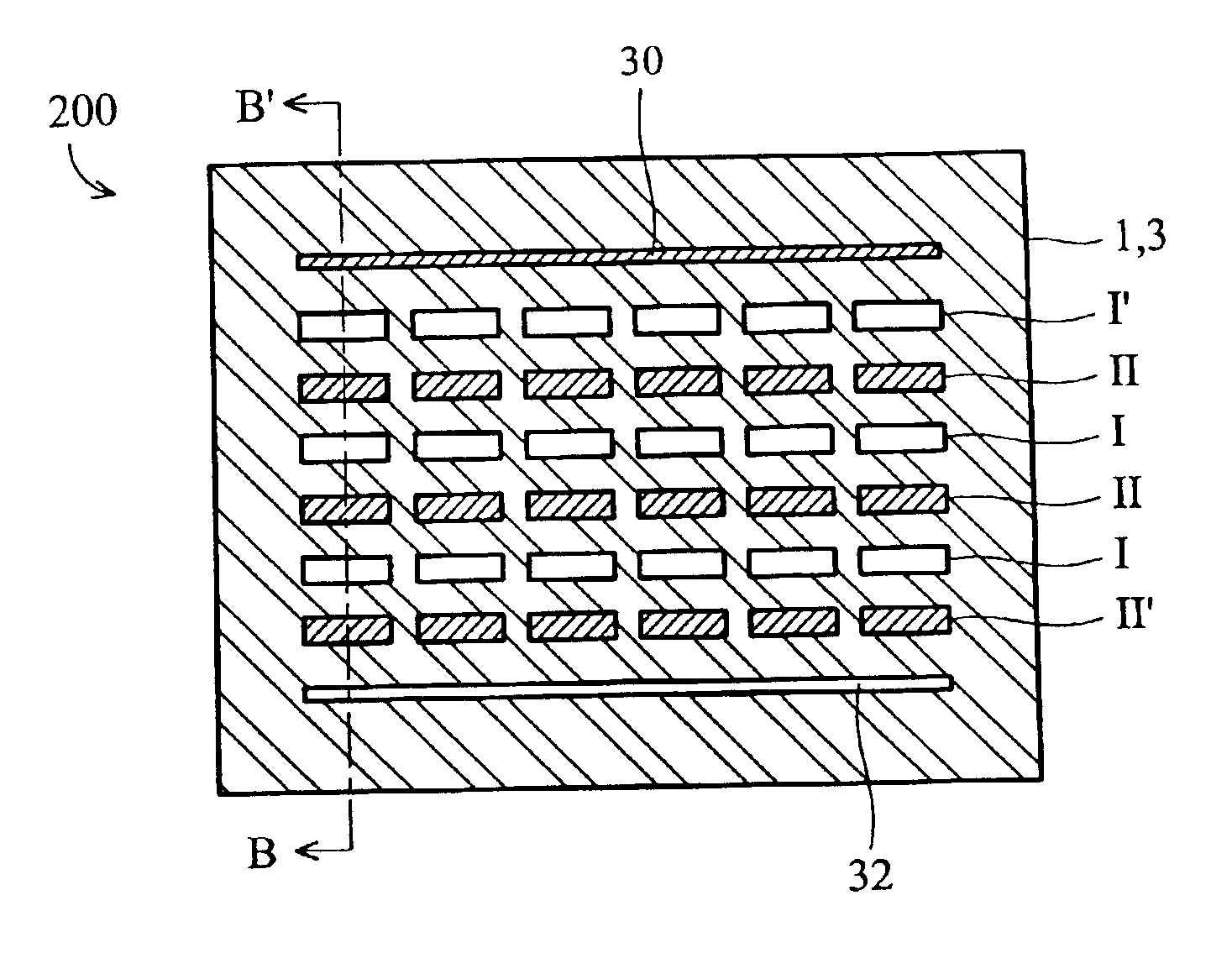

Alternating phase shift mask

InactiveUS6977127B2Convenient ArrangementCompensation for deformationPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringPhase-shift mask

An alternating phase shift mask. The alternating phase shift mask includes a transparent substrate, a light-shielding layer disposed on the transparent substrate to define a transparent array consisting of a plurality of first phase rows and a plurality of second phase rows alternately interposed between the first phase rows. The alternating phase shift mask further comprises a phase interference enhancement feature disposed a predetermined distance from the outermost row of the transparent array, wherein the phases of the phase interference enhancement feature and the outermost row are reverse.

Owner:WINBOND ELECTRONICS CORP

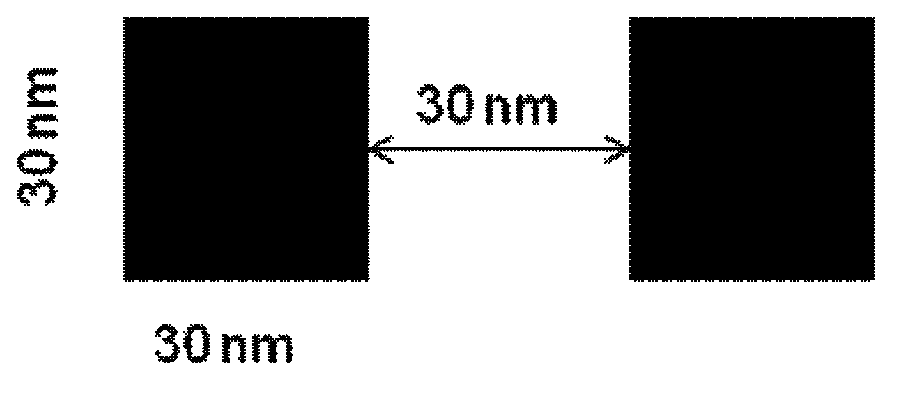

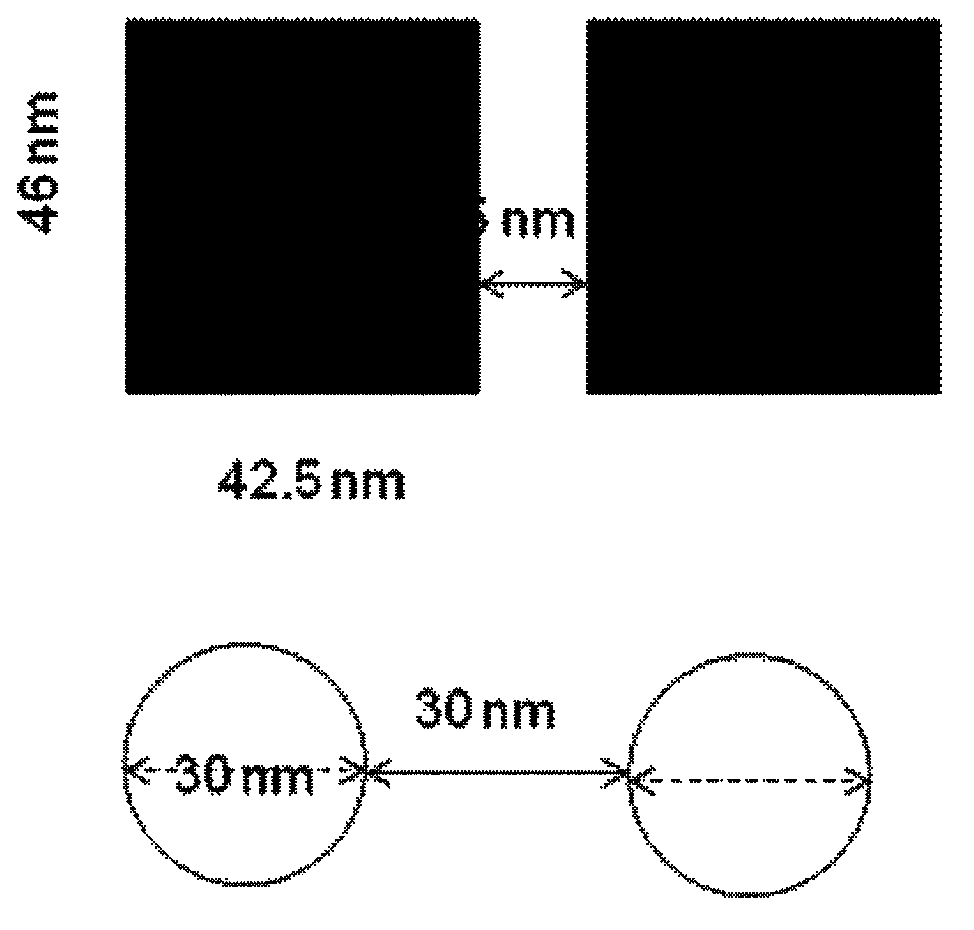

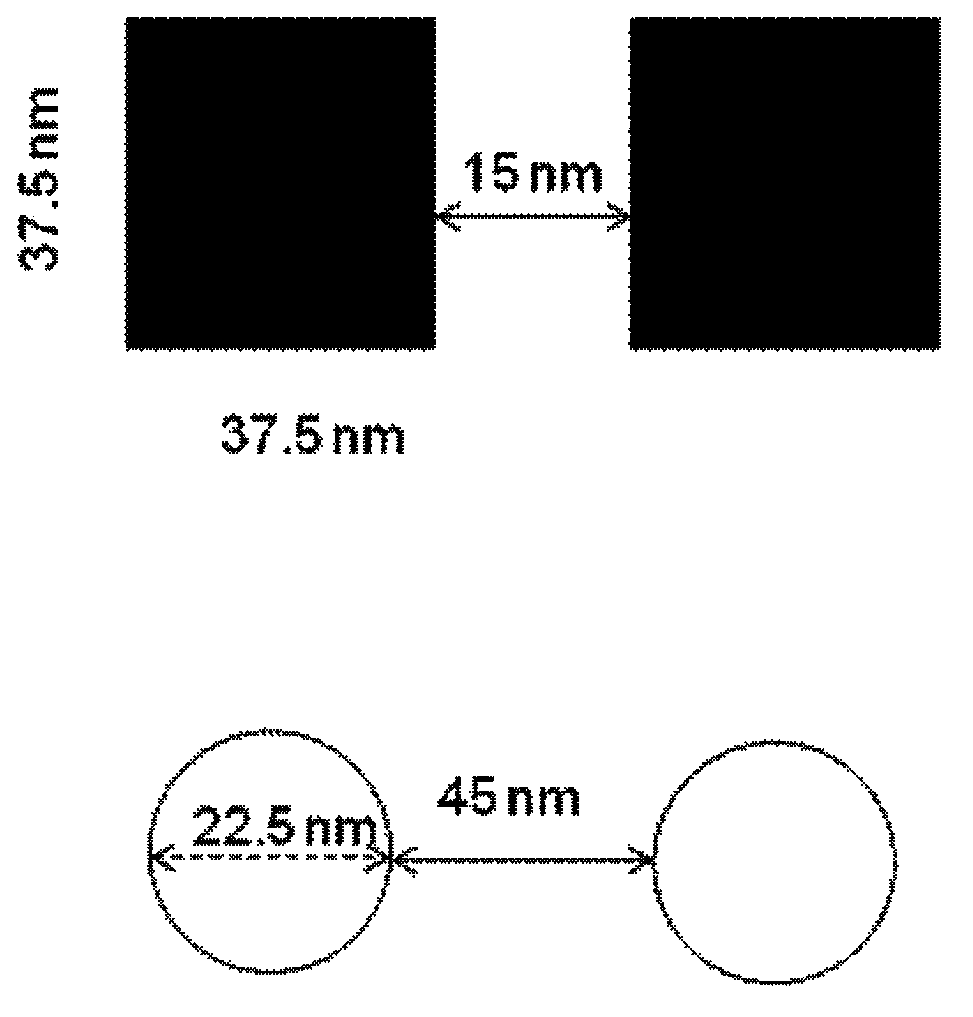

Optical proximity correction method for contact hole graphic design

ActiveCN103777457ACompensation for deformationOriginals for photomechanical treatmentGraphicsComputational physics

The invention provides an optical proximity correction method for contact hole graphic design, and the method comprises the following steps: providing a design layout with contact hole graph; implementing a first optical proximity correction for the contact hole figure in the design layout; determining whether the contact hole figure after the first optical proximity correction satisfies the requirement of mask layer rule examination, if the contact hole figure does not satisfy the requirement of mask layer rule examination, implementing a second optical proximity correction for the contact hole figure which is processed by the first optical proximity correction, and simultaneously adding another figure between the contact hole figures which are processed by the first optical proximity correction, and thereby connecting the two adjacent contact hole figures for forming a figure unit; carrying out a photoetching projection simulation for the figure unit. According to the invention, the optical proximity correction for the contact hole figure is not limited by the mask layer rule examination, and thereby the corrected contact hole figure can completely compensate the deformation of the contact hole figure caused by interference and diffraction of light during photoetching simulation.

Owner:SEMICON MFG INT (SHANGHAI) CORP

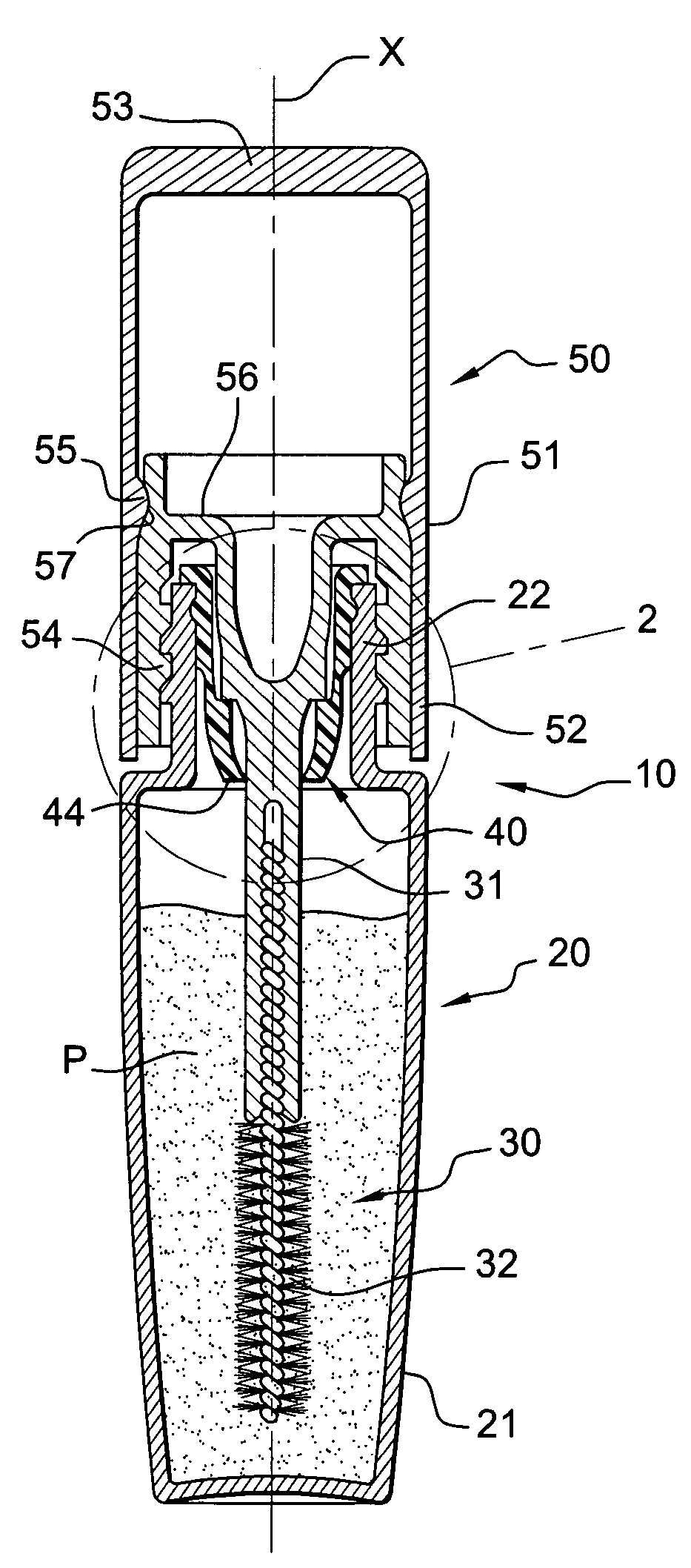

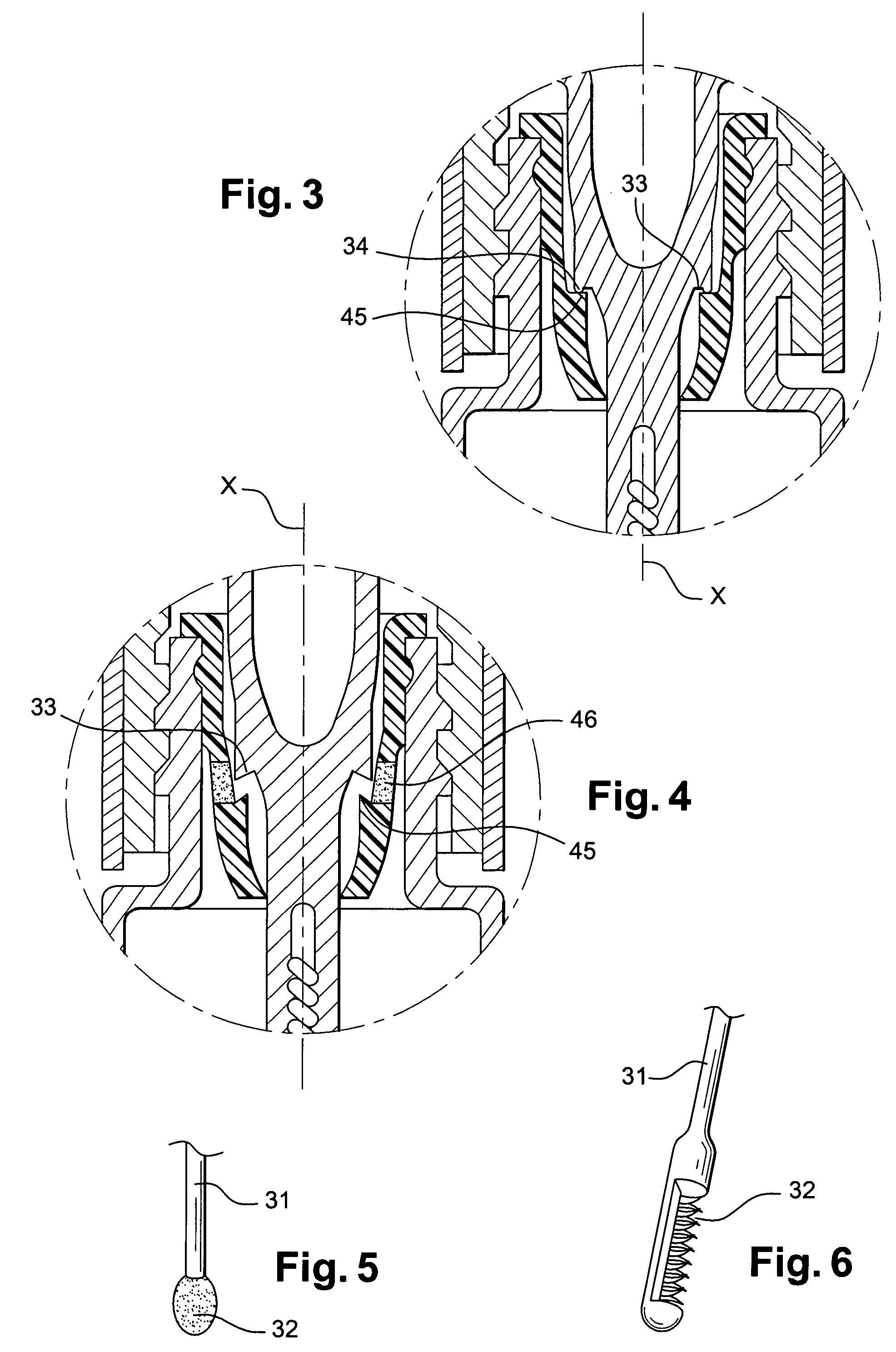

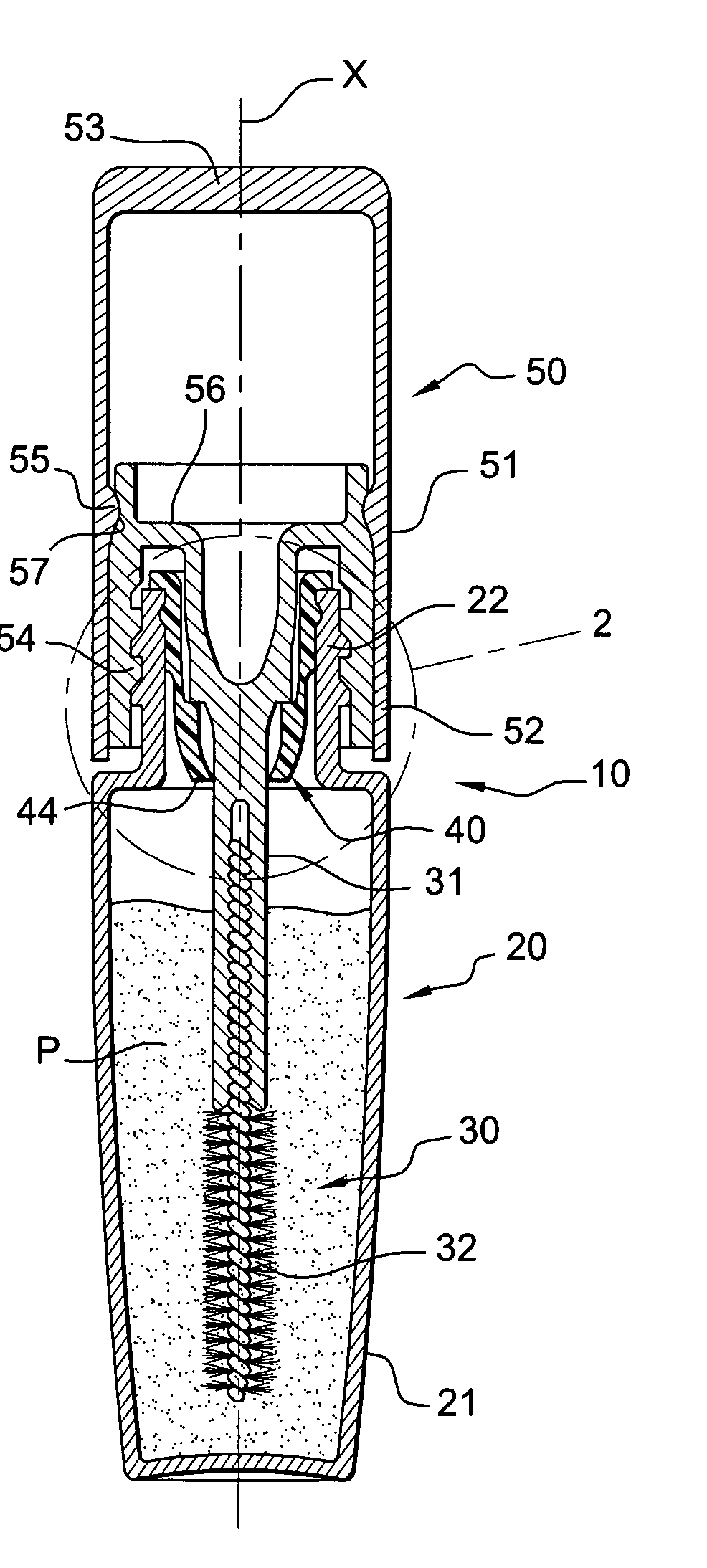

Device for packaging and application of a product

InactiveUS20060008314A1Disadvantage is reduced and avoidedEasy to manufactureBristlePackaging toiletriesEngineeringMechanical engineering

Owner:LOREAL SA

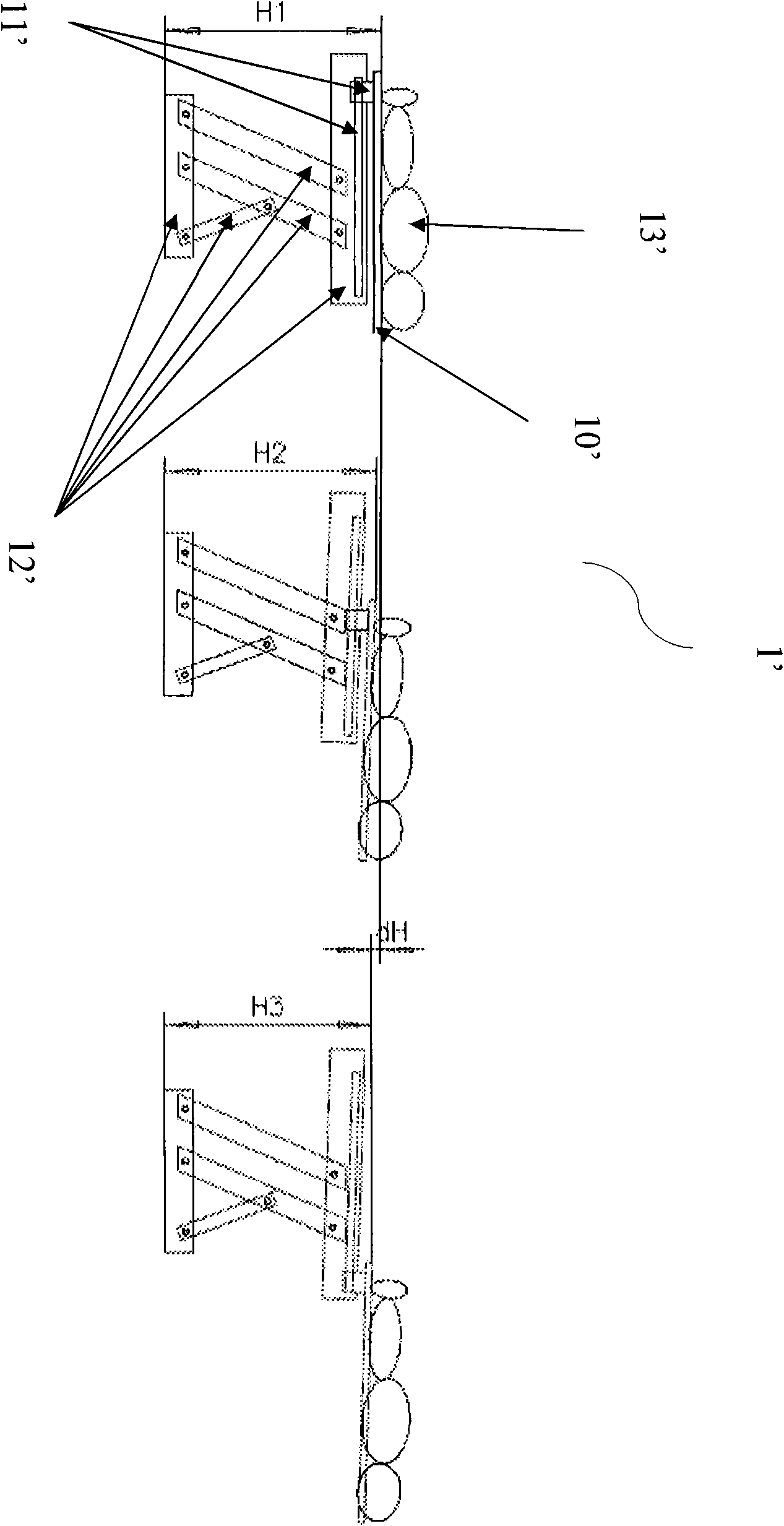

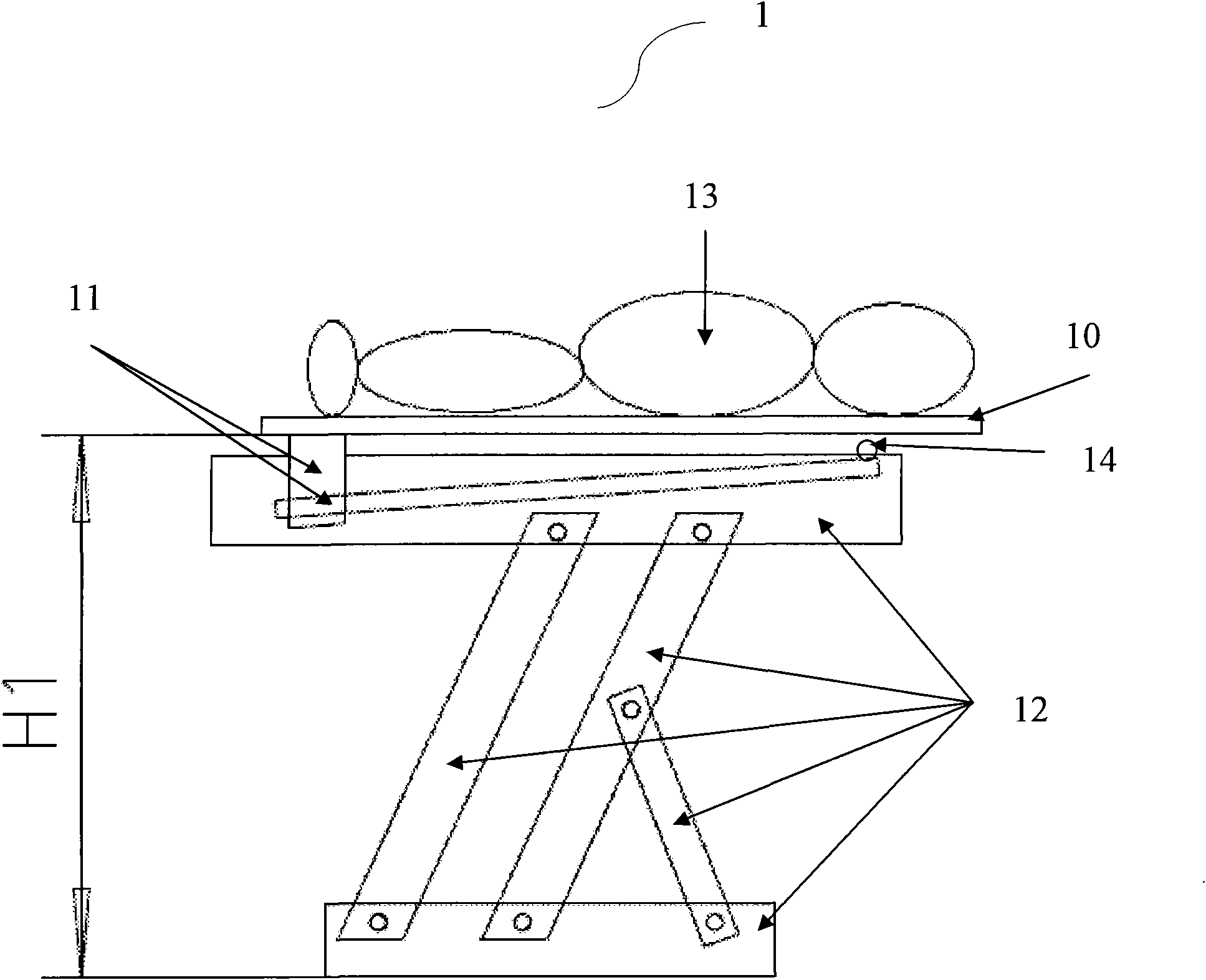

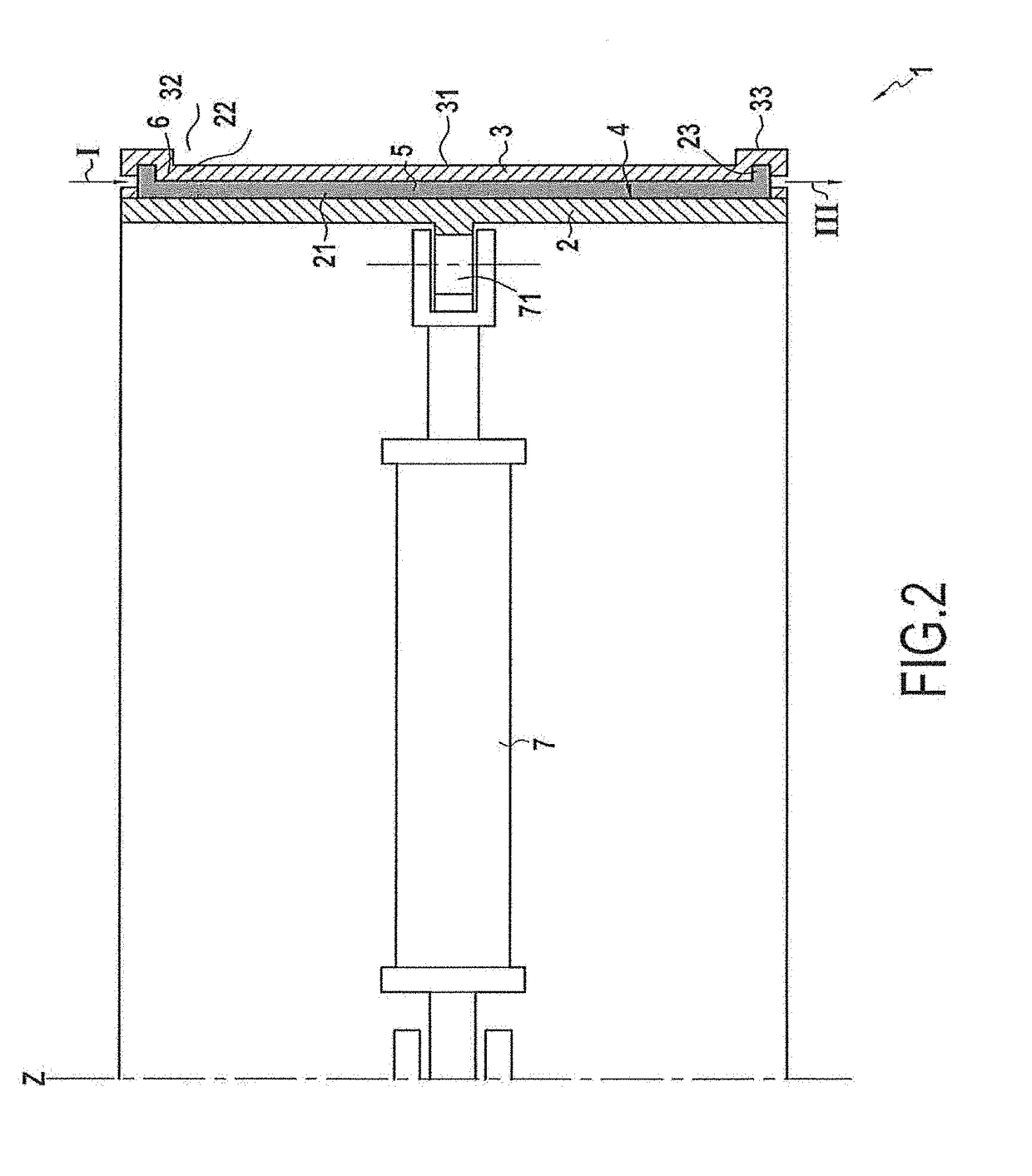

Scanning bed and computed tomography (CT) system or positron emission tomography (PET) system containing scanning bed

ActiveCN103126713AReduce saggingLow costPatient positioning for diagnosticsComputerised tomographsLinear motionPre deformation

The invention provides a scanning bed and a computed tomography (CT) system or a positron emission tomography (PET) system containing the scanning bed. The scanning bed comprises a bed plate, a linear motion device and a bed support, wherein the bed plate comprises a pre-deformation plate, the pre-deformation plate has pre-deformation, under the condition that actual load is exerted, and the direction of pre-deformation and the pre-deformation plate can produce opposite deformation directions. The linear motion device is used for guiding the bed plate to conduct linear motion, and the bed support is used for supporting the bed plate and the linear motion device. The bed plate can obviously reduce drooping and / or inclination of the bed plate of the scanning bed, shortens the range of deformation of the bed plate, and reduces vibration range of the bed plate, and the range of the deformation of the bed plate is caused by different weights of patients. In addition, the scanning bed has the advantage of being low in achieving cost.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

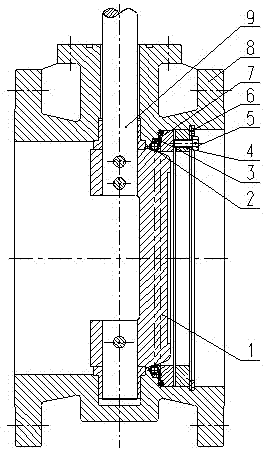

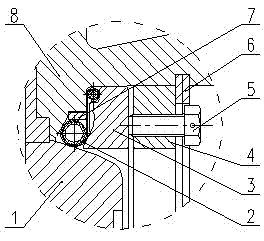

Hard sealing double eccentric butterfly valve for S-shaped elastic double O-shaped metal sealing ring

The invention discloses a hard sealing double eccentric butterfly valve for an S-shaped elastic double O-shaped metal sealing ring, which comprises a double eccentric butterfly plate, a valve body and a valve rod and is characterized in that the S-shaped elastic double O-shaped metal sealing ring is placed between the double eccentric butterfly plate and the valve body, and a regulation mechanism consisting of a pressing ring, a control ring, a positioning plate, a regulating screw bolt and a retainer ring is arranged at the sealing ring part. The S-shaped elastic double O-shaped metal sealing ring structure is adopted, so the problem of complicated sealing structures or single static sealing design structures caused by the dynamic and static sealing coupling is effectively solved, and the sealing structure is simplified. The sealing ring part is provided with a regulating structure, the elastic deformation quantity and the deformation direction of large and small elastic O-shaped metal sealing rings can be simultaneously regulated, the elastic deformation quantity and the elastic force can be effectively provided, the reliability of the sealing performance is improved, the deformation caused by the heat expansion and cold contraction of materials can be obviously and perfectly compensated particularly in high and low temperature application occasions with sharp temperature change, and the internal sealing performance of the butterfly valve is ensured.

Owner:704TH RES INST OF CHINA SHIPBUILDING IND CORP

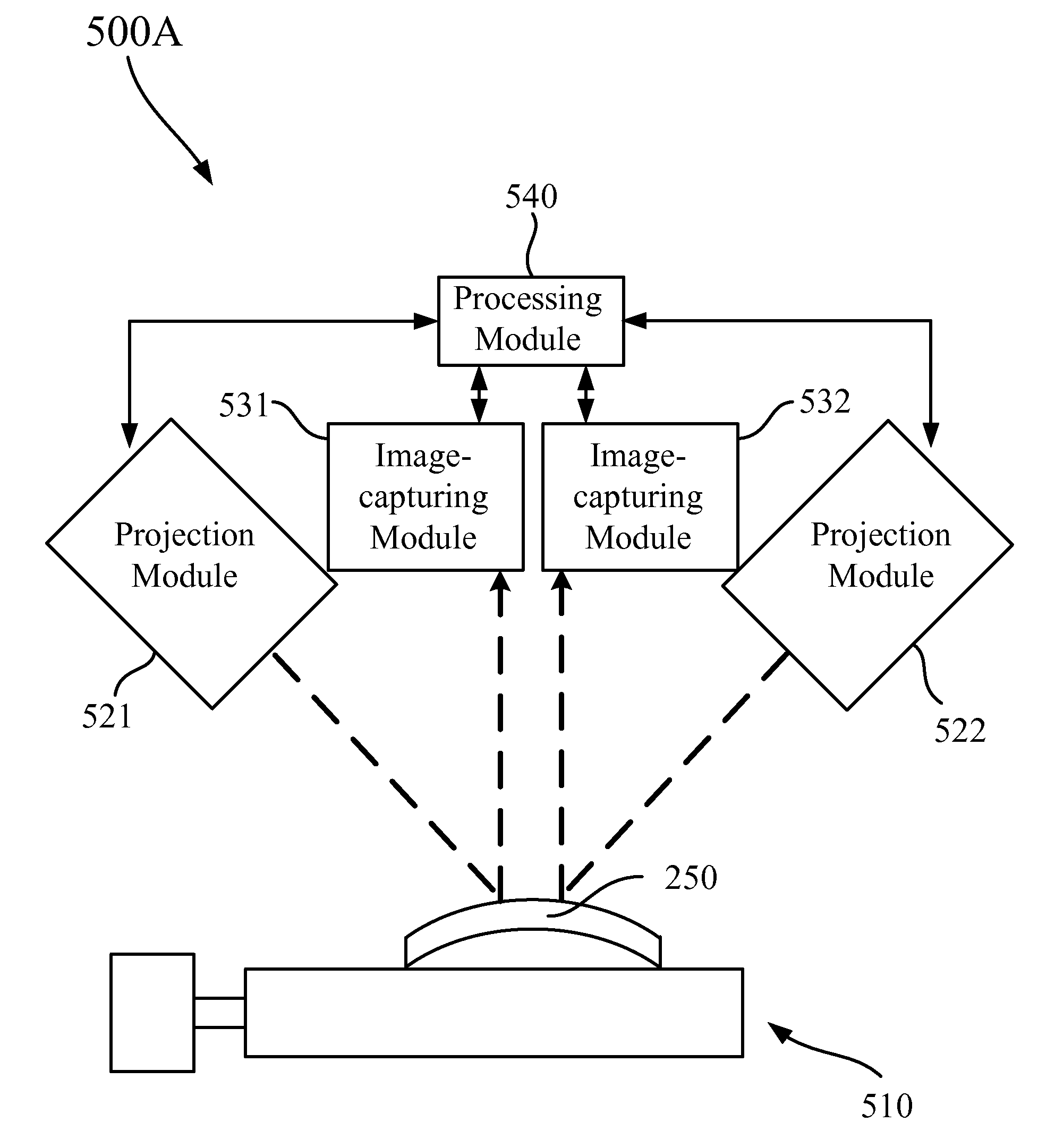

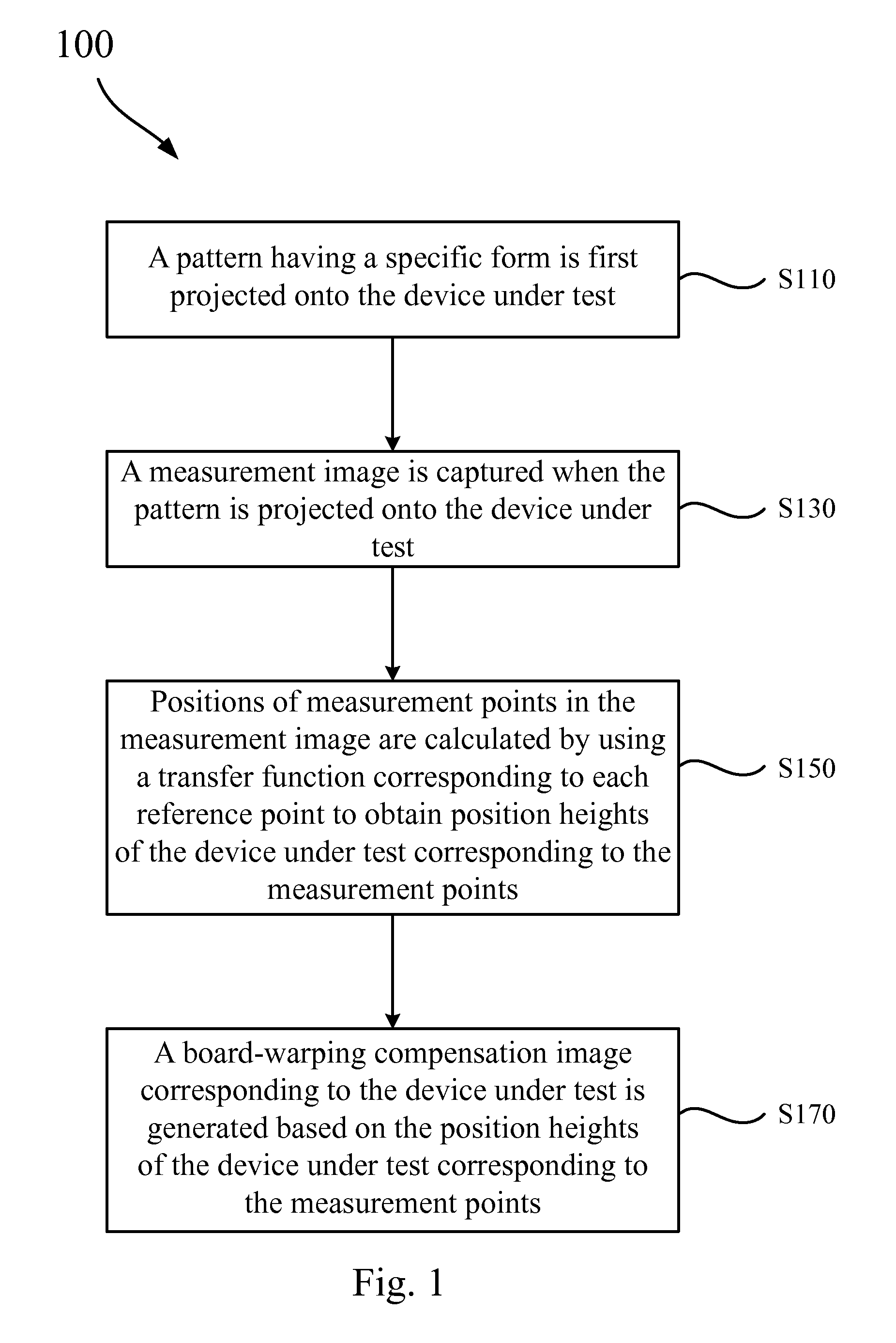

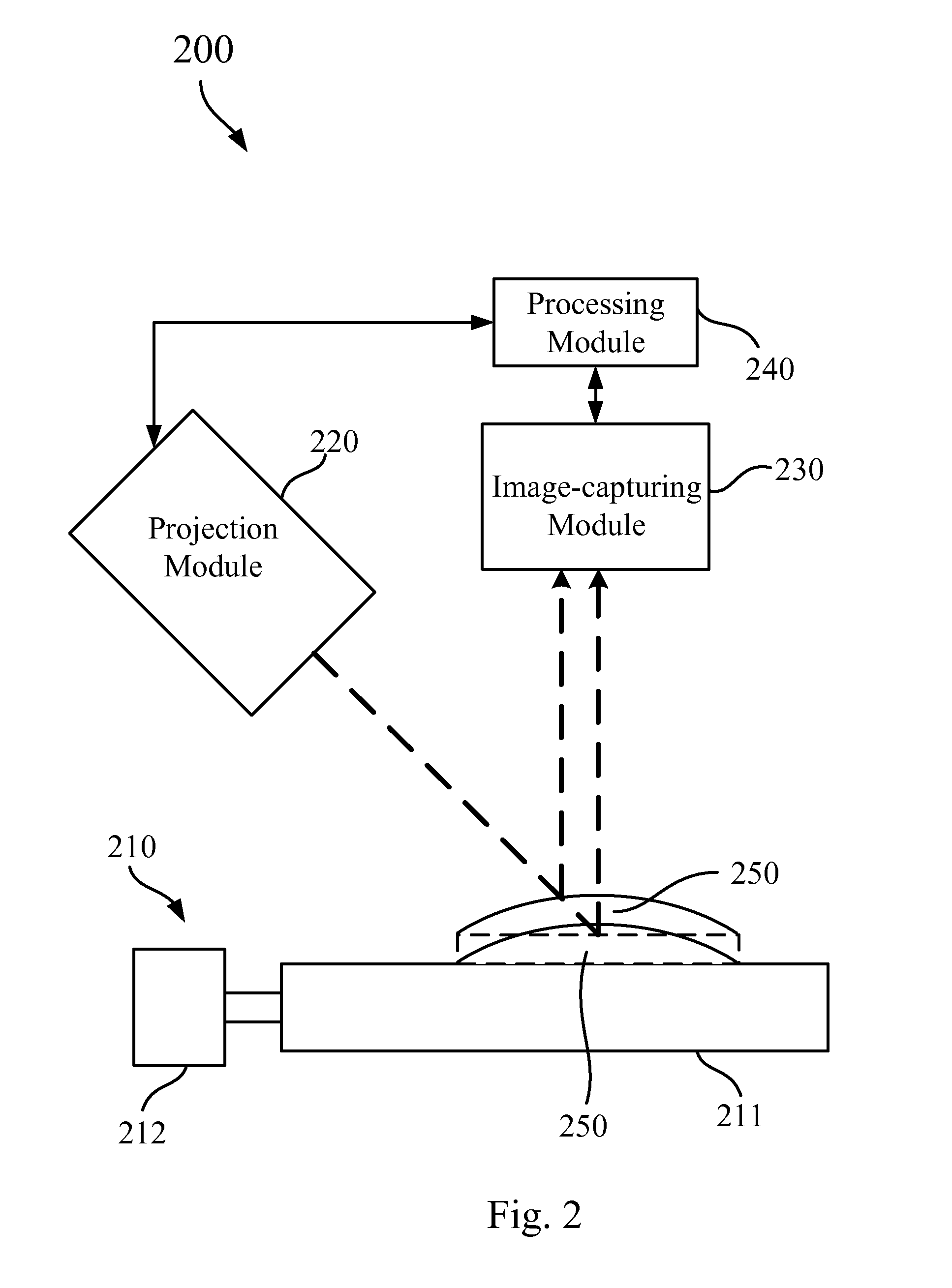

Board-warping measuring apparatus and board-warping measuring method thereof

ActiveUS20160209206A1Improve efficiencyImprove accuracyUsing optical meansMeasurement deviceMeasurement point

A board-warping measuring method is configured to measure a device under test. The device under test is disposed on a measuring carrier. The board-warping measuring method includes: projecting a pattern onto the device under test, wherein the pattern includes plural reference points; capturing a measurement image by an image-capturing module when the pattern is projected onto the device under test, wherein the measurement image includes plural measurement points respectively corresponding to the reference points; calculating a position of each of the measurement points in the measurement image by utilizing a transfer function corresponding to each of the reference points to obtain position heights of the device under test corresponding to the measurement points; and compensating for board warping of the device under test based on the position heights of the device under test corresponding to the measurement points.

Owner:TEST RES INC

Hydrodynamic axial bearing

InactiveUS20140241887A1Good effectLower capability requirementsPropellersPump componentsEngineeringMechanical engineering

Owner:ABB TURBO SYST

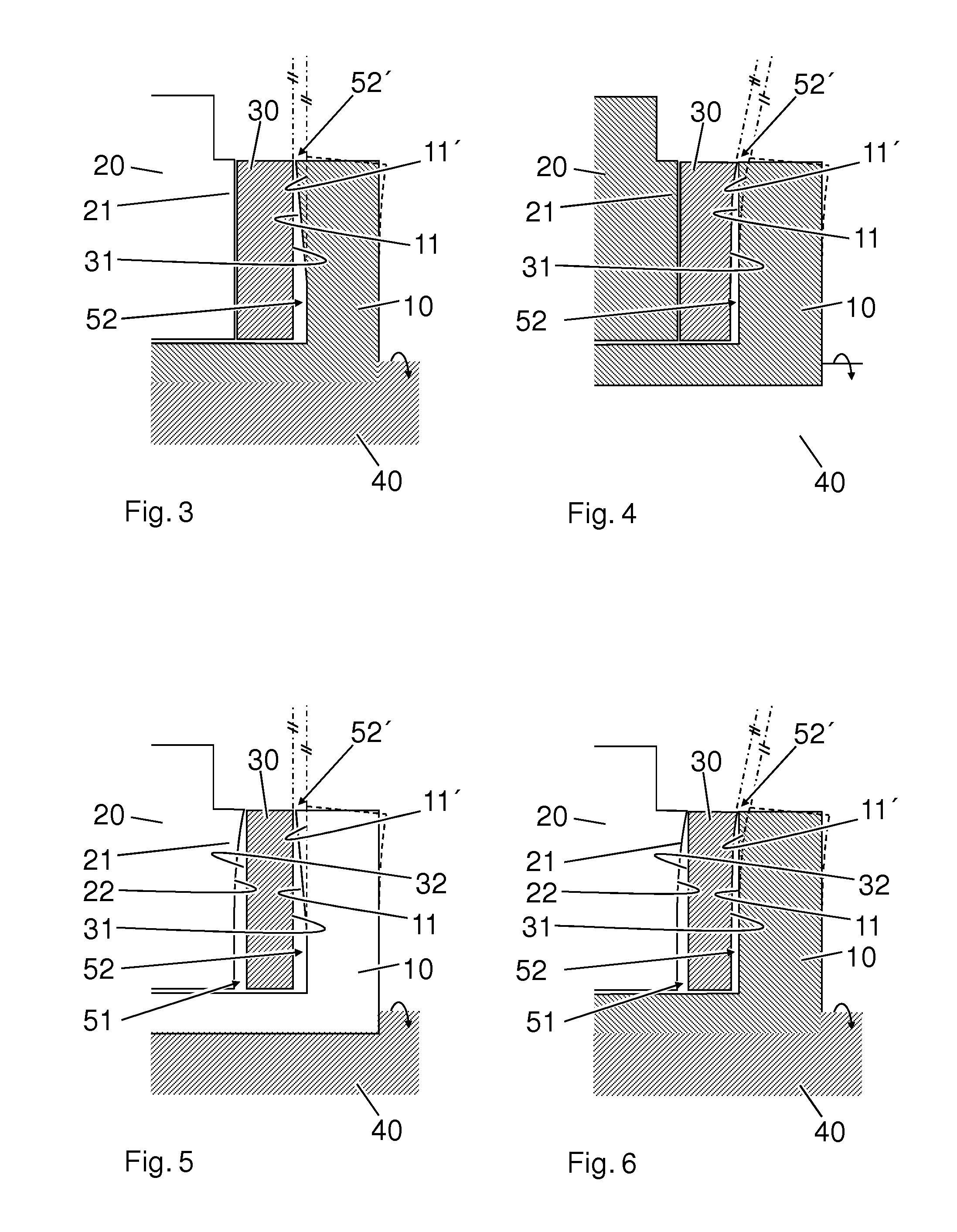

Microprism and microrod lenses, method and apparatus for the production thereof

InactiveUS20060059950A1Avoid deformationCompensation for deformationGlass furnace apparatusRotary drum furnacesEngineeringPrism

The invention relates to a method and an apparatus for producing optical glass elements, in particular optical prisms or optical rod lenses, using a drawing process. The geometry of the glass strand which is to be produced is controlled by means of cooling or heating elements positioned at least around portions of the periphery or longitudinal axis of the glass strand, inside or outside the heating apparatus.

Owner:SCHOTT AG

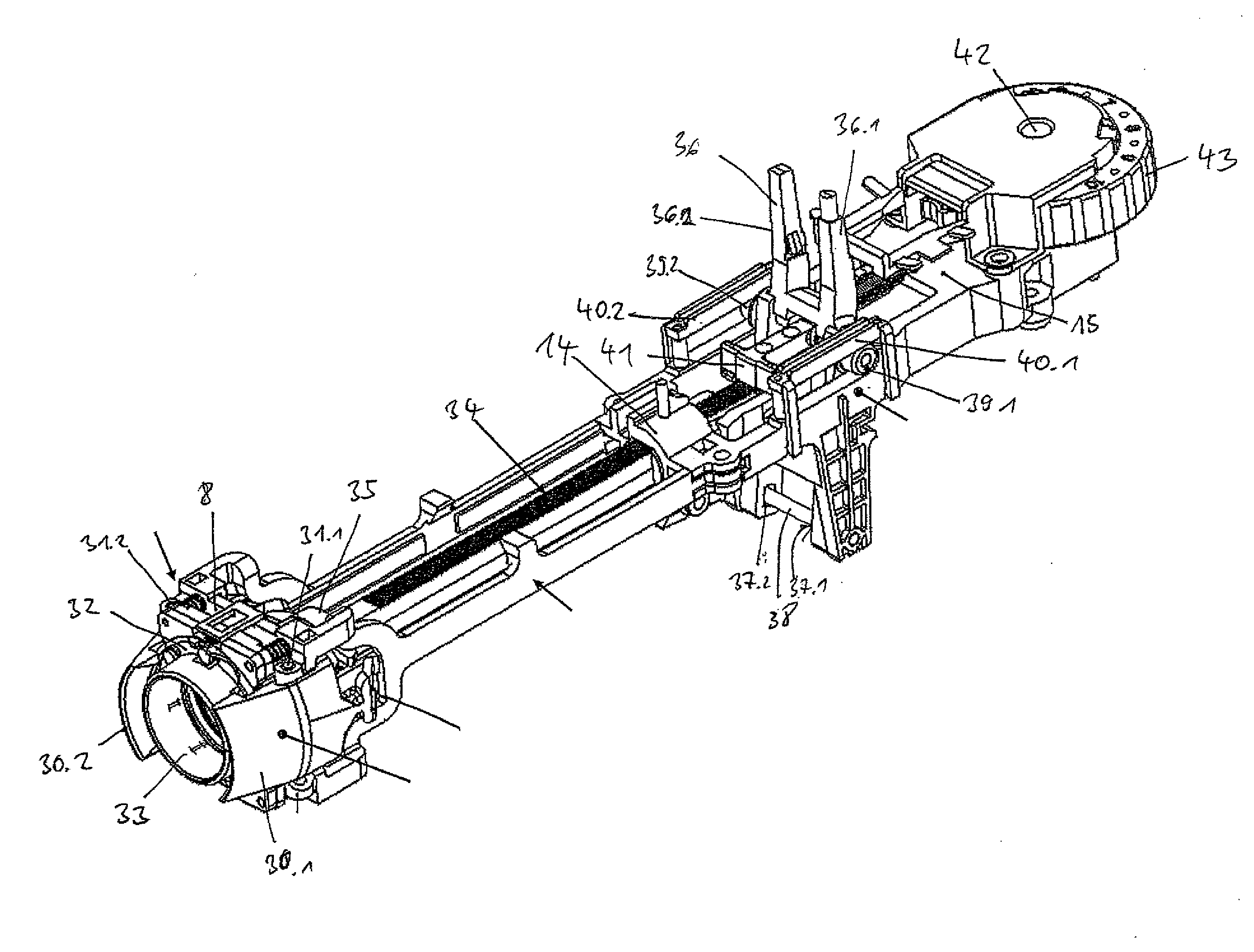

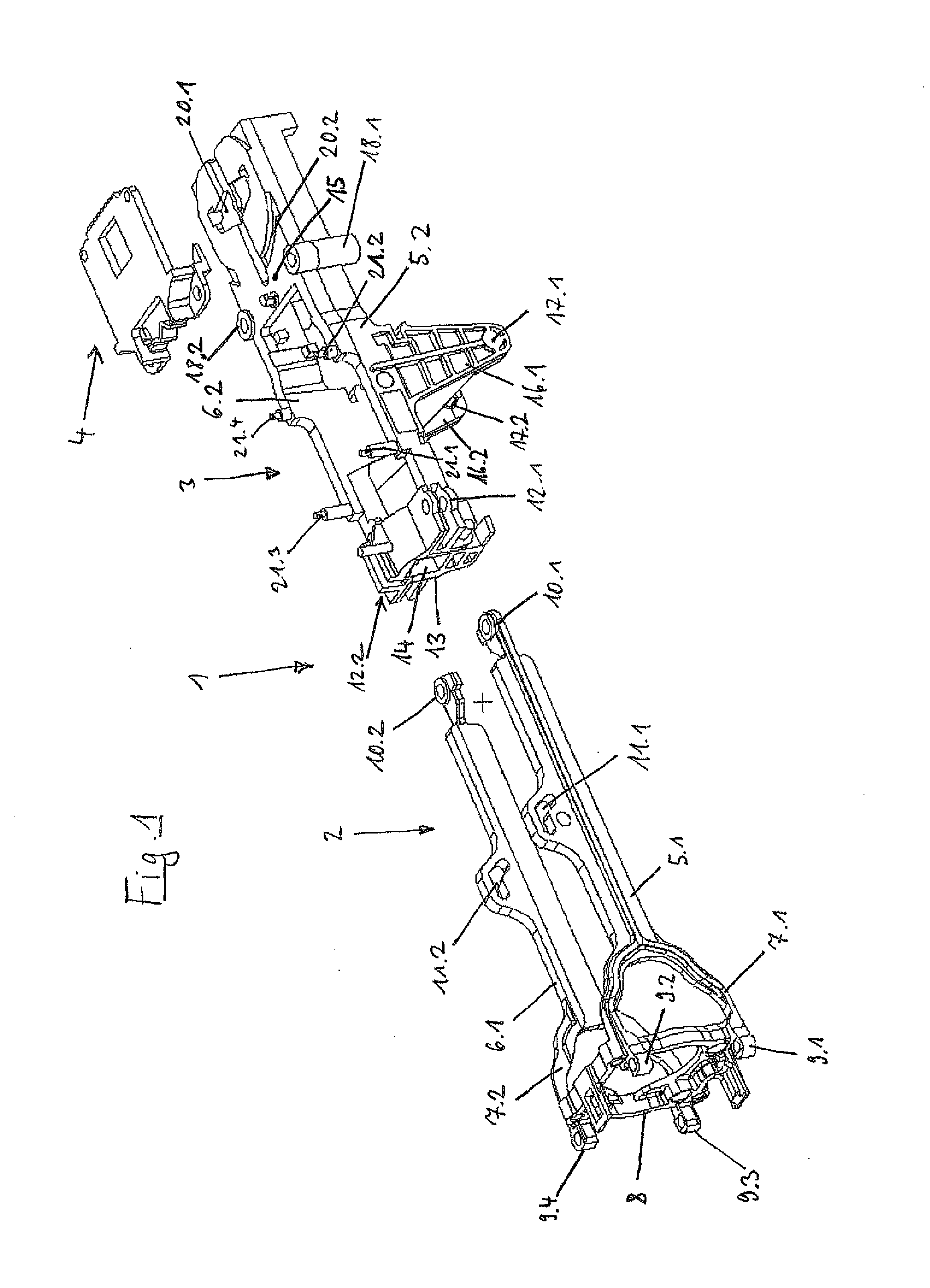

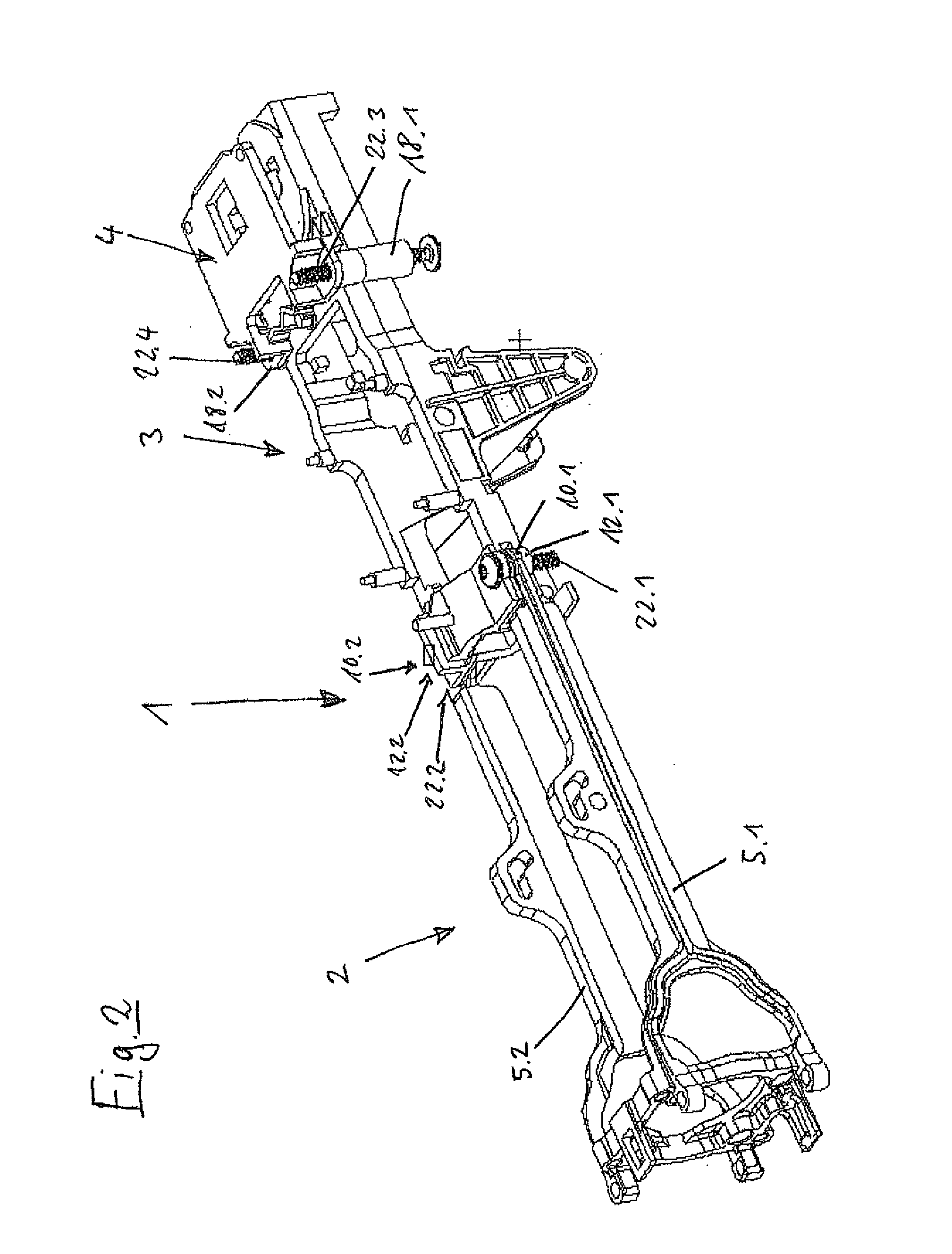

Manual Dosing Device

ActiveUS20130224087A1Relieve pressureGood choiceBurettes/pipettesSoftware engineeringProcess engineering

A manual dosing device comprisingan elongated frame as a support structure,means for releasably holding a syringe or pipette tip at the bottom end of the frame,drive means that are attached above the means for releasably holding to the frame,displacement means for displacing a fluid in the syringe or pipette tip that can be driven by the drive means and are connected to the means for releasably holding, anda housing encasing the frame.

Owner:EPPENDORF SE

Device for packaging and application of a product

InactiveUS7452151B2Disadvantage is reduced and avoidedEasy to manufactureBristlePackaging toiletriesEngineeringMechanical engineering

Owner:LOREAL SA

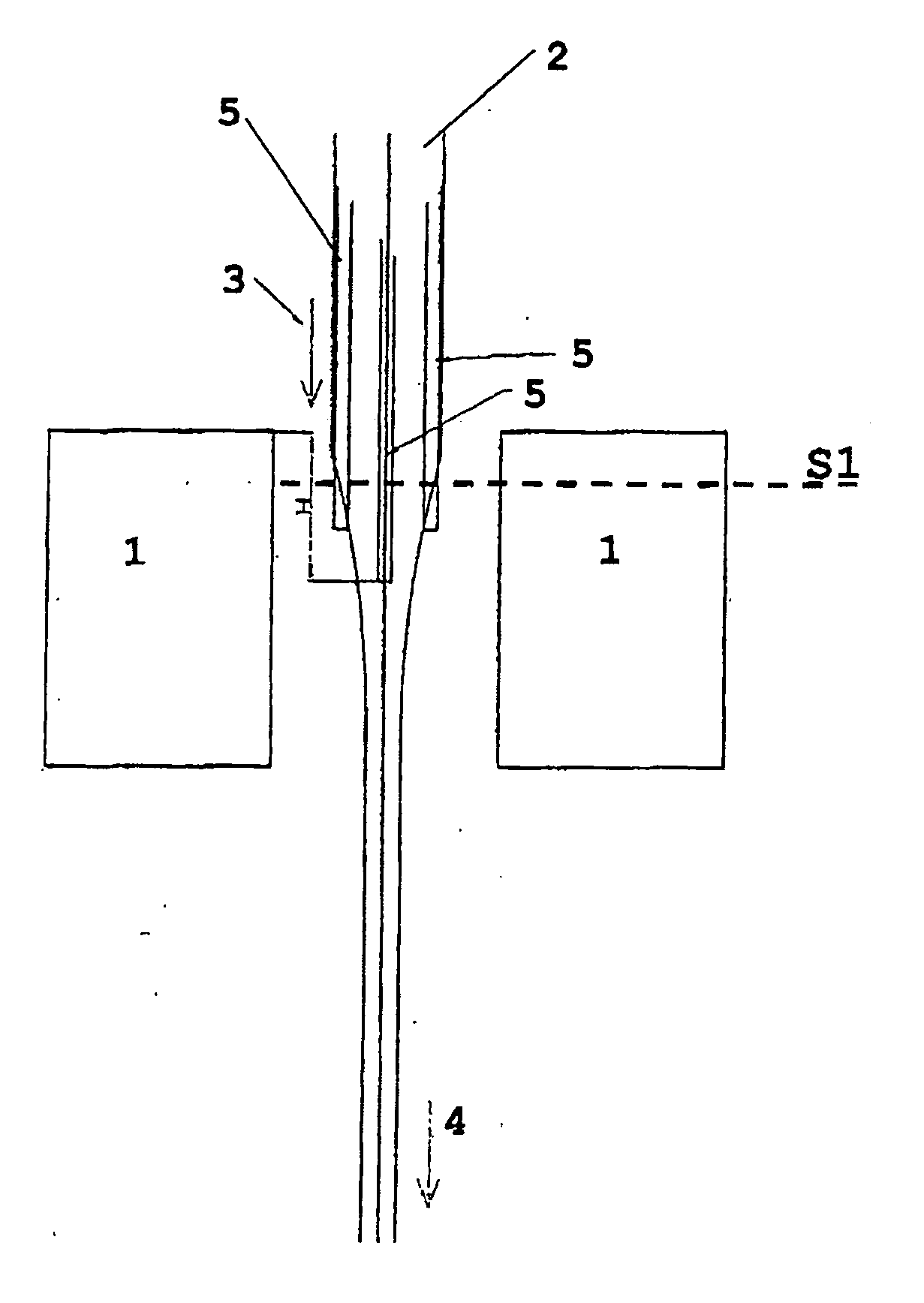

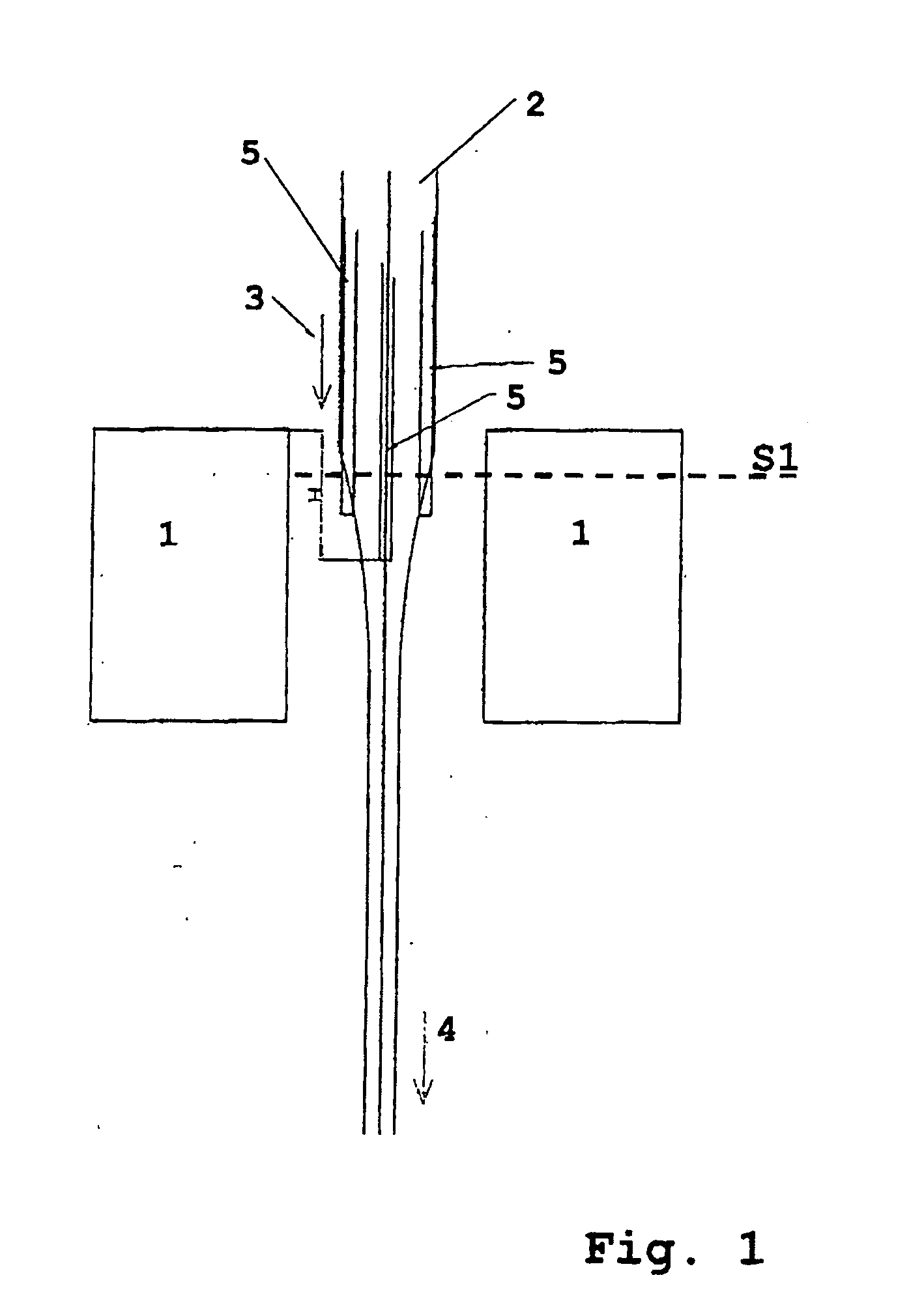

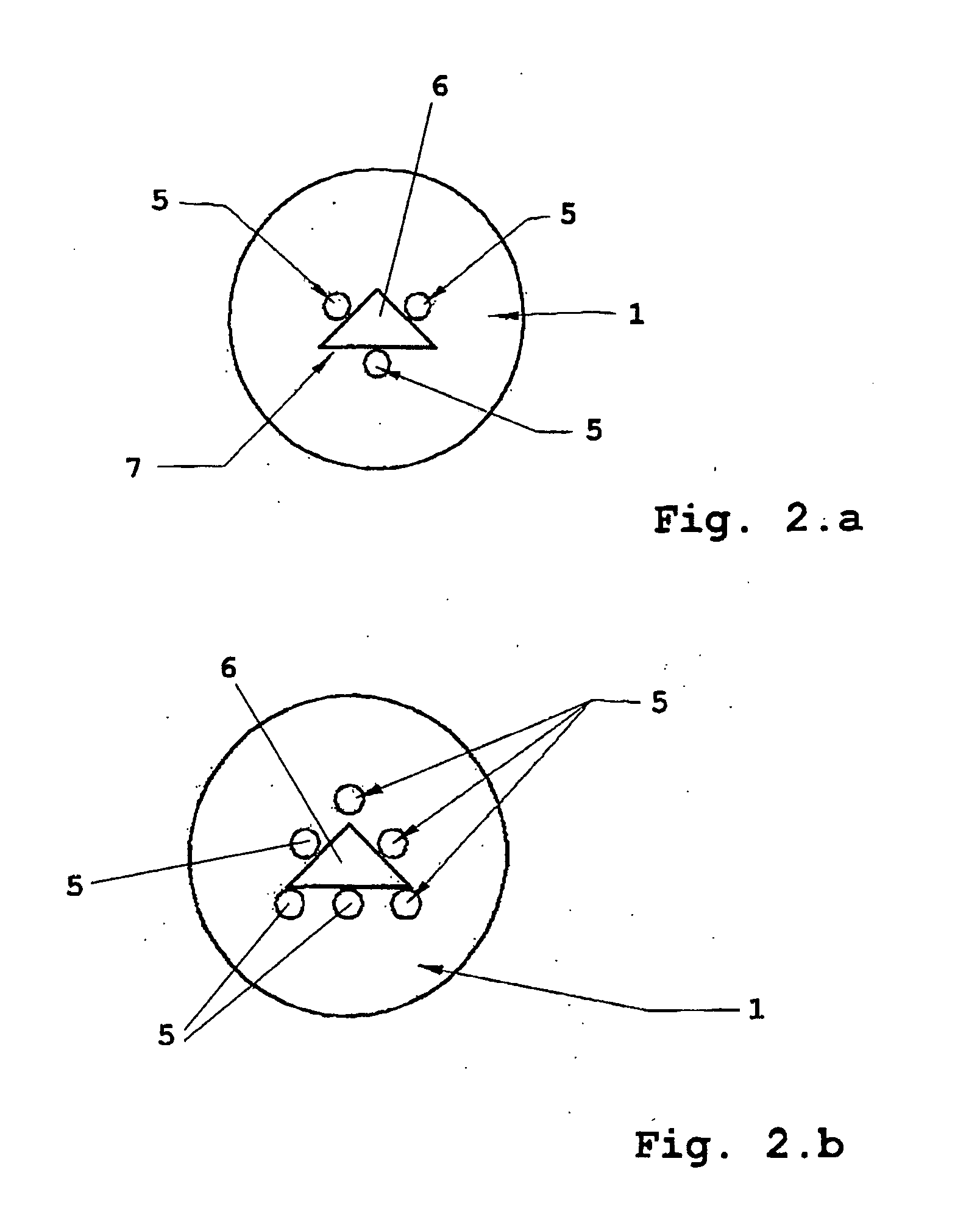

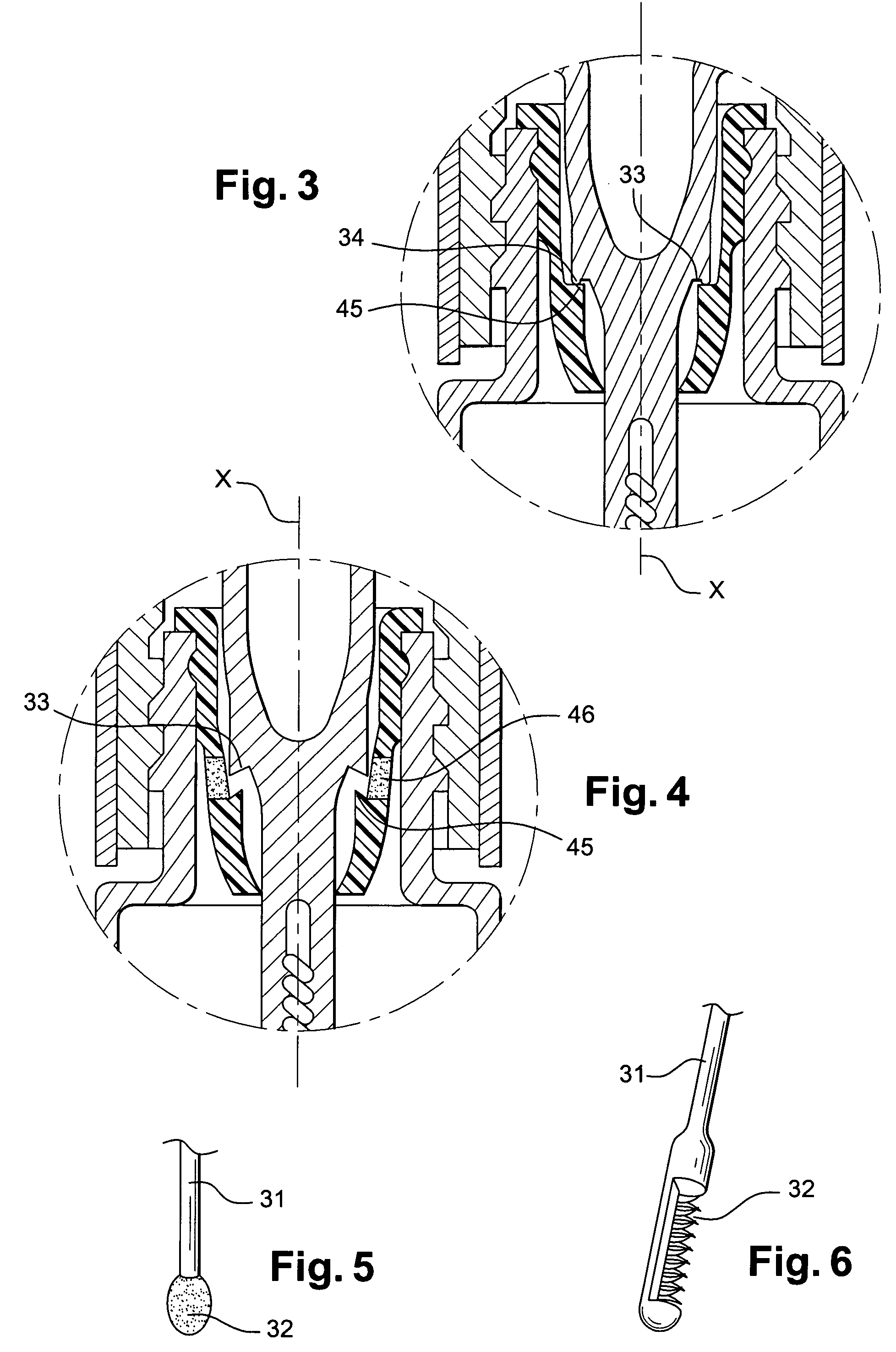

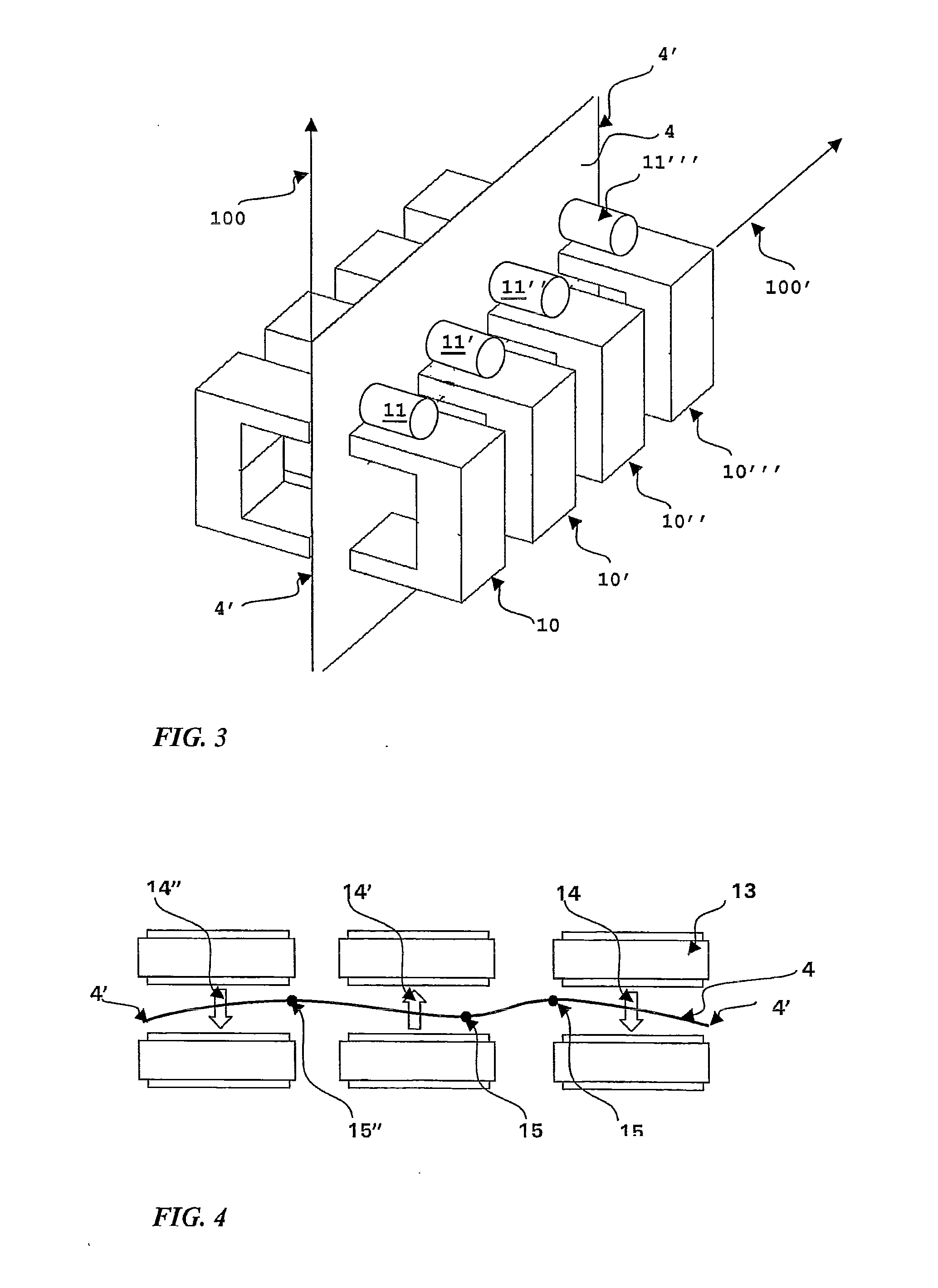

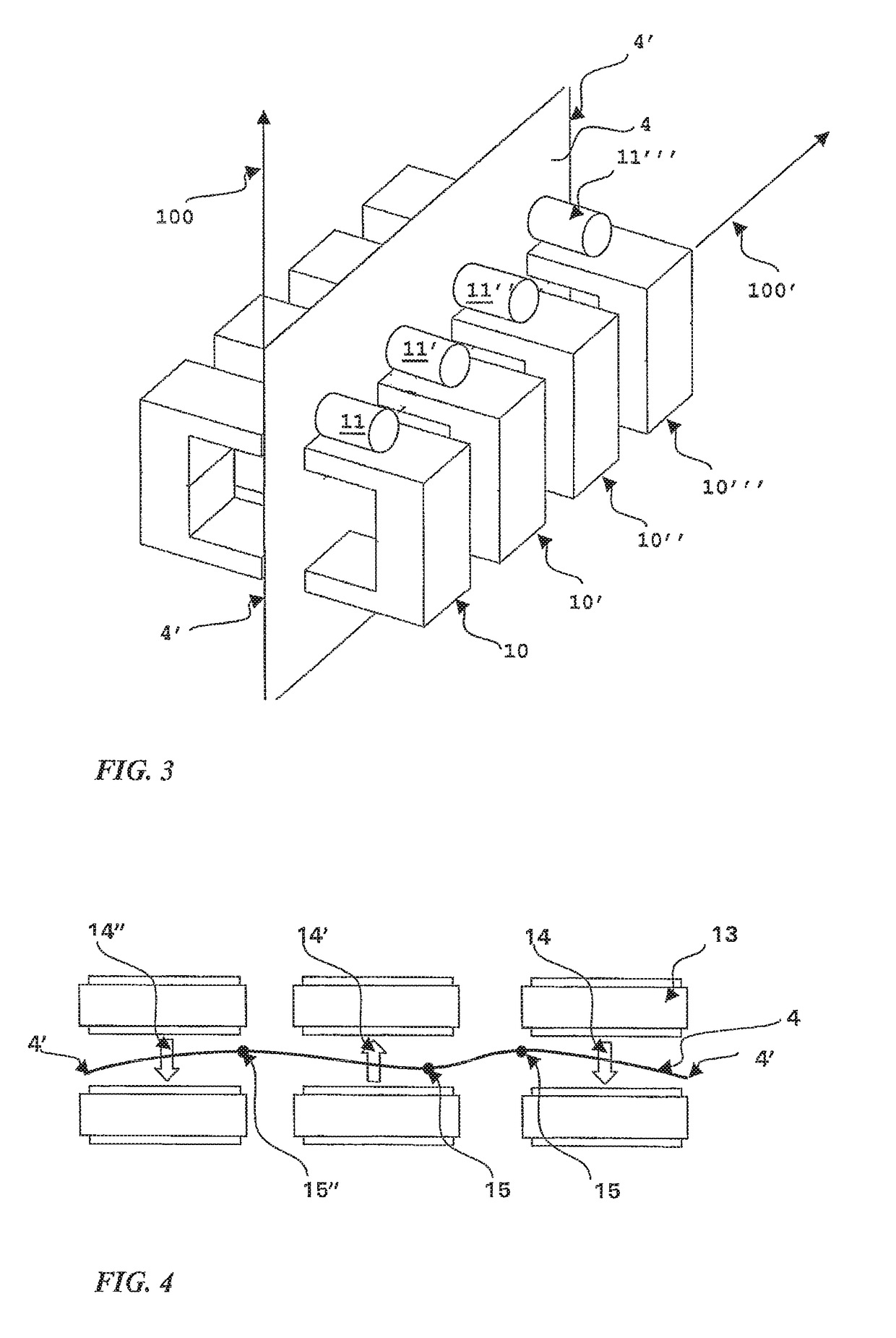

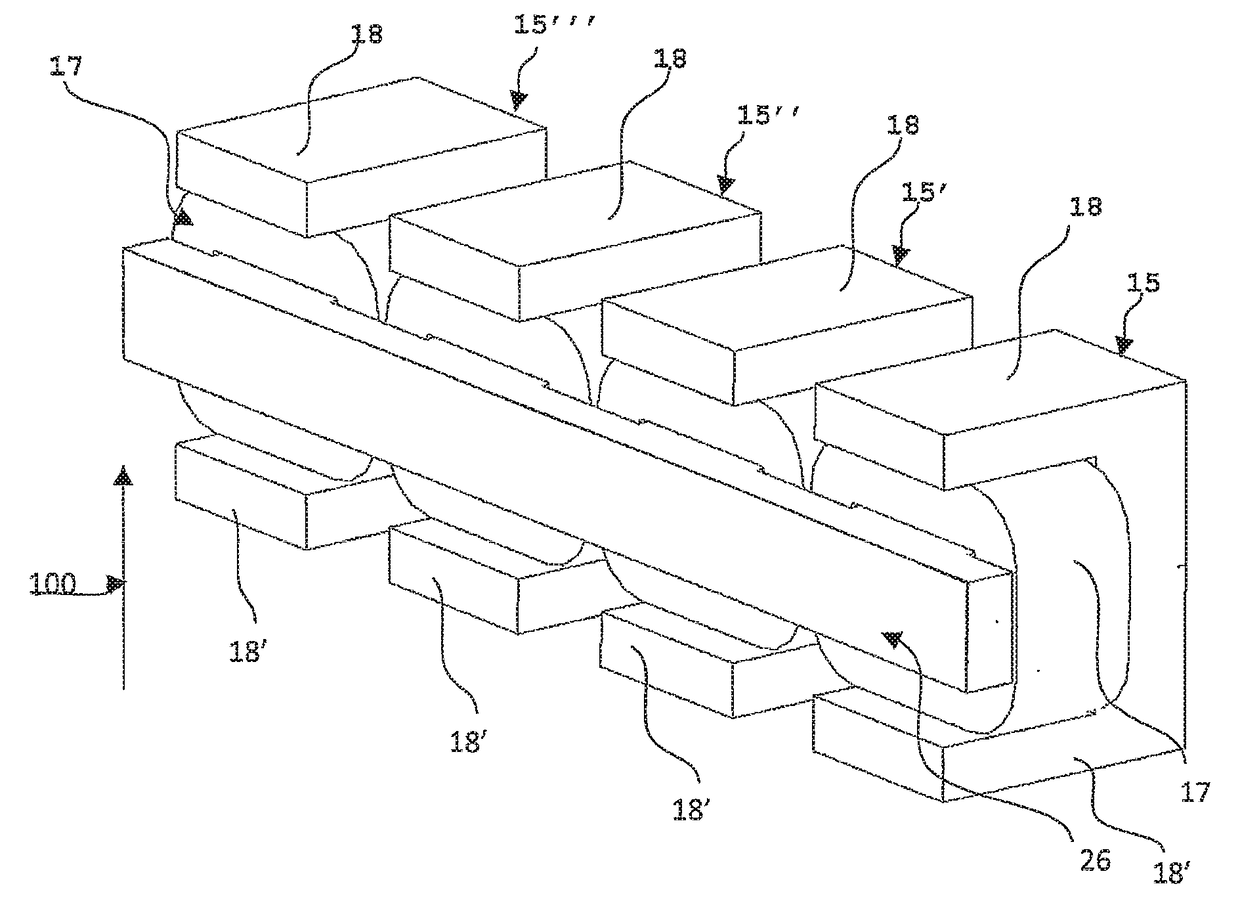

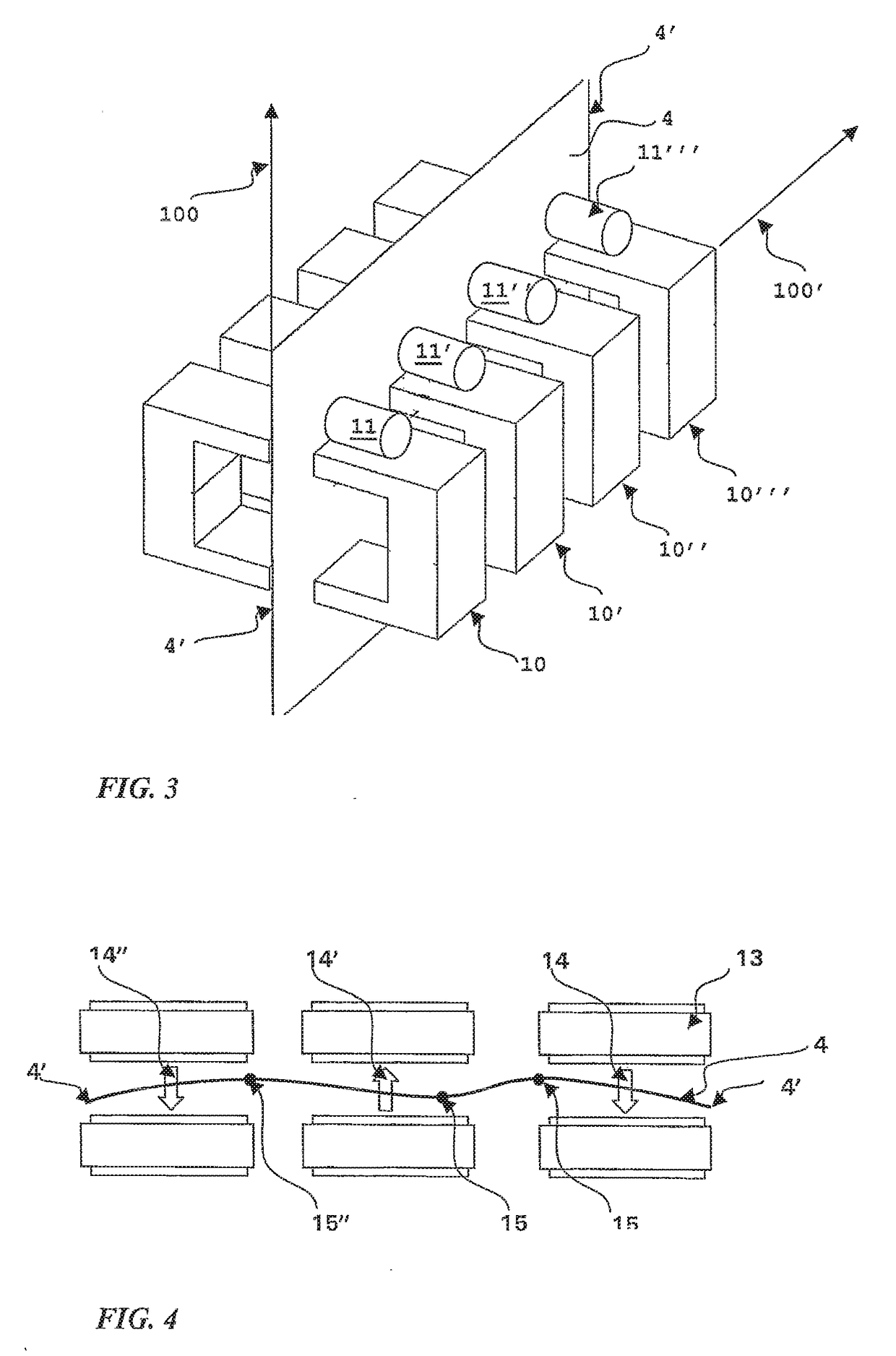

Electromagnetic device for stabilizing and reducing the deformation of a strip made of ferromagnetic material, and related process

ActiveUS20130319326A1Reduce productionEliminate leaksHot-dipping/immersion processesLiquid surface applicatorsEngineeringMirror image

An electromagnetic device (1) for stabilizing and minimizing the deformation of a strip (4) made of ferromagnetic material during its feeding in a system for coating the same strip with molten metal, by applying a distribution of force which is continuous in the direction transversal to the strip regardless of the width thereof. The device comprises first electromagnets and second electromagnets mirroring the first electromagnets with respect to said theoretical pass-line (50) of said strip (4). Each electromagnet includes a core comprising one pole and one feeding coil wound about the pole. The electromagnetic device comprises a connection element (26) made of ferromagnetic material which connects the cores of the first electromagnets (15, 15′, 15″, 15″′) and a connection element (26′) made of ferromagnetic material which connects the cores of the second electromagnets (16, 16′, 16″, 16′). The connection elements (26, 26′) mirror the theoretical pass-line (50) of the strip (4).

Owner:DANIELI & C OFF MEC SPA

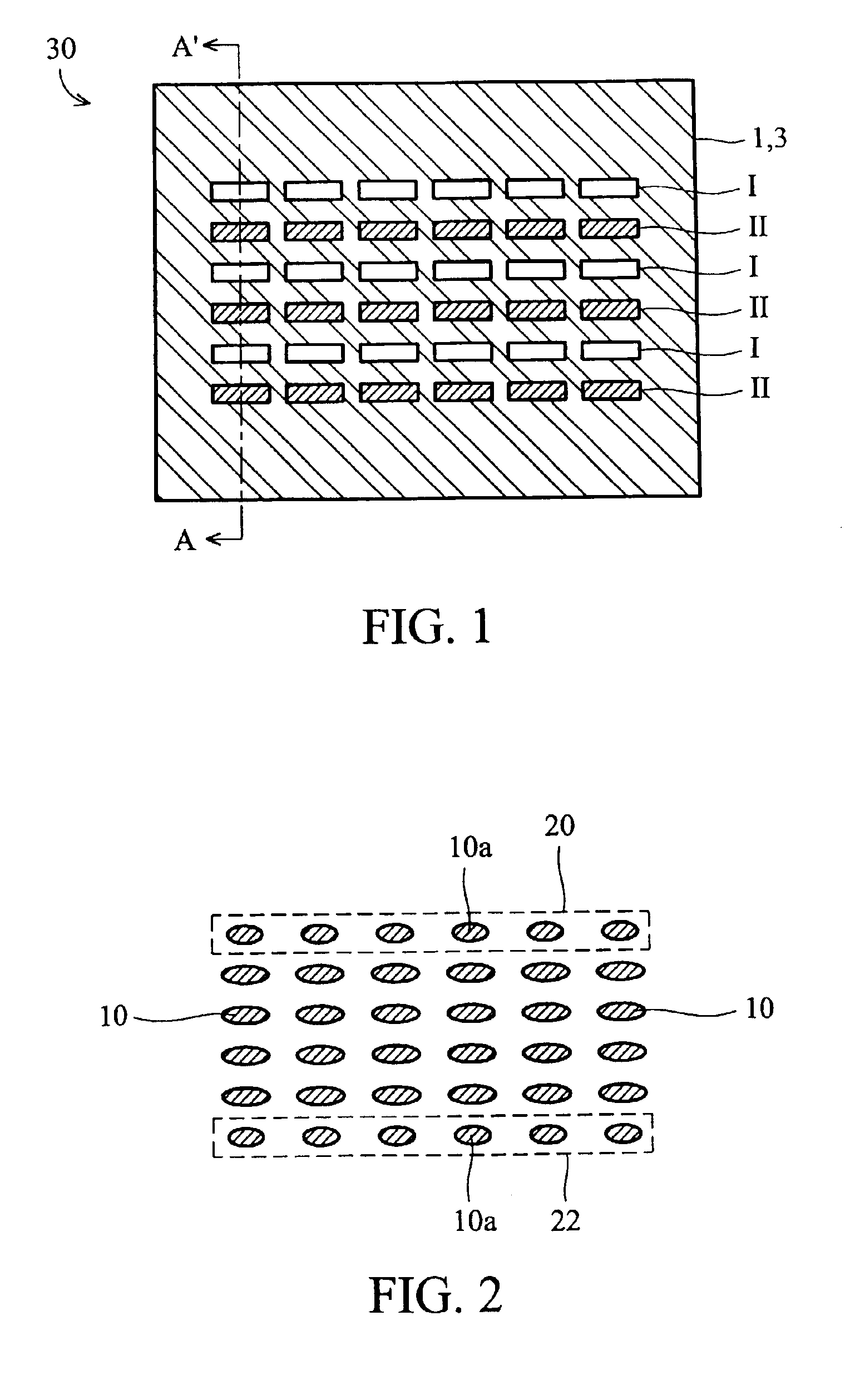

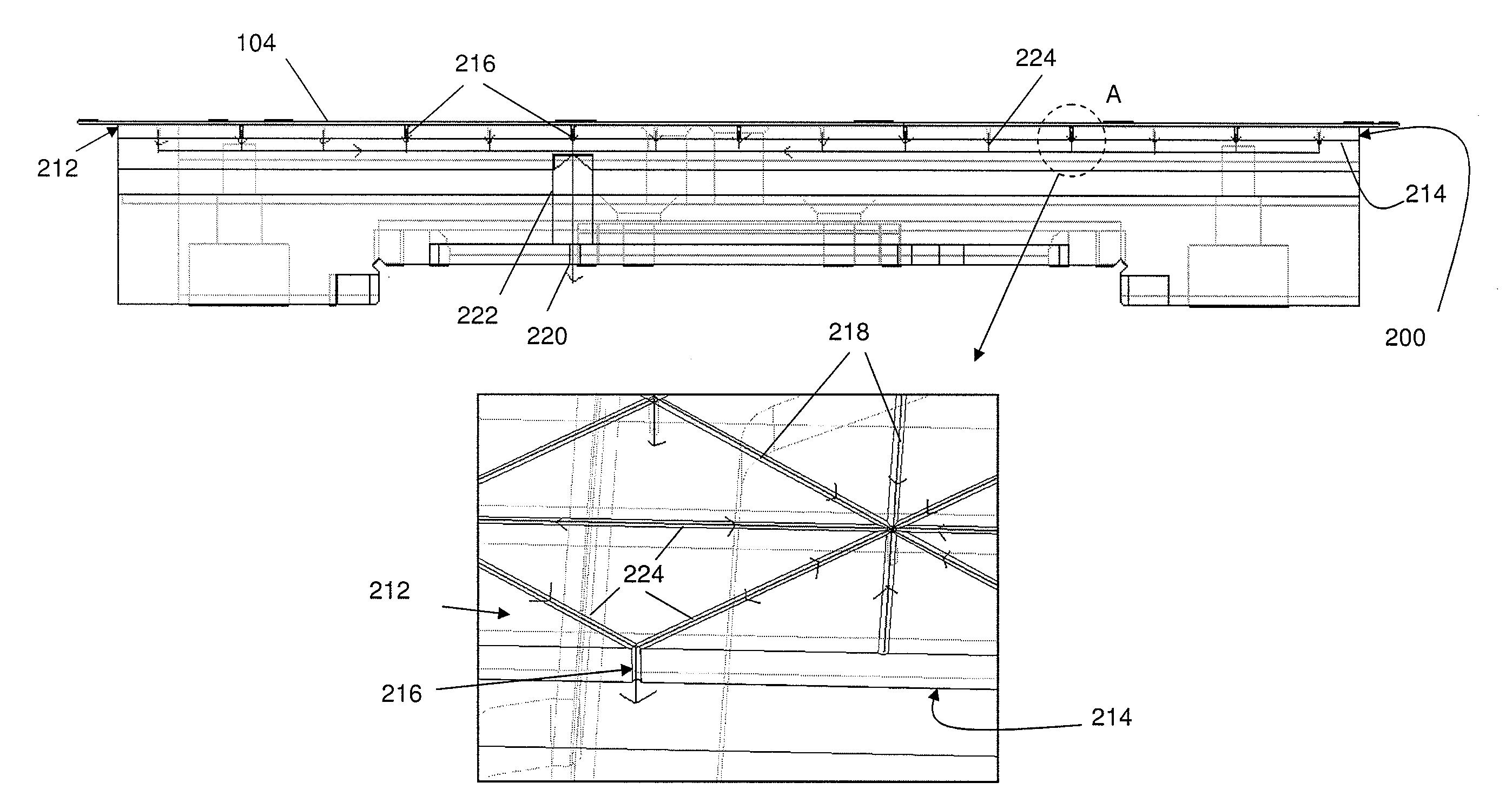

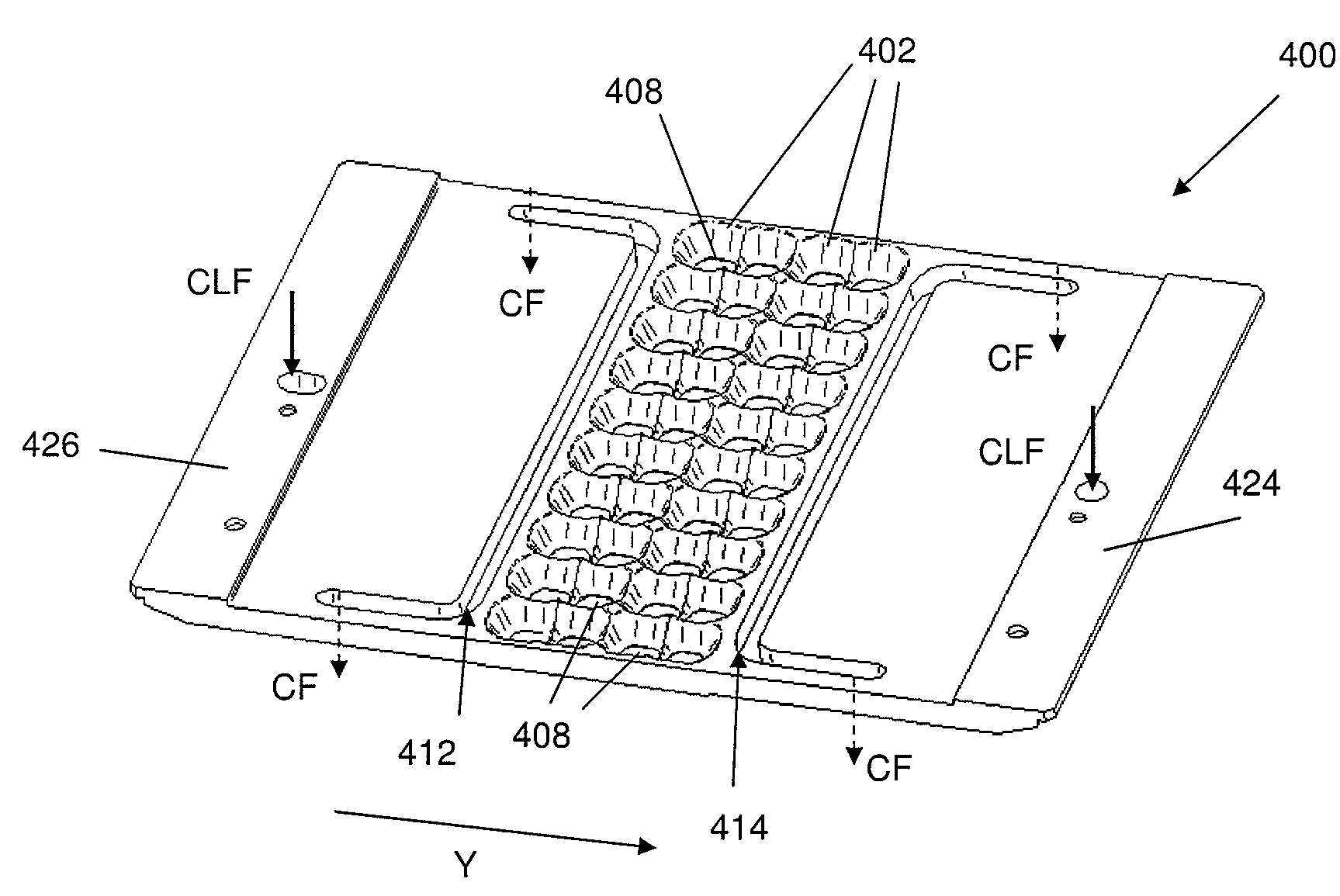

Lead frame support plate and window clamp for wire bonding machines

ActiveUS20140014708A1Force balanceShorten production timeSolid-state devicesWelding/cutting auxillary devicesSuction forceEngineering

A lead frame support plate 200 and a window clamp 400 for wire bonding machines are disclosed herein. In a described embodiment, the lead frame support plate 200 includes a network of suction grooves 218 provided on a support surface 212, each suction groove 218 being arranged to be in fluid communication with at least a vacuum hole 216 to enable a suction force to be created, in response to a vacuum force, along the network of suction grooves for holding a lead frame against the support surface. A window clamp 400 having slots for compensating deformation of the window clamp and a method of fabricating the lead frame support plate are also disclosed.

Owner:ASMPT SINGAPORE PTE LTD

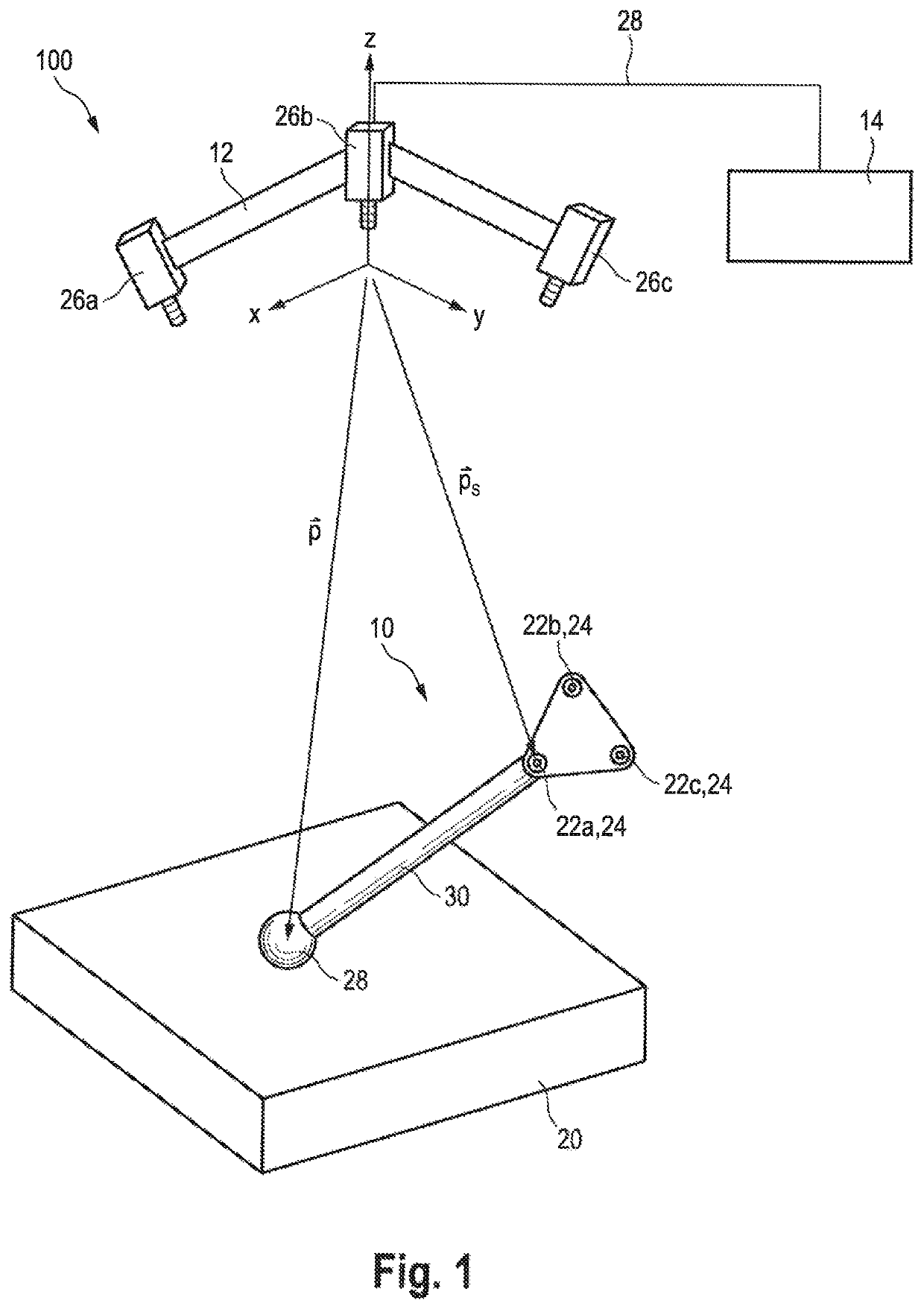

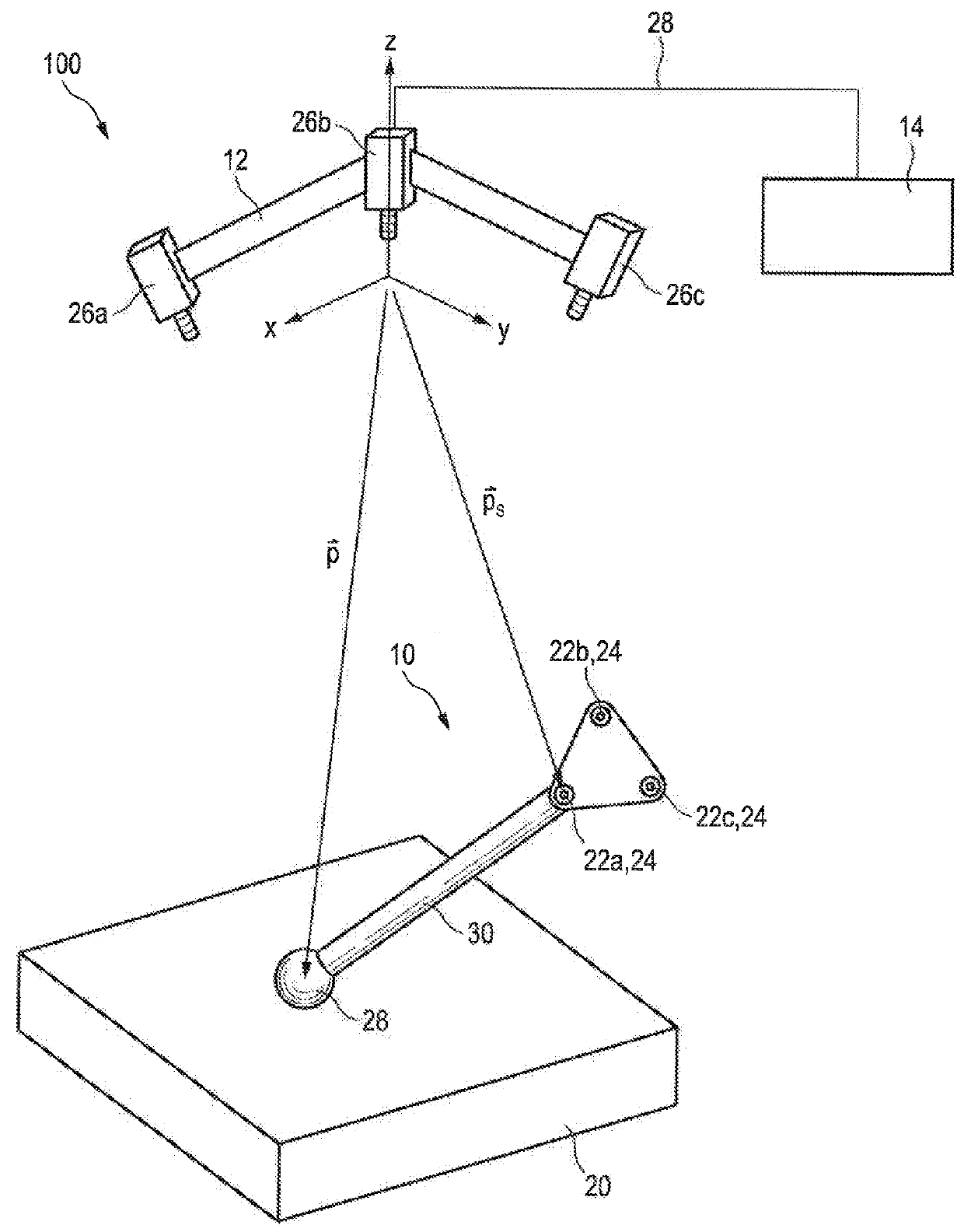

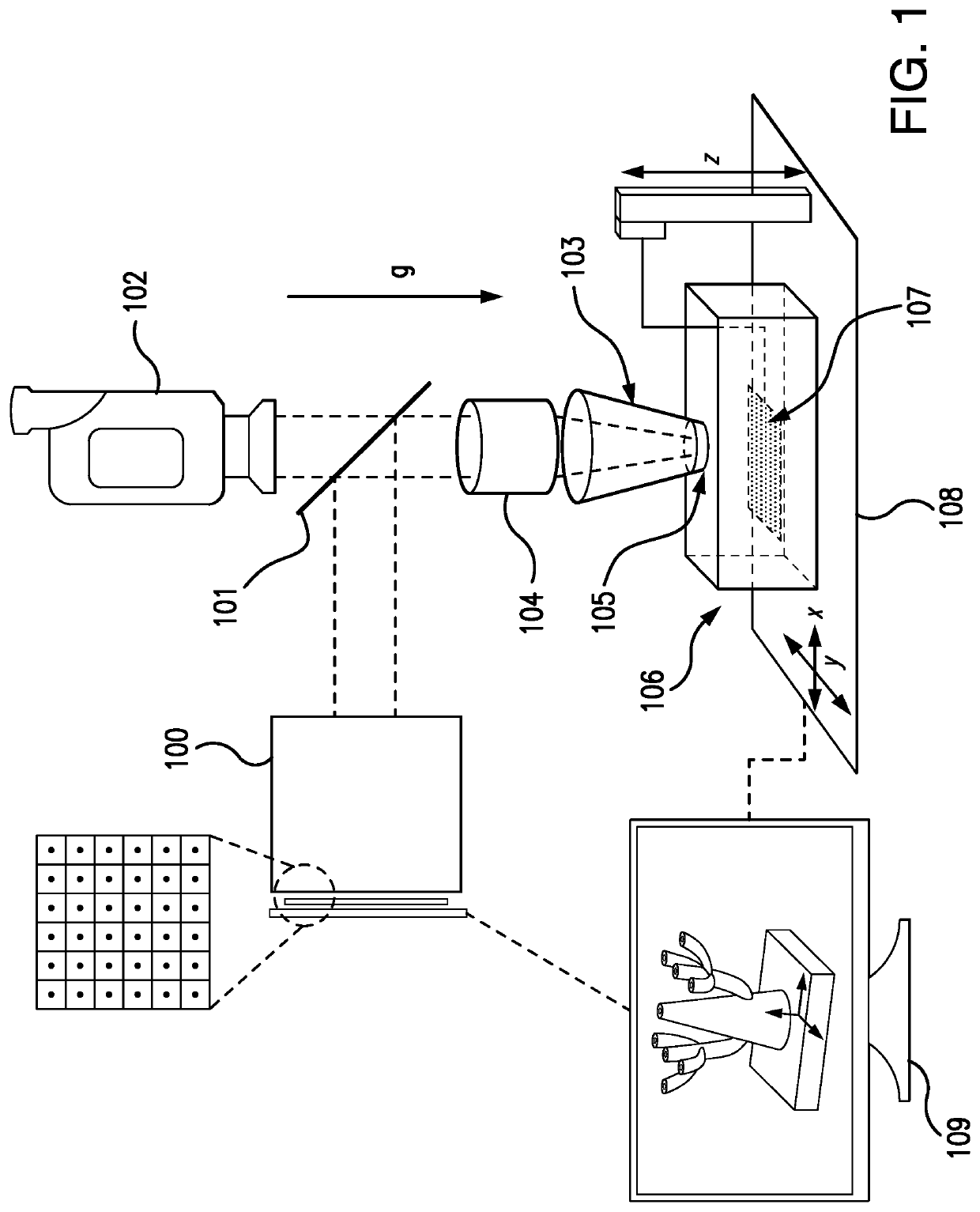

Measuring system and measuring method

ActiveUS10648792B2Simple structureHigh measurement accuracyImage enhancementImage analysisRadiologyControl cell

A measuring system having a measuring tool which includes a probe body and an optical marker, a camera for recording image data of the measuring tool, and an evaluation and control unit which is configured to evaluate the image data recorded by the camera and use the data to determine spatial position coordinates of the optical marker. The evaluation and control unit is also configured to calculate the deformation of the measuring tool due to external mechanical loading acting on the measuring tool, and to determine spatial position coordinates of the probe body based on the spatial position coordinates of the optical marker and the calculated deformation.

Owner:CARL ZEISS IND MESSTECHN GMBH

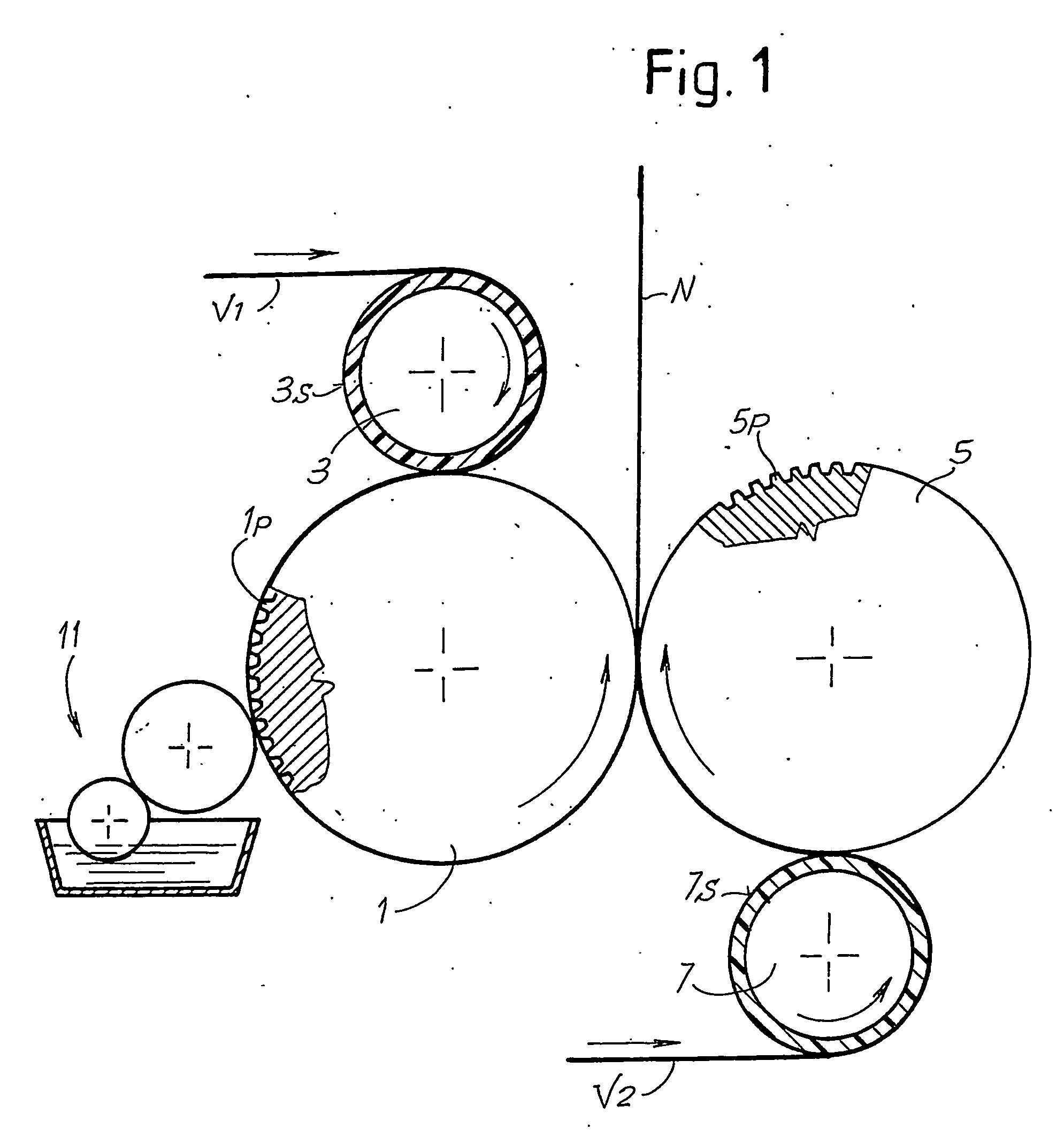

Variable crown roller for devices for processing continuous web material and device comprising said roller

InactiveUS20070015648A1Overcomes drawbackImprove working conditionsLiquid surface applicatorsMechanical working/deformationMechanical engineering

A pressure roller (3; 7) for devices for processing continuous web materials is described, comprising a lateral surface (3S; 7S), including a regulating system (29, 50) to impose an adjustable crown of the lateral surface (3S; 7S) of the roller deforming said lateral surface.

Owner:FABIO PERINI SPA

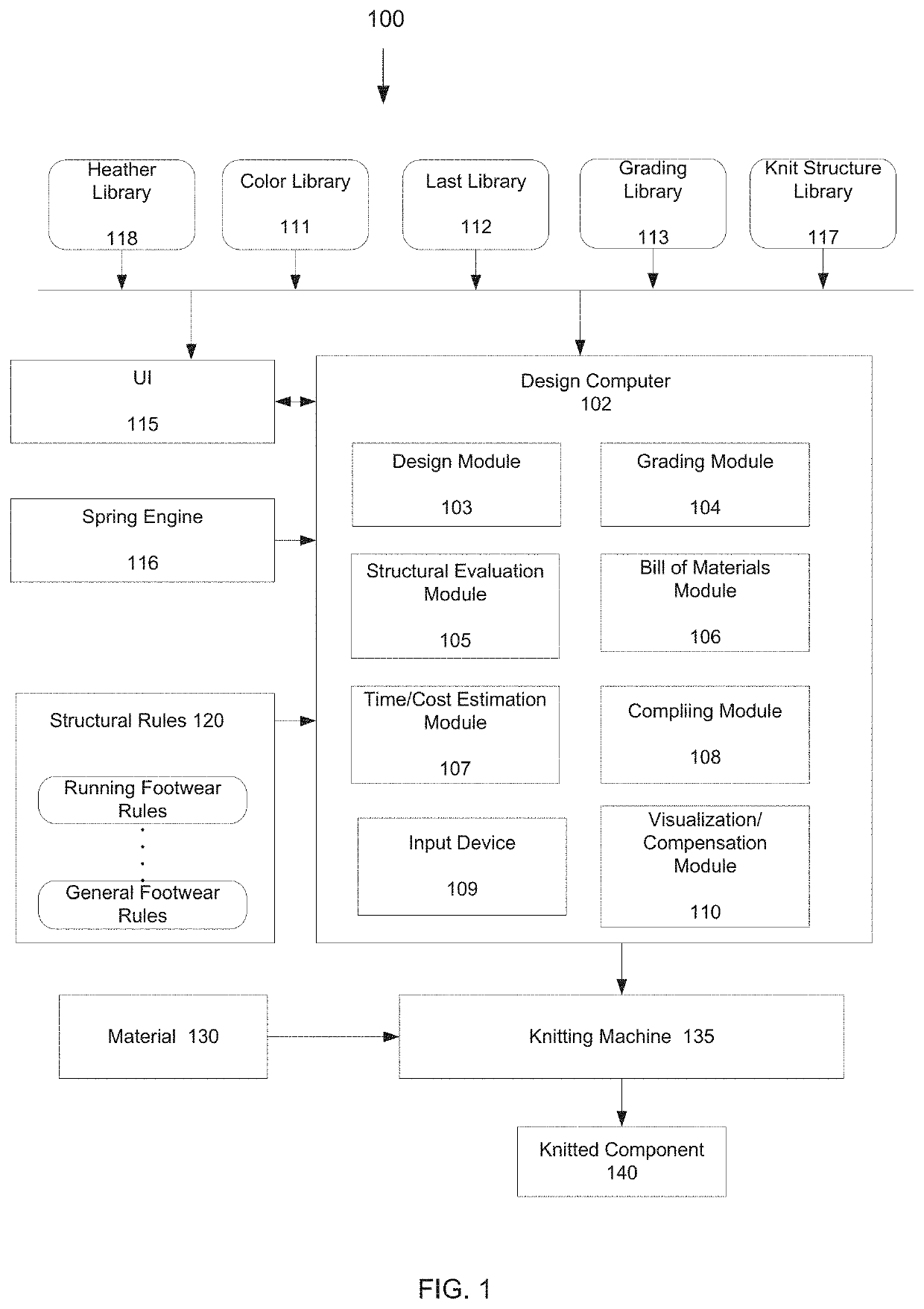

Tool for design and fabrication of knitted components

ActiveUS20190382931A1Increase flexibilityWasteful and costly and laboriousProgramme controlDesign optimisation/simulationDigital controlBraid

Computer based systems and methods for designing and manufacturing consumer products, including knit footwear uppers, and the like. The system provides digital controls for the customization of knitted components, including complex multi-structured knitted components. The system simulates deformations of knit structures and allows the user to control and visualize compensations in the structure(s) of the knitted component to better match between an intended knit design and the actual physical knitted component outcome. They system may manufacture / fabricate a knitted component based on the predicted / estimated deformation behavior of the knit.

Owner:NIKE INC

Lead frame support plate and window clamp for wire bonding machines

ActiveUS8752751B2Force balanceShorten production timeSolid-state devicesWelding/cutting auxillary devicesSuction forceLead frame

A lead frame support plate 200 and a window clamp 400 for wire bonding machines are disclosed herein. In a described embodiment, the lead frame support plate 200 includes a network of suction grooves 218 provided on a support surface 212, each suction groove 218 being arranged to be in fluid communication with at least a vacuum hole 216 to enable a suction force to be created, in response to a vacuum force, along the network of suction grooves for holding a lead frame against the support surface. A window clamp 400 having slots for compensating deformation of the window clamp and a method of fabricating the lead frame support plate are also disclosed.

Owner:ASMPT SINGAPORE PTE LTD

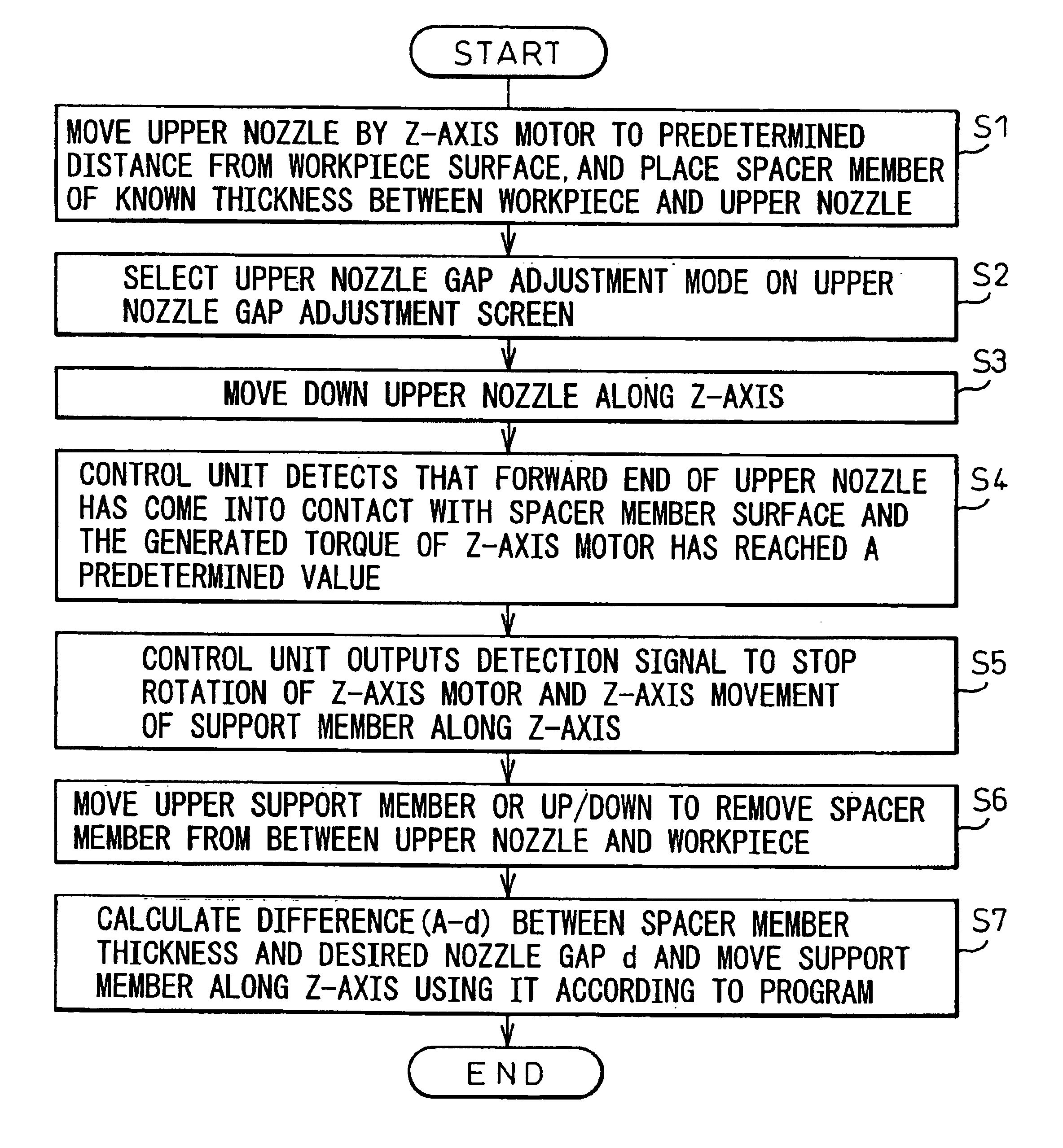

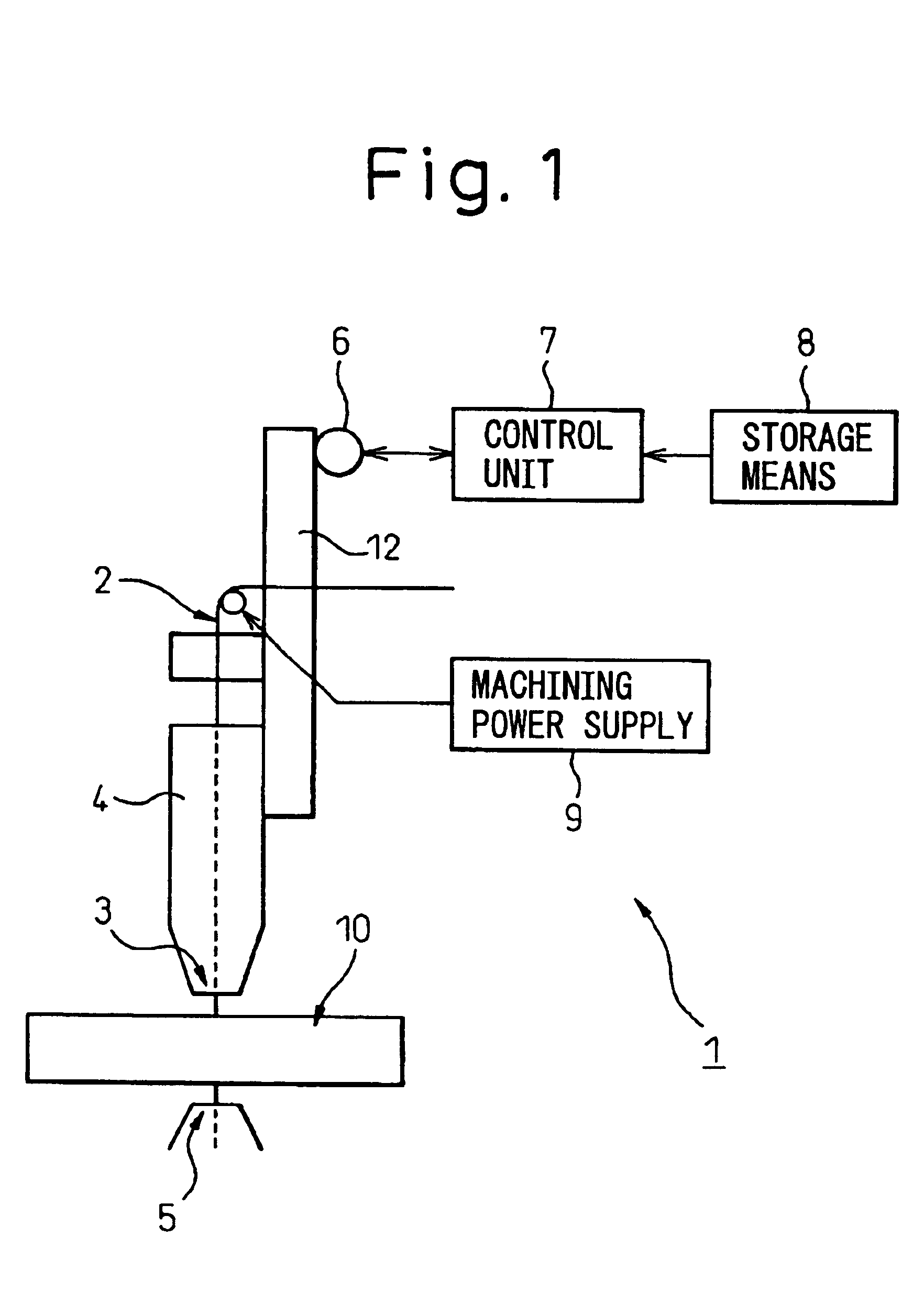

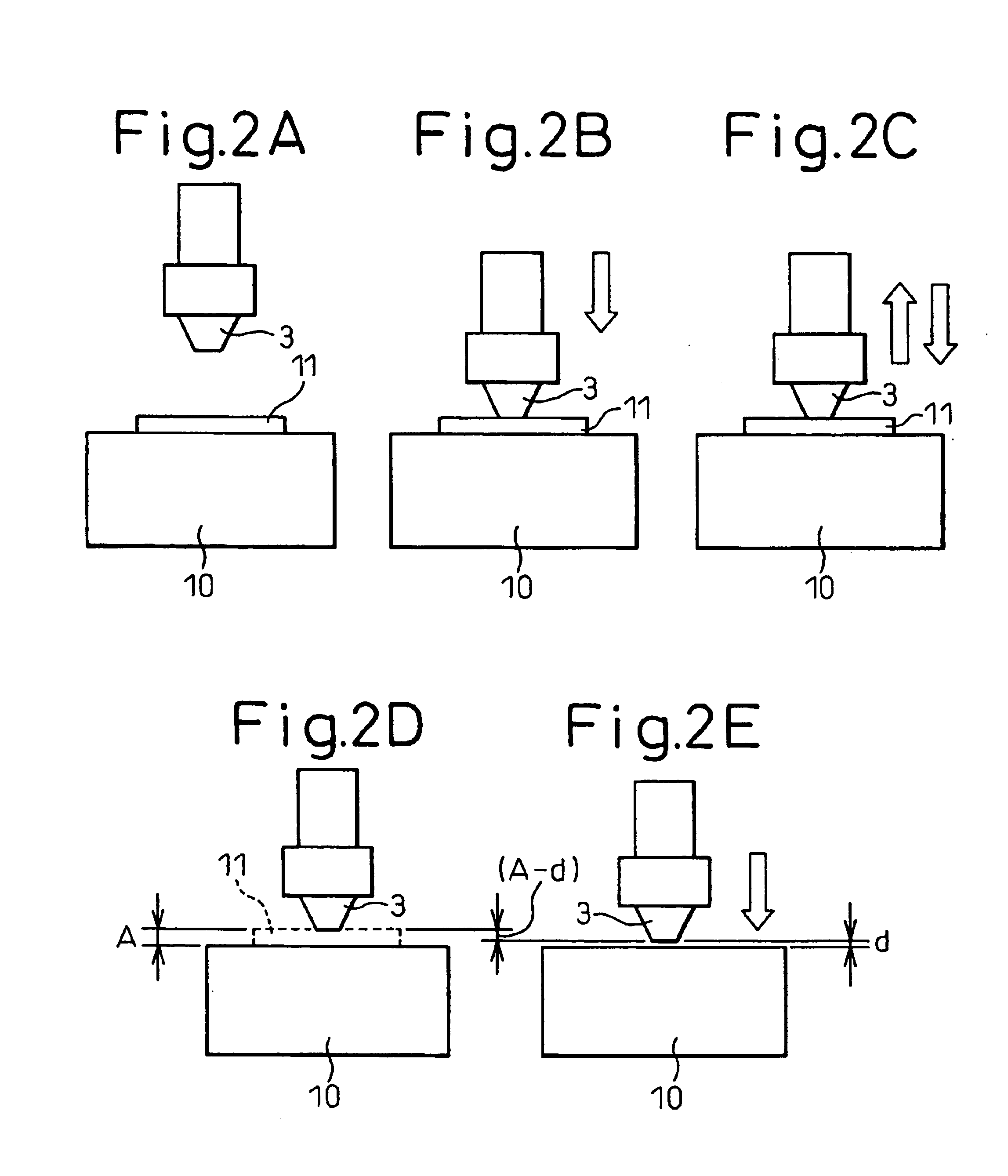

Method for adjusting nozzle gap

InactiveUS6921876B2Avoid damageCompensation for deformationElectrical-based machining electrodesElectric dischargeEngineering

A method for adjusting the gap between an upper nozzle of a wire electric discharge machine includes placing a spacer member of a known thickness between a forward end of the upper nozzle and a workpiece. The forward end of the upper nozzle is brought into contact with the spacer member, so that the forward end of the upper nozzle is prevented from coming into direct contact with the workpiece. A Z-axis position of the upper nozzle is controlled on the basis of the thickness of the spacer member and the desired nozzle gap to set the gap between the forward end of the upper nozzle and the workpiece to a predetermined value. In controlling the Z-axis position of the upper nozzle, correction is made to compensate for a deformation of the upper guide, the spacer member, the workpiece, and the upper nozzle, and / or for a displacement of the upper guide resulting from a pressure of a working fluid.

Owner:FANUC LTD

Measuring system and measuring method

ActiveUS20180094913A1Simple structureHigh measurement accuracyImage enhancementImage analysisImaging dataControl unit

A measuring system having a measuring tool which comprises a probe body and an optical marker, a camera for recording image data of the measuring tool, and an evaluation and control unit which is configured to evaluate the image data recorded by the camera and use the data to determine spatial position coordinates of the optical marker. The evaluation and control unit is also configured to calculate the deformation of the measuring tool due to external mechanical loading acting on the measuring tool, and to determine spatial position coordinates of the probe body based on the spatial position coordinates of the optical marker and the calculated deformation.

Owner:CARL ZEISS IND MESSTECHN GMBH

Electromagnetic device for stabilizing and reducing the deformation of a strip made of ferromagnetic material, and related process

ActiveUS9968958B2Reduce vibrationEliminate leaksHot-dipping/immersion processesLiquid surface applicatorsEngineeringMolten metal

An electromagnetic device (1) for stabilizing and minimizing the deformation of a strip (4) made of ferromagnetic material during its feeding in a system for coating the same strip with molten metal, by applying a distribution of force which is continuous in the direction transversal to the strip regardless of the width thereof. The device comprises first electromagnets and second electromagnets mirroring the tirst electromagnets with respect to said theoretical pass-line (50) of said strip (4). Each electromagnet includes a core comprising one pole and one feeding coil wound about the pole. The electromagnetic device comprises a connection element (26) made of ferromagnetic material which connects the cores of the first electromagnets (15, 15′, 15″, 15′″) and a connection element (26′) made of ferromagnetic material which connects the cores of the second electromagnets (16, 16′, 16″, 16′″). The connection elements (26, 26′) mirror the theoretical pass-line (50) of the strip (4).

Owner:DANIELI & C OFF MEC SPA

Flanged member and a flange joint comprising flange members

InactiveUS8313264B2Compensation for deformationReduce riskSleeve/socket jointsYielding couplingEngineeringEquipment/device

A flanged member (1), intended to be included as a component in a flanged joint, for installation in a pressure equipment device, and having a first flanged end (3) having a first end surface (10) intended to be assembled together with another end surface (4) of a flanged end (11) on another, second flanged member (2) constituting a second component in the flanged joint. The first end surface is slightly concave in the radial direction over at least a part of the extension thereof in the radial direction.

Owner:VERAX ENG

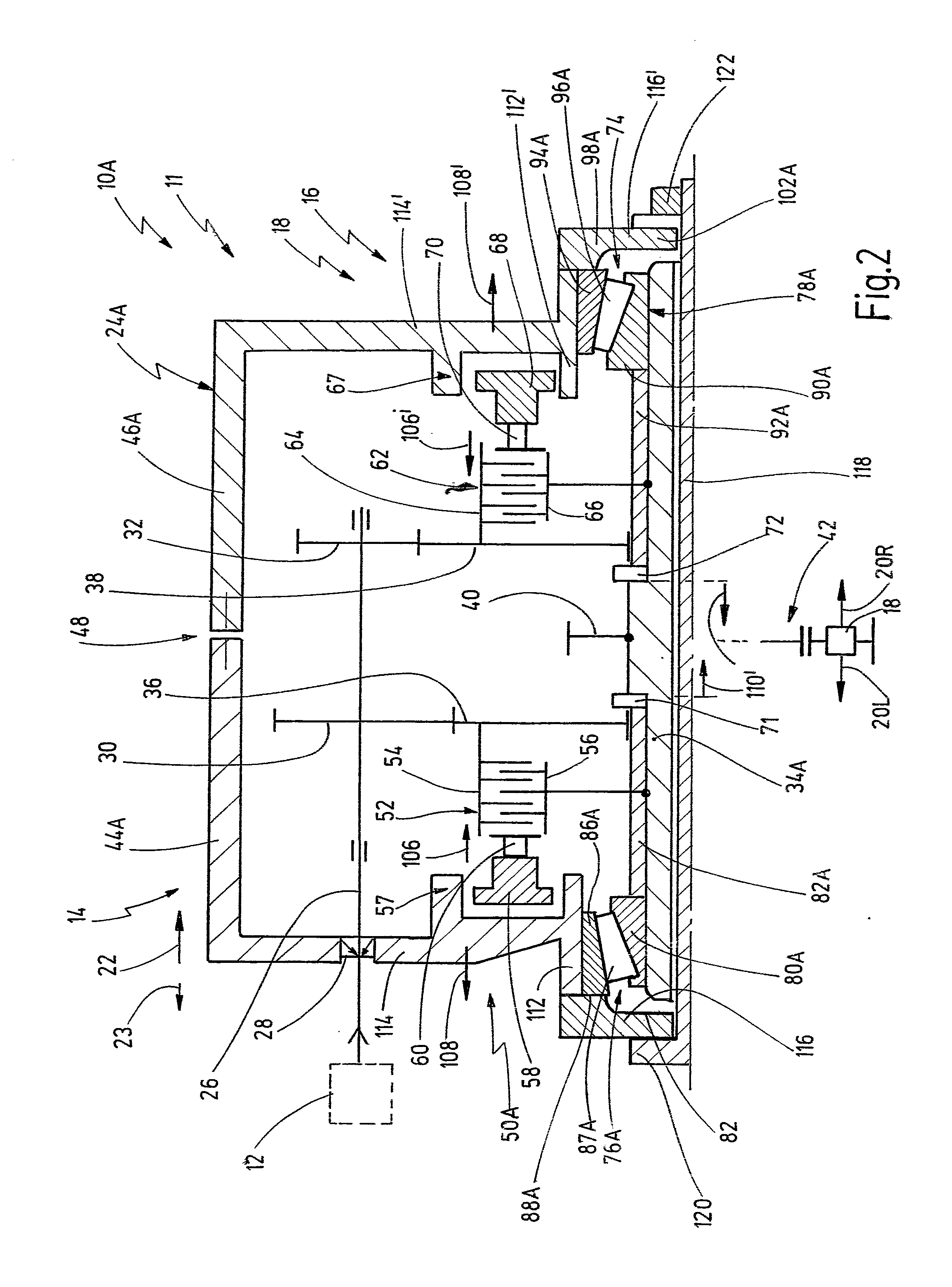

Device and a method for fabricating a part by injection molding

ActiveUS20170355117A1Low costCompensation for deformationMachines/enginesEngine componentsInjection molding machineInjection device

An injection molding device for fabricating a part, the device including an injection mold, the mold being formed of a support and a countermold that are distinct and that define between them a mold cavity presenting a first shape; and at least one injection device for injecting a fluid material into the mold cavity; the device including deformation elements configured to modify the shape of the mold cavity into a second shape distinct from the first shape.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

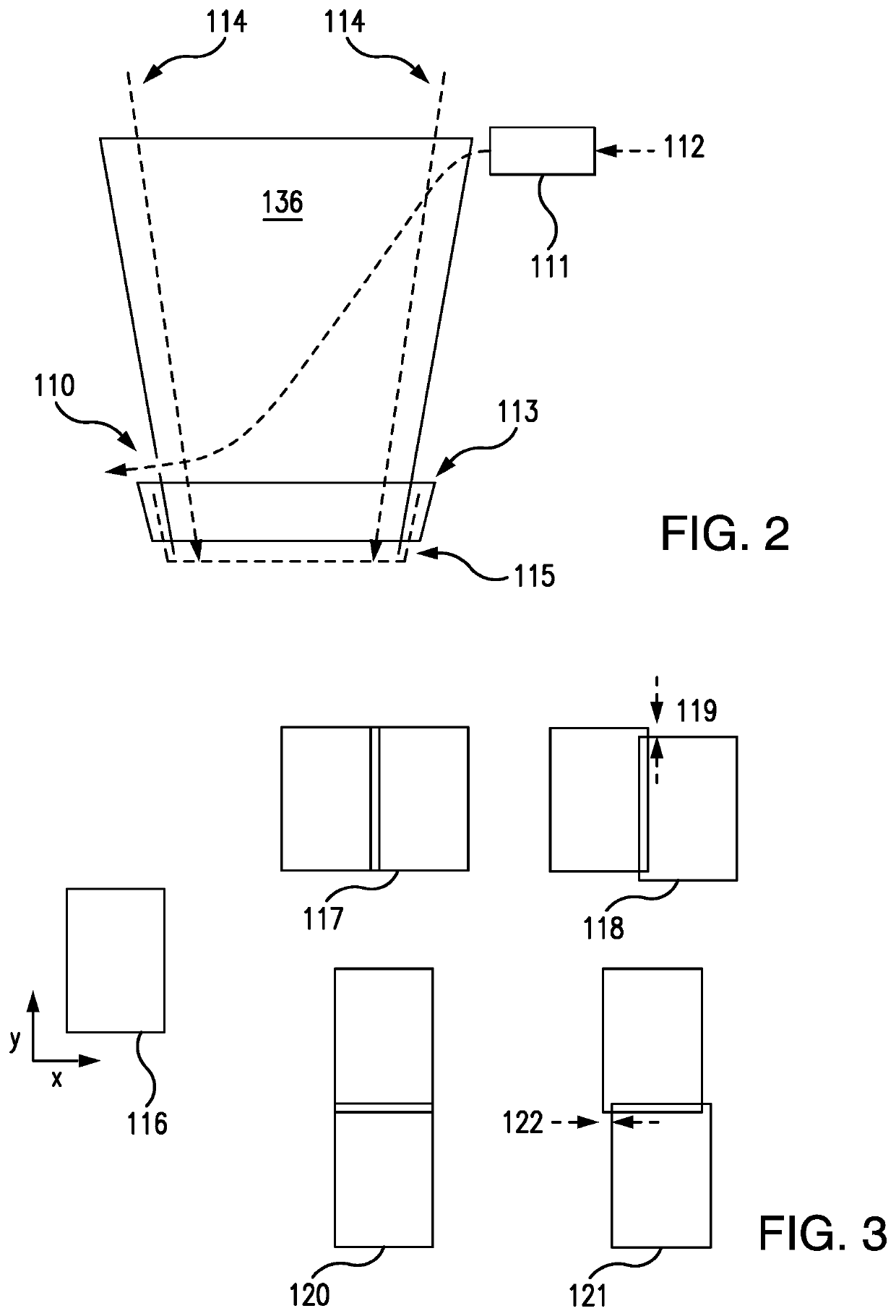

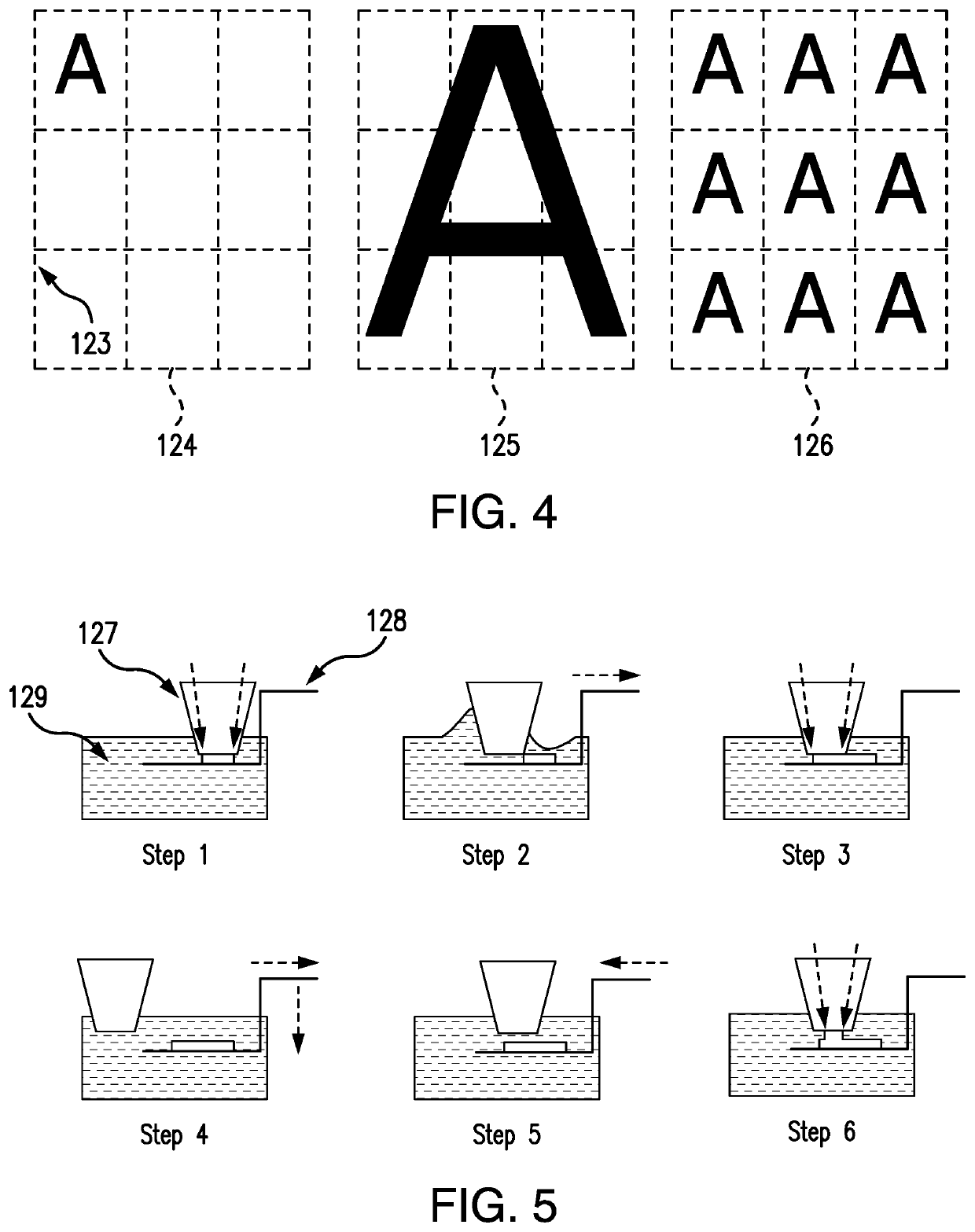

Immersion projection micro steriolithography

PendingUS20210237345A1Improve sampling accuracyPrint speed be improveManufacturing platforms/substratesManufacturing driving meansProjection imageEngineering

A method for high resolution projection micro stereolithography for 3-D printing comprising: generating a 3D digital model of the sample to be printed in a computer, slicing the digital model into a sequence of images, wherein each of the images of the sequence represents a layer of the 3D digital model, positioning a transparent printing head relative to a resin vat containing a photo-sensitive resin, moving the transparent printing head into position for selectively exposing the photosensitive resin, sending an image from the sequence of images to a LCD or DLP chip, and together with a light source projecting the image through a lens onto the flat tip of the transparent printing head to initiate cure of the photosensitive resin in areas where the projected image allows light from the light source to reach the photosensitive resin.

Owner:BMF NANO MATERIAL TECH CO LTD

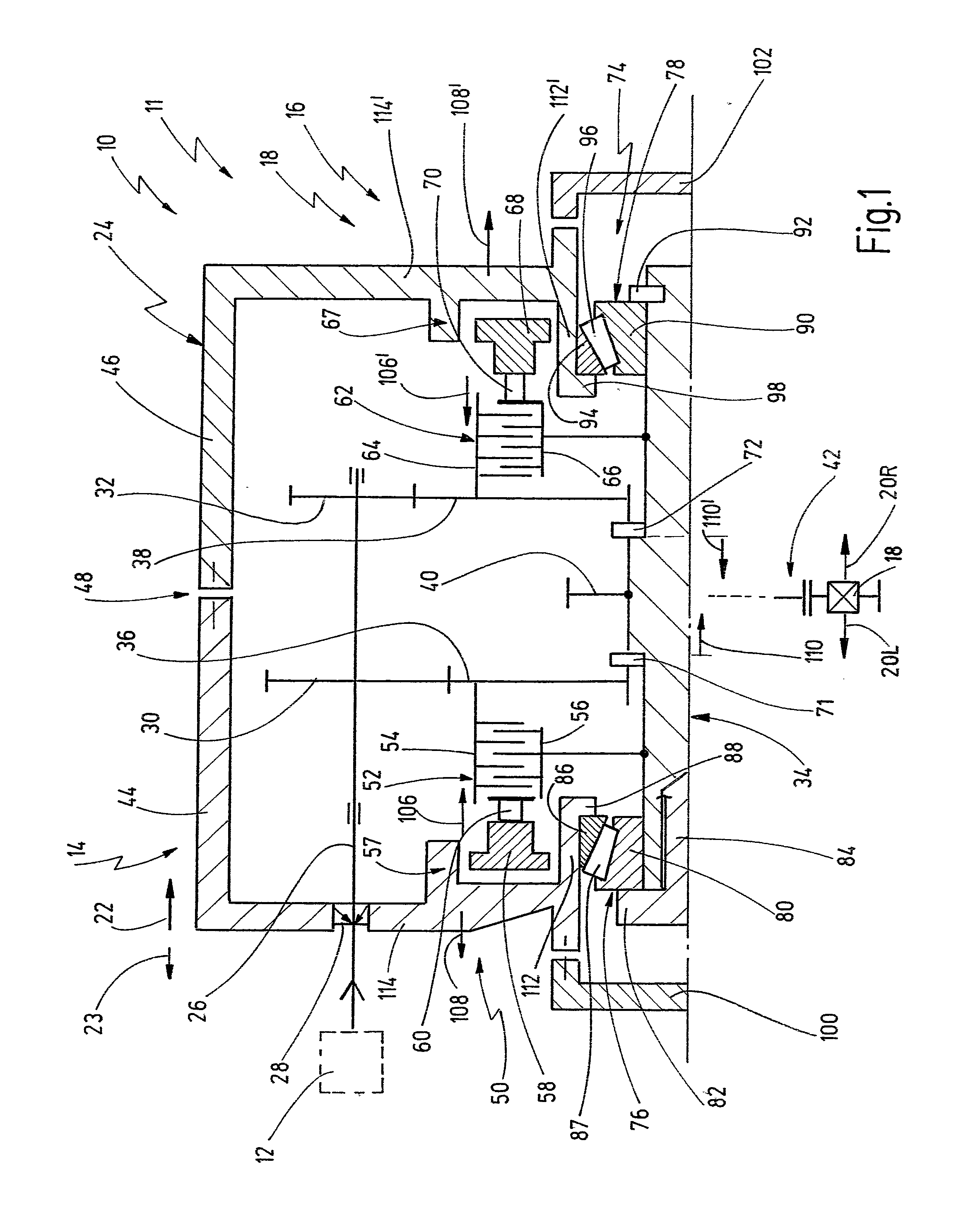

Clutch arrangement and two-speed gearbox

InactiveUS20130305861A1Short shift timesImprove rigidityFluid actuated clutchesToothed gearingsEngineeringAxial distance

Clutch arrangement for a motor vehicle gearbox. The clutch arrangement has a housing and a clutch. The clutch is arranged in the housing and is arranged concentrically with a shaft, which extends in a longitudinal axis. The shaft is supported on the housing by means of a first shaft bearing adjacent to the clutch and by means of a second shaft bearing spaced at an axial distance from the clutch. The clutch arrangement has an actuator arrangement for actuating the clutch. The actuator arrangement is designed to exert an actuating force on the clutch in a first longitudinal direction. The actuator arrangement here being axially braced on the housing and a force flux being introduced into the shaft as a result of the actuating force. The first shaft bearing is arranged so that the force flux introduced into the shaft can be axially braced on the housing by way of the first shaft bearing.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Electromagnetic device for stabilizing and reducing the deformation of a strip made of ferromagnetic material, and related process

ActiveUS20180085778A1Reduce vibrationEliminate leaksHot-dipping/immersion processesLiquid surface applicatorsEngineeringMirror image

An electromagnetic device (1) for stabilizing and minimizing the deformation of a strip (4) made of ferromagnetic material during its feeding in a system for coating the same strip with molten metal, by applying a distribution of force Which is continuous in the direction transversal to the strip regardless of the width thereof. The device comprises first electromagnets and second electromagnets mirroring the first electromagnets with respect to said theoretical pass-line (50) of said strip (4). Each electromagnet includes a core comprising one pole and one feeding coil wound about the pole. The electromagnetic device comprises a connection element (26) made of ferromagnetic material which connects the cores of the first electromagnets (15, 15′, 15″, 15′″) and a connection element (26′) made of ferromagnetic material which connects the cores of the second electromagnets (16, 16′, 16″, 16′″). The connection elements (26, 26′) mirror the theoretical pass-line (50) of the strip (4).

Owner:DANIELI & C OFF MEC SPA

Double side image scanner

ActiveUS8040575B2Improve image qualityImprove accuracyTelevision systemsElectrographic process apparatusEngineeringMechanical engineering

A double side image scanner includes a case having a medium guide track with a reference loading line, a main frame mounted inside the case, a first roll feed including a first feed roller mounted on a front side of the guide track and a first idle roller disposed above the first feed roller for cooperating with the first feed roller to load the medium, a second roll feed including a second feed roller mounted on a rear side of the guide track and a second idle roller disposed above the second feed roller for cooperating with the second feed roller to load the medium, a drive device for rotating the first feed roller and the second feed roller, first and second image sensors for scanning opposite surfaces of the medium to acquire image data, and a tracking device for biasing the medium toward the reference loading line.

Owner:WISECUBE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com