Exposure device and exposure method

A technology of exposure device and loading platform, which is applied in the direction of photolithography exposure device and microlithography exposure equipment, etc., which can solve the problems of resolution reduction, blurred image, and inability to expose fine patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

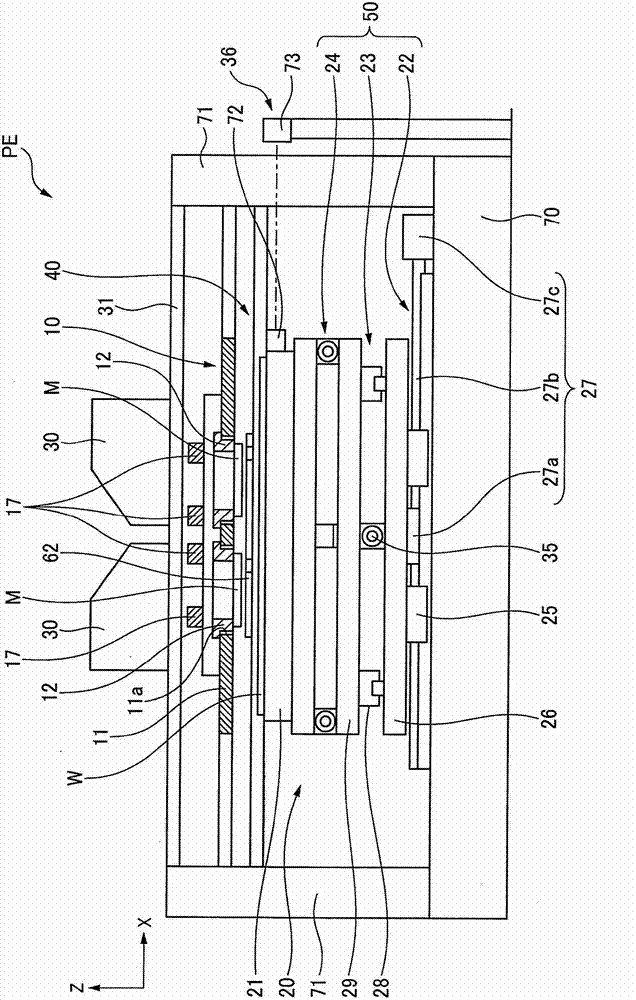

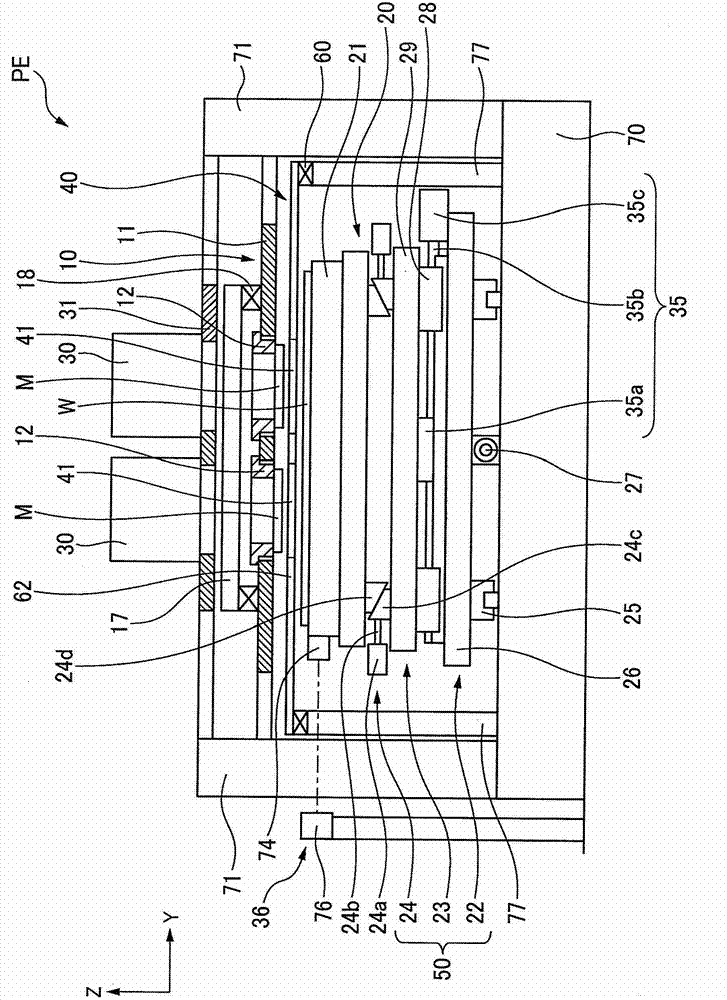

[0160] Hereinafter, an embodiment of the exposure apparatus according to the first embodiment of the present invention will be described in detail based on the drawings.

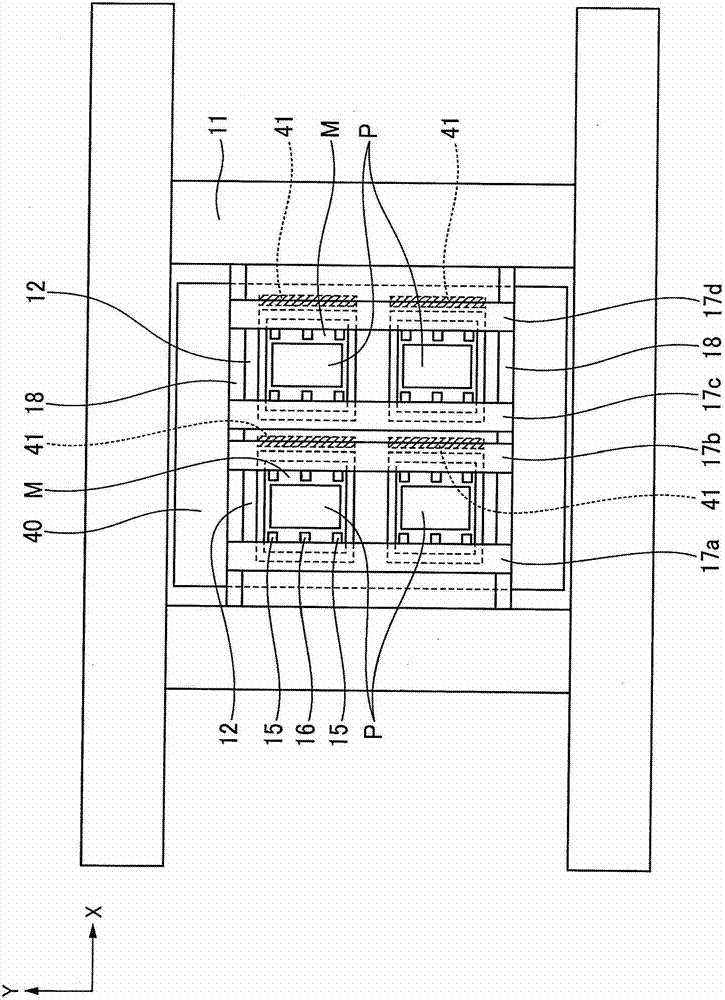

[0161] figure 1 is a front view of the exposure device of the present invention, figure 2 is its side view. Such as figure 1 and figure 2 As shown, the exposure apparatus PE of this embodiment has: a mask mounting table 10 holding a mask M; a substrate mounting table 20 on which a glass substrate (object to be exposed) W is mounted; Axis, Z-axis direction, and adjust the inclination of the substrate loading table 20 of the substrate loading table moving mechanism 50 and the microlens array 41, and arrange the microlens loading between the substrate loading table 20 and the mask loading table 10 stage 40 ; and illumination optical system 30 for irradiating pattern exposure light to substrate W via mask M and microlens array 41 .

[0162] It should be noted that the glass substrate W (hereinafter, simpl...

no. 2 approach

[0214] Figure 10 (a) and (b) are the top view and cross-sectional view of the microlens mounting plate provided with the nozzle which is the exposure apparatus of 2nd Embodiment. Such as Figure 10 As shown, on both sides of the microlens mounting plate 62 extending in the Y direction that is not held by the microlens mounting plate 62 , a plurality of nozzles 45 are formed on the upper and lower surfaces thereof. The plurality of nozzles 45 communicate with air supply holes 46 formed in the microlens mounting plate 62 . The plurality of nozzles 45 spray air supplied from an air supply device (not shown) in at least one of upward and downward directions through the air supply holes 46 .

[0215] As a result, as shown by the dotted line in the figure, deflection of the microlens mounting plate 62 deflected by its own weight can be corrected, thereby preventing uneven exposure due to deflection of the microlens mounting plate 62 . It should be noted that it is also possible ...

no. 3 approach

[0223] Below, refer to Figure 12 to Figure 14 An exposure apparatus according to a third embodiment of the present invention will be described. In addition, the same or equivalent parts as those of the first embodiment are assigned the same symbols, and descriptions thereof are omitted or simplified.

[0224] Such as Figure 12 and Figure 13 As shown, in this embodiment, the mask stage 10 is provided with a cover glass 90 made of glass or resin on the upper part of the mask holding frame 12, and is formed by the mask M, the mask holding frame 12, and the cover glass 90. In the highly airtight space, the pressure in the highly airtight space is adjusted by a pressure control mechanism not shown to compensate for the deformation of the mask.

[0225] In addition, if Figure 14 As shown, on the surface facing the mask holding frame 12 around the cover glass 90, a film 91 made of a resin such as polyacetal, polyamide, or ABS resin is pasted as a covering member. Thus, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com