Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Short shift times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

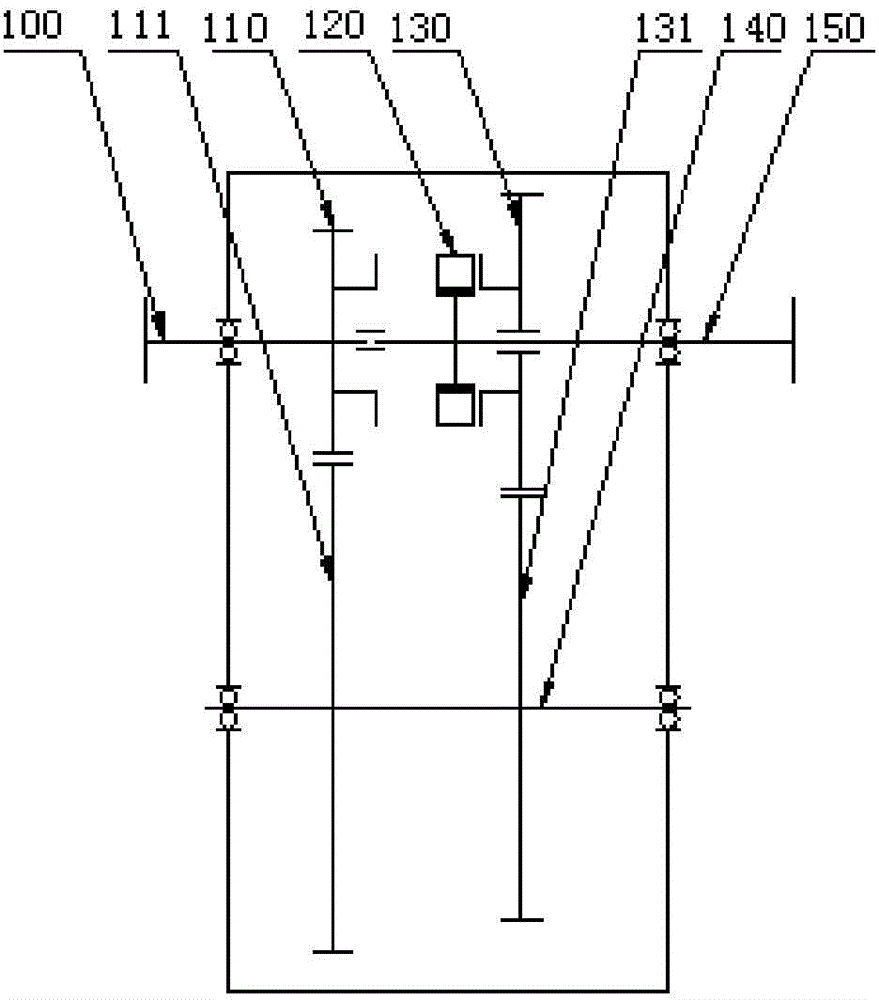

Electric vehicle and three-clutch transmission device for same

InactiveCN102678871AWith power shiftShort shift timesGearingTransmission elementsAutomatic controlEngineering

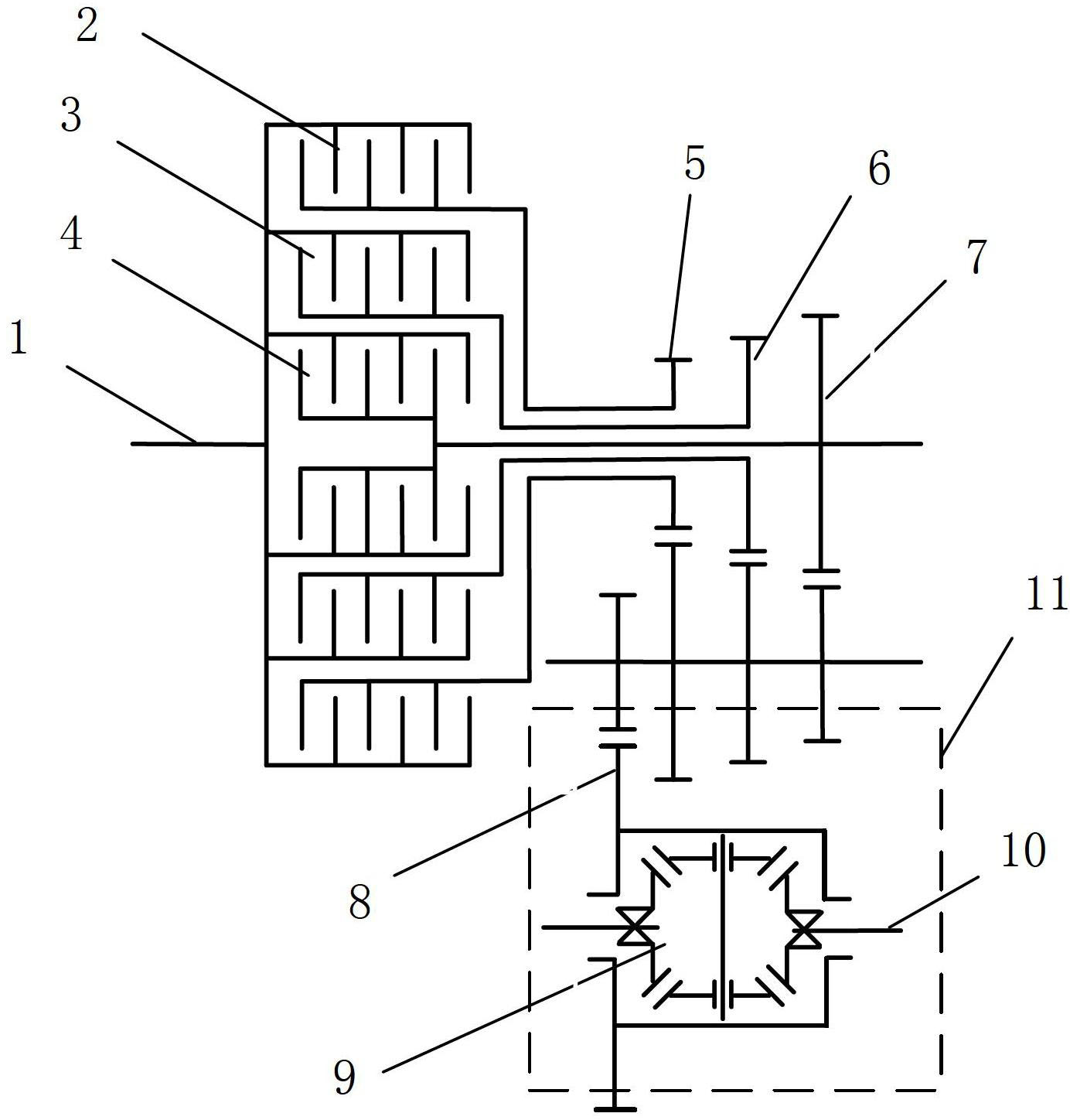

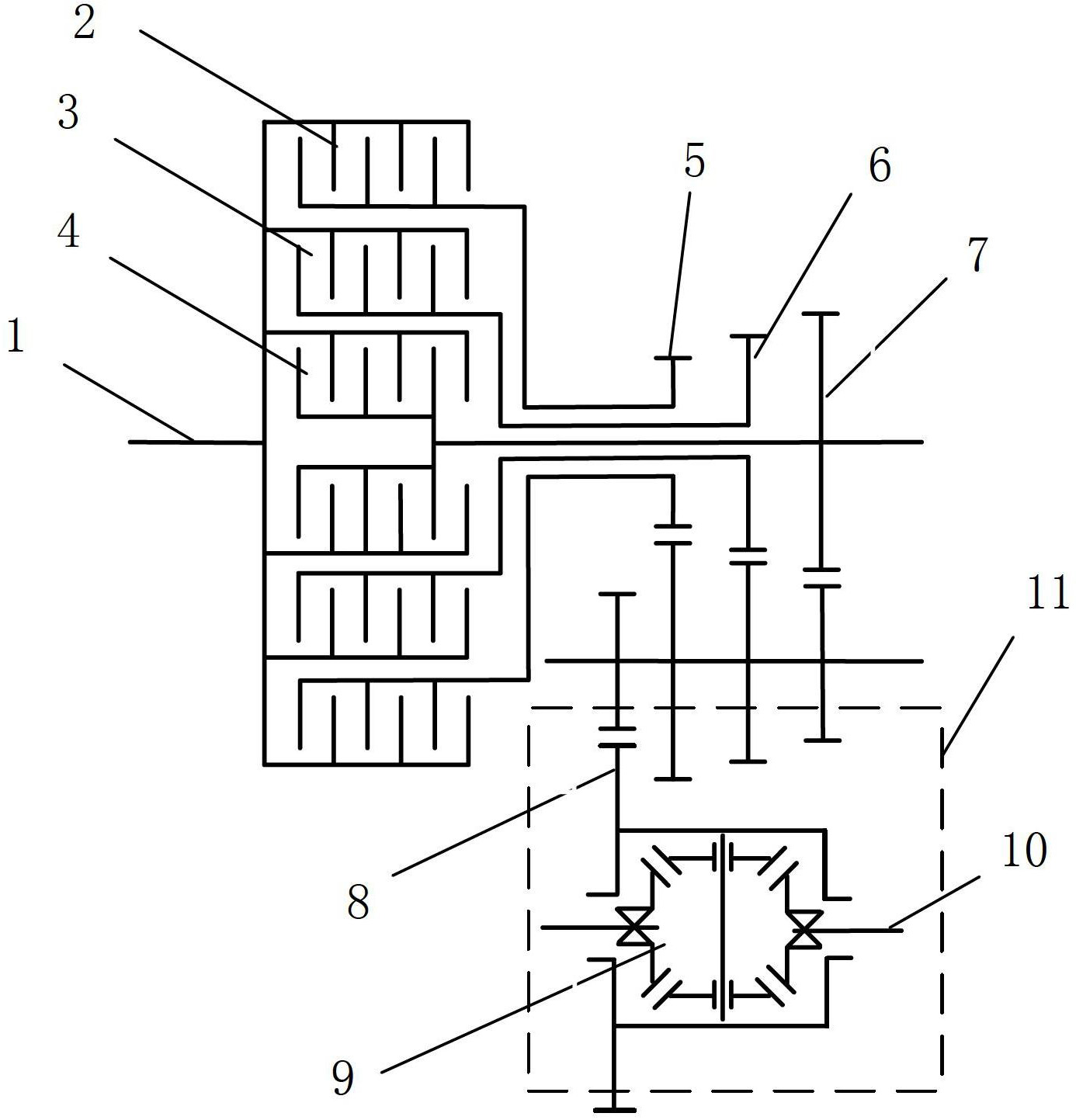

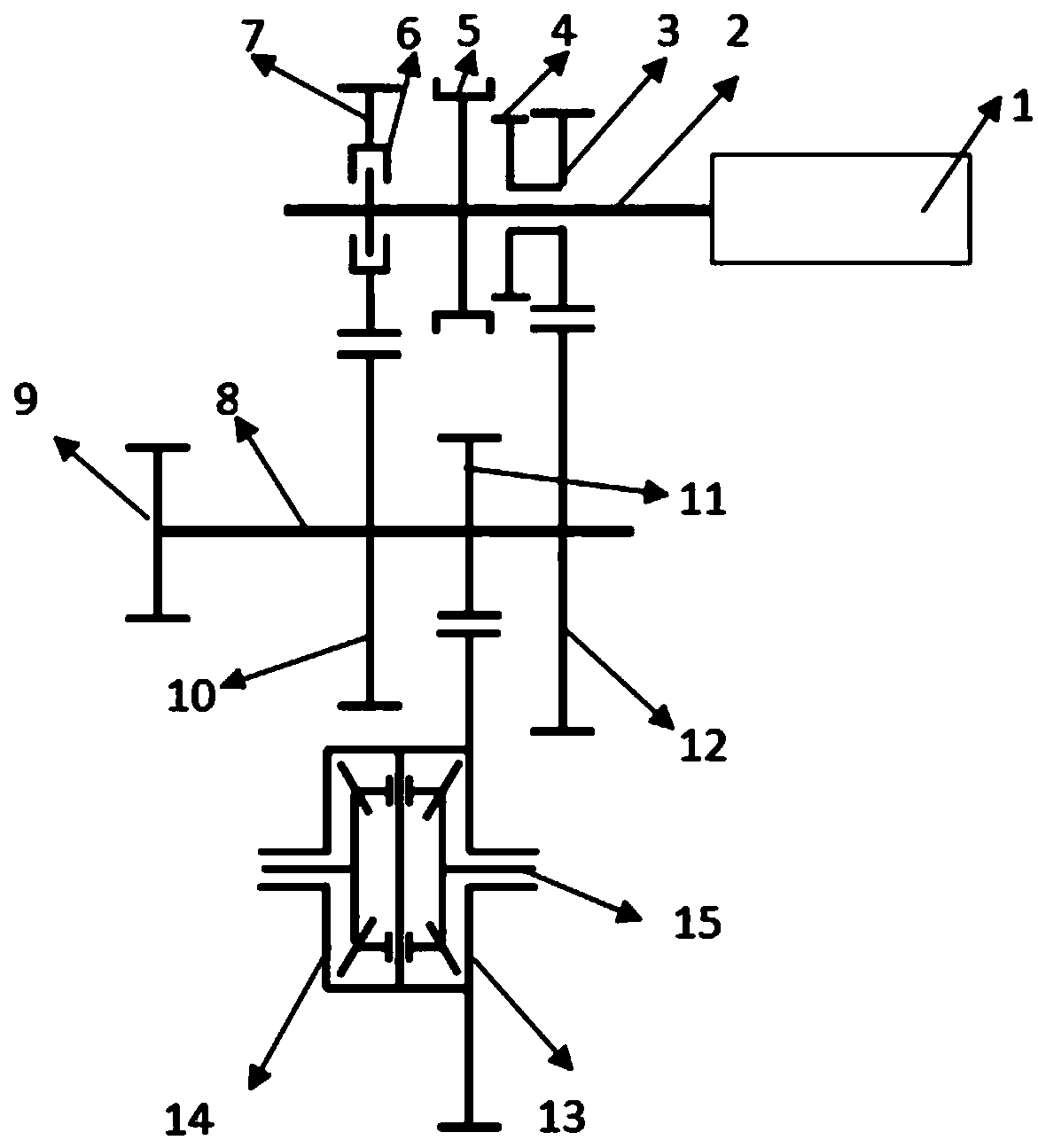

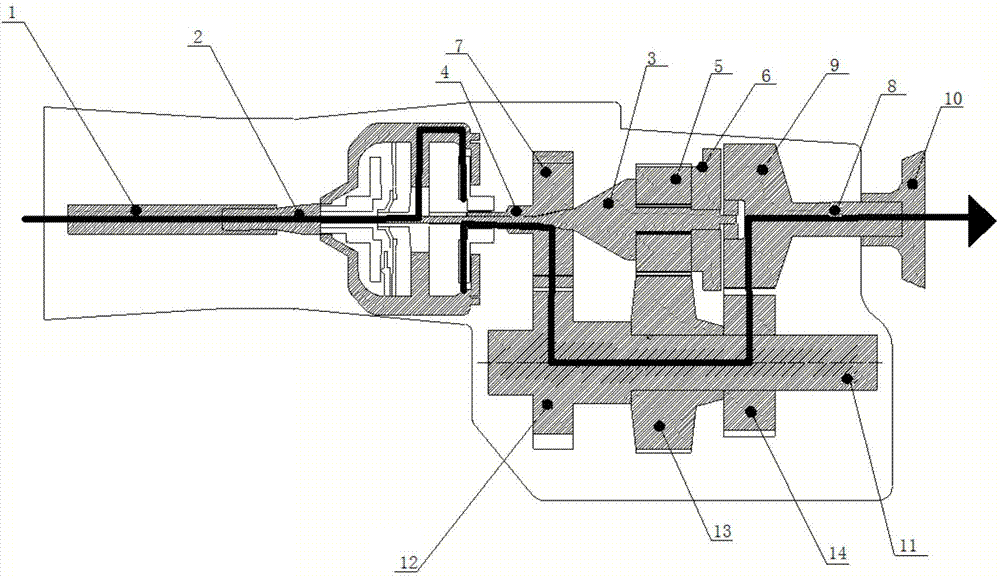

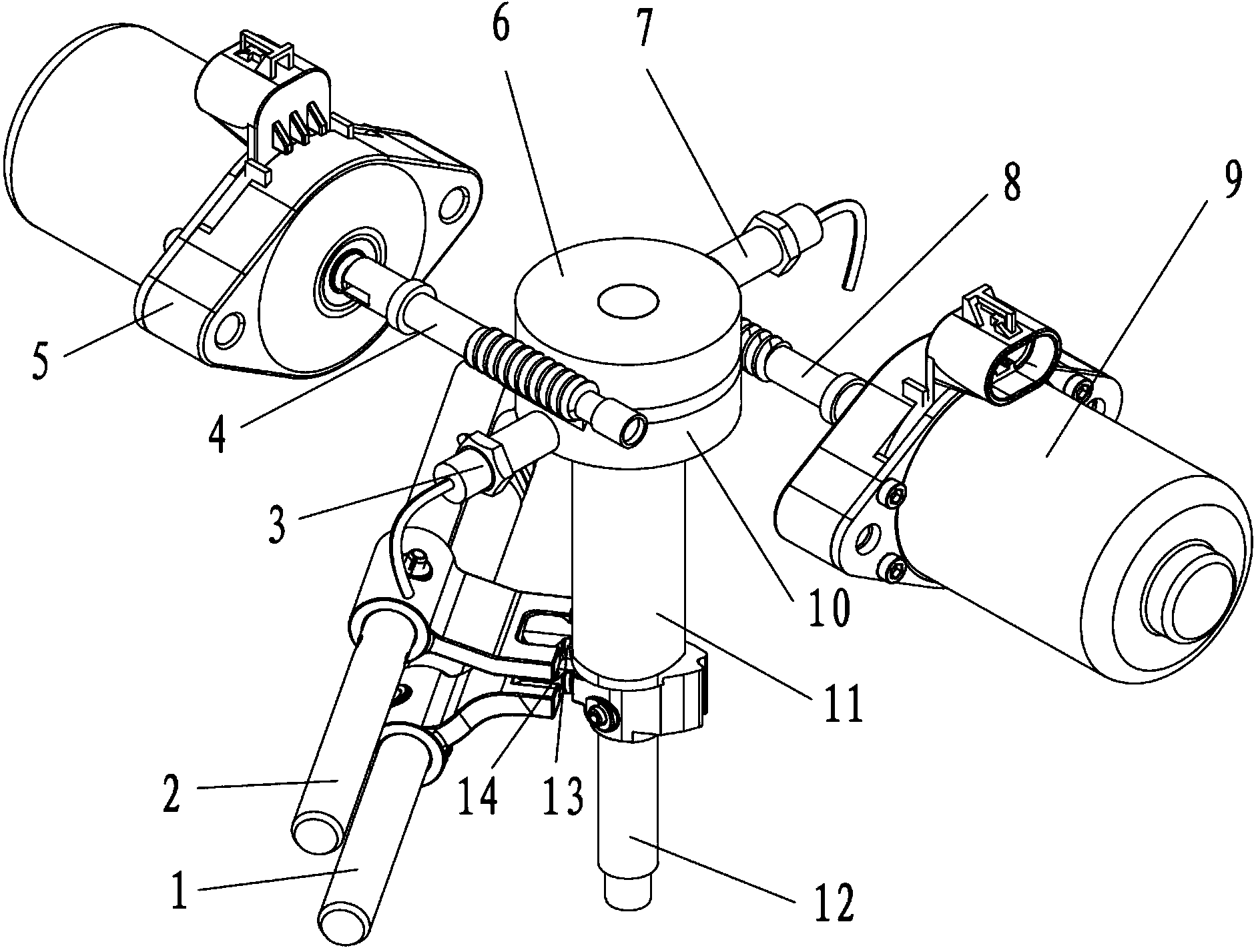

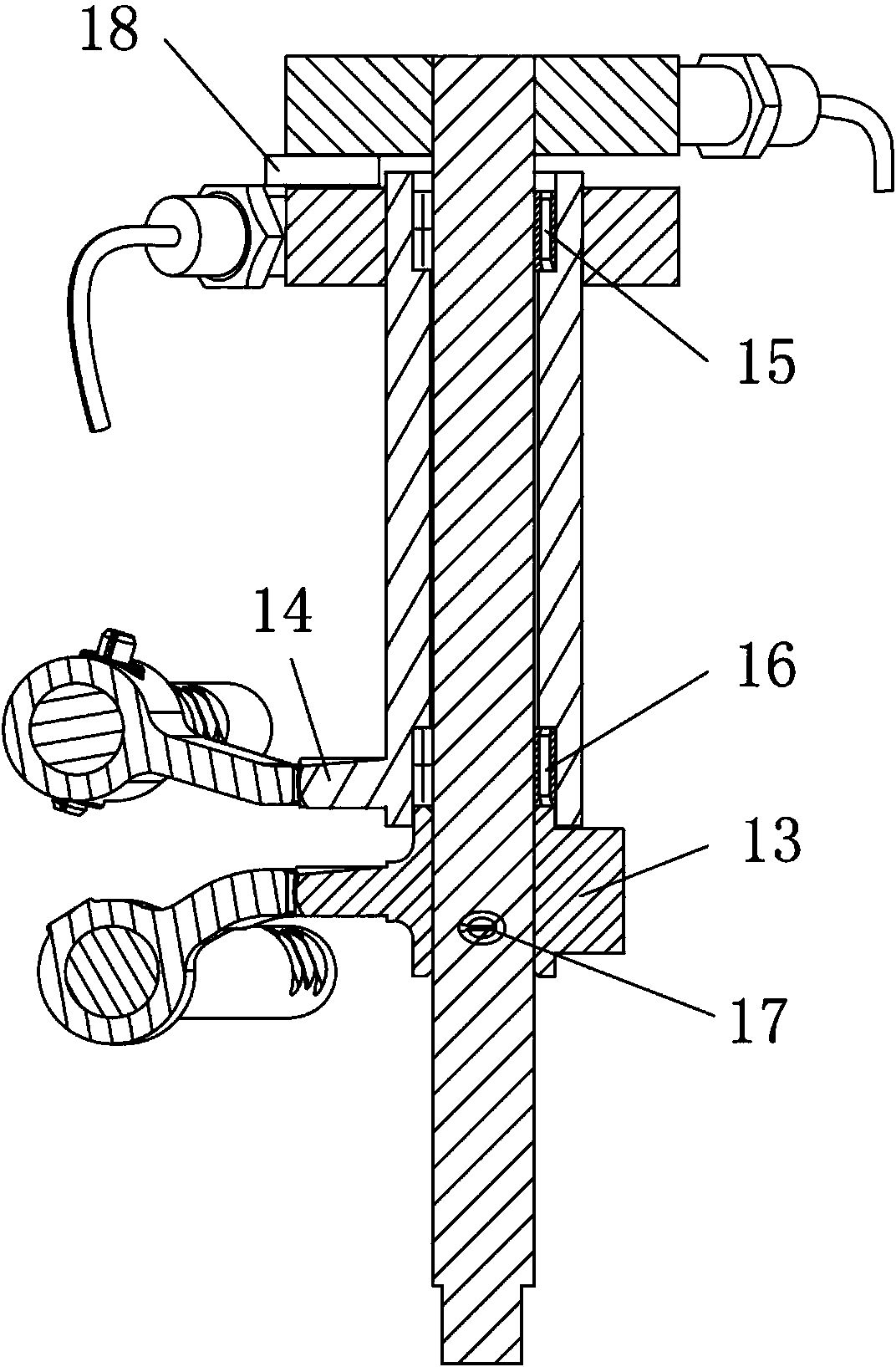

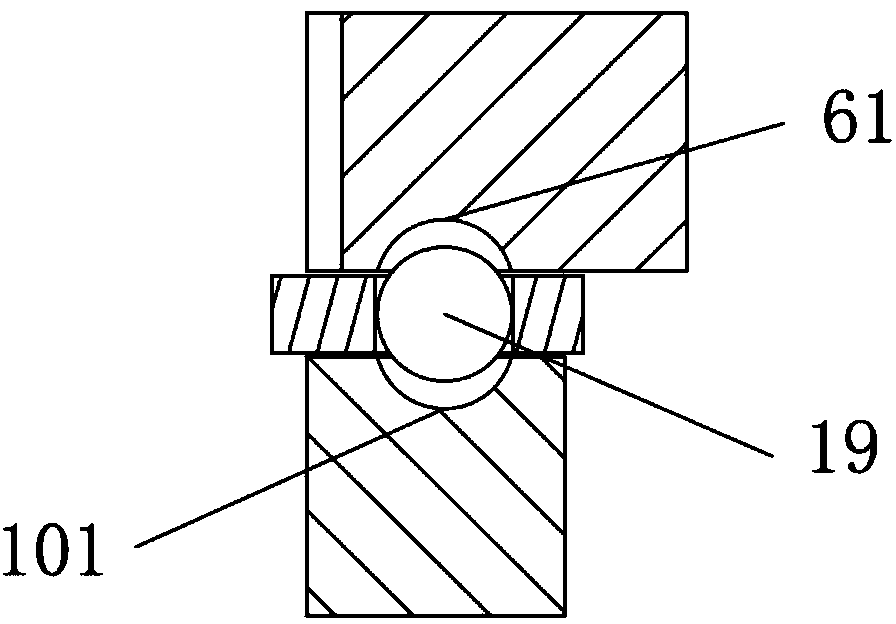

The invention discloses a three-clutch transmission device for an electric vehicle. The three-clutch transmission device is characterized by comprising an input shaft (1), a K1 clutch (2), a K2 clutch (3), a K3 clutch (4), a first-gear gear (5), a second-gear gear (6), a third-gear gear (7), an output shaft (10), a conduction device (11) and a gear controller, wherein the K1 clutch (2), the K2 clutch (3) and the K3 clutch (4) are respectively connected with the first-gear gear (5), the second-gear gear (6) and the third-gear gear (7); the gear controller automatically controls the output shaft (1) to be switched into different shifts through different clutches; and the output shaft (10) is connected with a gear-shifting gear through the conduction device (11). The three-clutch transmission device for the electric vehicle can be used for the electric vehicle and has the advantages of power gear shifting, short gear shifting time, good gear shifting quality, simple structure, low cost and the like.

Owner:BEIJING ELECTRIC VEHICLE

Automatic speed changer

ActiveCN104930137AOptimize layoutImprove reliabilityGearboxesToothed gearingsAutomatic transmissionEngineering

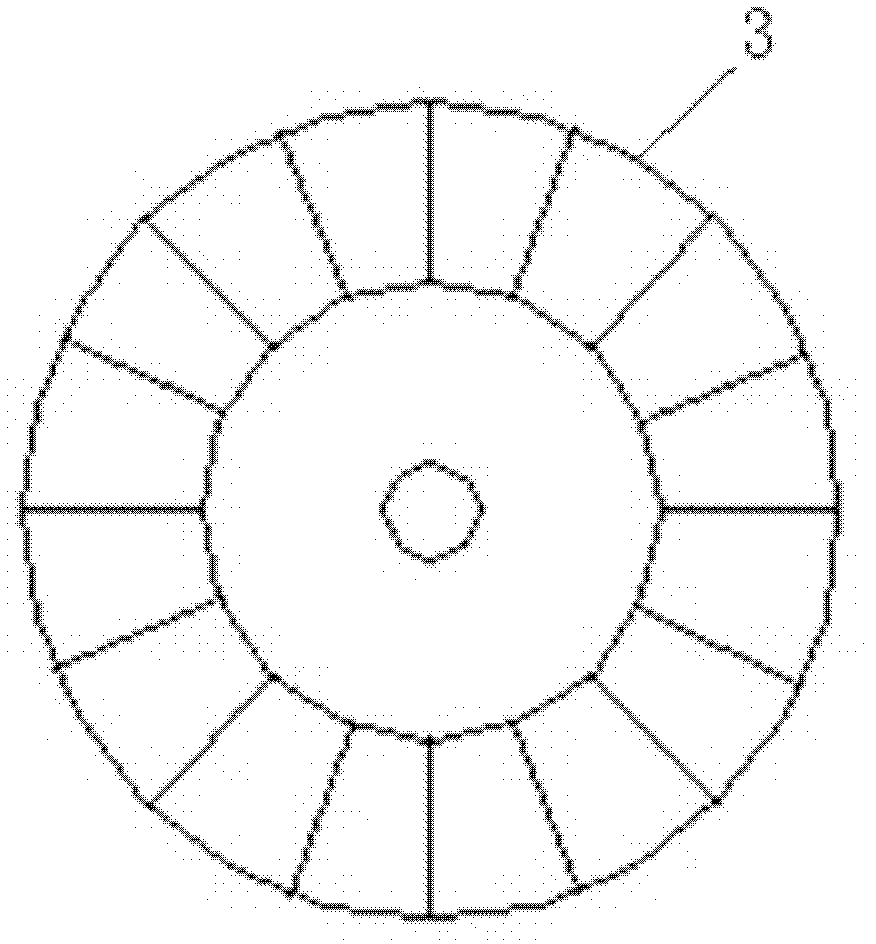

The invention discloses an automatic speed changer. The automatic speed changer comprises a double-end-face tooth combined fluted disc and a two-level speed reduction fixed shaft wheel train. A gear shifting mechanism of the speed changer is the double-end-face tooth combined fluted disc and is provided with double-end-face teeth including the left end face teeth and the right end face teeth. The double-end-face tooth combined fluted disc axially moves on an output shaft of the speed changer, the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are engaged with end face teeth of a one-level speed reduction gear and a two-level speed reduction gear respectively, the two-gear position and the one-gear position are achieved, and when the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are not combined with the end face teeth of the one-level speed reduction gear and the two-level speed reduction gear, the speed changer is at a neutral position. According to the technical scheme, compared with a traditional AMT, a synchronizer is removed, the structure is simple, reliability is high, the gear shifting time is short, the gear shifting impact is small, the production cost is low, and industrialization is easy to achieve. The gear arrangement mode of the speed changer is simple, the axial size is short, the occupied space is small, the weight is low, and the automatic speed changer conforms to the development trend of light weight and energy saving.

Owner:JING JIN ELECTRIC TECH CO LTD +1

Automatic gear shift mechanism for transmission

ActiveCN101457831ASimple structureShort shift timesGearing controlMotor driveElectrical and Electronics engineering

Owner:BYD CO LTD

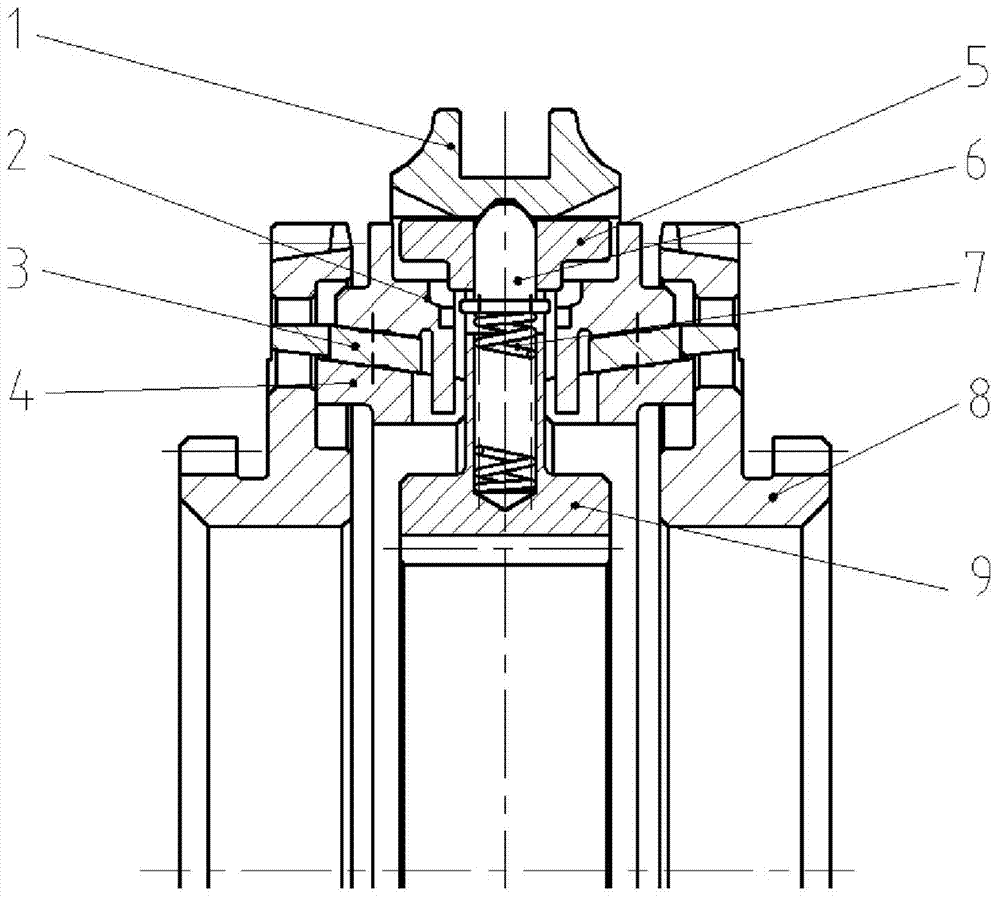

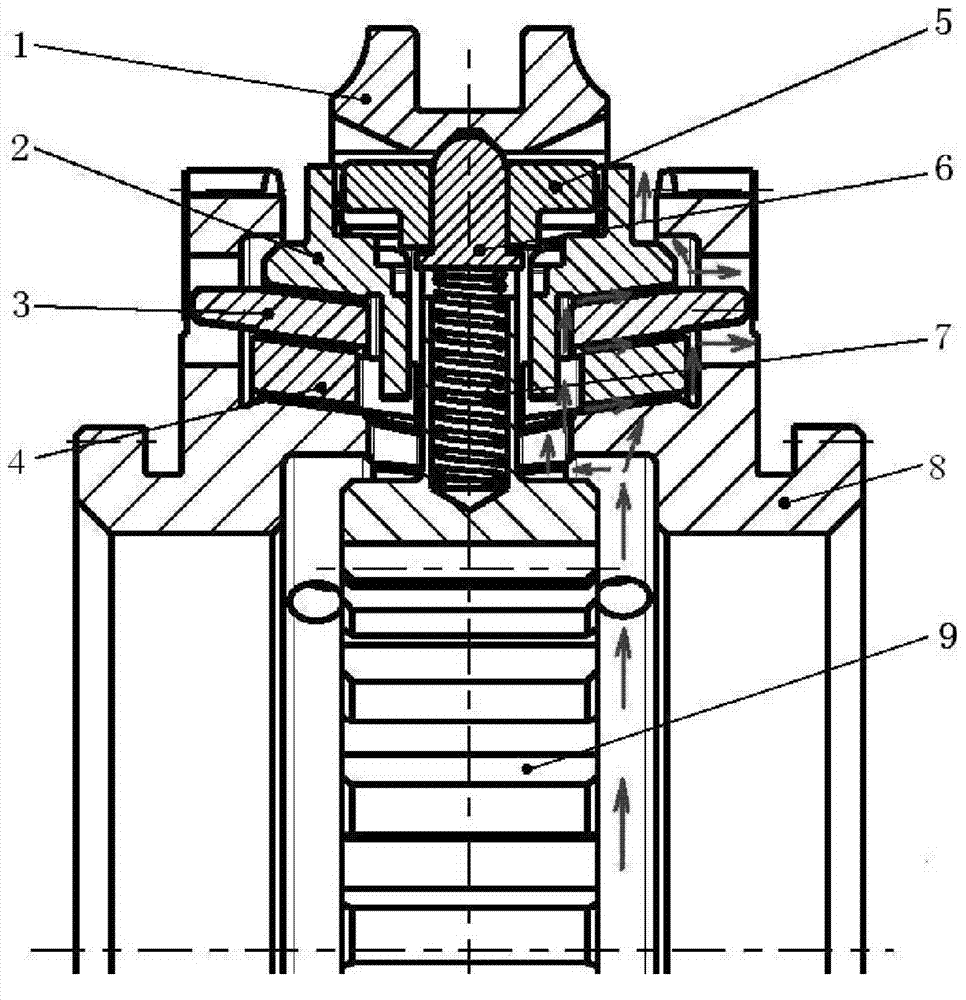

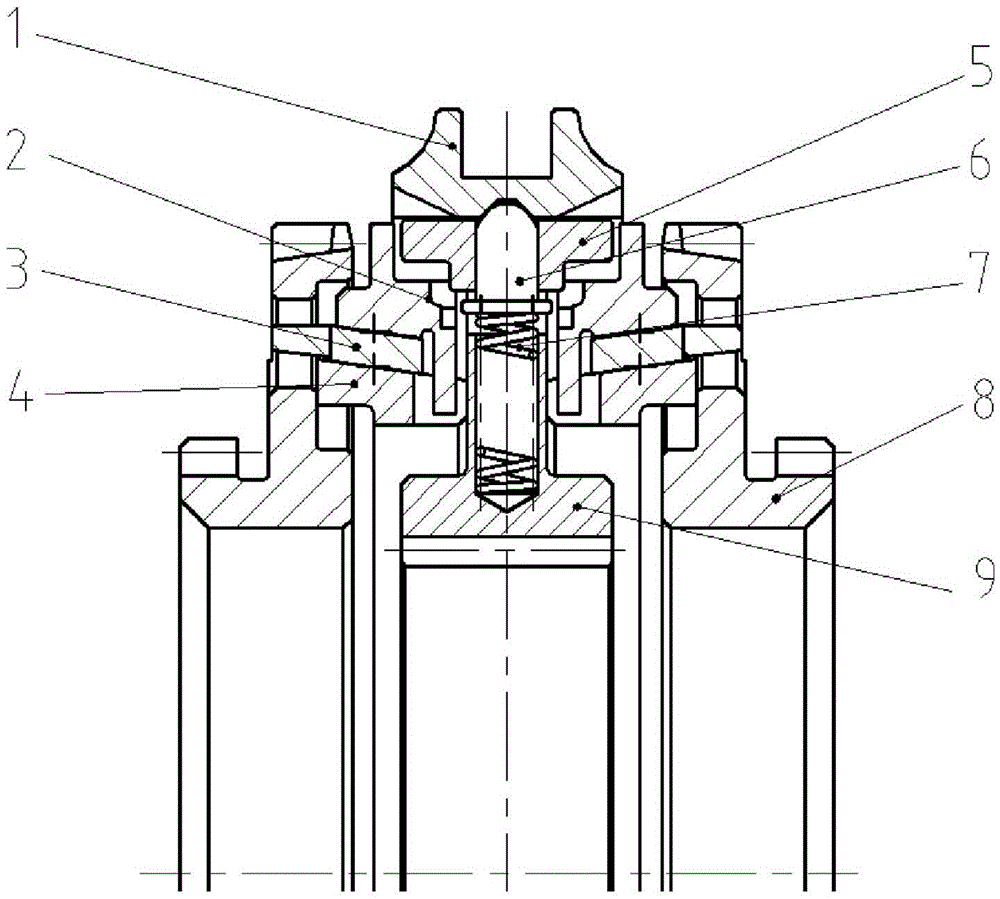

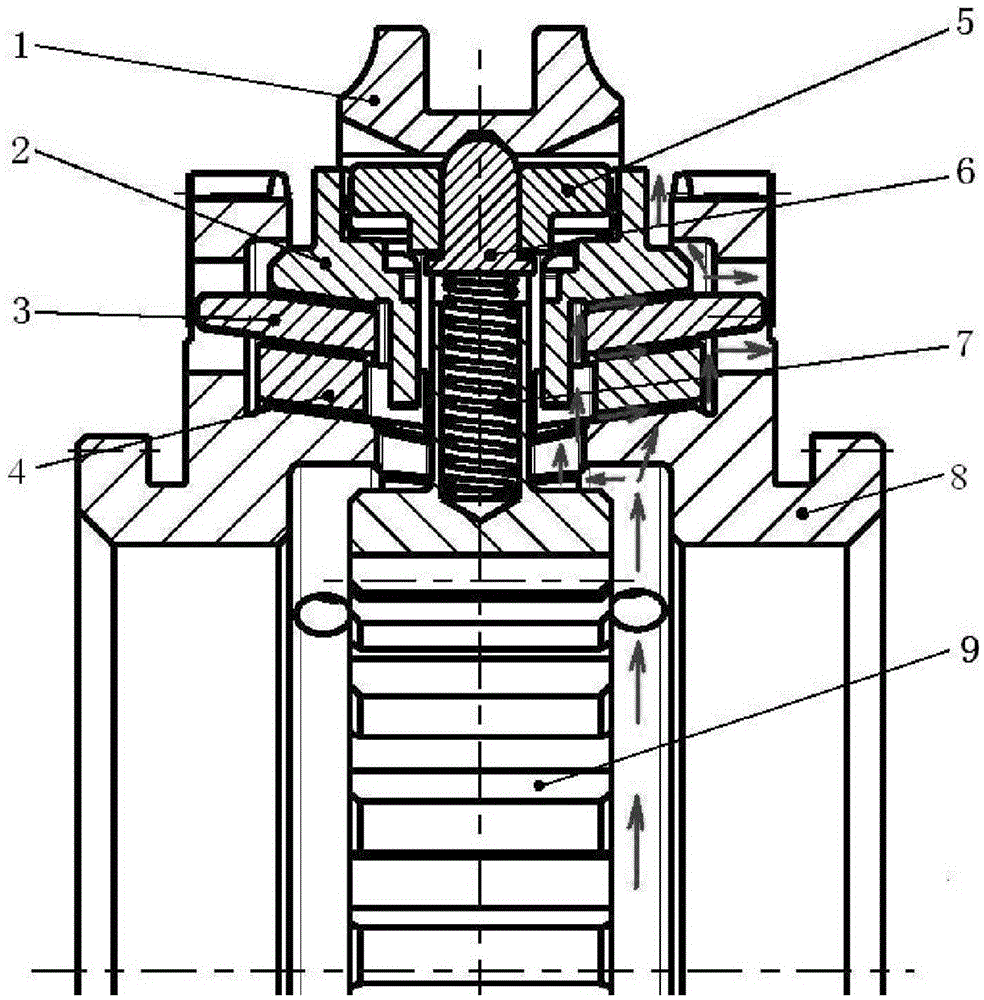

Three-conical-face synchronizer with lubricating oil way

ActiveCN103790994ASimple structureShort shift timesMechanical actuated clutchesCouplingsEngineeringShift time

The invention discloses a three-conical-face synchronizer with a lubricating oil way. The three-conical-face synchronizer comprises a sliding gear sleeve, external friction rings, middle friction rings, internal friction rings, a sliding block, a pin, a spring, combined gear rings and a gear hub. A pair of the combined gear rings are symmetrically arranged on the two sides of the gear hub, and conical face bodies of the combined gear rings face one side of the gear hub. A pair of the internal friction rings are arranged on the combined gear rings and provided with a pair of the middle friction rings. Second claws of the middle friction rings extend into oil passing holes of the combined gear rings. A pair of the external friction rings are arranged on the middle friction rings. First claws of the external friction rings extend into oil passing grooves of the internal friction rings. The sliding gear sleeve, the sliding block, the pin and the spring are arranged between the external friction rings. One end of the pin penetrates through the sliding block and is matched with the sliding gear sleeve, and the other end of the pin makes contact with the gear hub through the spring. Compared with a double-conical-face synchronizer, the three-conical-face synchronizer is shorter in shift time, smaller in shift force, more comfortable to control and longer in service life.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Two-gear transmission for electric vehicle

InactiveCN106763619AImprove transmission efficiencySimple structureGearboxesGearingElectricityElectric machine

The invention discloses a two-gear transmission for an electric vehicle. The two-gear transmission is applicable to front-engine front-drive or rear-engine rear-drive vehicles, is positioned at the output end of a driving motor, and is of a three-shaft structure. The two-gear transmission comprises an input shaft assembly, an intermediate shaft assembly, an output assembly and a case assembly, wherein rotation central lines of the input shaft assembly, the intermediate shaft assembly and the output assembly are parallel; the input shaft assembly, the intermediate shaft assembly and the output assembly are mounted and supported on the case assembly. According to the two-gear transmission, the transmission efficiency is high, the structure is simple, the transmission ratio is liable to match, and the production and manufacturing cost is relatively low; the transmission torque is large, gear shifting control is accurate, reliability is high, and performance requirements that power is not interrupted during the gear shifting process, the time of the gear shifting process is short, and the gear shifting process is smooth can be met; the lighter driving motor can be adopted, and the cost of the driving motor is reduced; and the driving motor and a transmission system are integratedly designed, so that the comprehensive cost of an electric driving system is greatly reduced, and the loading compatibility on different vehicles is higher.

Owner:BEIHANG UNIV

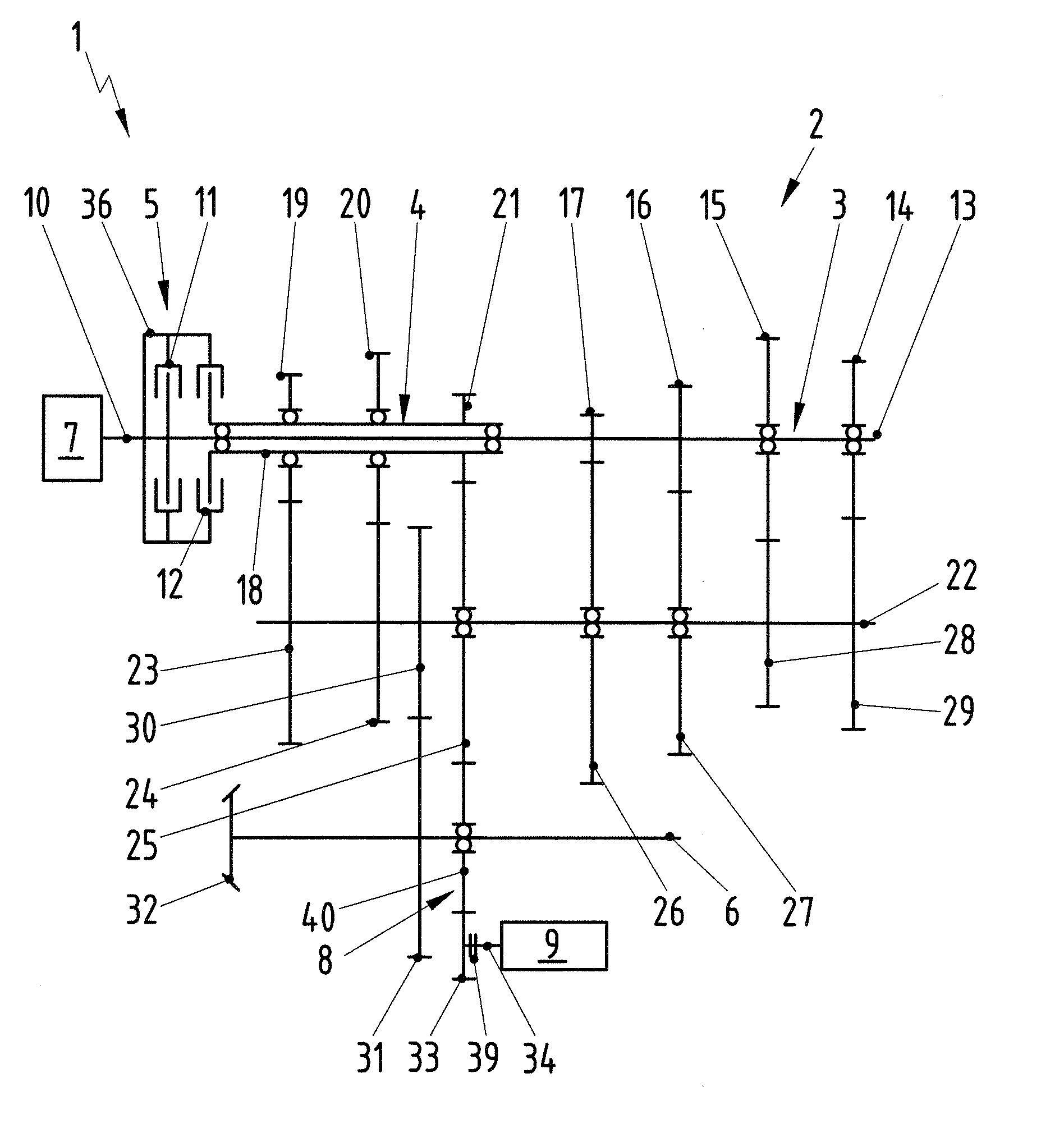

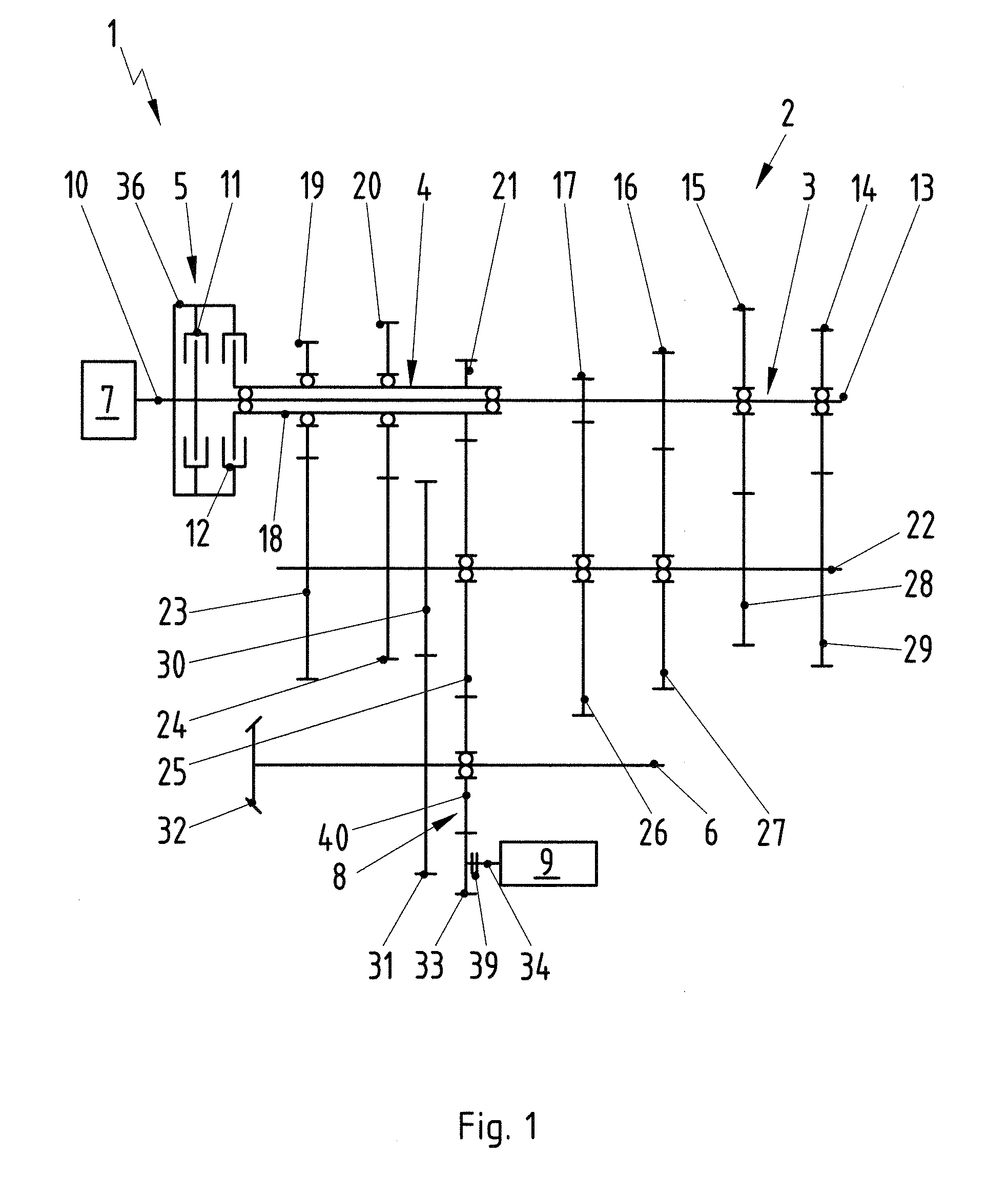

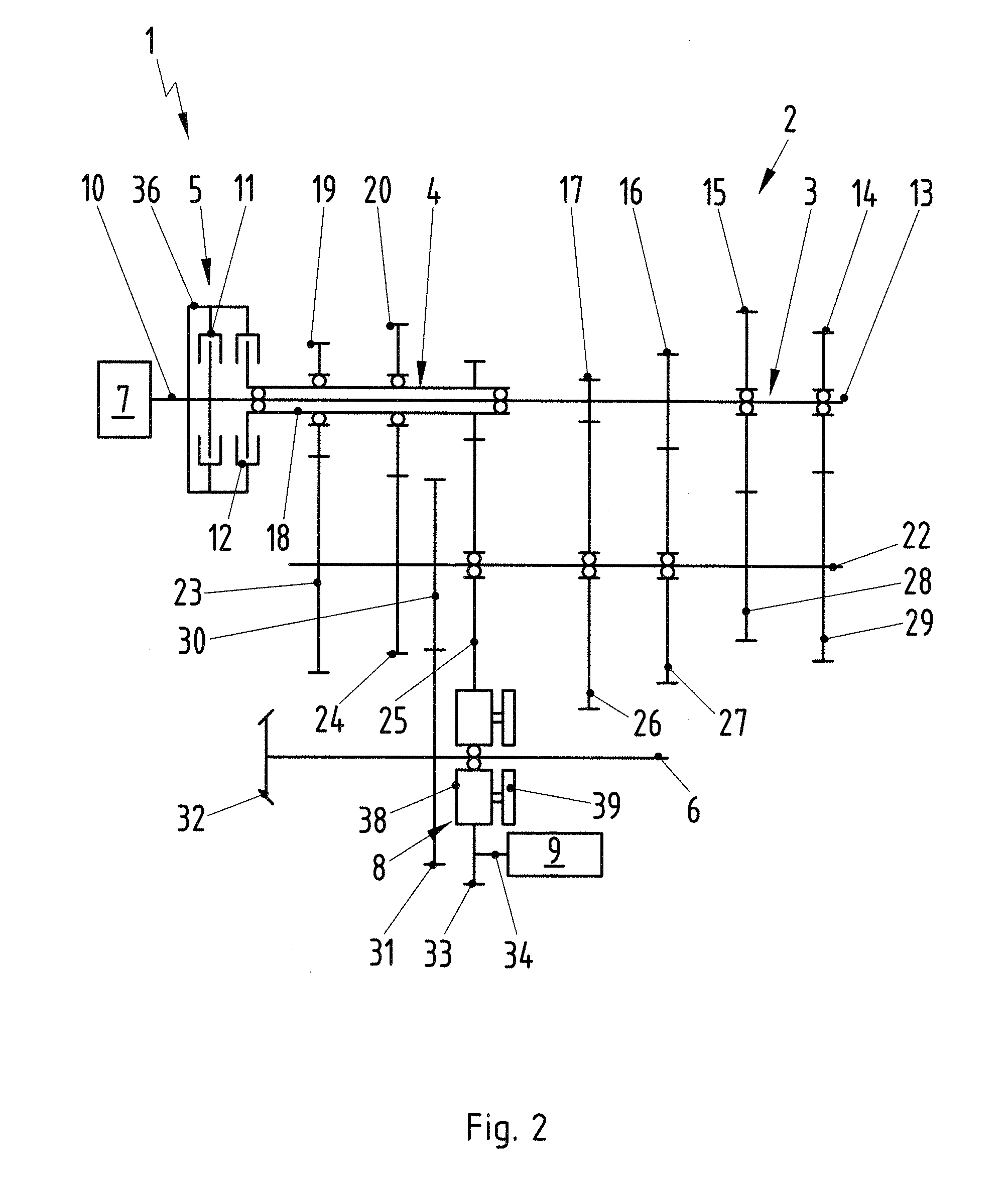

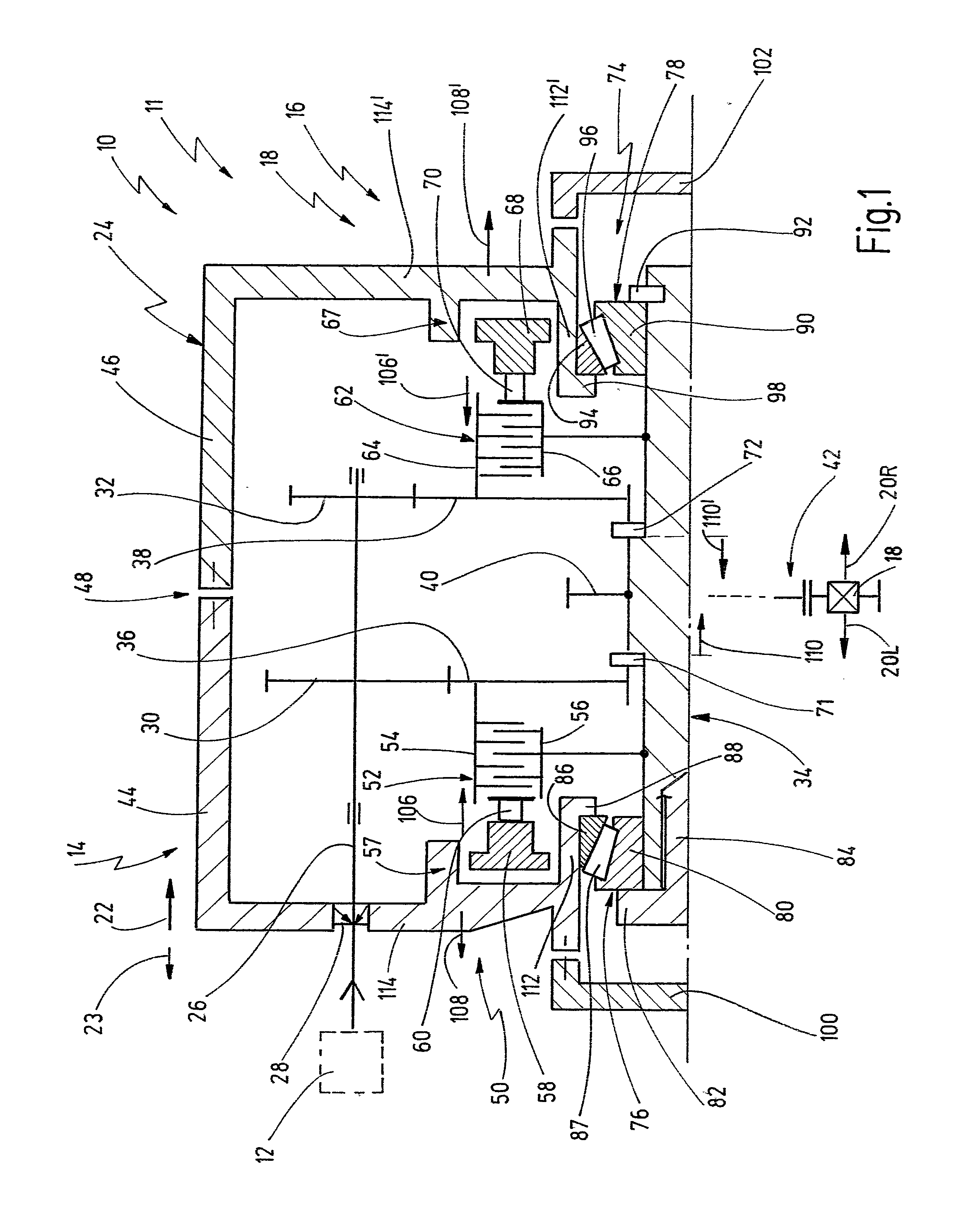

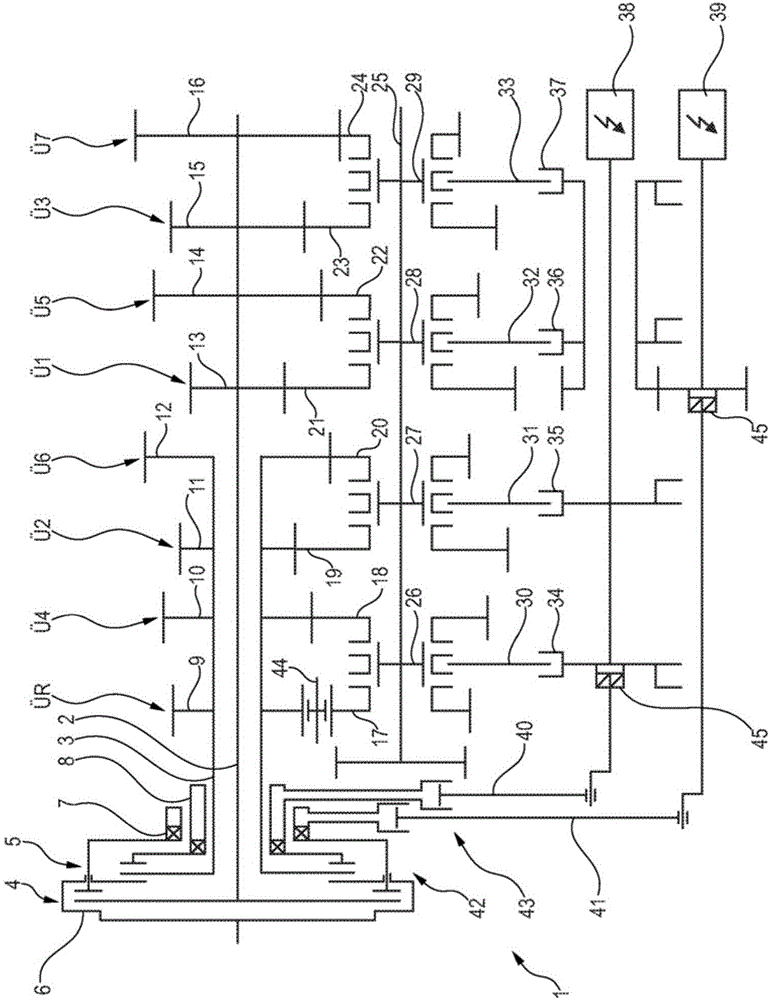

Drive system and method for operating such a drive system, in particular for a motor vehicle

ActiveUS20110212801A1Reduced space requirementsShort shift timesGas pressure propulsion mountingToothed gearingsGear driveElectric machine

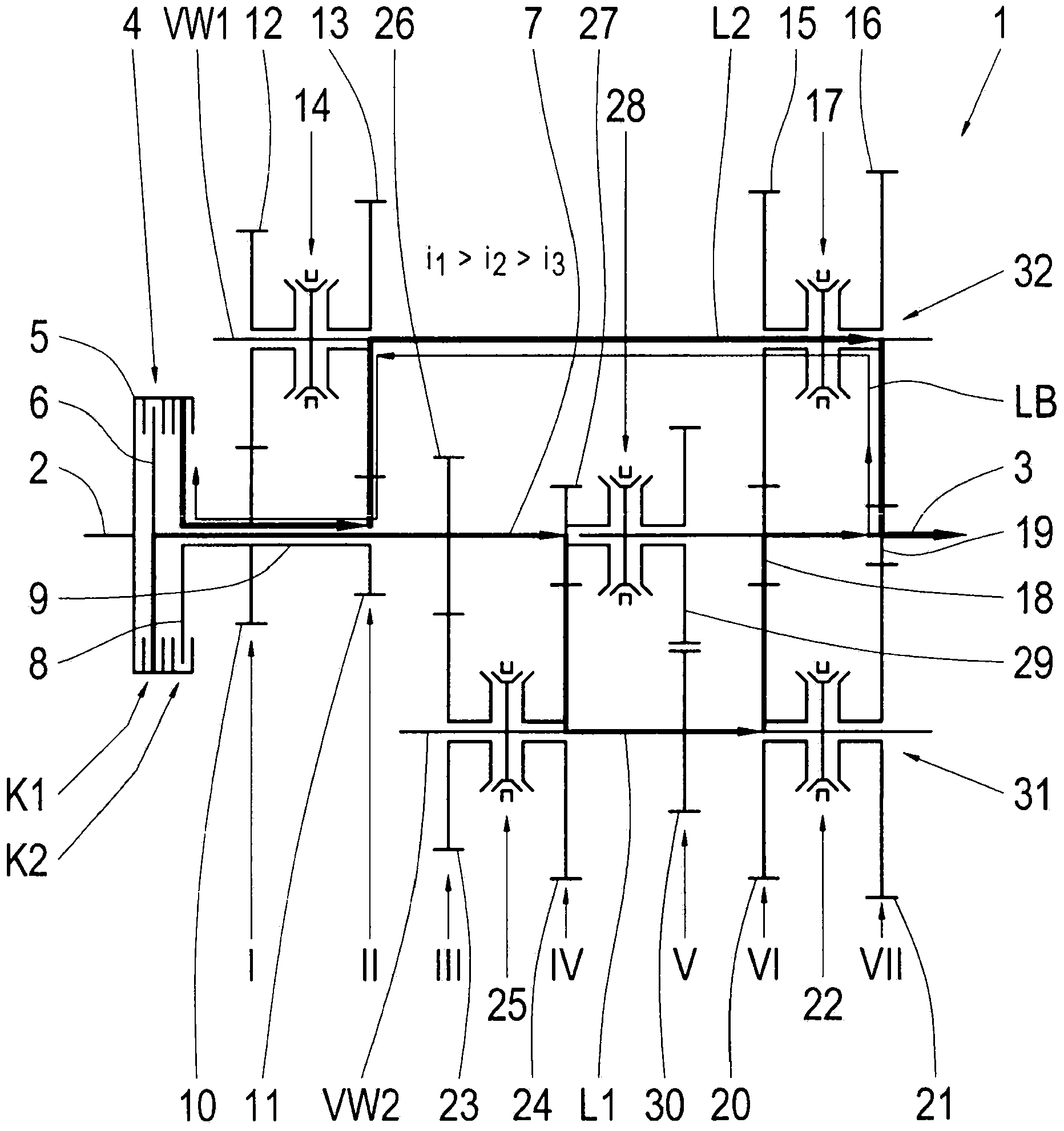

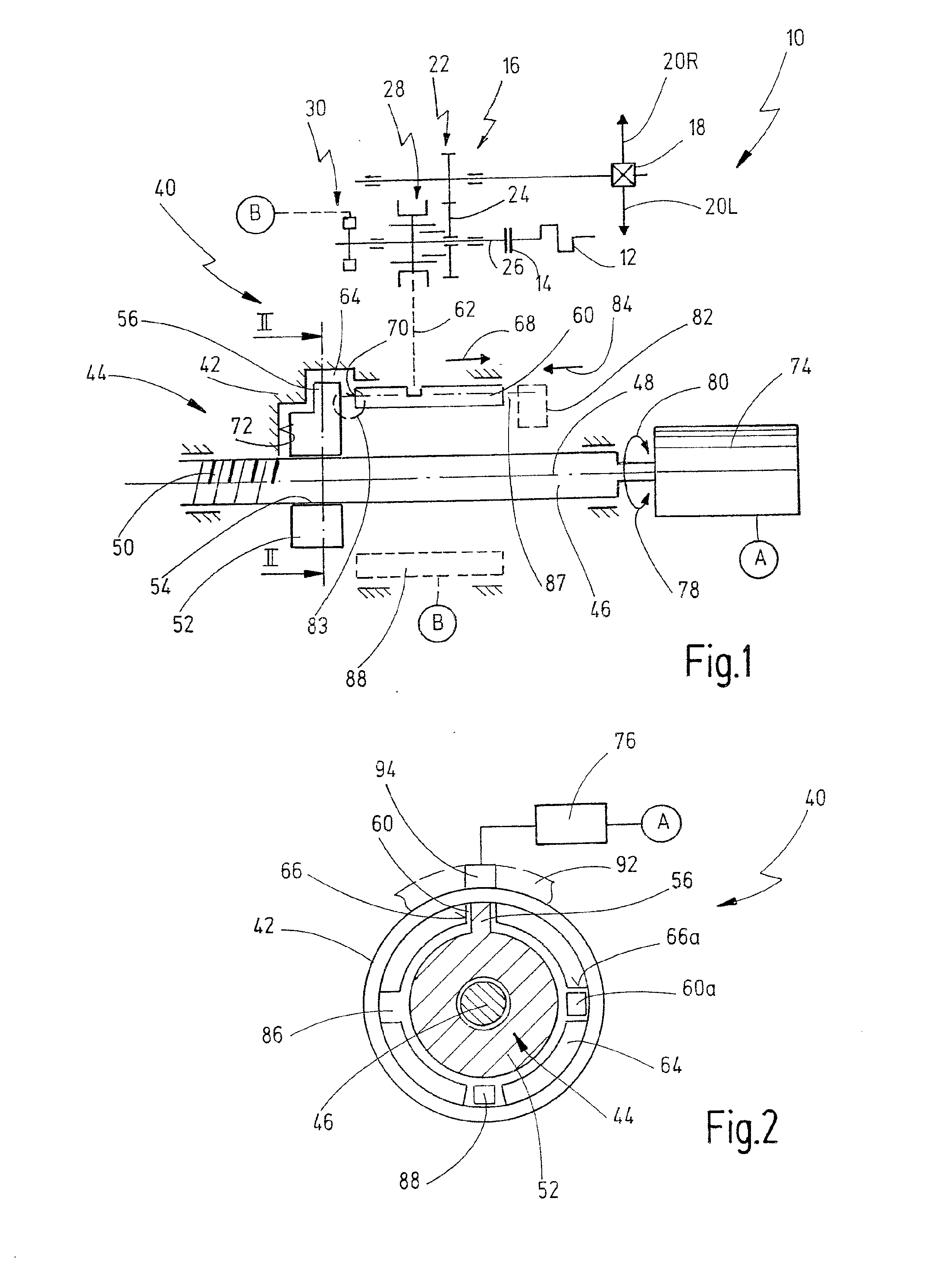

A drive system (1) for a motor vehicle has a double clutch transmission (2), with two component transmissions (3, 4), a double clutch (5) and an output shaft (6). An internal combustion engine (7) optionally can be connected operatively to one of the component transmissions (3, 4) via the double clutch (5) to drive the output shaft (6). A gear drive (8) is arranged rotatably on the output shaft (6). An electric machine (9) can be connected operatively via the gear drive (8) to at least one fixed gear (16, 17, 21) of one of the component transmissions (3, 4) to drive the output shaft (6) and / or to recover kinetic energy from the drive system (1).

Owner:DR ING H C F PORSCHE AG

Electric vehicle driving system and control method

InactiveCN107117160AReduce the numberReduce manufacturing costSpeed controllerElectric energy managementGear wheelElectric machine

The embodiment of the invention provides an electric vehicle driving system and a control method. The system comprises a drive motor, a motor controller, an AMT transmission and an AMT transmission controller; the motor controller is connected with the drive motor, and the transmission controller is connected with the transmission; the drive motor comprises a drive motor rotor; the AMT transmission comprises a gear tooth ring, a shifting fork, a joint sleeve, a shifting motor, a transmission input shaft, a rotational speed sensor and a transmission output shaft; the drive motor rotor of the drive motor is connected with the transmission input shaft of the transmission; the gear tooth ring is arranged on the transmission input shaft; the joint sleeve is arranged on the transmission output shaft to be engaged with different dimensions of tooth rings of the gear tooth ring; the drive motor further comprises the shifting motor and the shifting fork; and the shifting motor is connected with the shifting fork so as to control the joint sleeve to be disengaged from the gear tooth ring through the shifting fork to achieve downshift or control the joint sleeve to be engaged with the different tooth rings of the gear tooth ring through the shifting fork to achieve gear engaging.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Variable speed-change gearbox

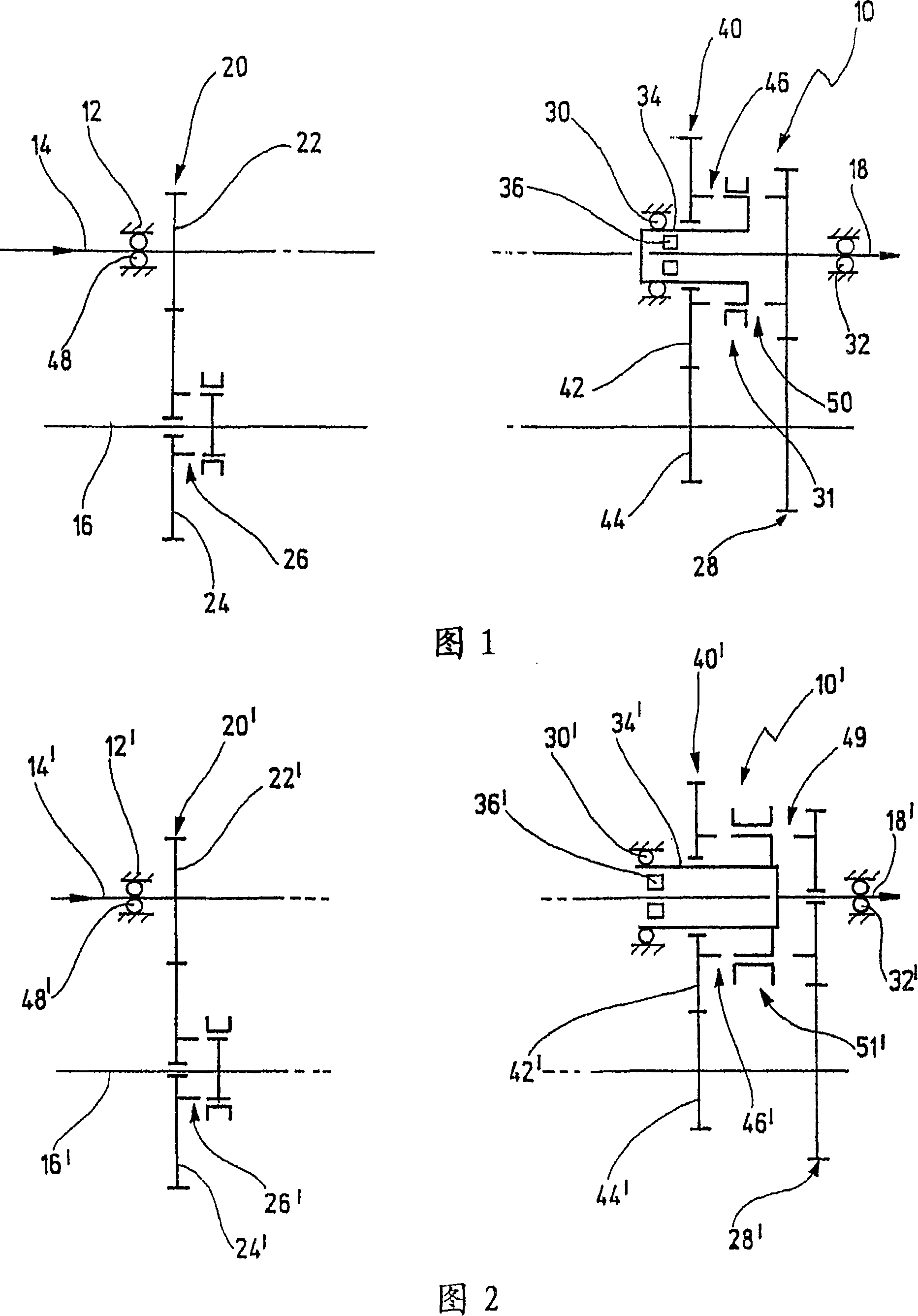

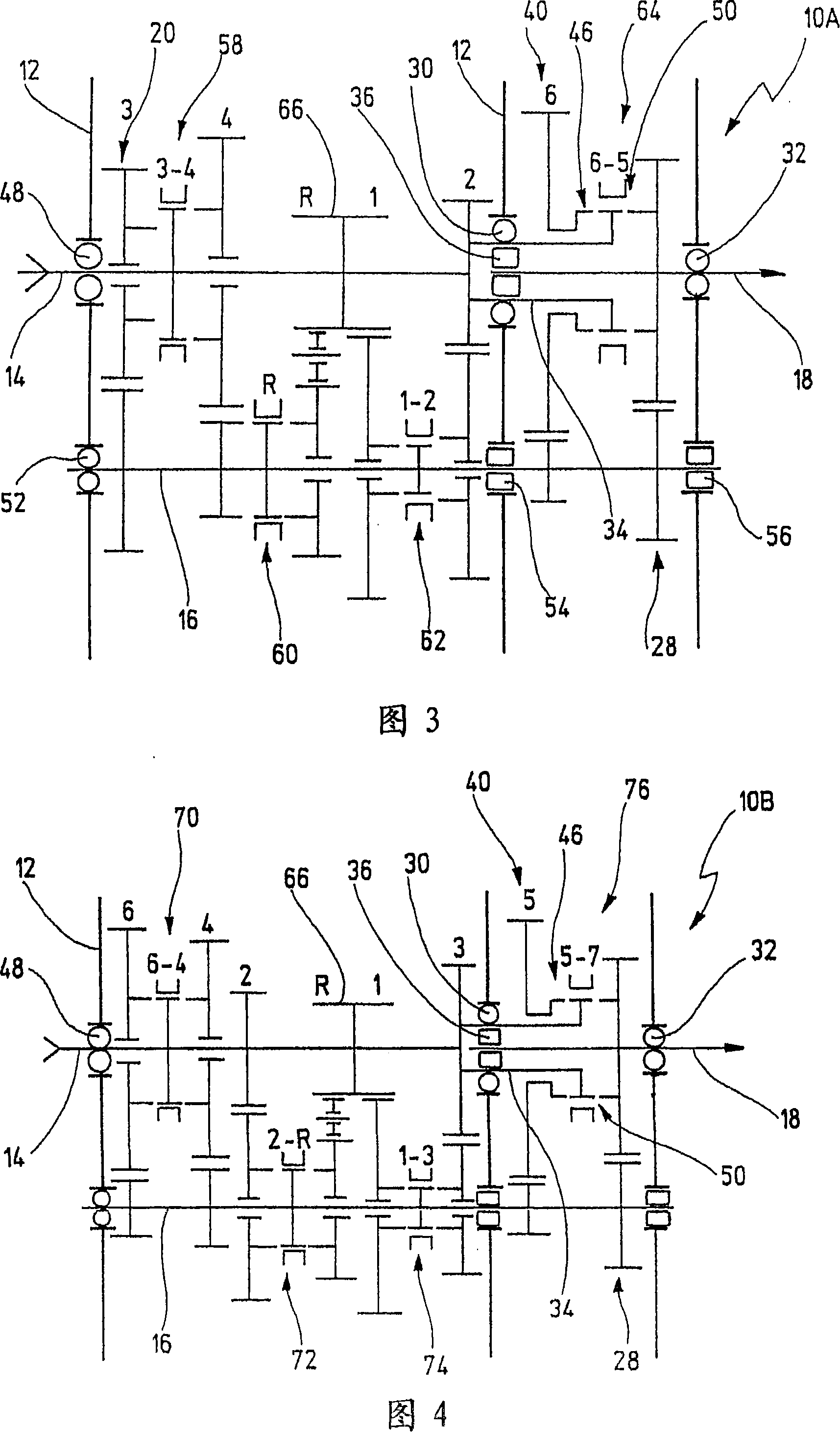

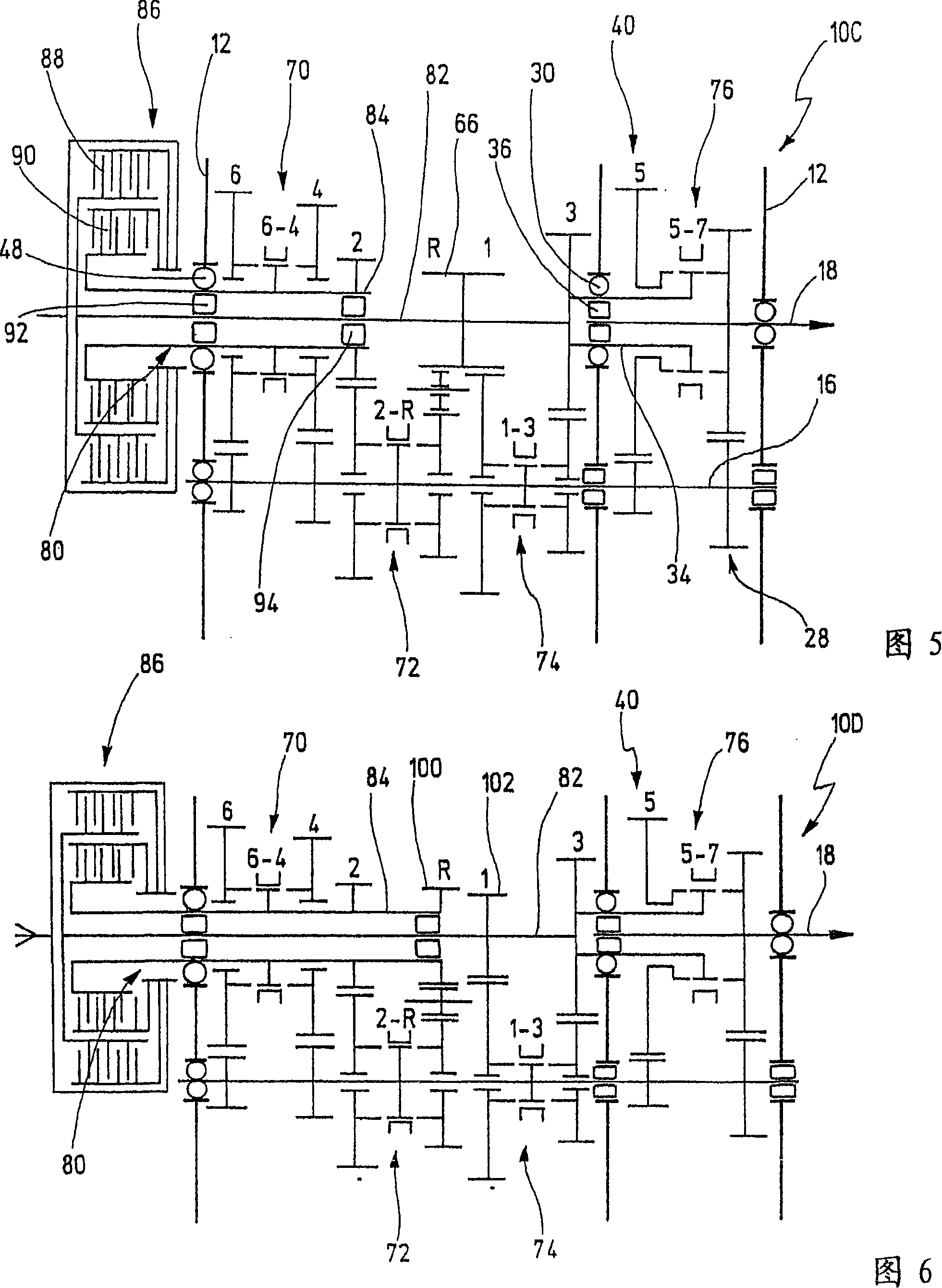

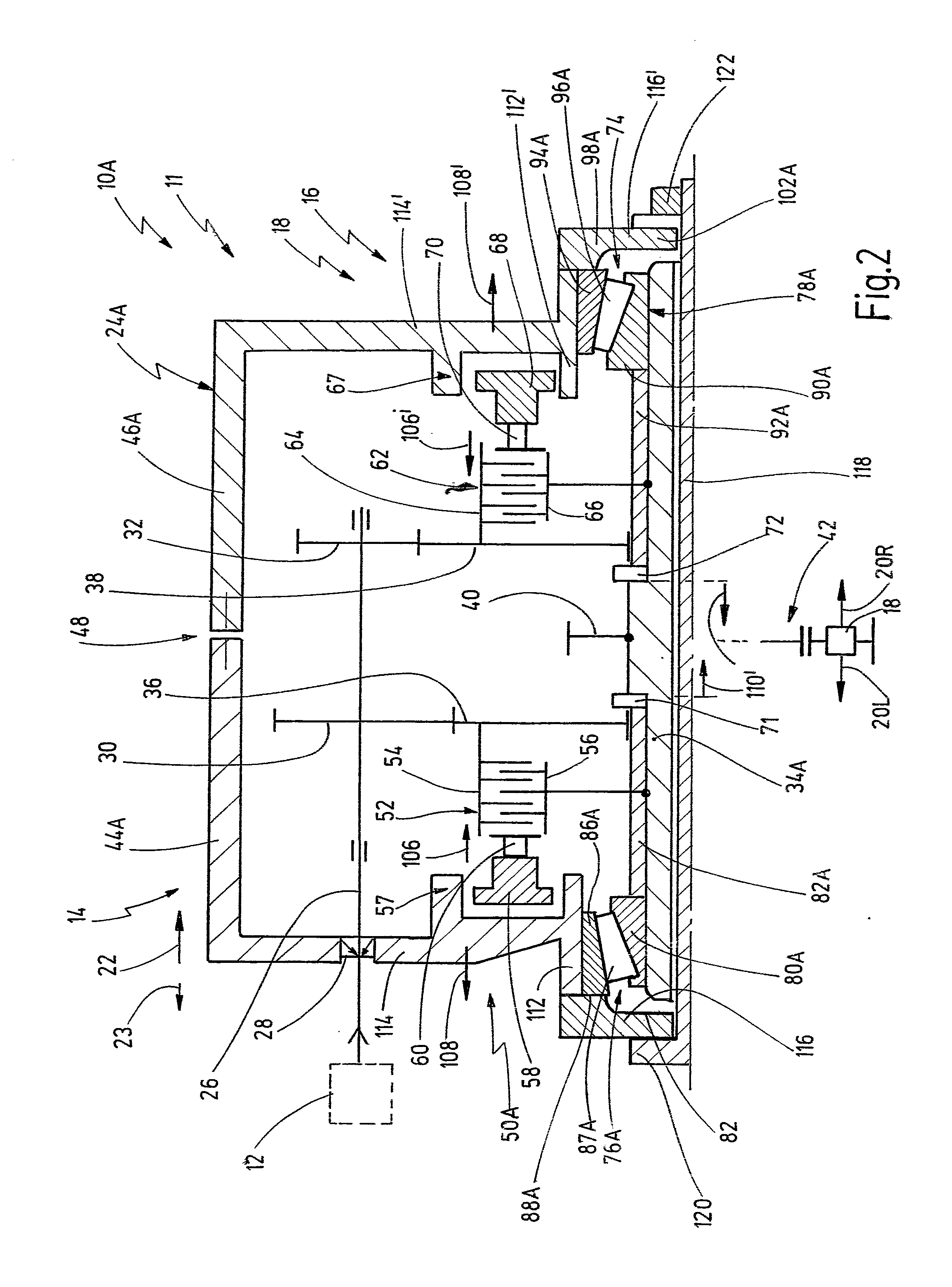

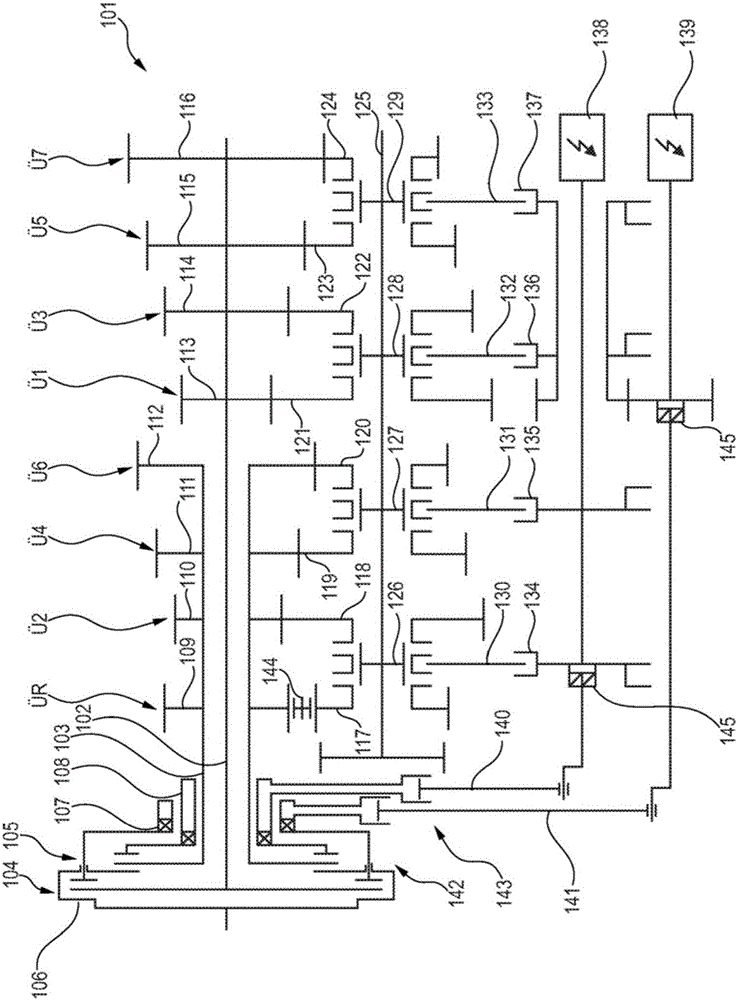

InactiveCN101111695AThe relative installation positionFavorable relative installation positionToothed gearingsTransmission elementsControl theoryClutch

The invention relates to a transmission (10), in particular for a vehicle, comprising: a housing (12), a drive shaft arrangement (14; 80), a driven shaft (18) and an intermediate shaft (16), a plurality of gear sets (20, 40) are installed on the driven shaft (18) or the intermediate shaft (16) and set different transmission ratios through the engagement of the corresponding shift clutches (26, 46). The intermediate shaft (16) is driven by the normal The meshing gear set (28) is connected to a driven (18), the driven shaft (18) is arranged in the housing (12) and rotates on its opposite end regions via two bearings (30, 32). At least one gear set (20, 40) is mounted in the axial region between two bearings (30, 32) of the driven shaft (18).

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

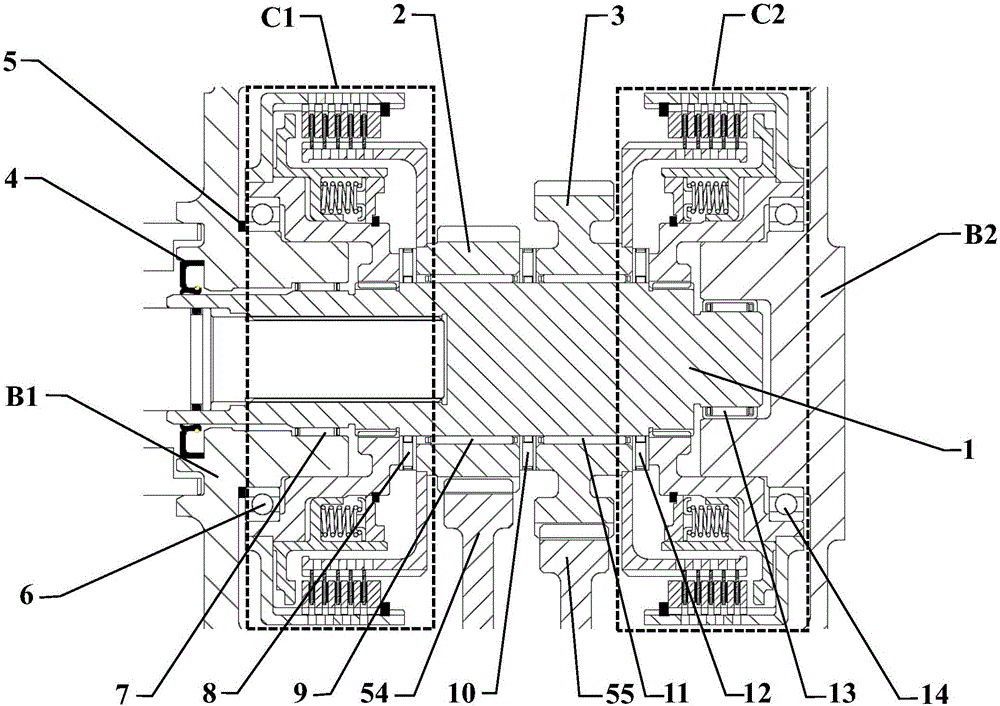

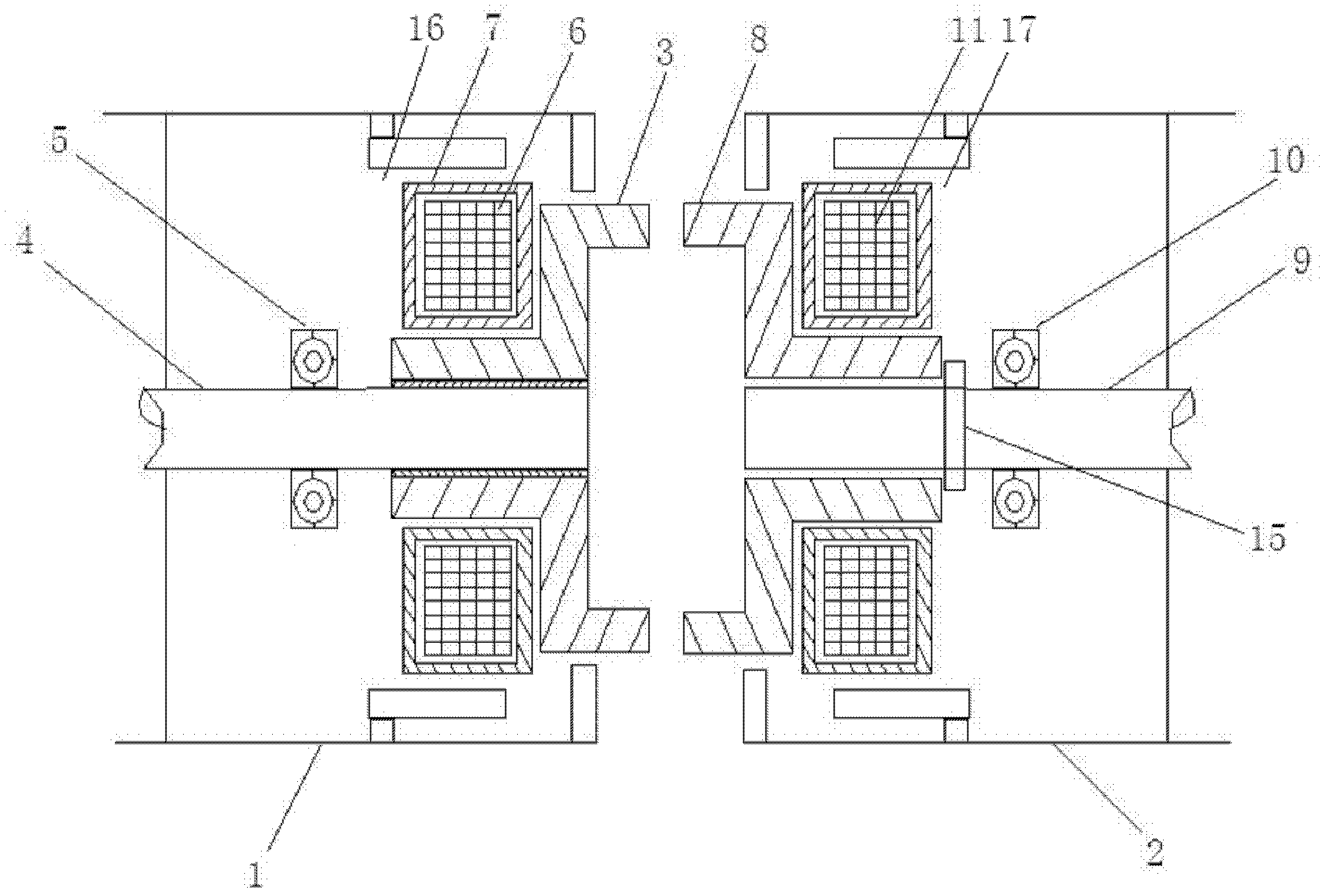

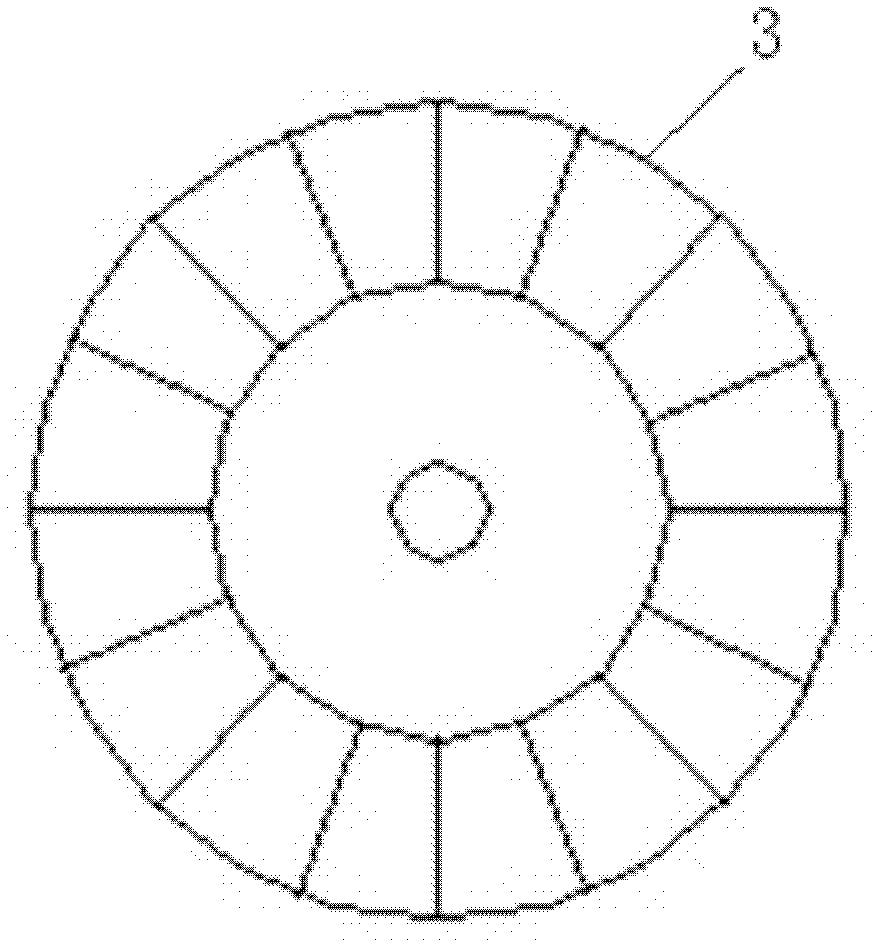

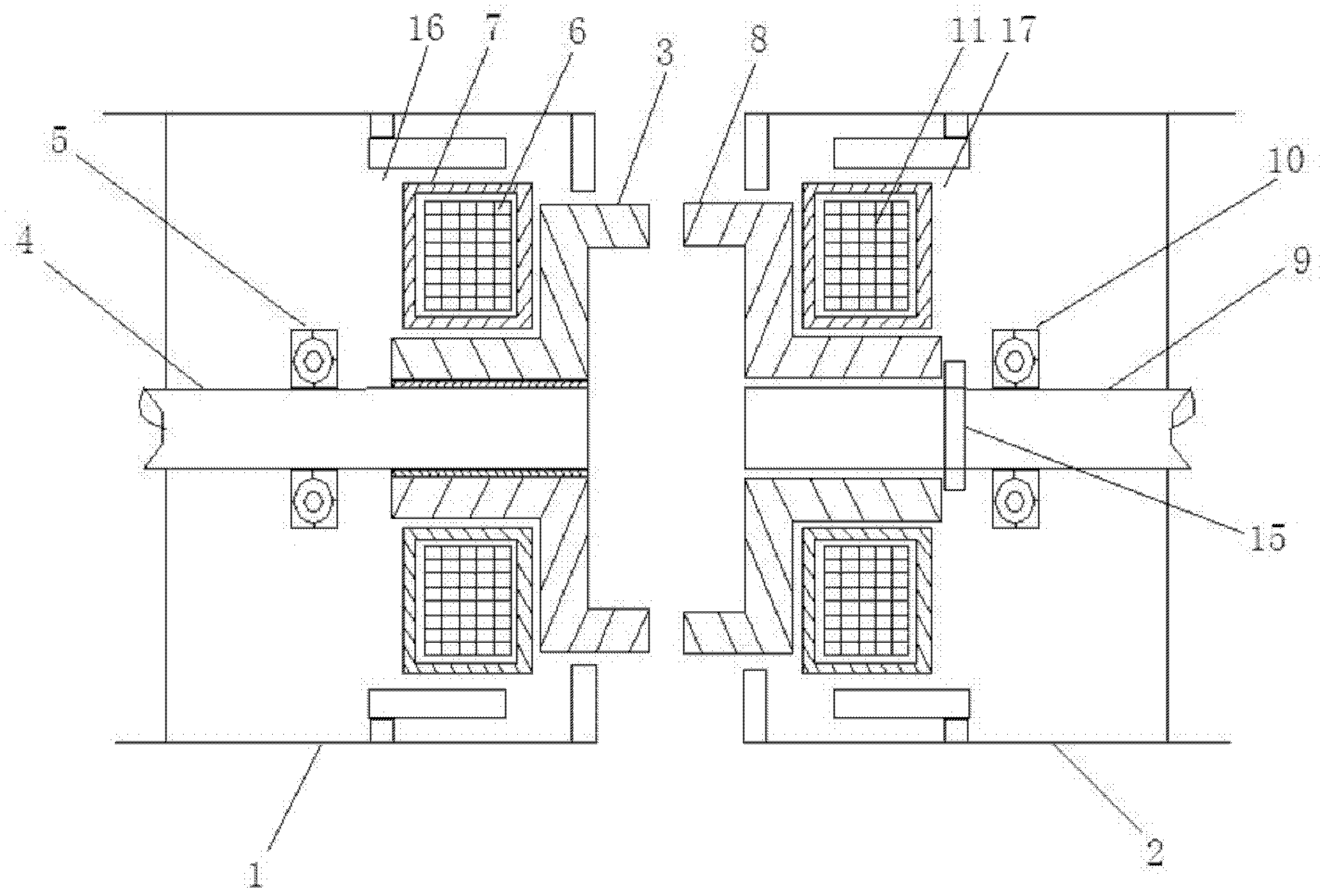

Three-clutch three-gear speed change transmission device and three-clutch method thereof

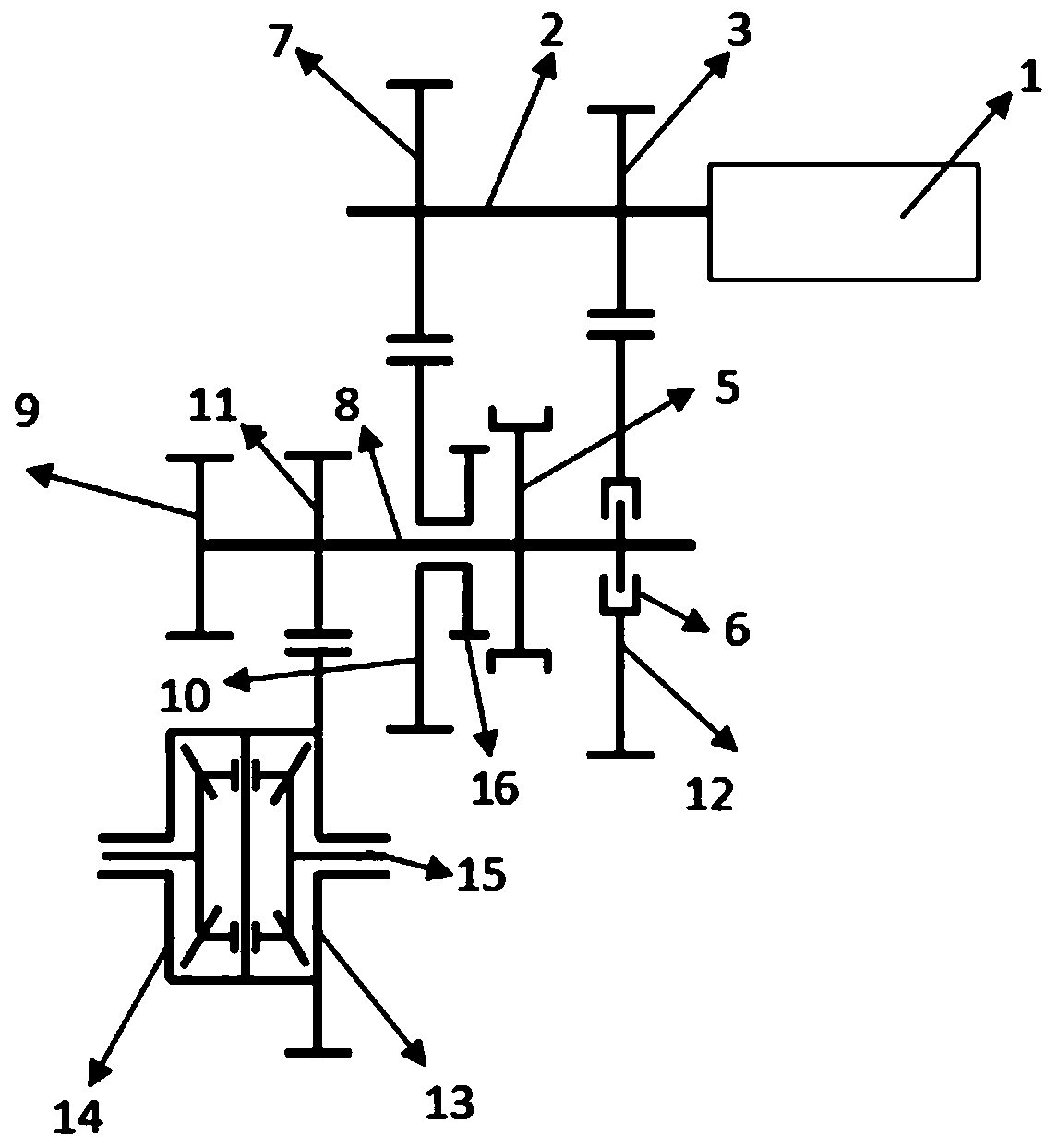

InactiveCN102619936AMeet high speed requirementsGreat tractionMagnetically actuated clutchesToothed gearingsLow speedGear wheel

The invention relates to the field of electric automobiles and in particular relates to a three-clutch three-gear speed change transmission device for changing the speed of an electric automobile and a three-clutch method thereof. The three-clutch three-gear speed change transmission device comprises a box body, wherein an input shaft and an output shaft sleeved on the input shaft are arranged in the box body; the input shaft is connected with the output shaft through a first clutch; a first middle shaft and a second middle shaft are arranged in the box body; the first middle shaft is connected with the second middle shaft through a second clutch; a third middle shaft and a fourth middle shaft are arranged in the box body; the third middle shaft is connected with the fourth middle shaft through a third clutch; and the shafts are provided with gears which have different sizes and are meshed with one another. When the second clutch is controlled to be closed, the automobile can get relatively large traction and relatively large torque at a low speed; when the first clutch is closed, a motor is in a stable running state; when the third clutch is closed, the rotating speed of the motor is increased to a designed value; and therefore, the requirement of the electric automobile on high rotating speed is met.

Owner:CHENGDU K & M METALS

Method for controlling a dual clutch transmission

The invention relates to a method for controlling a dual clutch transmission that has two partial transmissions which are each connected to a clutch on the input side, via which a drive connection can be established to a drive motor, wherein a target gear following a currently active gear can be pre-selected in a particular load-free partial transmission of the two partial transmissions. The following steps are performed: determining a potential target gear, - measuring a total loss of the transmission with the aid of measurements and / or model calculations and / or variables derived therefrom, - in the first case in which the target gear is pre-selected and - in the second case in which no gear is selected, - ascertaining whether the total loss is greater or lesser when the target gear is pre-selected or when no gear is selected, - deciding whether or not a target gear should be pre-selected with the aid of the measured total loss as a criterion, and - implementing measures according to the decision that is made.

Owner:ZF FRIEDRICHSHAFEN AG

Double-clutching two-gear speed transforming transmission and double-clutching method of speed transforming transmission

InactiveCN102619932AReduce speedStable operationToothed gearingsGearing controlGear wheelElectric machinery

The invention relates to the field of an electric automobile and particularly relates to a double-clutching two-gear speed transforming transmission and a double-clutching method of the speed transforming transmission. The double-clutching two-gear speed transforming transmission comprises a box body, wherein the box body is internally provided with an input shaft, a first driving gear sleeved on the input shaft, an output shaft and a second driven gear sleeved on the output shaft; the input shaft is connected with the output shaft through a first clutch; the double-clutching two-gear speed transforming transmission is further provided with a first middle shaft, a first driven gear sleeved on the first middle shaft, a second middle shaft and a second driven gear sleeved on the second middle shaft; the first middle shaft is connected with the second middle shaft through a second clutch; and the first driving gear is engaged with the first driven gear and the second driving gear is engaged with the second driven gear. According to the double-clutching method, the requirements of an electric state and a power generation state of a motor on the change of a rotary-speed torque are considered, so that the motor can maintain efficient and stable working states when operating at the electric state and the power generation state.

Owner:CHENGDU K & M METALS

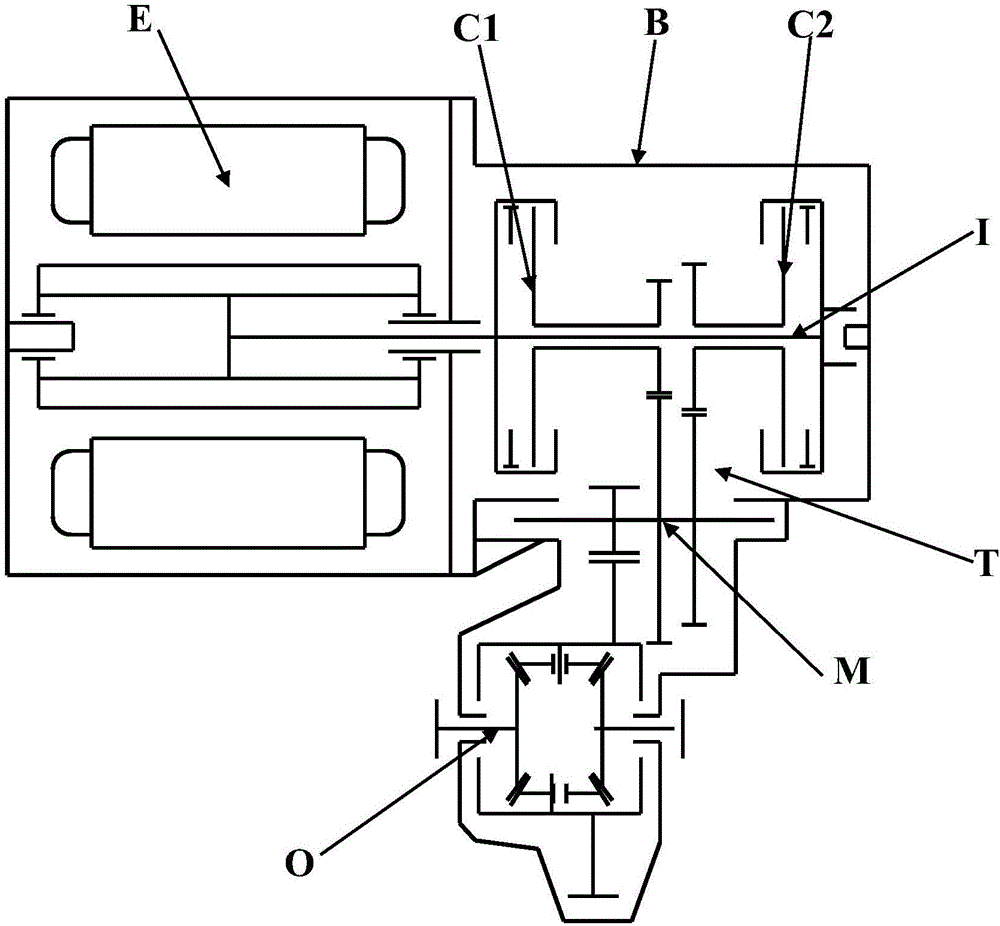

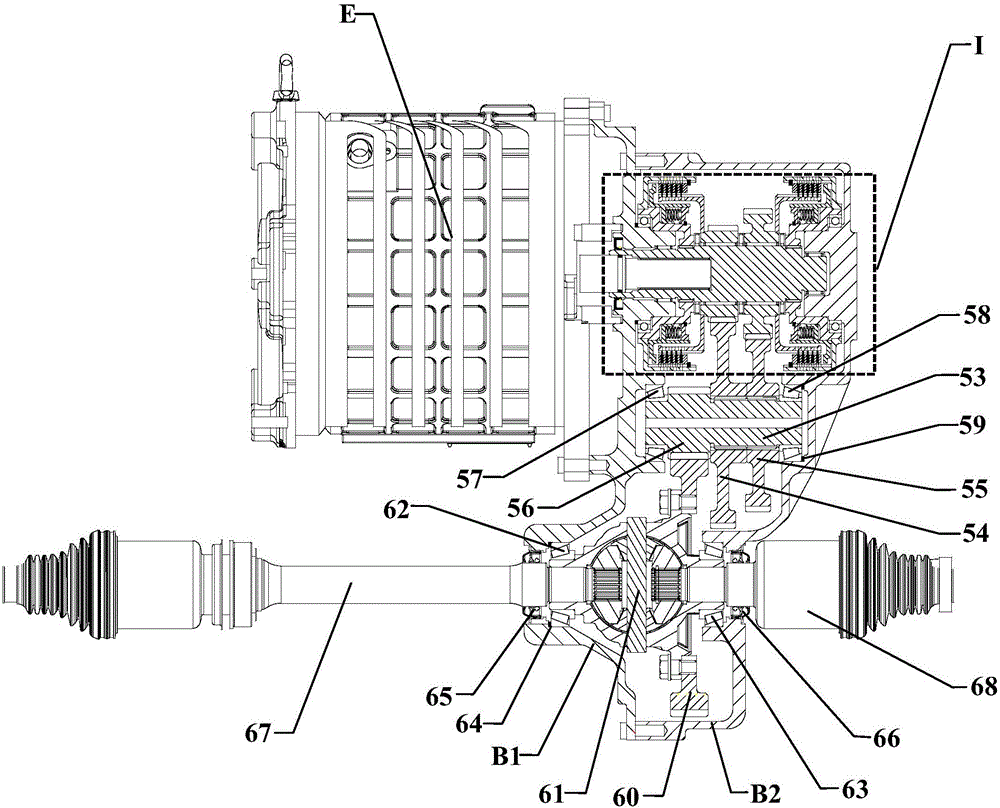

Two-gear type electric transmission free of gear shift power interruption

PendingCN108825728AImprove compactnessCompact structureToothed gearingsGearing controlGear driveReduction drive

The invention relates to a two-gear type electric transmission free of gear shift power interruption. The electric transmission comprises a driving motor, a transmission gear assembly and a differential mechanism which are connected in sequence, wherein the transmission gear assembly comprises a first gear shifting element, a second gear shifting element, an input shaft, a middle shaft, an outputshaft, a first-gear driving gear, a first-gear driven gear, a second-gear driving gear, a second-gear driven gear, a main reducer driving gear and a main reducer driven gear, the input shaft is connected with the driving motor, the first-gear driving gear and the second-gear driving gear are connected with the input shaft correspondingly, the first-gear driven gear, the second-gear driven gear andthe main reducer driving gear are connected with the middle shaft correspondingly, the main reducer driven gear is connected with the differential mechanism, the first gear shifting element comprisesa left joint part, a right joint part and a synchronous part, the synchronous part is connected with the input shaft or the middle shaft, and the second gear shifting element is arranged between thesecond-gear driving gear and the input shaft or between the first-gear driven gear and the middle shaft. Compared with the prior art, the electric transmission has the advantages of no power interruption, compact structure and the like.

Owner:SUZHOU GETENA AUTOMOTIVE TECH CO LTD

Method for operating a double clutch transmission

The invention relates to a method for the operation of a dual-clutch transmission (1) including sub-transmissions (31, 32) wherein, through a clutch of a dual-clutch device (4), the sub-transmissions are able to be switched on in the power flux of the dual-clutch transmission or are able to be switched off from the power flux. In the sub-transmissions, two different transmission ratios are able to be engaged or disengaged through the actuation of shifting elements. In the operation of the dual-clutch transmission, one of the sub-transmissions (31 / 32) is switched on, while the other sub-transmission (32 / 31) is switched off. If the transmission ratio in the switched-on sub-transmission (31 / 32) is engaged, all transmission ratios in the switched-off sub-transmission are simultaneously disengaged through the shifting elements(14, 17 / 22, 25), as long as there is no request for a change of transmission ratio in the dual-clutch transmission (1).

Owner:ZF FRIEDRICHSHAFEN AG

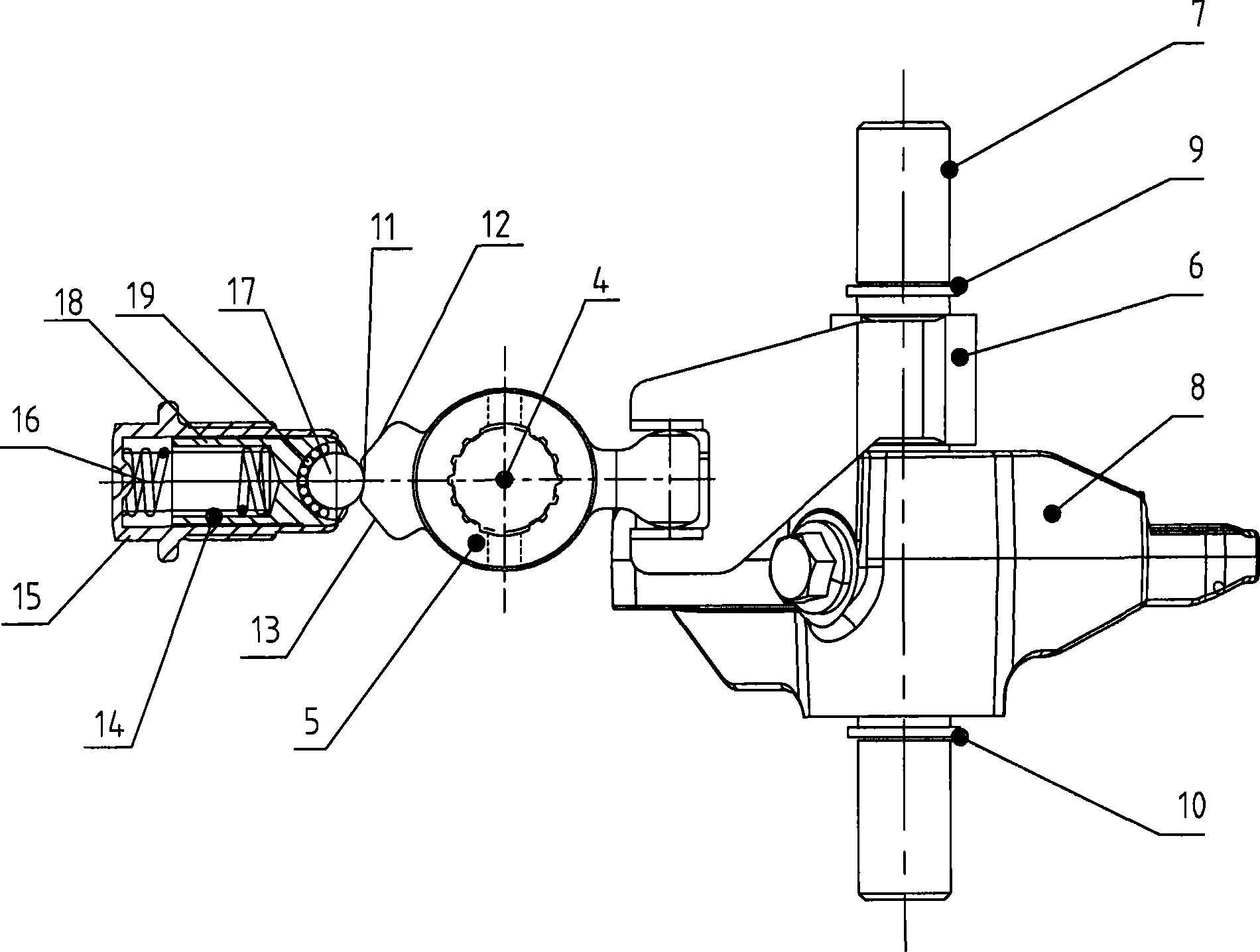

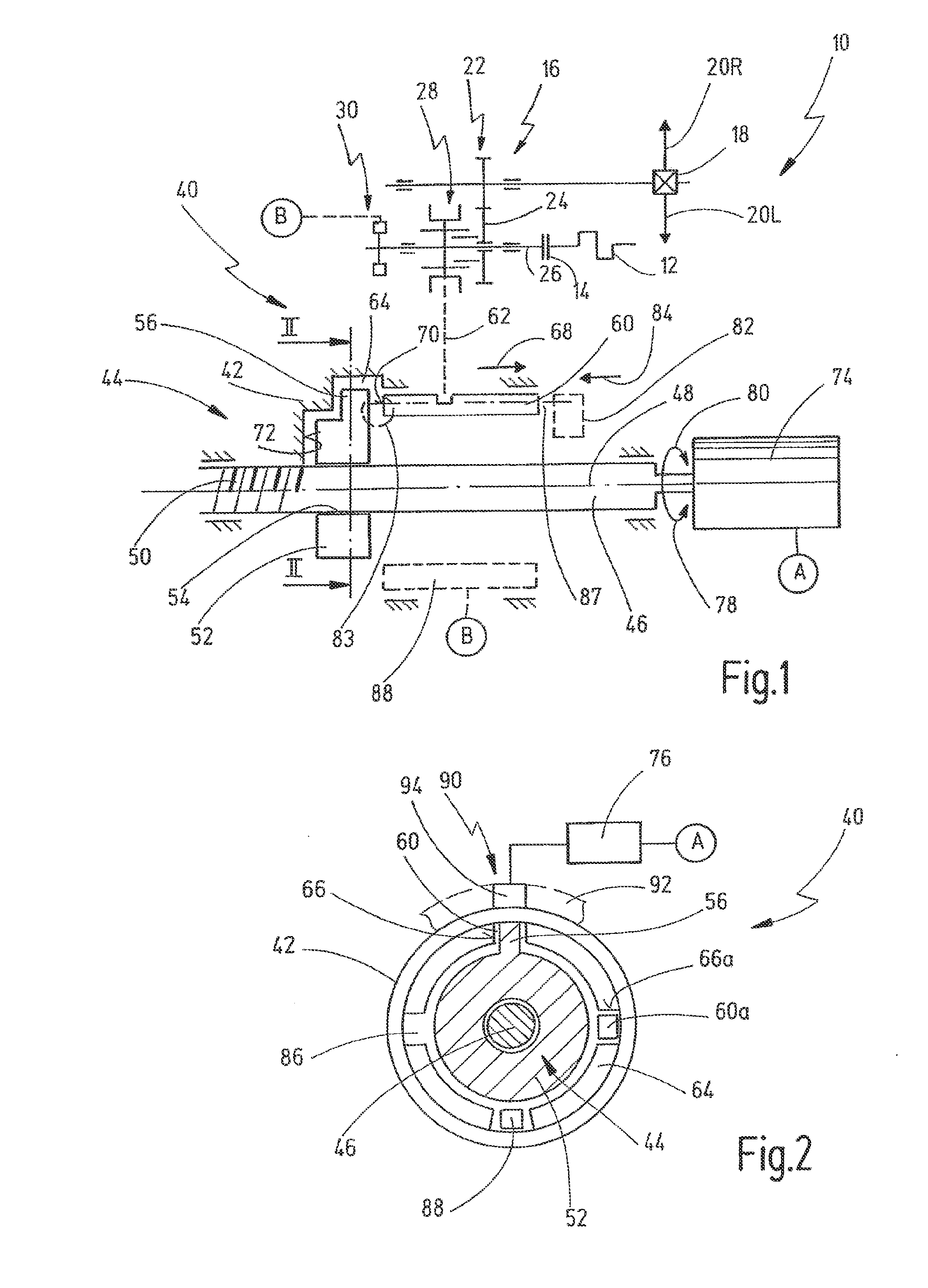

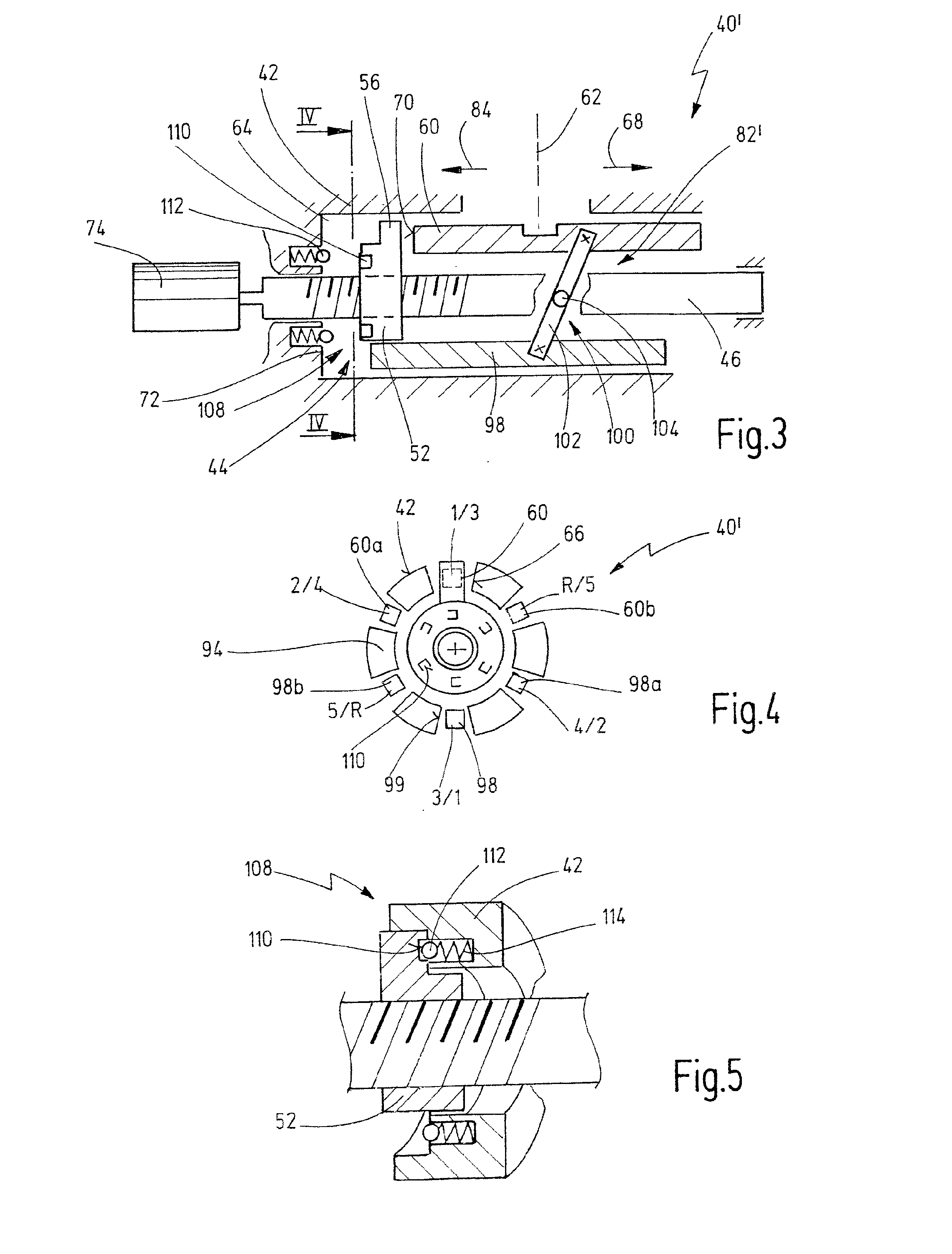

Shift Arrangement for a Motor Vehicle Transmission

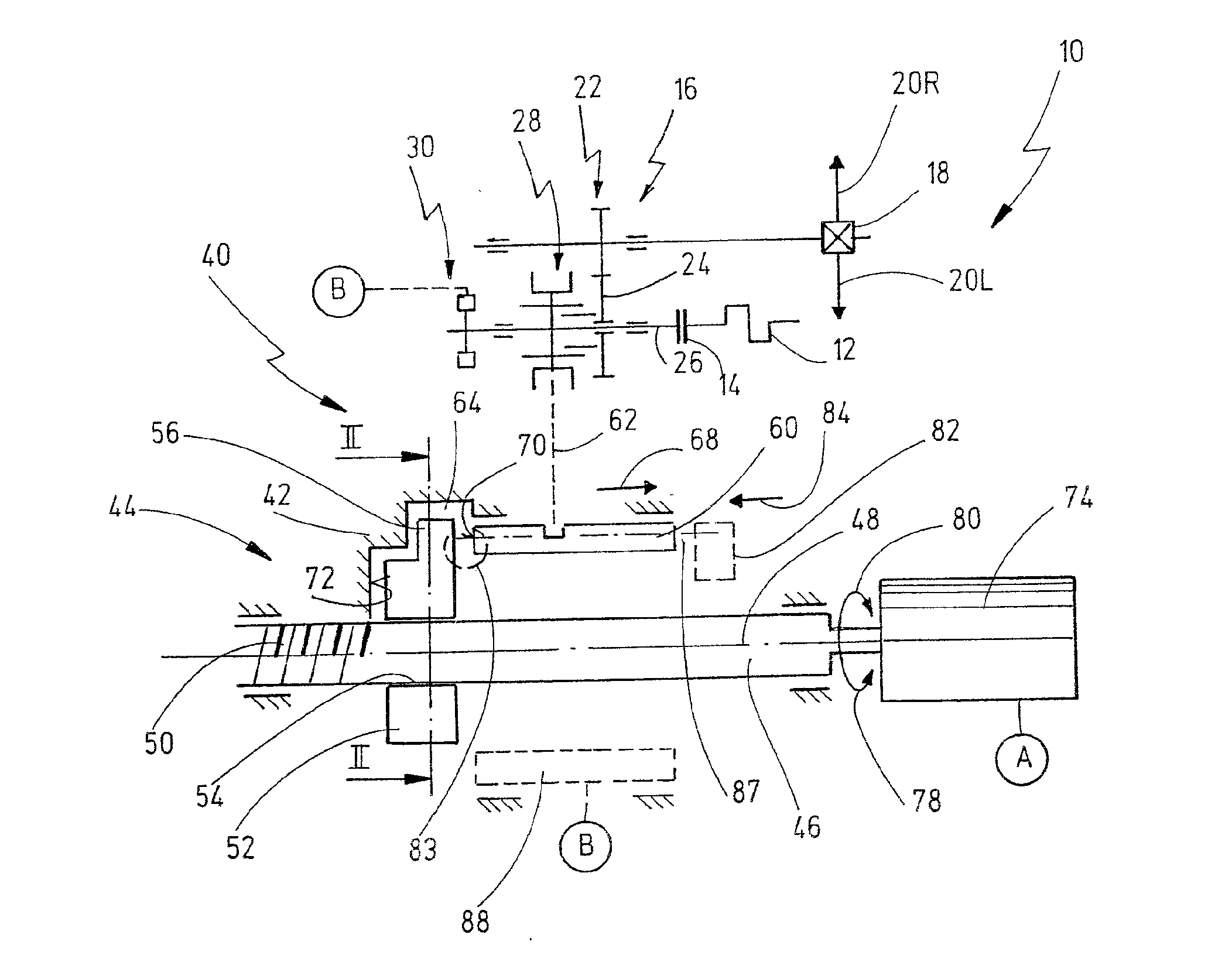

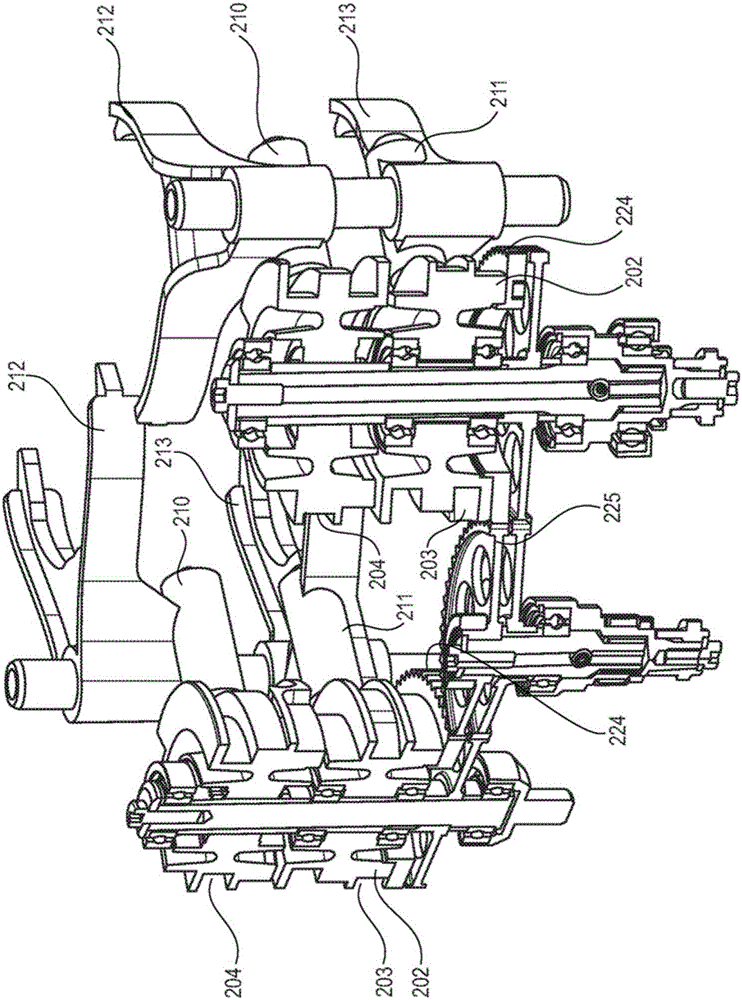

ActiveUS20140326094A1Short shift timesLow packaging requirementGearing controlMobile vehicleEngineering

Shift arrangement for a motor vehicle transmission. At least one gear stage can be engaged and disengaged by means of an associated shift clutch. A spindle which is aligned along a spindle axis, has a spindle thread and is rotatably mounted on a housing. A nut has a nut thread, which is in engagement with the spindle thread. A shift finger is formed on the nut. At least one shift rod is mounted movably on the housing and can be coupled to the shift clutch. Provided on the housing are a radial groove, in which the shift finger engages in an axial base position of the nut and within which the shift finger can be turned, and an axial guide, which axially adjoins the radial groove and in which the shift finger can engage in order to hold the nut in the circumferential direction, thus ensuring that said nut is moved axially in a first axial direction when the spindle is rotated.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

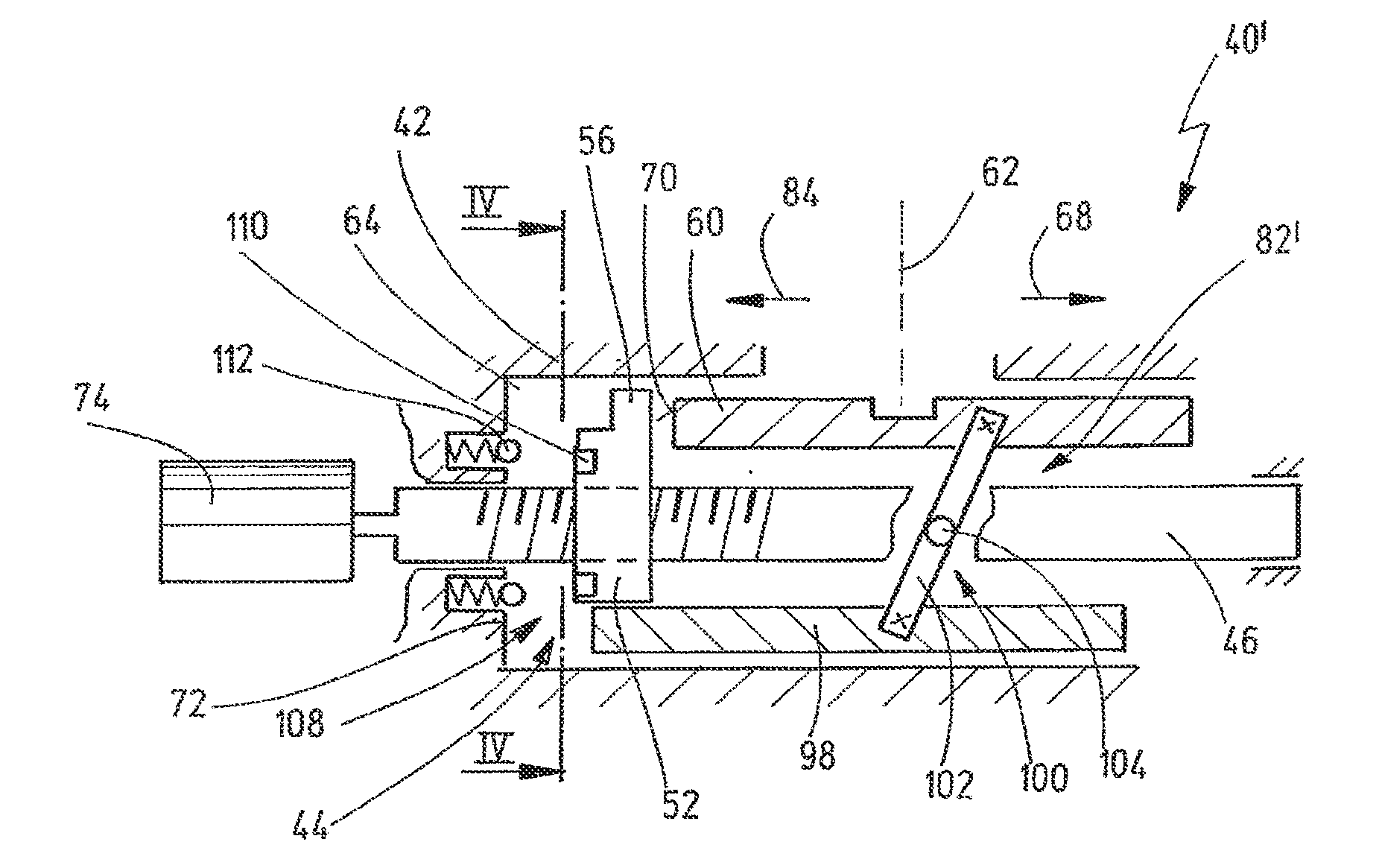

Clutch arrangement and two-speed gearbox

InactiveUS20130305861A1Short shift timesImprove rigidityFluid actuated clutchesToothed gearingsEngineeringAxial distance

Clutch arrangement for a motor vehicle gearbox. The clutch arrangement has a housing and a clutch. The clutch is arranged in the housing and is arranged concentrically with a shaft, which extends in a longitudinal axis. The shaft is supported on the housing by means of a first shaft bearing adjacent to the clutch and by means of a second shaft bearing spaced at an axial distance from the clutch. The clutch arrangement has an actuator arrangement for actuating the clutch. The actuator arrangement is designed to exert an actuating force on the clutch in a first longitudinal direction. The actuator arrangement here being axially braced on the housing and a force flux being introduced into the shaft as a result of the actuating force. The first shaft bearing is arranged so that the force flux introduced into the shaft can be axially braced on the housing by way of the first shaft bearing.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

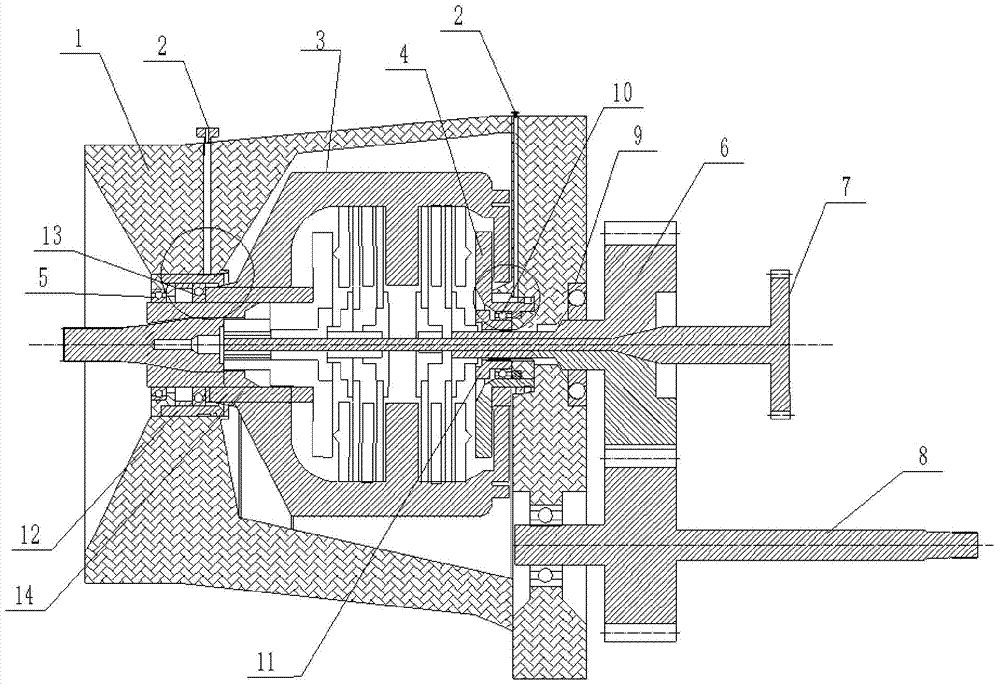

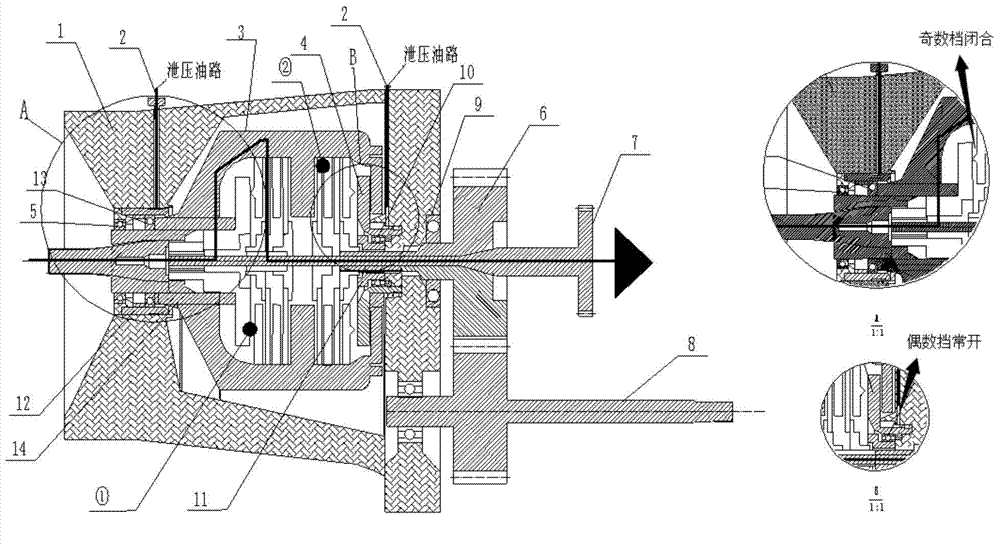

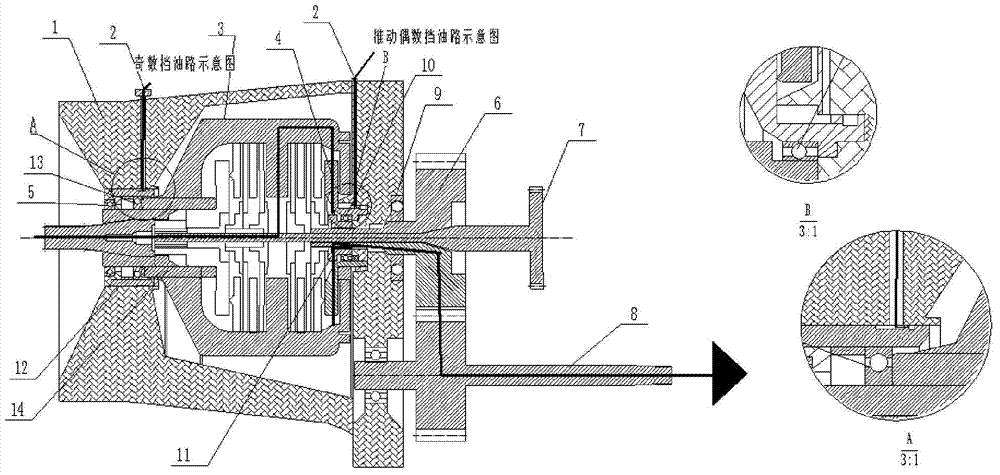

Three-gear double-clutch type automatic gearbox for pure electric bus

InactiveCN104763798AHigh torque transmissionReasonable speed ratio configurationGearboxesToothed gearingsElectric controlShift time

The invention discloses a three-gear double-clutch type automatic gearbox for a pure electric bus. The three-gear double-clutch type automatic gearbox comprises a double clutch and a three-gear transmission mechanism, wherein the odd clutch in the double clutch is connected with transmission chains of the first gear and the second gear of the gear mechanism, and while the even clutch is connected with the transmission chain of the second gear in the gear mechanism. The three-gear double-clutch type gearbox is large in transmission torque, reasonable in speed ratio configuration, accurate to shift under the electric control hydraulic and the control of a TCU, small in shifting time, high in transmission efficiency, and effectively suitable for the pure electric bus.

Owner:沃新动力系统(上海)有限公司 +1

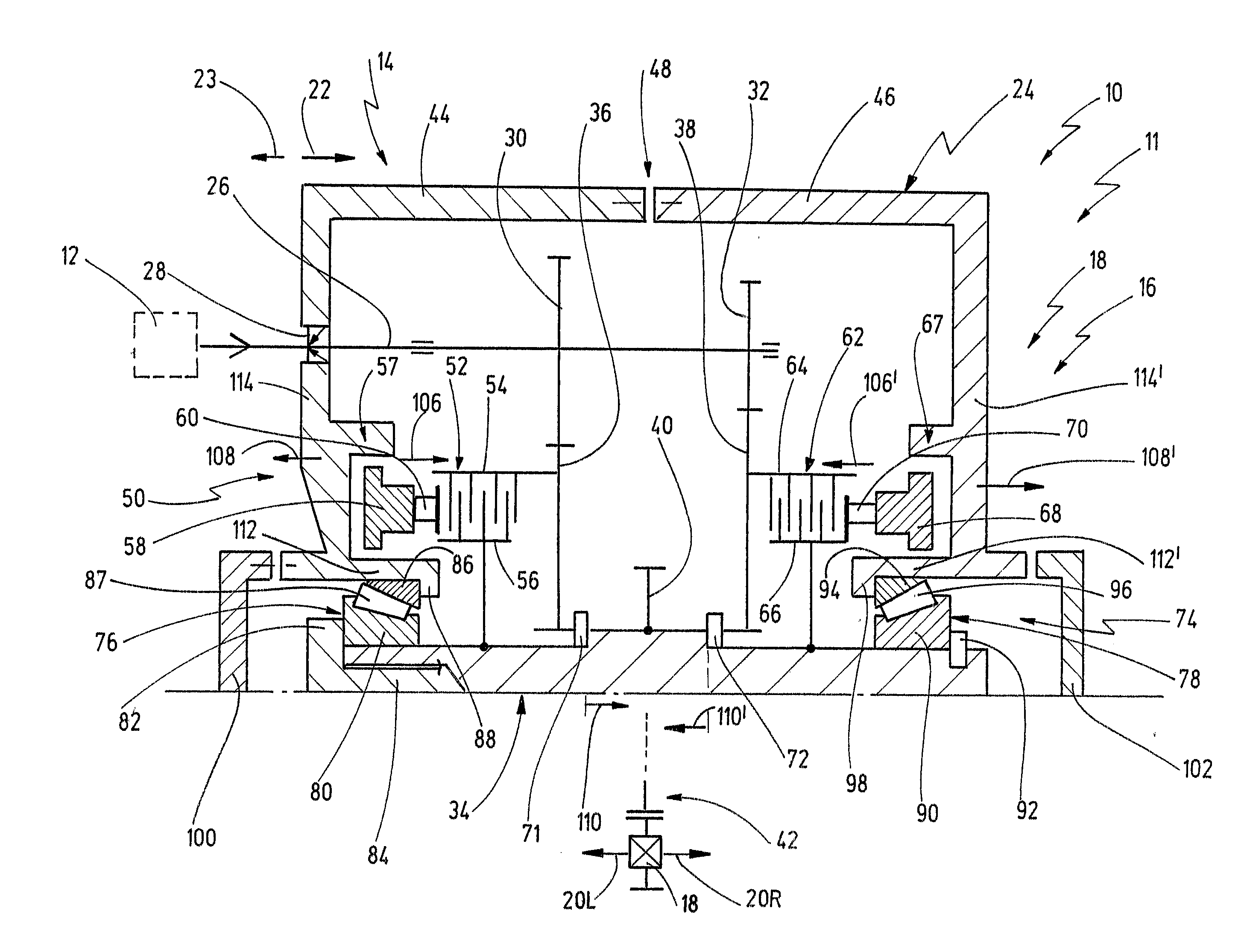

Shift Arrangement For A Motor Vehicle Transmission and Method for Actuating Said Shift Arrangement

InactiveUS20150152944A1Short shift timesLow packaging requirementGearingGearing controlMobile vehicleGear wheel

Shift arrangement for a motor vehicle transmission which has at least two gear stages that can be engaged and disengaged by means of different rods has a housing. At least two push rods are mounted on the housing in such a way as to be movable in an axial direction between a neutral position and at least one shift position and which can each be coupled to a shift clutch or a shift clutch pack. At least two return rods are mounted on the housing in such a way as to be movable in an axial direction between a neutral position and at least one shift position. The return rods are each coupled to one of the push rods in such a way that a push rod and the return rod associated therewith are moved in opposite axial directions. A shift member is mounted on the housing in such a way that a shift cam of the shift member can be aligned with a push rod or with a return rod for the purpose of selecting, and can transmit a pushing force to the selected rod and move it in a first axial direction for a shift operation. At least one driving feature is arranged on the shift member in such a way that, before or during a shift operation on a selected rod, the driving feature can transmit a pushing force to at least one unselected rod in order to move said unselected rod into the neutral position.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

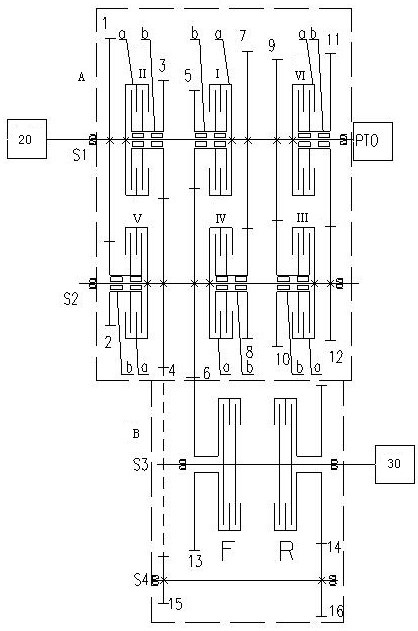

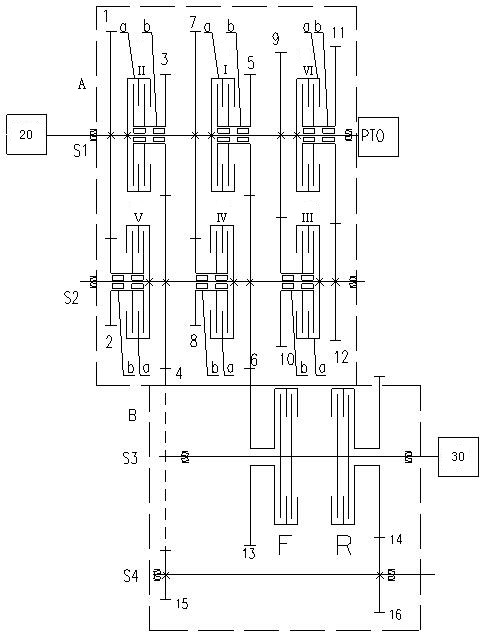

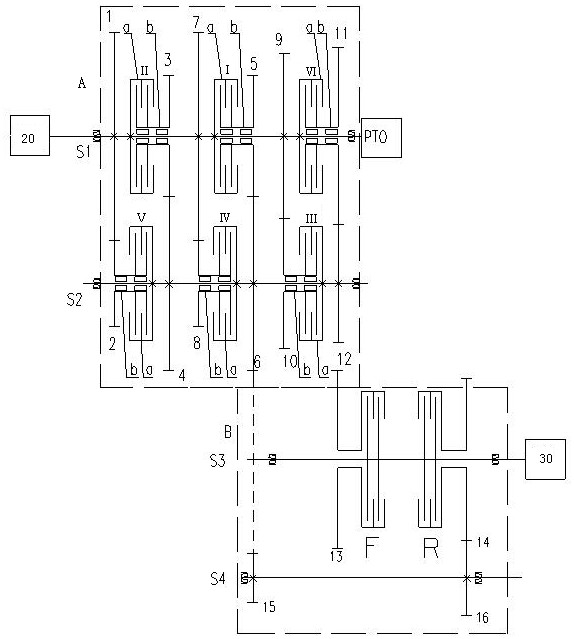

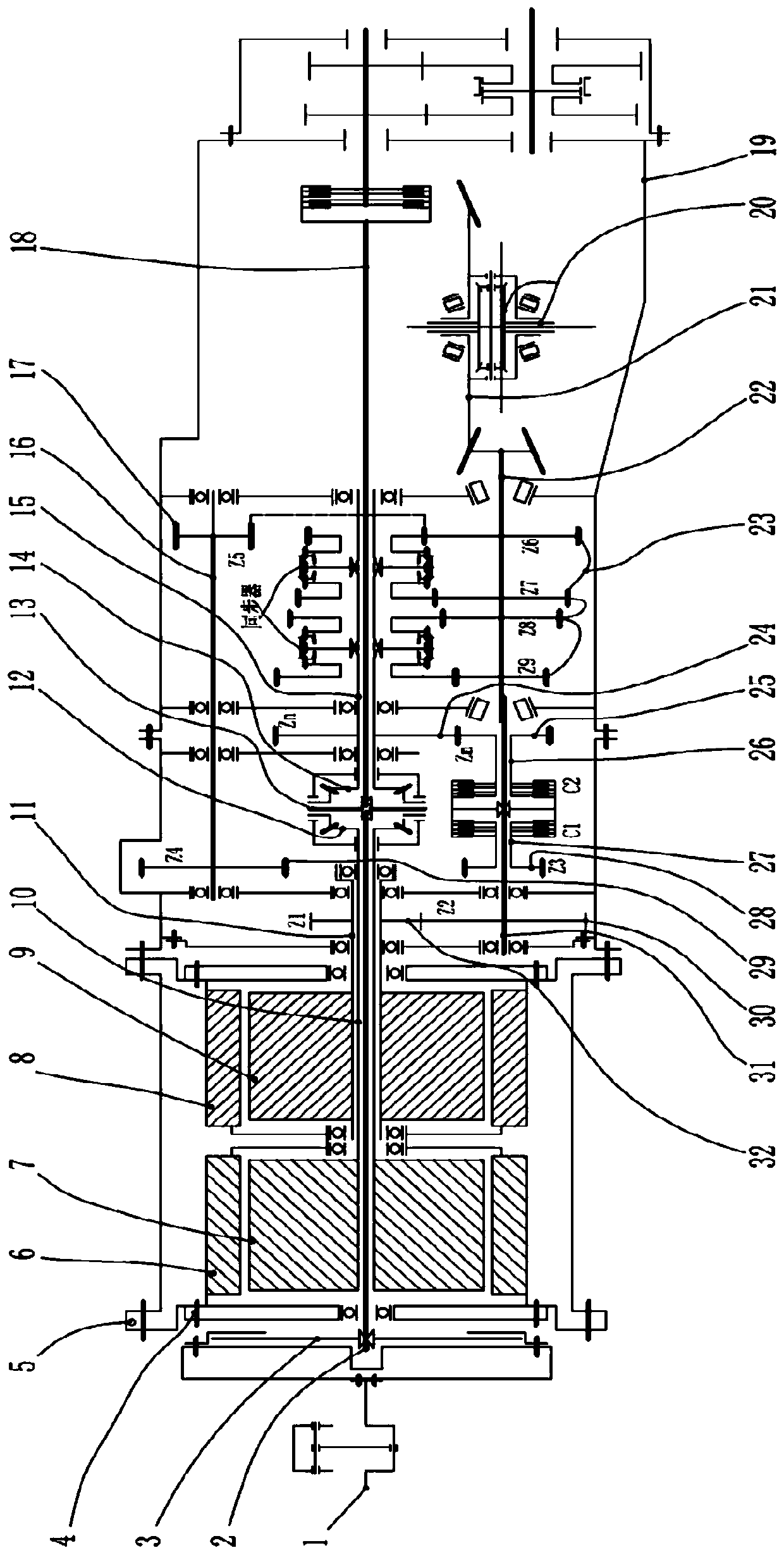

Tractor power gear shifting and power reversing transmission device

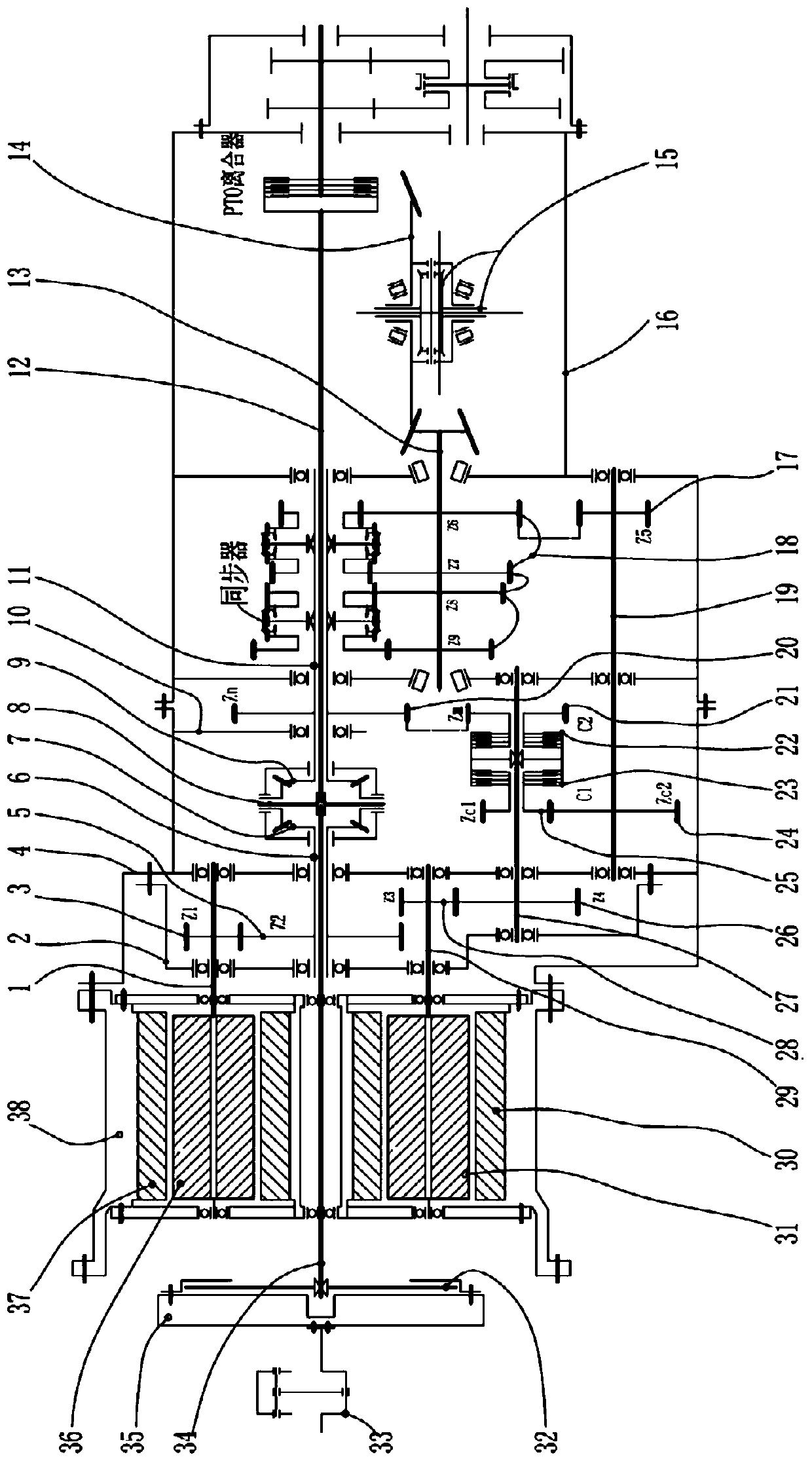

PendingCN112664623AImprove transmission efficiencySimple logic controlGearboxesToothed gearingsGear wheelControl theory

A tractor power gear shifting and power reversing transmission device comprises a power gear shifting module and a power reversing module, wherein the power gear shifting module comprises an input shaft and an output shaft; a plurality of clutches are mounted on the input shaft and the output shaft according to the number of gears; a plurality of meshed gears I are also arranged on the input shaft and the output shaft; the front end of the input shaft is in transmission connection with an engine; the rear end of the input shaft is connected with a tractor PTO device; the power reversing module comprises a reversing shaft and an idler shaft; the reversing shaft is provided with a forward clutch, a backward clutch and a gear II; the gear II is connected with both the forward clutch and the backward clutch; the rear end of the reversing shaft is connected with an auxiliary variable-speed driving shaft of a rear box body of a gearbox; two gears III are fixedly arranged on the idler shaft to form two-stage transmission; the power gear shifting module and the power reversing module are in gear-meshing transmission with each other; and the input shaft, the output shaft, the reversing shaft and the idler shaft are arranged by the adoption of parallel space. The tractor power gear shifting and power reversing transmission device has the advantages that the gear shifting time is short; the number of the gears is large; and the repairing and the maintenance are convenient.

Owner:FIRST TRACTOR

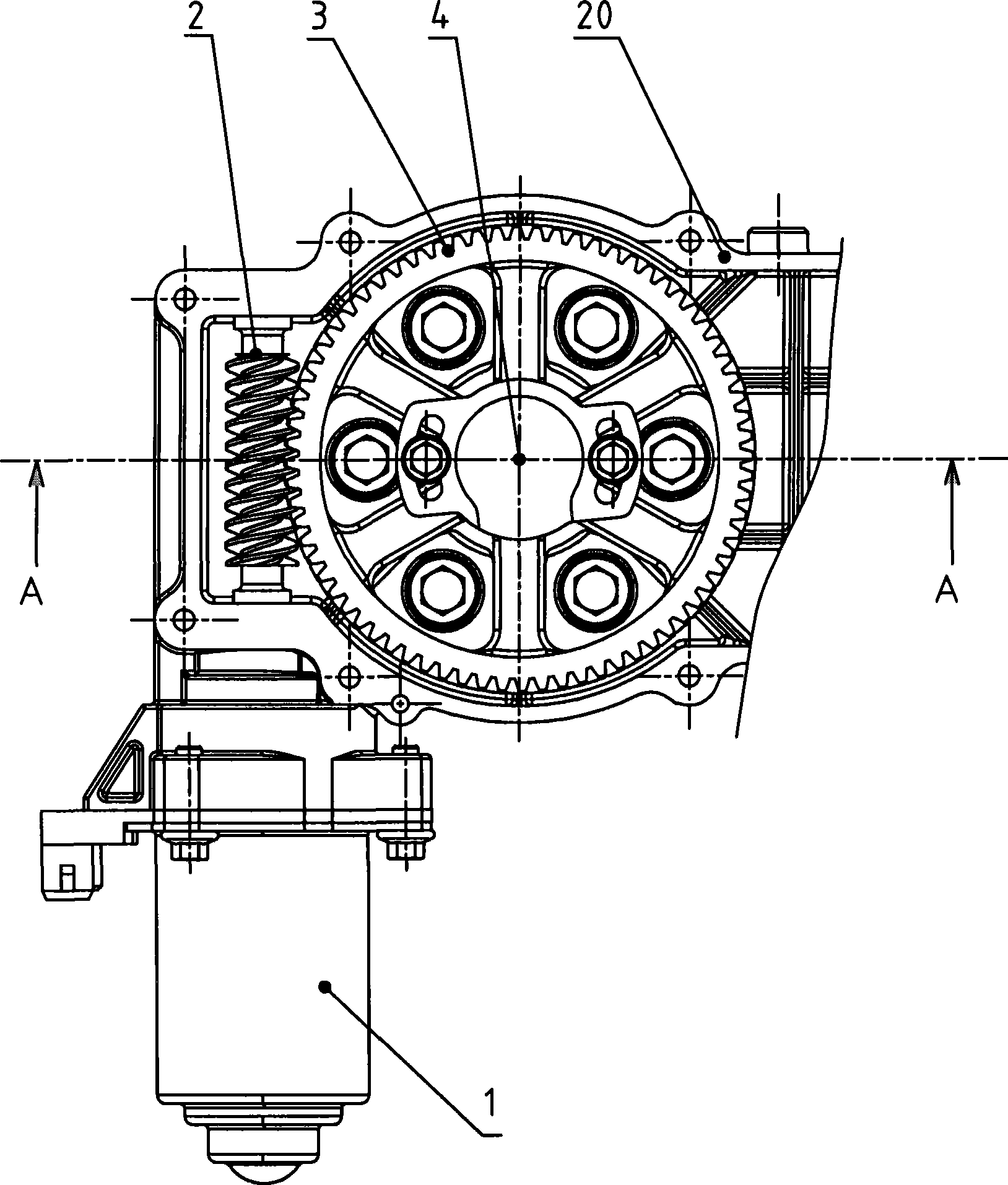

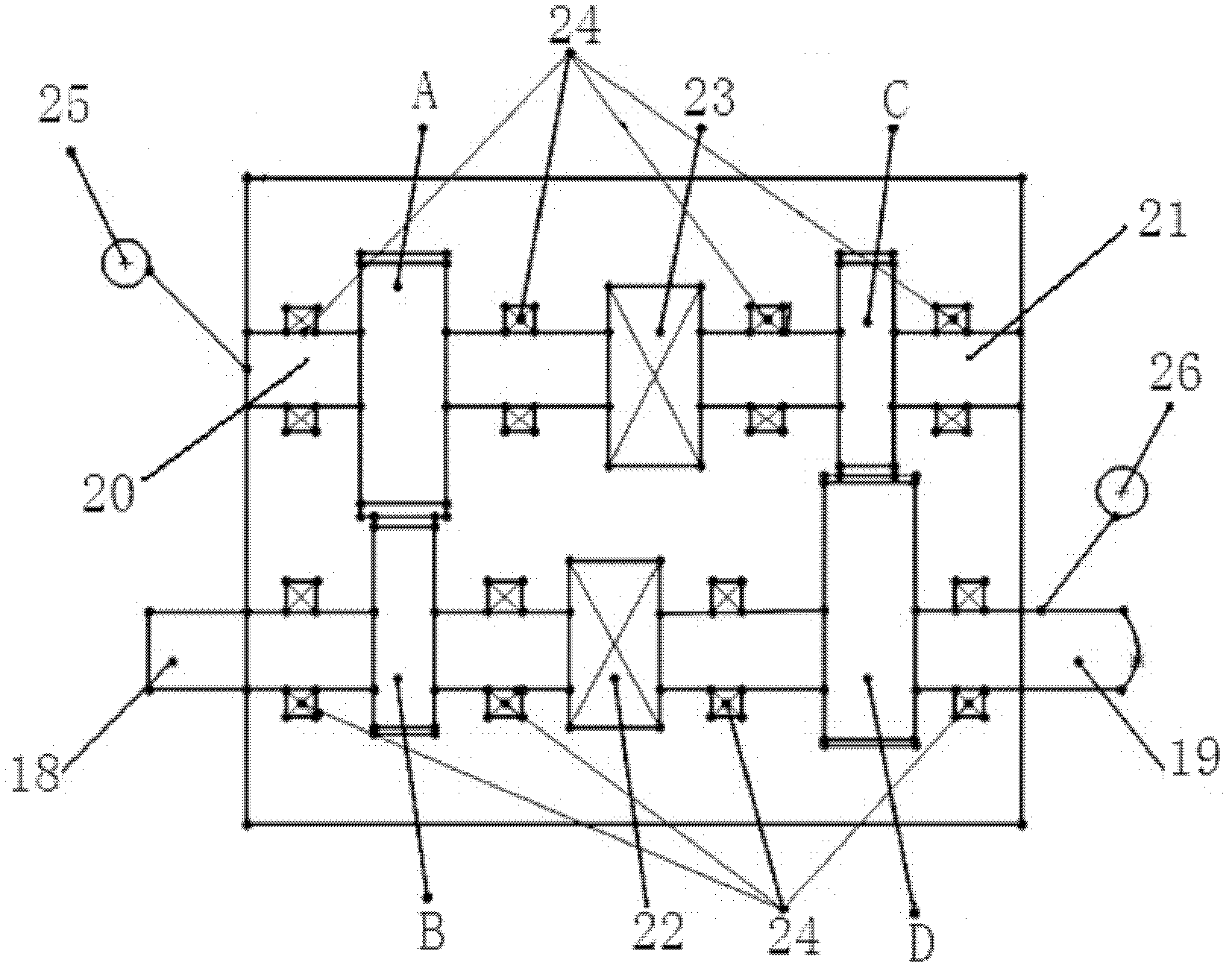

Interlocking type gear shifting device of electric automobile

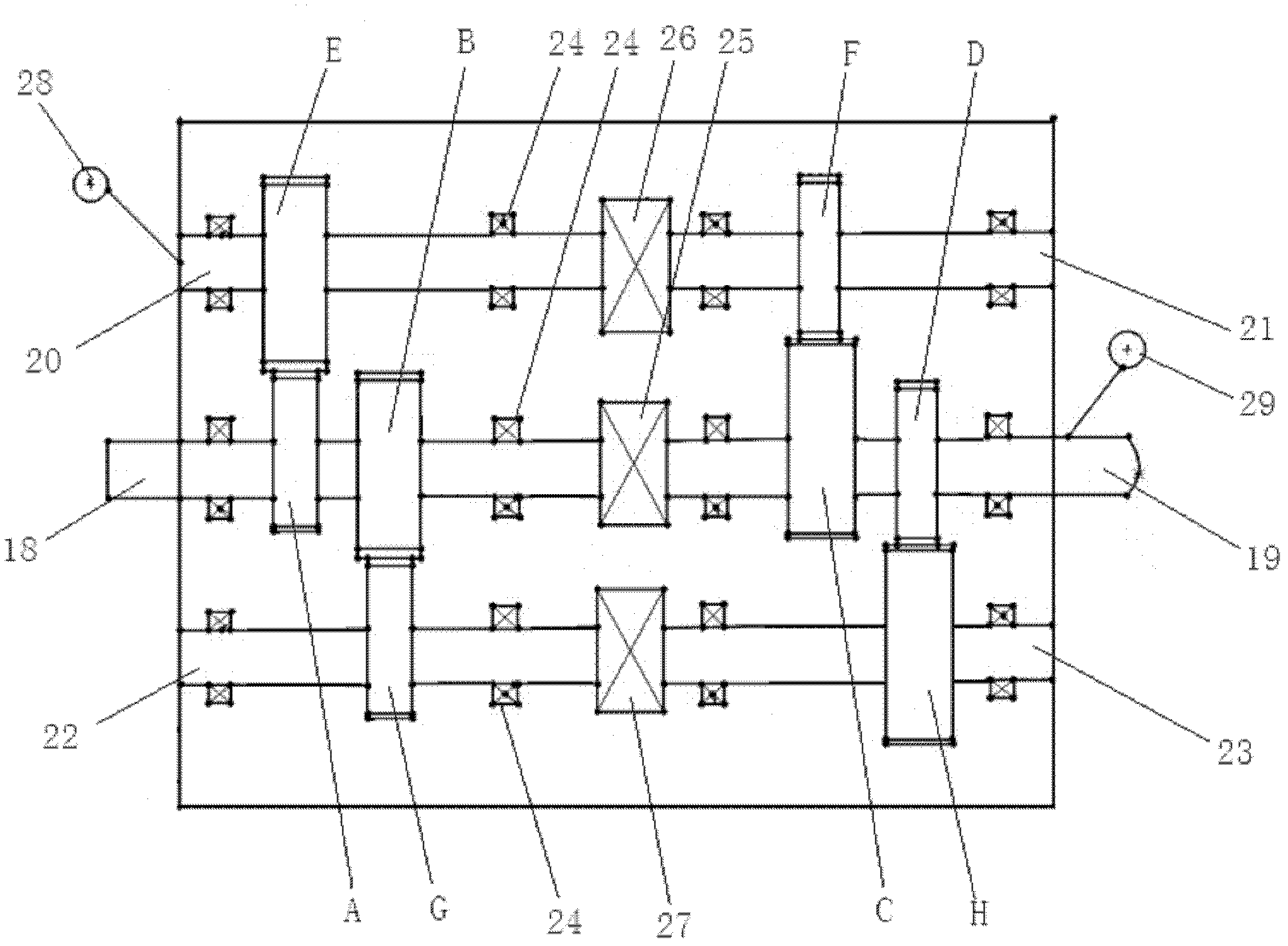

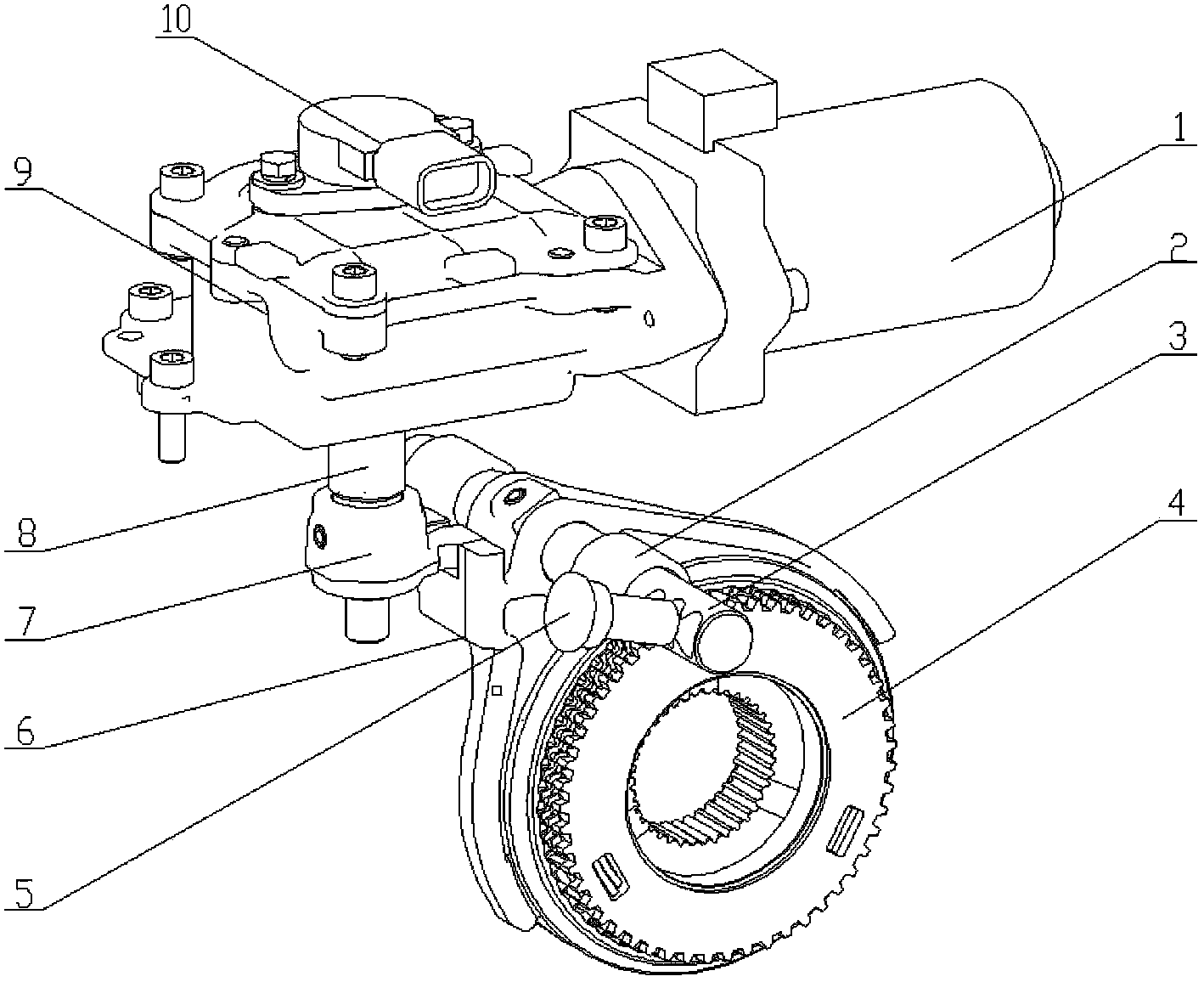

ActiveCN103410961AShort shift timesDriving comfortGearing controlHigh volume manufacturingElectric machine

The invention relates to an interlocking type gear shifting device of an electric automobile. The interlocking type gear shifting device comprises a first gear shifting mechanism and a second gear shifting mechanism. The first gear shifting mechanism and the second gear shifting mechanism are both arranged in a transmission box, an interlocking mechanism is arranged between a first worm gear and a second worm gear, the first worm gear is interlocked with the second worm gear through the interlocking mechanism, and a sensor detects the rotation states of the first worm gear and the second worm gear. By means of the interlocking type gear shifting device of the electric automobile, gear shifting time is short, a gear selecting device is not required to be arranged additionally, and the structure is compact. The cost of a transmission is greatly reduced, and large-batch production is facilitated. Interlocking of the two worm gears is achieved through an interlocking steel ball, the interlocking structure prevents gear disorder caused by the fact that a motor is subjected to external disturbing or receives wrong control signals and a gear shifting motor works simultaneously, and the device is reliable in performance and suitable for the multi-gear electric automobile. The device has excellent expansibility and can be designed into a multi-gear shifting device according to actual design requirements of automobiles.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

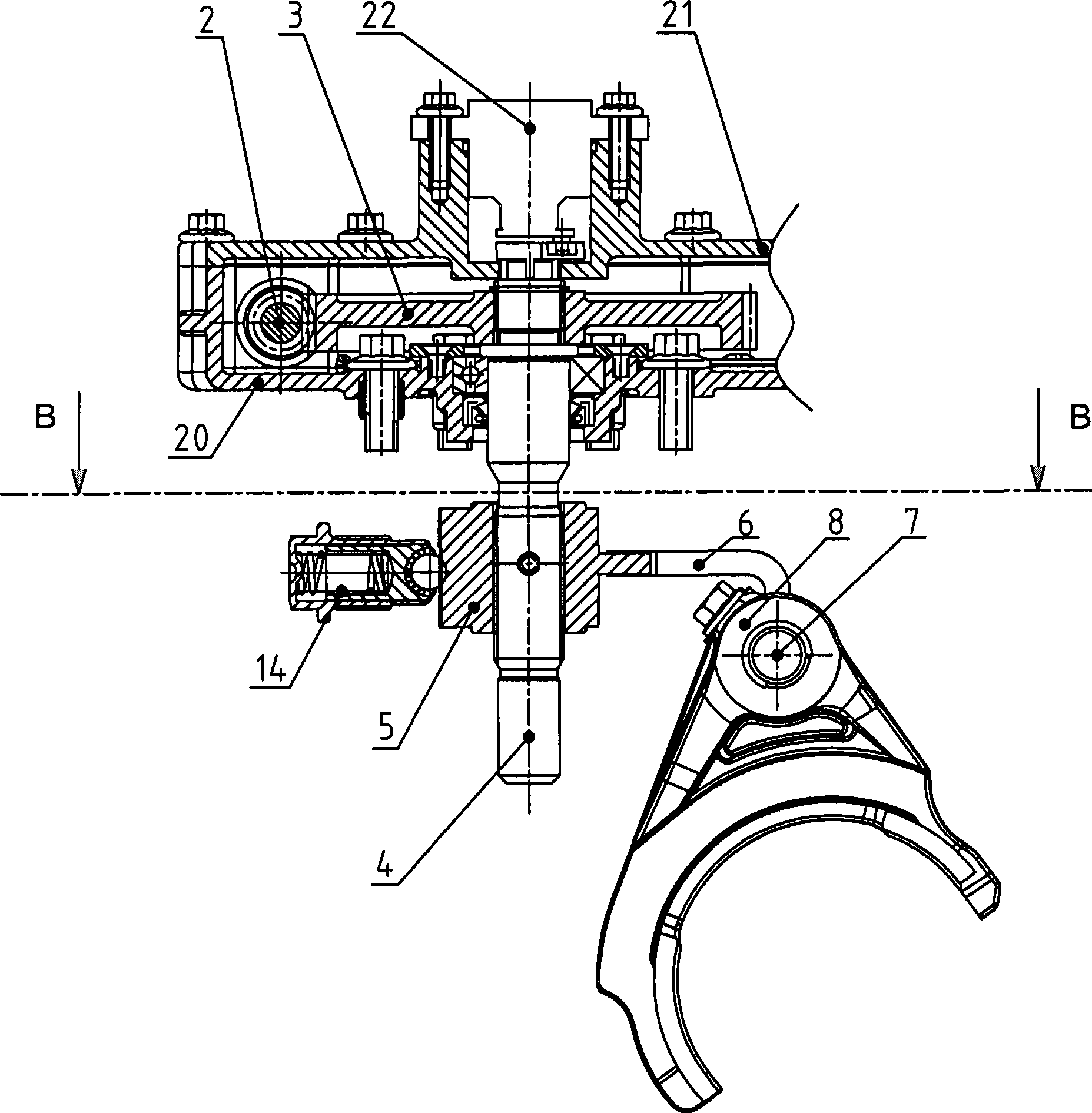

Transmission shifting mechanism for all-electric cars

The invention relates to a transmission shifting mechanism for all-electric cars. According to the technical scheme, the transmission shifting mechanism mainly comprises a shifting motor, linear bearings, a shift fork shaft, a triple-cone synchronizer, a self-locking pin, a shift fork, a shift block, a shift shaft, a buffer, an angle sensor and the like. The buffer is connected with the shifting motor. The shift shaft is mounted on the buffer in a connected manner through splines. Two ends of the shift shaft are provided with the angle sensor and the shift block respectively. An oil seal is disposed between the angle sensor and the shift block. The shift block is inserted into a shift fork hole. The shift fork is connected with the shift fork shaft through the pin. The shift fork shaft is connected to front and rear shells through the linear bearings. The shift fork is inserted into a gear ring of the triple-cone synchronizer. The transmission shifting mechanism has the advantages that shifting force is small, shifting is stable, shifting time is short, and accordingly ECT shifting is higher in quality and reliability.

Owner:姜华

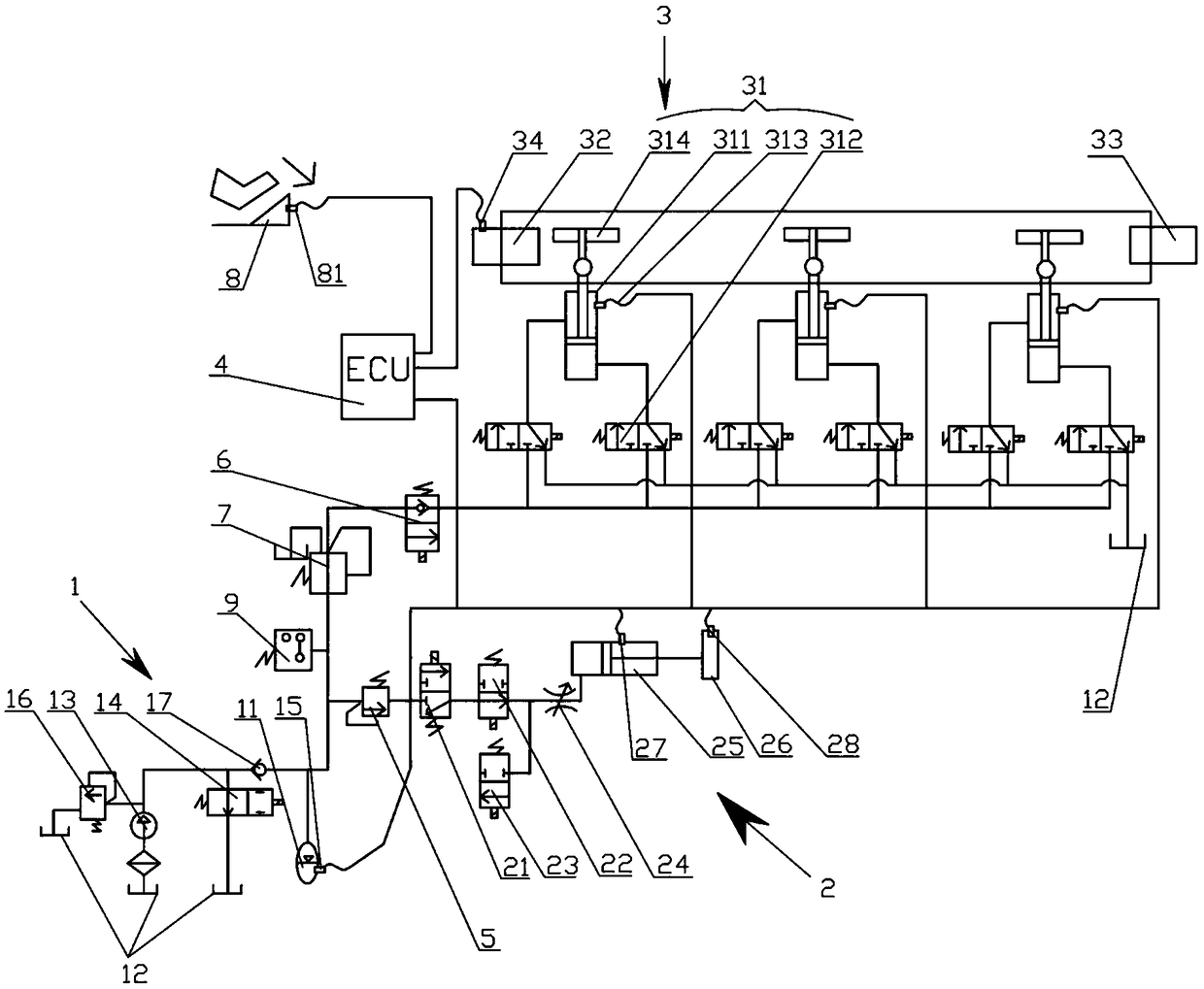

Automatic gear shifting control device of wheeled tractor and control method thereof

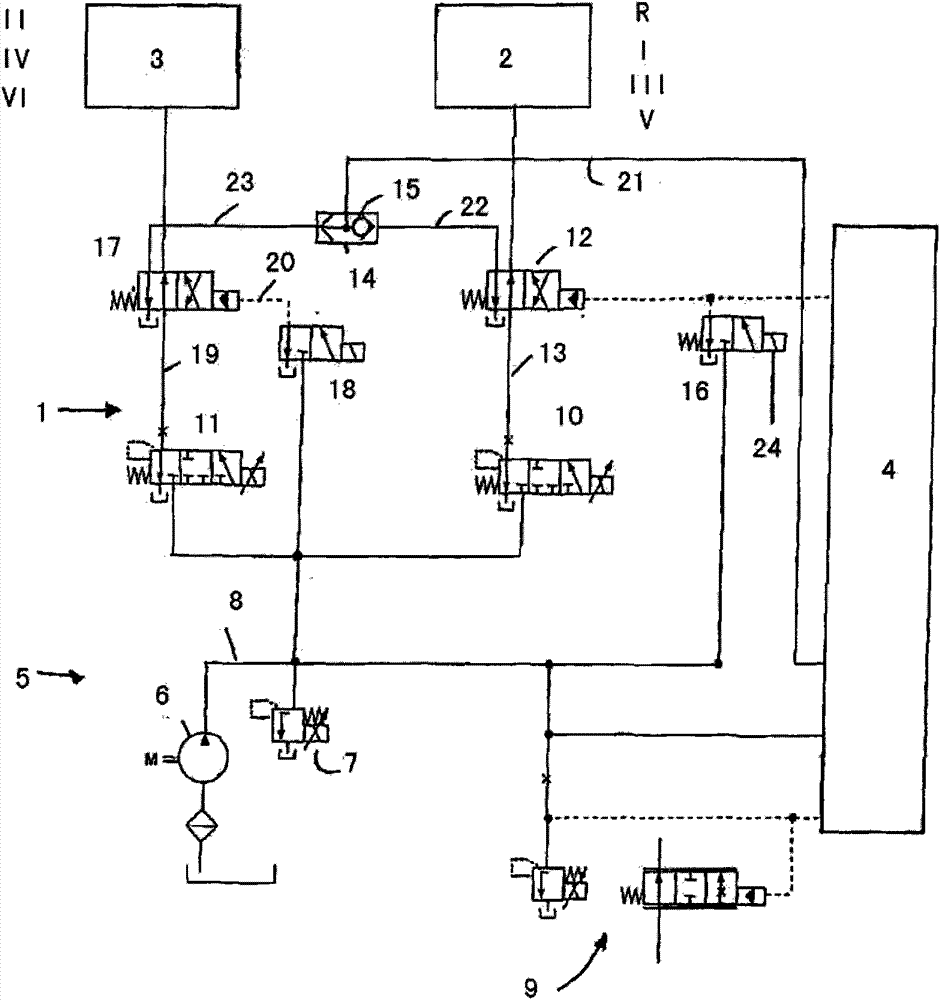

The invention discloses an automatic gear shifting control device of a wheeled tractor. The device comprises a hydraulic control main oil path system, a clutch control oil path system, a gear shiftingcontrol oil path system and a tractor ECU for controlling the three systems; the clutch control oil path system is connected with the hydraulic control main oil path system through a pressure limiting valve, the gear shifting control oil path system is connected with the hydraulic control main oil path system and the clutch control oil path system through a gear control valve and a pressure reduction valve, and the hydraulic control main oil path system comprises an energy storage device, an oil tank, a hydraulic pump and an oil returning electromagnetic valve. The tractor ECU is further connected with an accelerator pedal used for detecting the accelerator opening degree changes and provided with a position sensor; the invention further comprises a control method of the device. Parameters of the tractor engine accelerator opening degree and the speed change are adopted to serve as gear shifting basis, gear shifting labor saving and convenient operation can be achieved, operation strength of a driver is effectively reduced, and speed change gear shifting smoothness of a high-power tractor in the work running process can be improved.

Owner:HUNAN AGRICULTURAL UNIV

A three-cone synchronizer with lubricating oil passage

ActiveCN103790994BSimple structureShort shift timesMechanical actuated clutchesCouplingsEngineeringMechanical engineering

The invention discloses a three-cone synchronizer with a lubricating oil path, which comprises a sliding gear sleeve, an outer friction ring, a friction intermediate ring, an inner friction ring, a slider, a pin, a spring, a combined ring gear and a tooth hub; , a pair of combined ring gears are symmetrically arranged on both sides of the gear hub, and the conical body of the combined ring gear faces the side of the gear hub, a pair of inner friction rings are arranged on the pair of combined ring gears, and a pair of friction intermediate rings are arranged on it. The second claws of the pair of friction intermediate rings extend into the oil holes of the pair of combined ring gears, the pair of outer friction rings are arranged on the pair of friction intermediate rings, and the first claws of the pair of friction intermediate rings extend into the pair of inner friction rings In the oil groove, the sliding gear sleeve, slider, pin and spring are all arranged between a pair of outer friction rings, and one end of the pin passes through the slider to match the sliding gear sleeve, and the other end of the pin is connected to the gear hub through the spring. touch. Compared with the double-cone synchronizer, the three-cone synchronizer of the present invention has shorter shift time, smaller shift force, comfortable operation and long service life.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Transmission speed change device

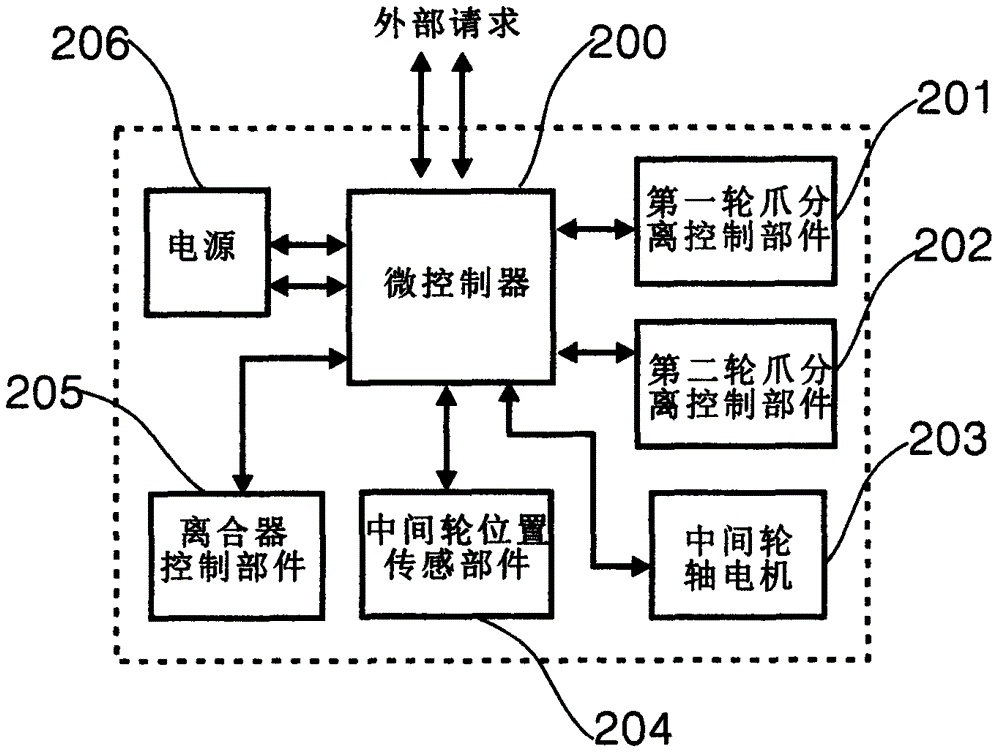

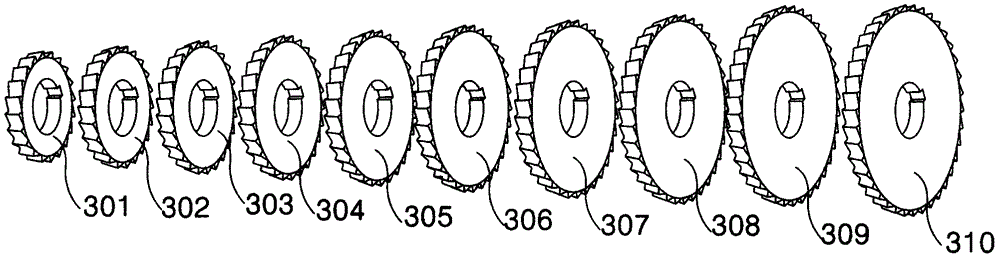

InactiveCN106015483AEasy to implementRealize the speed change functionGearing controlFriction gearingsMicrocontrollerClutch control

A transmission transmission device, the transmission transmission device mainly includes a clutch, a clutch controller, a microcontroller, an input cone, an output cone and an intermediate wheel. The input cone and the output cone are formed by combining multiple cone rings. The busbar of the ring coincides with the busbar of the cone barrel, and there are gears on the outer edge of the cone ring. The gears are in a sawtooth shape. Between the barrels, the intermediate wheel has two sets of claws, which can rotate along the axis of the intermediate wheel, and can also adjust the angle with its own axis. When the cone barrel bevel ring gear is used, a gear transmission and speed change function of the transmission transmission device is realized. When the intermediate gear is switched and coupled to another set of input cone barrel bevel ring gears and output cone barrel bevel ring gear sets with different diameter ratios, The multi-gear speed change function of the transmission speed change device is realized.

Owner:王国伟

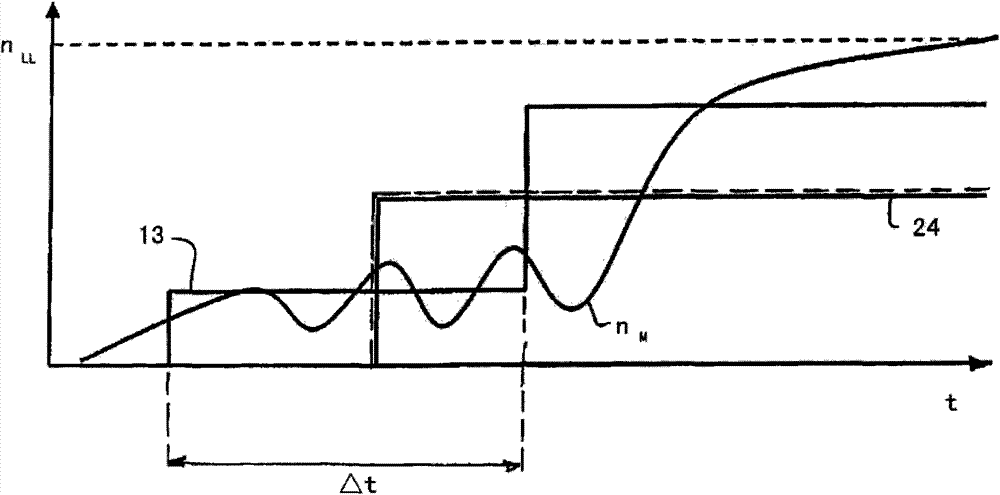

Method for operating automated dual clutch transmission in motor vehicle, involves setting starting value for pressure in starting phase, where starting value is smaller than transmission minimal value

The method involves setting a starting value for a pressure (13) in a starting phase, where the starting value is smaller than a transmission minimal value. The overrun of a clutch (2) transmits a torque during the pressure application. An operating value is set for the pressure after completing the starting phase. The target value is higher than the transmission minimal value of the clutch. The presetting of the operation value is performed immediately after setting the starting value.

Owner:GETRAG FORD TRANSMISSIONS GMBH

Double-clutch hydraulic control device

The invention discloses a double-clutch hydraulic control device. The switch between double clutches is finished through hydraulically controlling the open / close of double clutches. By means of the scheme, the double-clutch hydraulic control device is simple in structure, excellent in performance, capable of realizing high-speed and high-precision gear shifting through matching with double electric clutches, short in gear shifting time, comfortable in riding, safe and environmental friendly.

Owner:沃新动力系统(上海)有限公司 +1

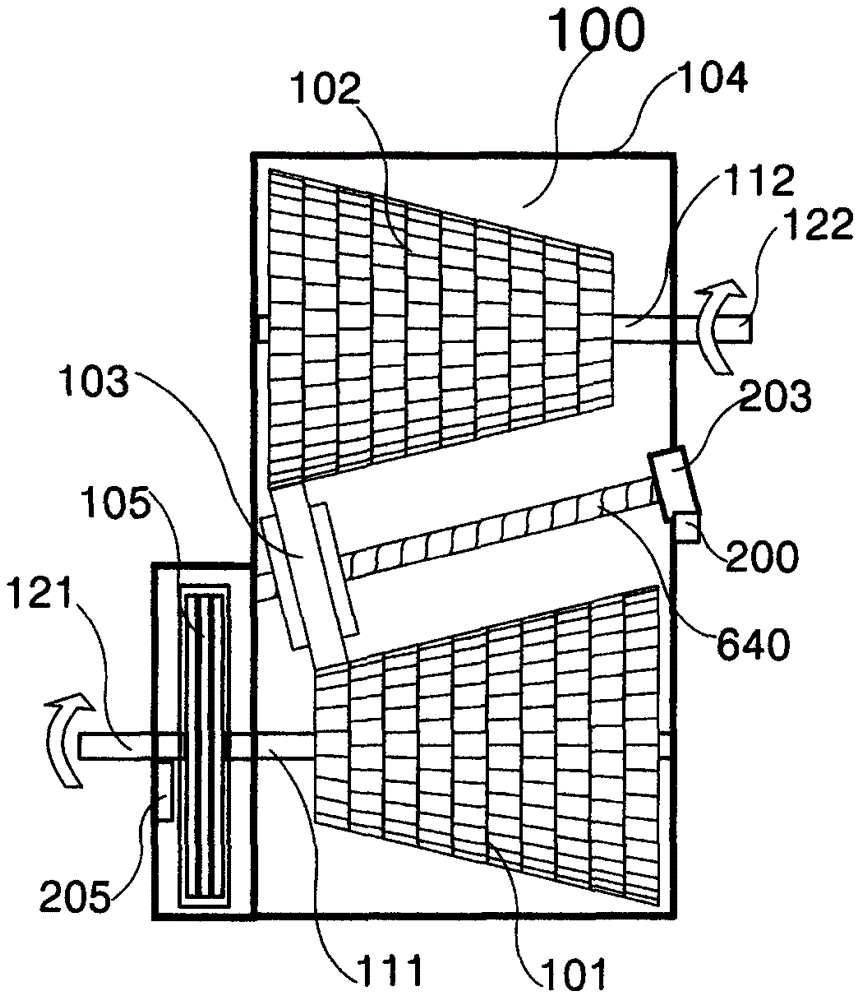

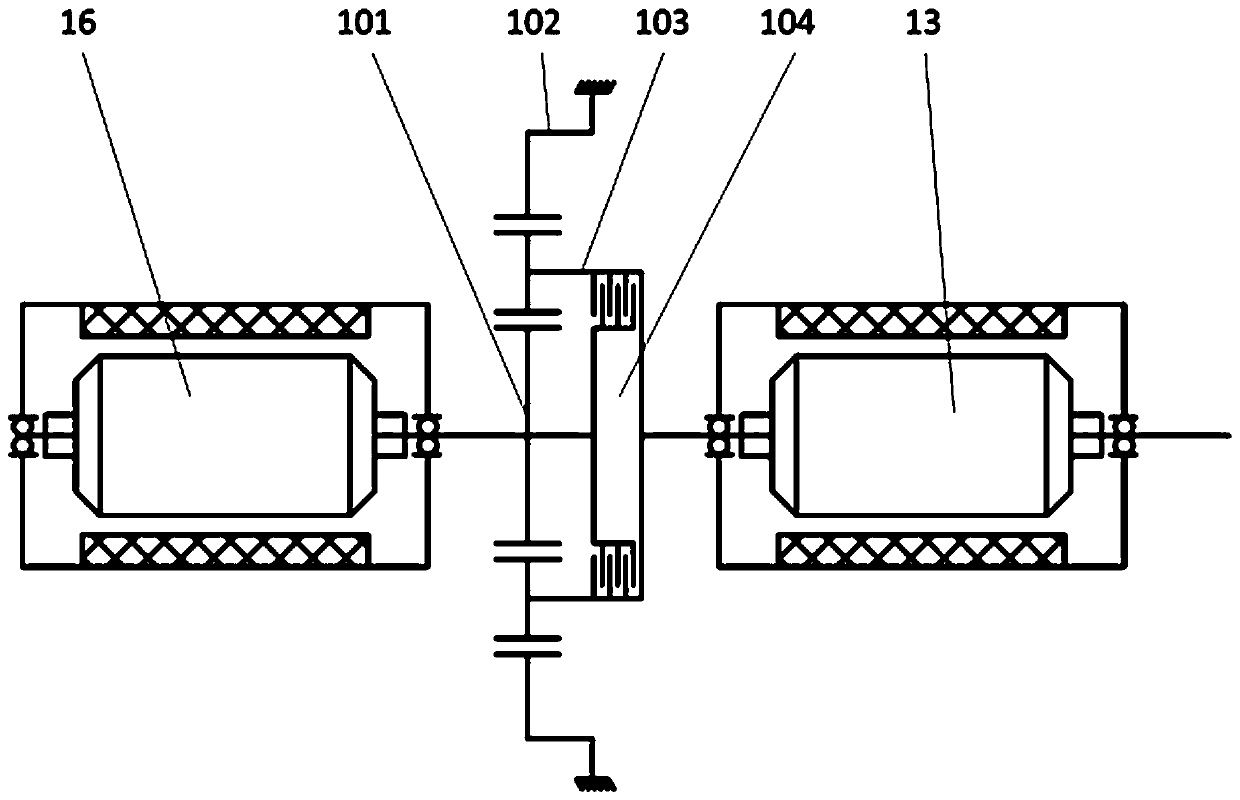

Electric drive device with double motors and single planetary gear train

PendingCN107738569ASmooth and shock-free gear shiftingShort shift timesElectric propulsion mountingControl devicesClutchElectric drive

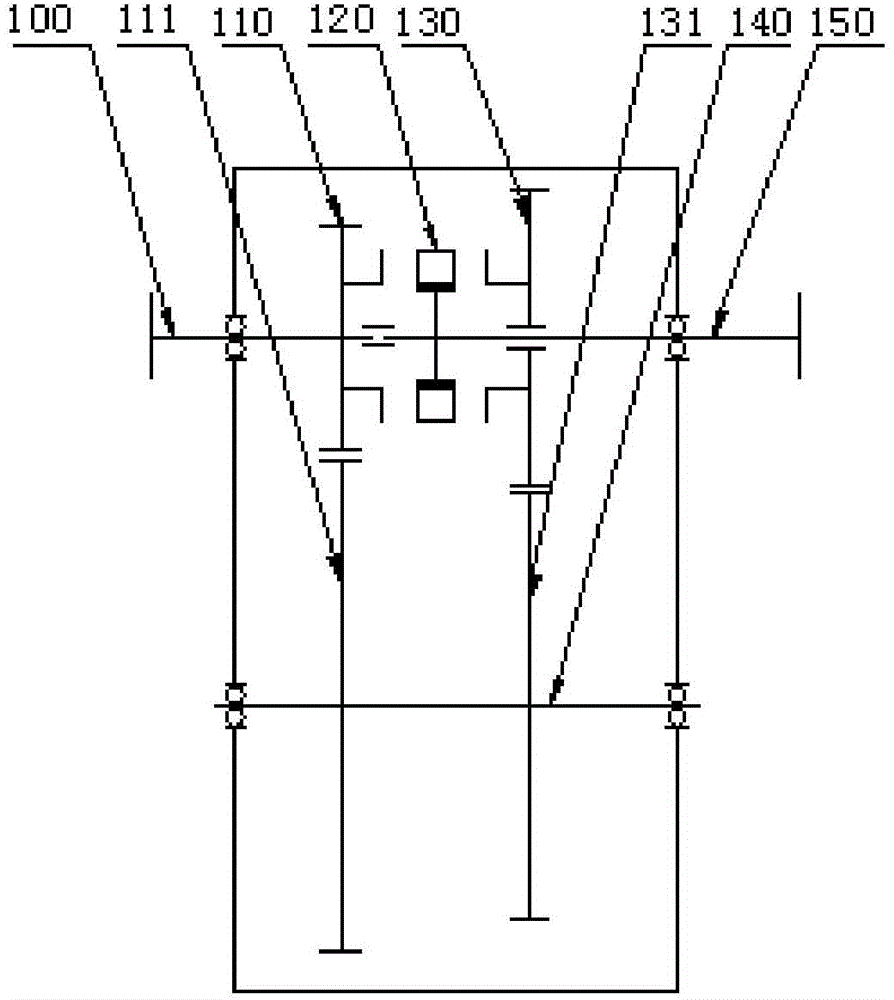

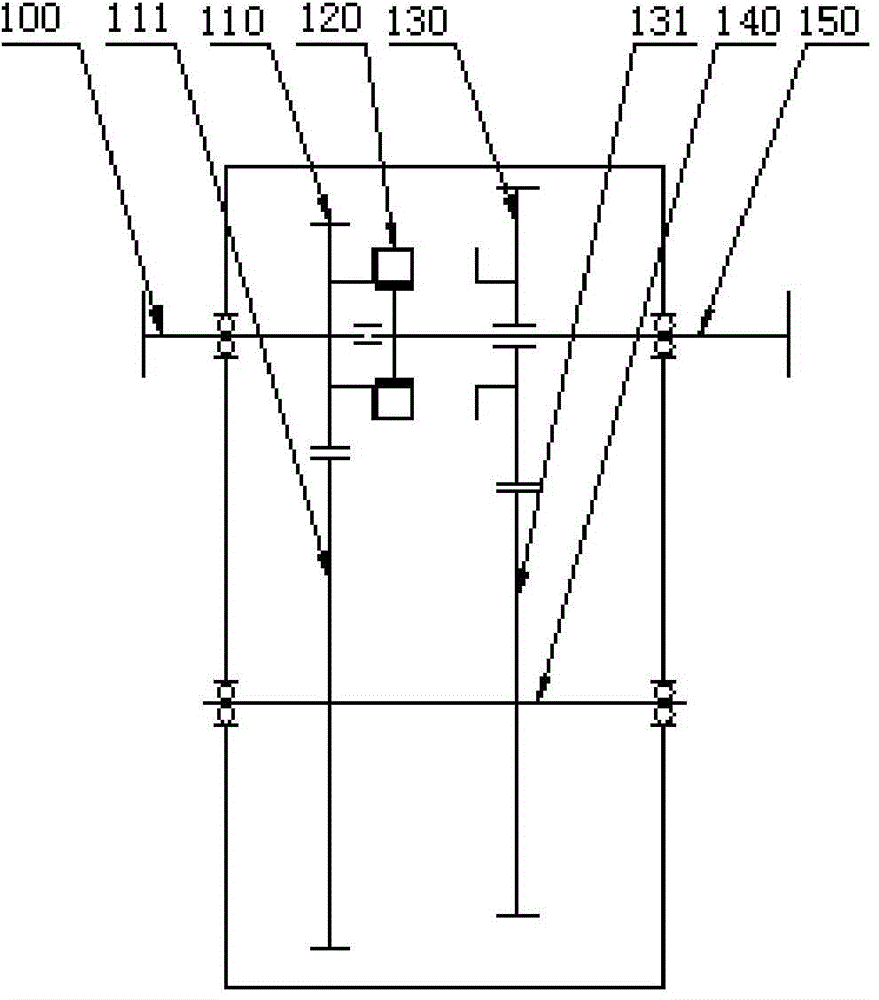

The invention relates to an electric drive device with double motors and single planetary gear train. The electric drive device comprises a first drive motor (16), a planetary gear train (100), a second drive motor (13) and a wet clutch (104), wherein the planetary gear train (100 ) comprises a sun gear (101), a gear ring (102), a planet carrier (103) and a planetary gear train housing, the firstdrive motor (16) is connected with the sun gear (101), the gear ring (102) is fixedly connected with the planetary gear train housing, the second drive motor (13) is connected with the planet carrier(103), one end of the wet clutch (104) is connected with the sun gear (101), and the other end of the wet clutch (104) is connected with the planet carrier (103). Compared with the prior art, the electric drive device has the advantages that the electric drive device can realize two speed transmission without power interruption, achieve the purpose of decelerating and increasing the torque of thefirst driving motor and satisfy the power requirements of a vehicle, meanwhile complete the shifting process through the wet clutch, and achieve smooth shifting process, short shifting time and good driving comfort.

Owner:BIT HUACHUANG ELECTRIC VEHICLE TECH

Gearbox transmission system

The invention provides a gearbox transmission system. The gearbox transmission system comprises a first input shaft, a second input shaft, a first confluence gear, a first transmission structure unit and a second transmission structure unit, a second confluence gear, an intermediate shaft, a first synchronizer gear and a second synchronizer gear, a third confluence gear, a fourth confluence gear and a fifth confluence gear, a planet row, a first synchronizer, a second synchronizer, an L / H gear shifting synchronizer, and an output shaft. The transmission structure is compact, the arrangement space is saved, and no interruption of power when a vehicle climbs a slope can be guaranteed.

Owner:北方汤臣传动科技有限公司

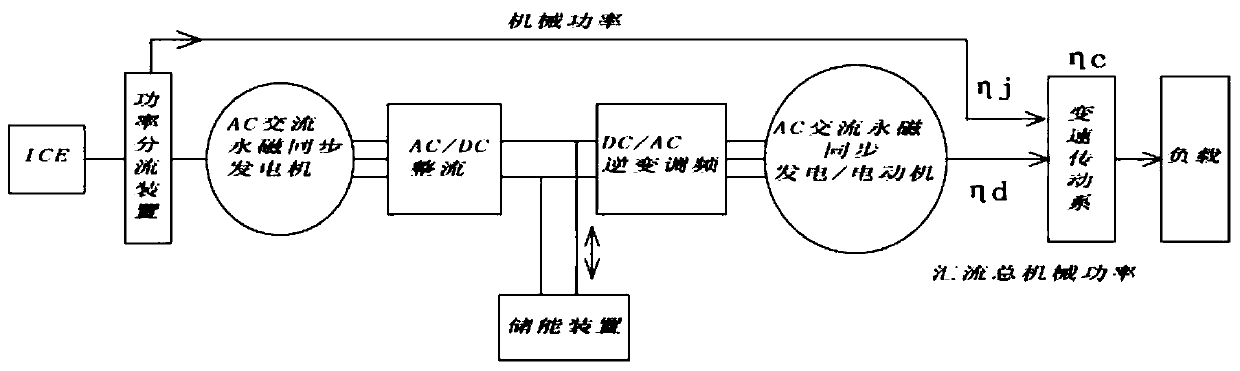

Stepless variable drive system for series dual-motor differential power dividing

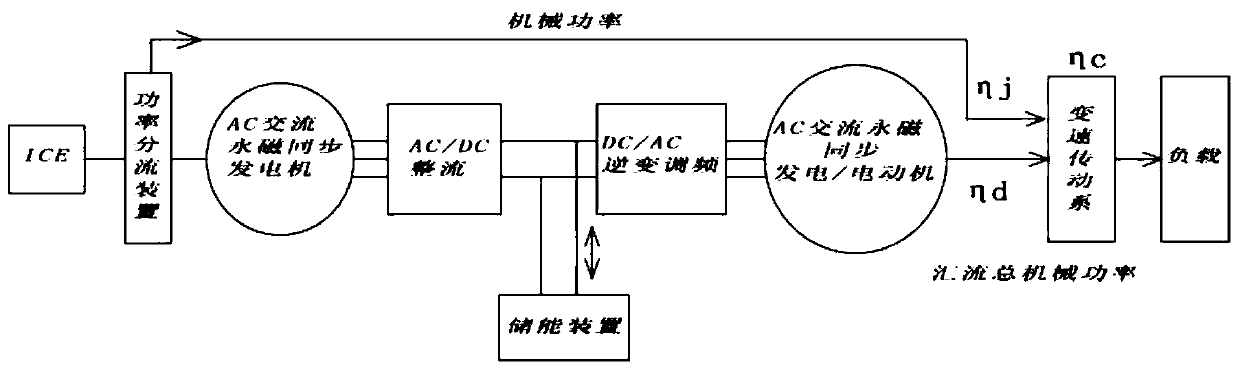

PendingCN110303865AGuaranteed to workQuick responseElectric propulsion mountingControl devicesElectric machineElectric power system

The invention discloses a stepless variable drive system for series dual-motor differential power dividing. The system comprises an engine output / differential input shaft, a first motor, a second motor, a motor controller, a power dividing device, a clutch, a gearbox, an engine power output shaft and a storage battery; the first motor and the second motor are connected in series, power of an engine is transmitted to the first motor through the engine output / differential input shaft for power generation, and meanwhile, the engine output / differential input shaft outputs power outwards through the power dividing device, the clutch and the gearbox to form a first power path; the first motor supplies power to the second motor and the storage battery through the motor controller, and the secondmotor outputs power outwards through the power dividing device, the clutch and the gearbox to form a second power path. The stepless variable drive system has the two power paths of mechanical power and electric power.

Owner:GUANGXI YUCHAI MASCH CO LTD

Dual-clutch transmission

InactiveCN106164535AShort shift timesQuick backstopToothed gearingsGearing controlEngineeringCrankshaft

The invention relates to a transmission (1), comprising a first input shaft (102), a second input shaft (103), an output shaft (125), a first clutch (104), and a second clutch (105). Each of the input shafts (102, 103) can be connected to the crankshaft of a drive engine by means of one of the clutches (104, 105) and each of the input shafts (102, 103) can be connected to the output shaft (125) in a torque-transmitting manner by means of gear pairs (113 / 121, 110 / 118, 114 / 122, 111 / 119, 115 / 123, 112 / 120, 116 / 124, 109 / 117). Groups of two gear pairs (113 / 121 and 114 / 122; 115 / 123 and 116 / 124; 111 / 119 and 112 / 120) can be connected to the output shaft (125) in a torque-transmitting manner by means of an actuatable shifting fork (130, 131, 132, 133). A gear ratio (U R, U 1 to U 7) is associated with each gear pair (113 / 121, 110 / 118, 114 / 122, 111 / 119, 115 / 123, 112 / 120, 116 / 124, 109 / 117), wherein a number of gear ratios graded in relation to each other is provided. The two gear ratios of a group of gear pairs are a first gear ratio (N) and the next gear ratio but one (N+2), wherein N is an integer, in particular N = 1, 2, 3, 4, or 5.

Owner:SCHAEFFLER TECH AG & CO KG

Parallel dual-motor differential power dividing continuously variable transmission system

PendingCN110303861AGuaranteed to workQuick responseElectric propulsion mountingControl devicesElectricityTransmitted power

The invention discloses a parallel dual-motor differential power dividing continuously variable transmission system. The parallel dual-motor differential power dividing continuously variable transmission system is connected with an engine output shaft and comprises the engine output shaft, a first motor, a second motor, a motor controller, a differential mechanism, a clutch, a gearbox, a power output shaft and a storage battery; the first motor and the second motor are arranged in parallel, the engine output shaft transmits power of the engine to the first motor for generating electricity, meanwhile, the engine output shaft outputs power outwards to form a first power path through the differential mechanism, the clutch and the gearbox, the first motor supplies power to the second motor andthe storage battery through the motor controller, and the second motor outputs power outwards to form a second power path through the differential mechanism, the clutch and the gearbox. Accordingly,two power paths of mechanical power and electric power can be achieved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com