Electric drive device with double motors and single planetary gear train

A planetary gear train, single-planet technology, applied in the field of pure electric vehicle drive devices, can solve the problems of inability to realize large speed ratio motor drive and small speed ratio motor drive, difficulty in ensuring that the motor works in a high-efficiency area, and complex shift control, etc. To achieve the effect of easy implementation, avoiding torsional vibration, and good driving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment is only a preferred technical solution, and the various components and connection relationships involved are not limited to the following implementation described in this embodiment. The configuration and connection relationship of the various components in the preferred solution can be Carry out arbitrary permutations and combinations to form a complete technical solution.

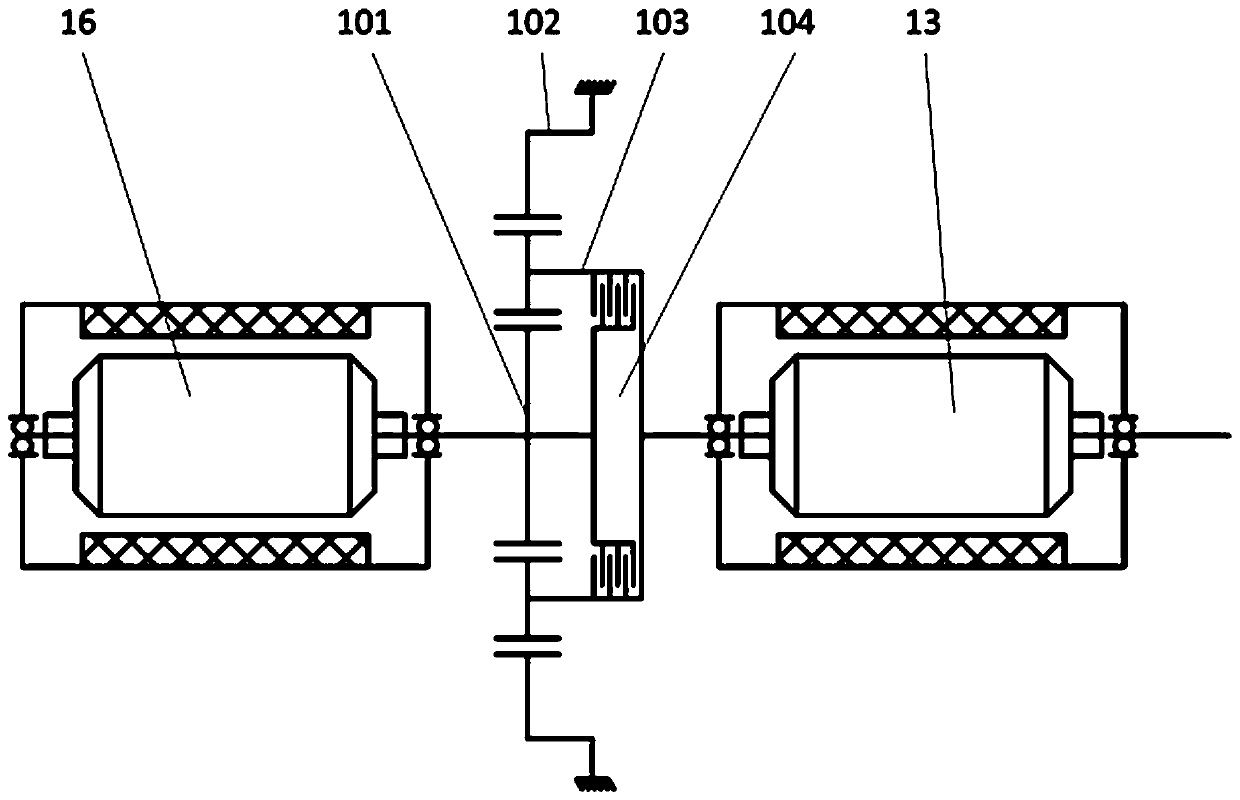

[0026] Combine below figure 1 , 2 Describe in detail the technical solution of the dual-motor single-planetary gear train electric drive device:

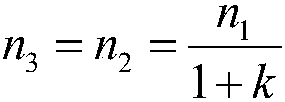

[0027]A dual-motor single planetary gear train electric drive device, including a first drive motor 16, a planetary gear train 100, a second drive motor 13, and a wet clutch 104, and the planetary gear train 100 includes a sun gear 101, a ring gear 102, and a planet carrier 103 and the planetary gear train housing, the first drive motor 16 is connected with the sun gear 101, the ring gear 102 is fixedly connected with the planet gear tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com