Dual-clutch transmission

A technology of transmission and clutch, applied in the field of transmission of motor vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

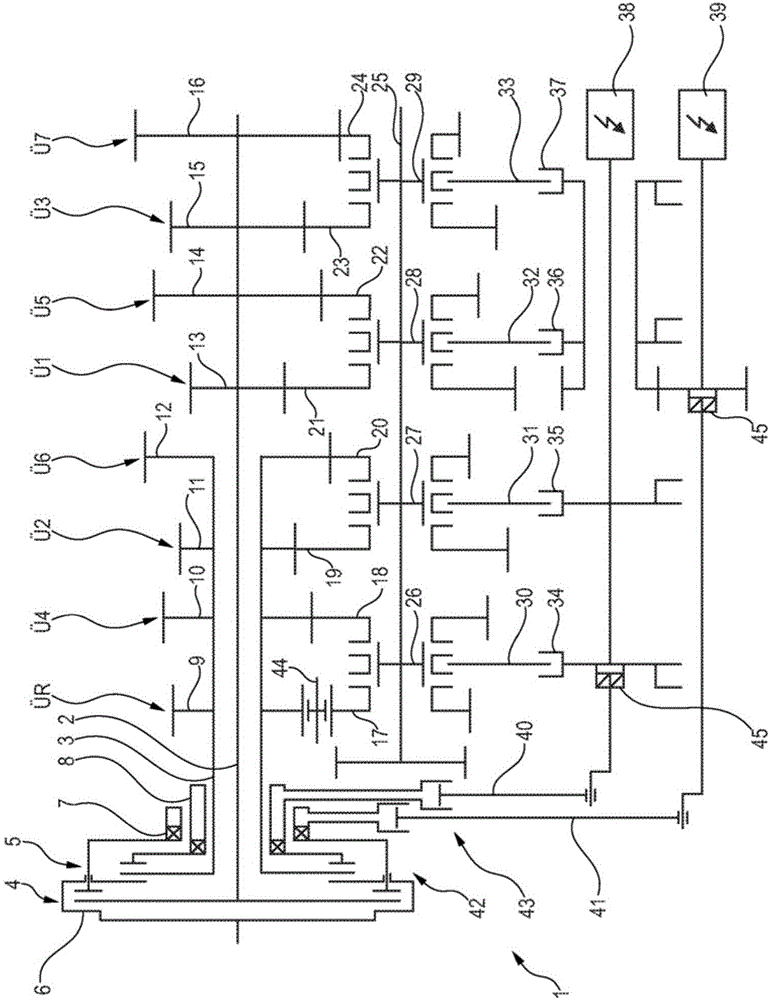

[0026] figure 1 A schematic diagram of a transmission 1 according to the prior art is shown. The transmission 1 has a first input shaft 2 and a second input shaft 3 , which are connectable via clutches 4 , 5 to a crankshaft (not shown) of the engine. The clutches 4, 5 are arranged in a clutch housing 6, which can be connected to the crankshaft, and for actuating the clutches 4, 5 are provided actuating devices 7, 8 which can be controlled by a control unit in order to be able to actuate a clutch 4 and / or another clutch 5. The input shafts 2 , 3 are at least partially arranged coaxially with one another, wherein the actuating devices 7 , 8 are preferably also arranged coaxially with one another. Gears 9, 10, 11, 12, 13, 14, 15, 16 for gear pairs 9 / 17; 10 / 18; 11 / 19; 12 / 20; 13 / 21; 14 / 22; It is non-rotatably connected to the two input shafts 2 , 3 . Here, the gears 9 , 10 , 11 and 12 are connected in a rotationally fixed manner to the shaft 3 , while the gears 13 , 14 , 15 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com