Three-clutch three-gear speed change transmission device and three-clutch method thereof

A three-speed transmission and transmission technology, applied in the field of three clutches, can solve the problems of reducing energy recovery efficiency, energy consumption, failure to recover braking energy, etc., and achieve the effect of improving energy recovery efficiency, high operating efficiency, and optimal driving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

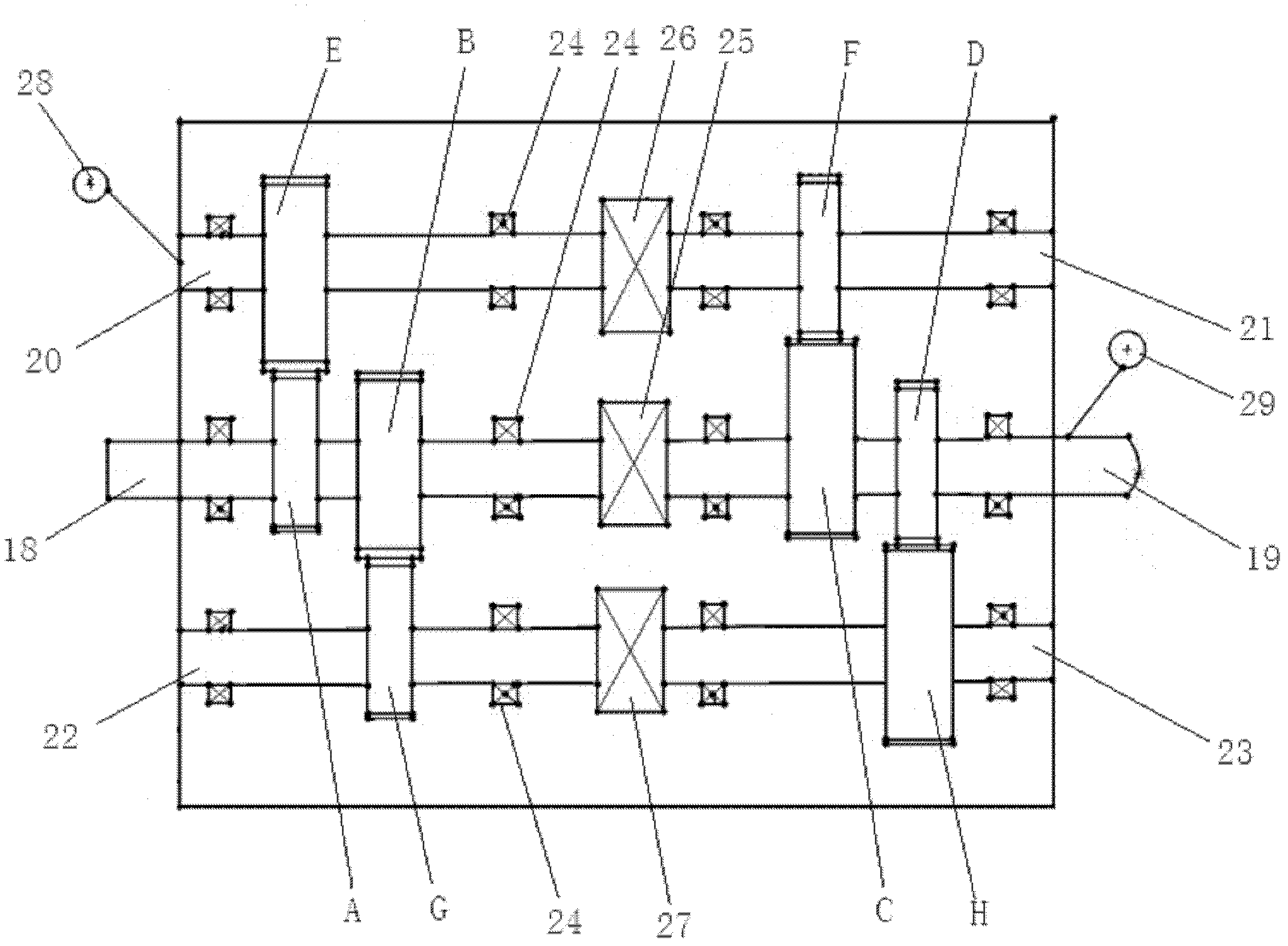

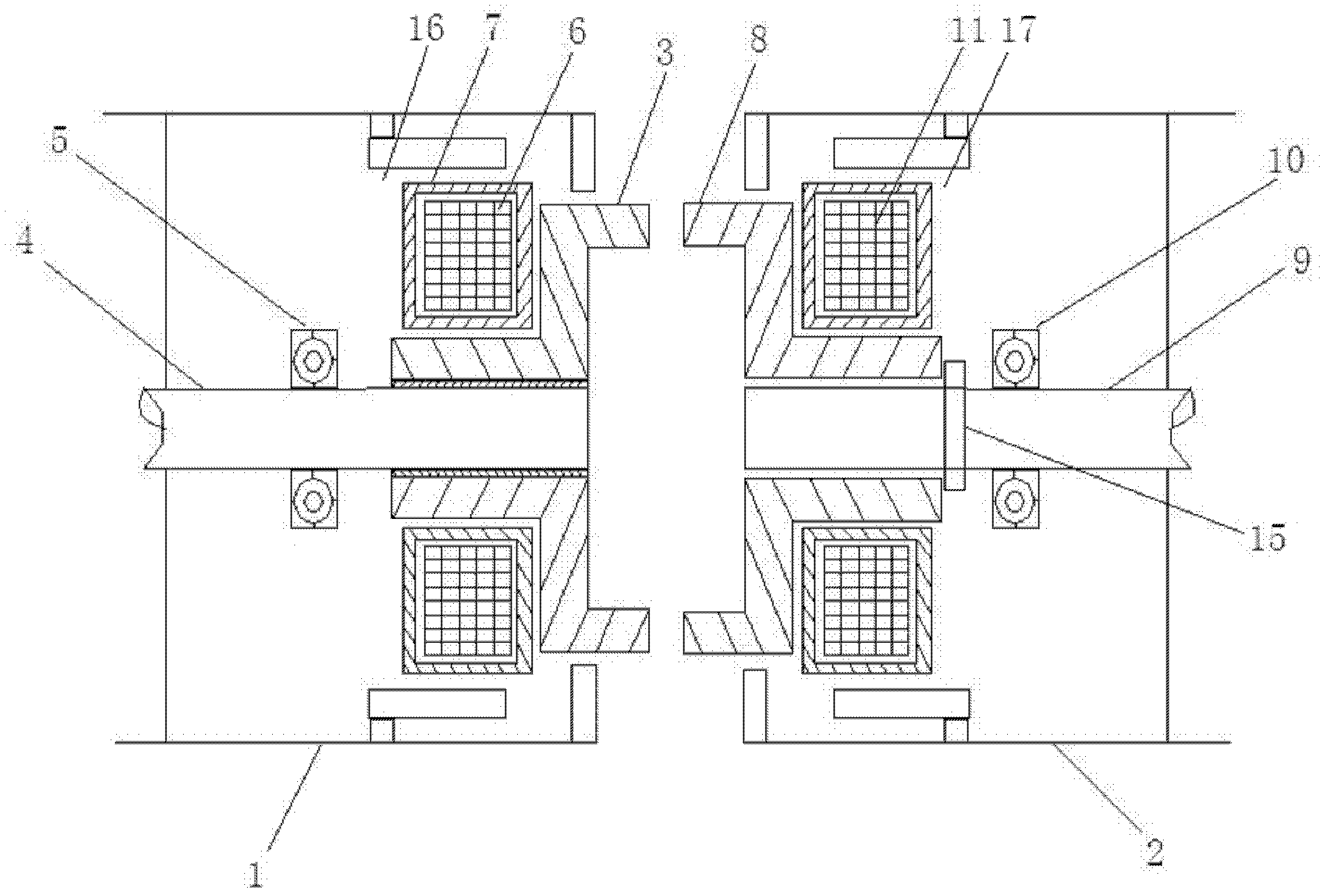

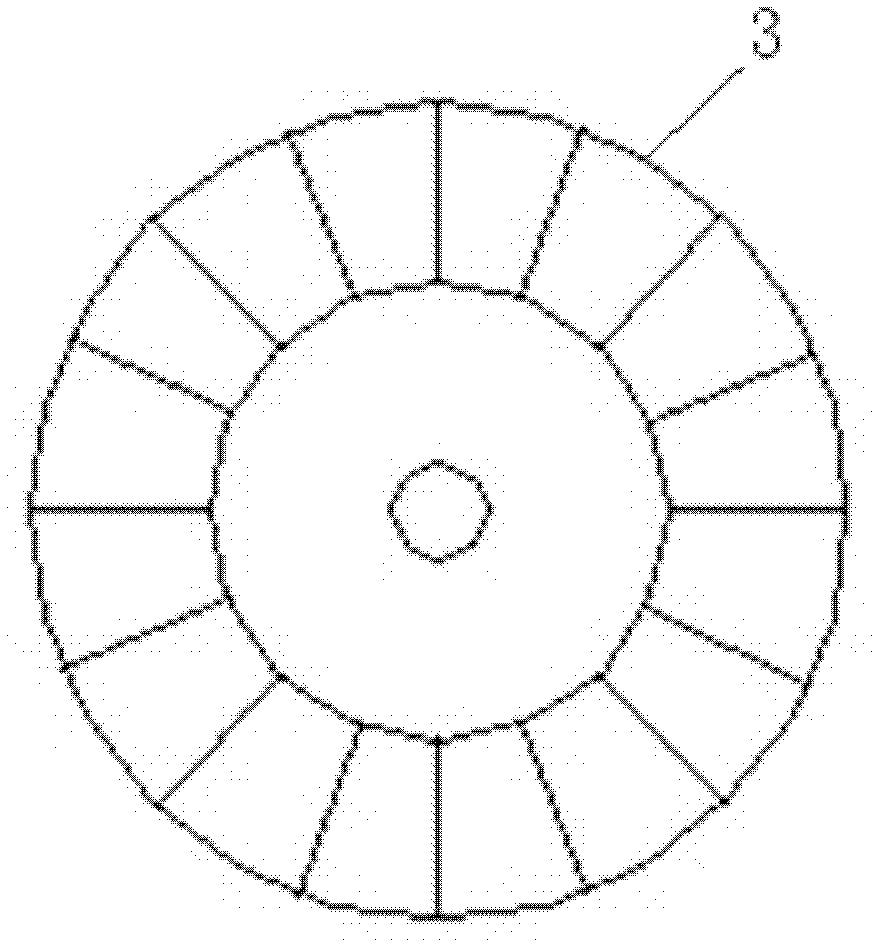

[0045] as attached figure 1 As shown, the three-clutch three-speed transmission device of this embodiment includes a box body, and an input shaft 18 and a first driving gear A and a third driving gear B sleeved on the input shaft 18 are arranged in the box body, and the output The shaft 19 and the second driven gear C and the fourth driven gear D set on the output shaft 19, the input shaft 18 and the output shaft 19 are respectively set in the bearing 24, and the input shaft 18 passes through the first The clutch 25 is connected with the output shaft 19, the first countershaft 20 and the first driven gear E fitted on the first countershaft 20 are arranged in the said box, the second countershaft 21 and the first driven gear E fitted on the second countershaft 21 The second driving gear F, the first countershaft 20 and the second countershaft 21 are respectively sleeved in the bearings 24, the first countershaft 20 is connected with the second countershaft 21 through the ...

Embodiment 2

[0051] In the three-clutch method of the speed change transmission device in this embodiment, the first clutch 25, the second clutch 26 and the third clutch 27 in the speed change transmission device are closed or disconnected according to the difference in the rotational speed of the motor in the electric and power generation states. The speed change transmission device is a three-clutch three-speed transmission device, and the three-clutch method of the speed change transmission device is:

[0052] When the motor is in the electric state, the motor shaft is connected with the input shaft 18, and in the variable speed transmission,

[0053] The input shaft 18 serves as the input end, and the output shaft 19 serves as the output end.

[0054] (1) When the car is running at low speed during the starting period or uphill period, the required traction force is relatively large. Disengage the first clutch 25 and the third clutch 27, close the second clutch 26, and the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com