Method for operating automated dual clutch transmission in motor vehicle, involves setting starting value for pressure in starting phase, where starting value is smaller than transmission minimal value

A dual-clutch, transmission technology, applied to clutches, mechanical equipment, vehicle components, etc., can solve problems such as long time and clutch collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

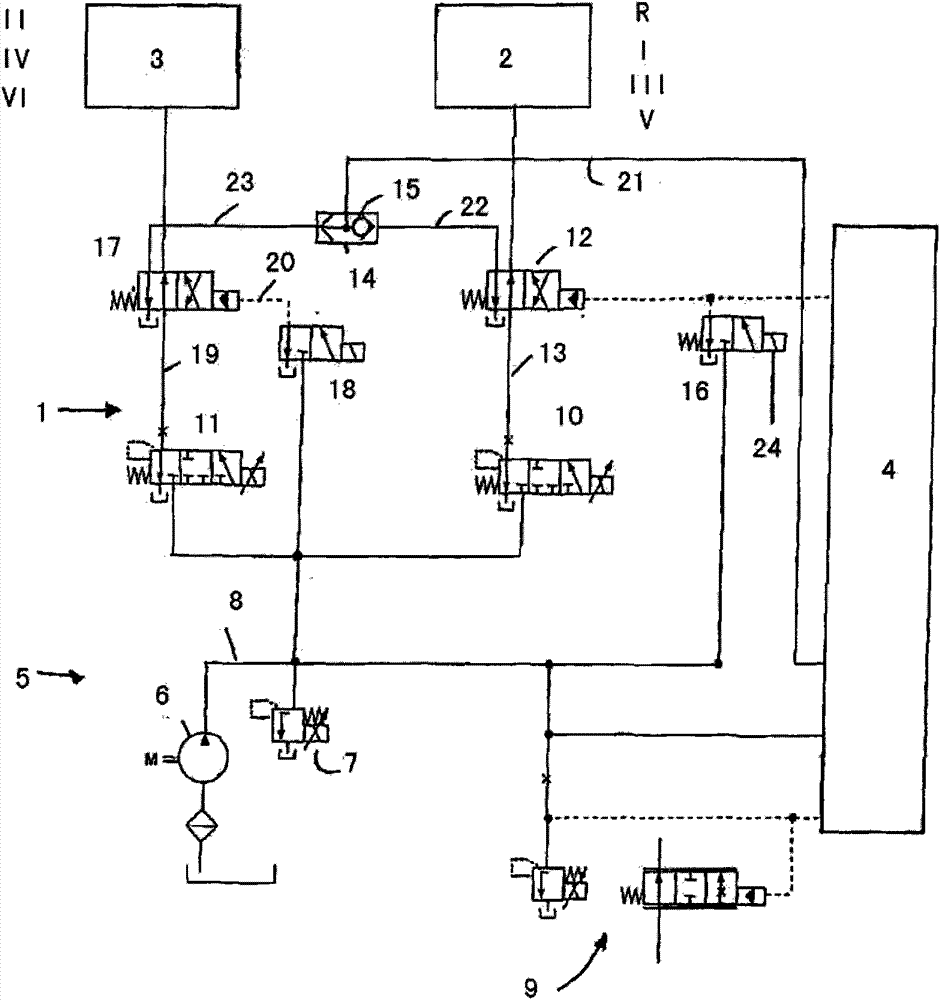

[0025] figure 1 The control unit identified with 1 is shown. The control device 1 is used to selectively apply pressurized oil to the first clutch 2 and the second clutch 3 of a dual-clutch transmission (not shown further here), so that the dual-clutch transmission can be operated in a desired manner. In addition, in figure 1 The gearshift system marked 4 of the dual clutch transmission is only schematically shown in FIG. The shifting system is used for shifting in and out of a dual clutch transmission.

[0026]The first clutch 2 is to be assigned to the first sub-transmission of the dual-clutch transmission, to which a reverse gear R, a first forward gear I and further odd-numbered forward gears III, V are also assigned. Because these gears R, I, III, V and the first clutch are assigned to the same sub-transmission (first sub-transmission), in figure 1 In addition to the first clutch 2 shown schematically, the symbols R, I, III, V are listed in the illustration. In a sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com