Hard sealing double eccentric butterfly valve for S-shaped elastic double O-shaped metal sealing ring

A metal sealing ring, double eccentric technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of complex sealing structure, achieve the effect of simplifying the sealing structure, improving reliability and ensuring the internal sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

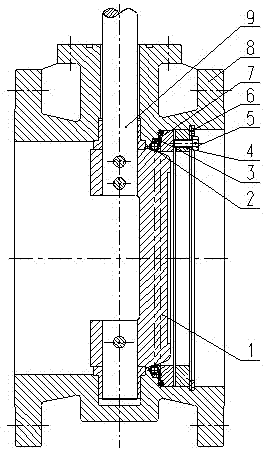

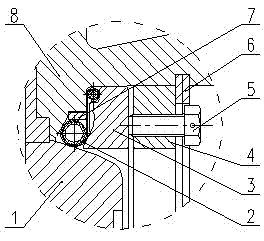

[0010] Depend on figure 1 , figure 2 As shown, an S-shaped elastic double O-shaped metal seal ring hard-sealed double eccentric butterfly valve includes a double eccentric butterfly plate 1, a valve body 8, and a valve stem 9. It is characterized in that, between the double eccentric butterfly plate 1 and the valve body 9 There is an integrated S-shaped elastic double O-shaped metal seal ring 2, which is formed by connecting large and small elastic O-shaped metal seal rings through the metal of the S-shaped outer ring. Shaped metal sealing ring 2 is provided with an adjustment mechanism composed of pressure ring 3, control ring 7, positioning plate 4, adjusting bolt 5, and retaining ring 6 to adjust the deformation amount and deformation direction of large and small elastic O-shaped metal sealing rings.

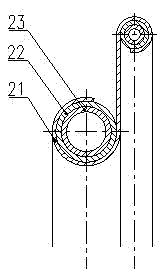

[0011] Depend on image 3 As shown, the S-shaped elastic double O-shaped metal seal ring 2 is formed by connecting large and small elastic O-shaped metal seal rings th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com