Chamfering method for brittle substrate

A brittle material substrate and chamfering technology, applied in stone processing equipment, stone processing tools, fine working devices, etc., can solve the problems of chamfering surface depression, control, and difficult chamfering surface shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be described below using the drawings. In addition, this invention is not limited to embodiment demonstrated below, Various aspects are included in the range which does not deviate from the summary of this invention.

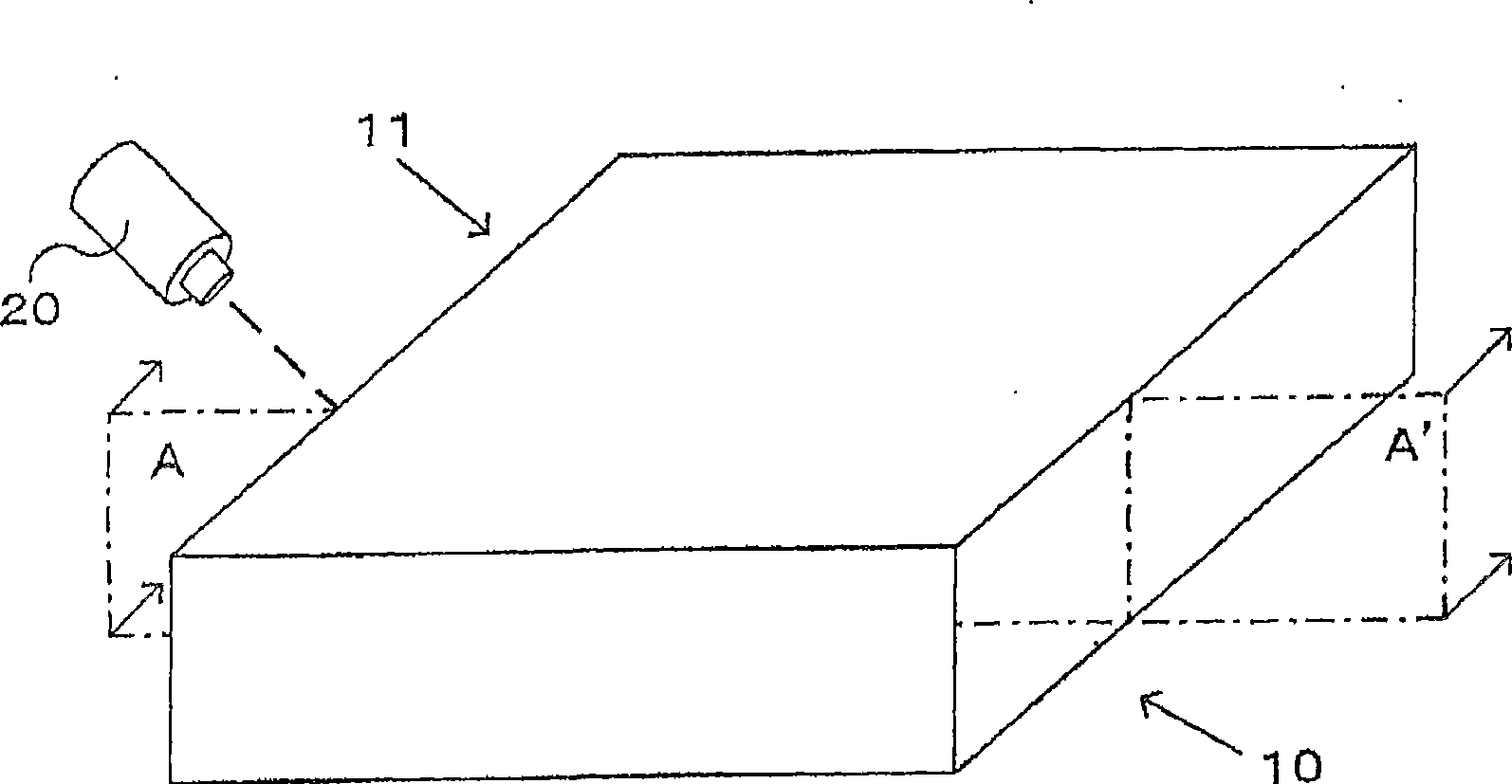

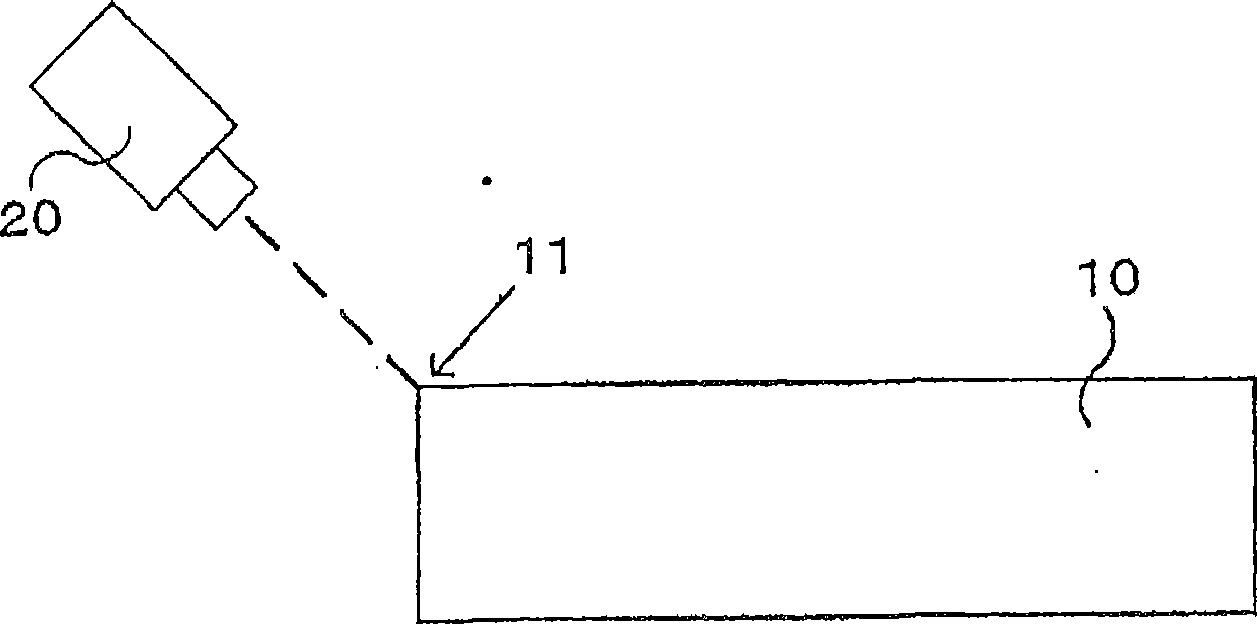

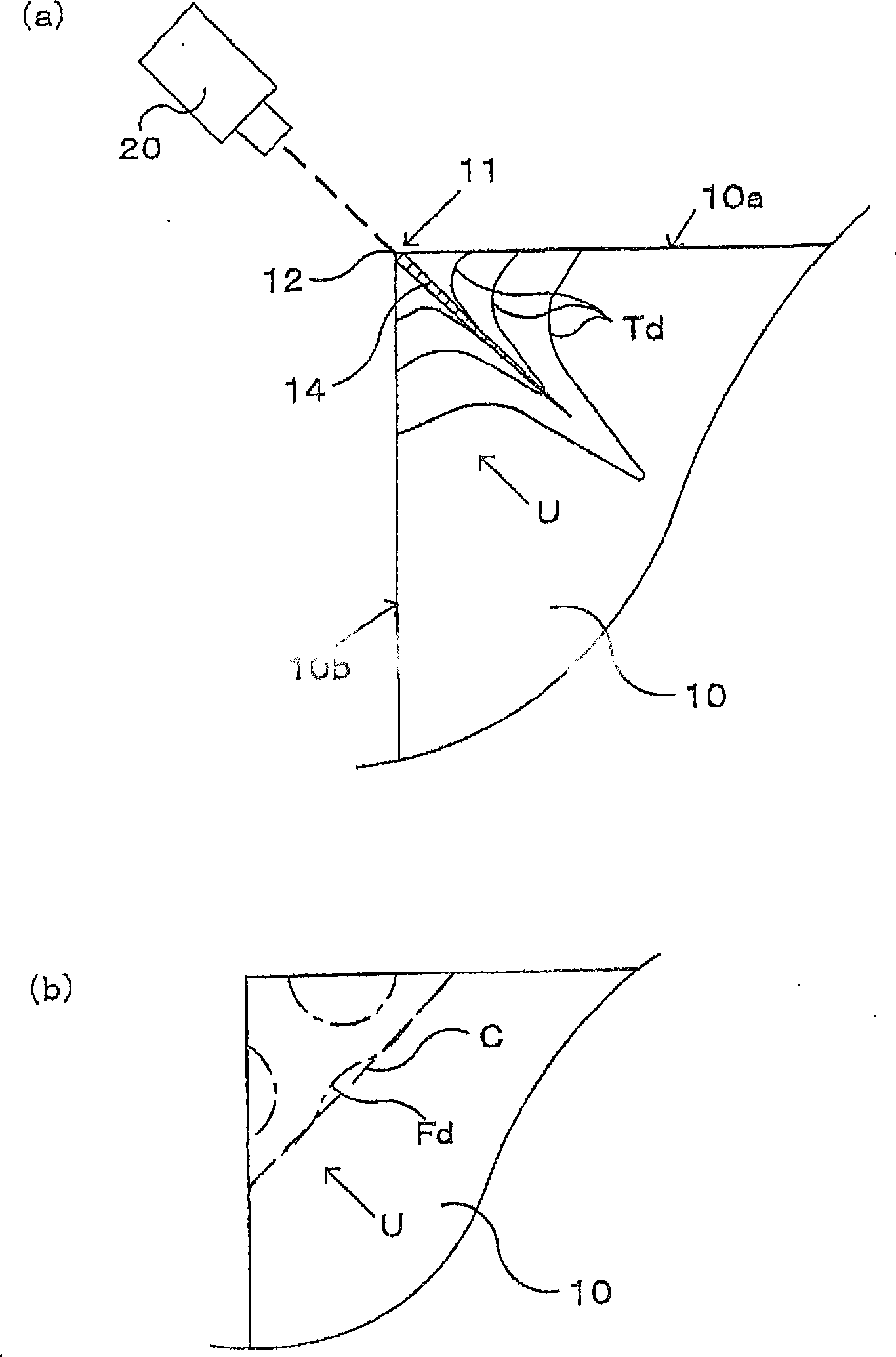

[0058] figure 1 It is a figure which shows the chamfering processing method of the brittle material substrate which is one embodiment of this invention. figure 2 is shown along the figure 1 The A-A' section diagram. An Er:YAG laser light source 20 (hereinafter referred to as Er laser light source 20) is arranged at a position opposite to the edge line 11 of the glass substrate 10 to be chamfered, and the laser light is inclined from the edge line 11 of the substrate toward the inside of the substrate. incident. Then, the glass substrate 10 is relatively moved with respect to the laser light source 20 , and the laser light is scanned along the edge line 11 . Specifically, scanning is performed by operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com