Preparation method of SiCf/SiC ceramic matrix composite turbine blades

A technology of turbine blades and composite materials, which is applied in the field of composite material parts manufacturing, can solve problems such as high density, limited operating temperature, and restricted engine performance, and achieve the effect of improving the silicon corrosion resistance of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

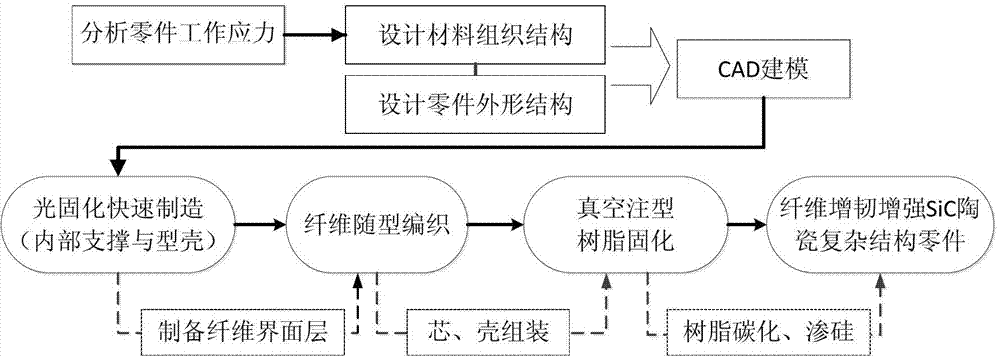

[0053] see figure 1 , the preparation method of fiber toughened SiC ceramic matrix composite material turbine blade, comprises the following steps:

[0054] 1. Analyze the working stress of parts

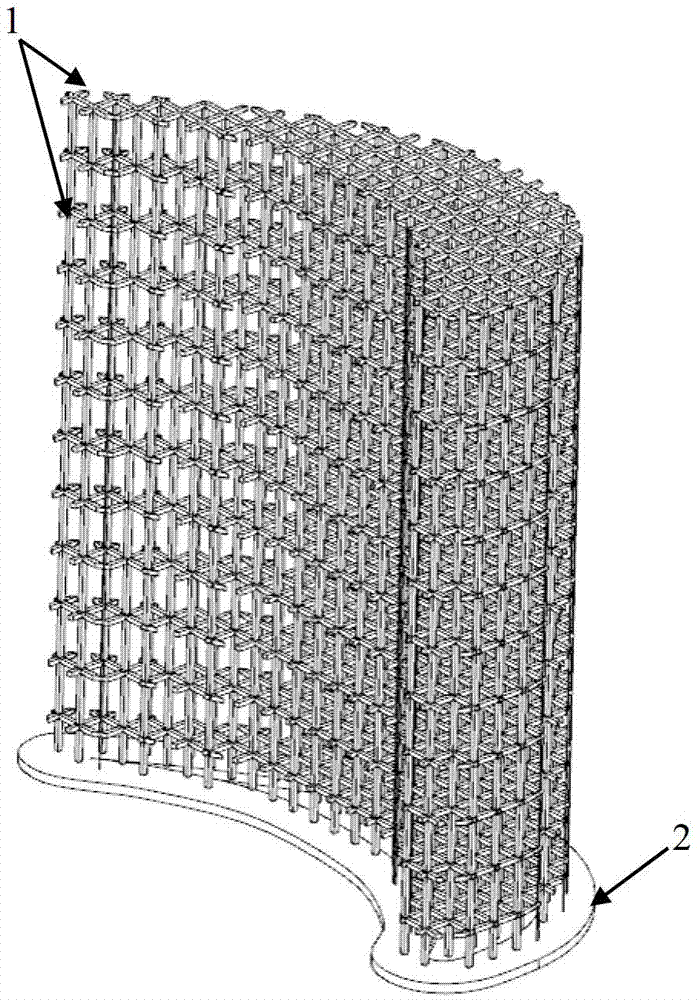

[0055] Firstly, the stress distribution of the parts under the service conditions is analyzed, and the parts are divided into different regions according to the stress range, and the material structure of different regions is different. Design a material unit structure that meets the characteristics of light-curing rapid prototyping technology, and obtain its performance requirements for local materials by analyzing the state of the parts under service conditions. Each region is integrated to finally obtain a stress balance model, which can be regarded as a weaving model of the reinforcement (SiC fiber), and then the three-dimensional data of the fiber-guided scaffold with a spatial topology is obtained through CAD modeling.

[0056] 2. Fabrication of internal supports and negati...

Embodiment 2

[0082] see figure 1 , the preparation method of fiber toughened SiC ceramic matrix composite material turbine blade, comprises the following steps:

[0083] Steps 1 and 2 are the same as in Example 1.

[0084] 3. Preparation of ceramic slurry

[0085] 3.1 Preform solution preparation

[0086] The monomer and crosslinking agent used in gel injection molding are acrylamide and N,N'-methylenebisacrylamide respectively. The initiator adopts ammonium persulfate as the initiator and tetramethylethylenediamine as the catalyst. Sodium polyacrylate was used as a dispersant.

[0087] First, the monomer acrylamide (AM, analytically pure) and the cross-linking agent N,N'-methylenebisacrylamide (MBAM, analytically pure) are made into a pre-preparation solution for gel injection molding, and the monomer and The mass ratio of the cross-linking agent is 6-10:1, and the content of the monomer and the cross-linking agent is 12-20% of the total mass of the solution.

[0088] 3.2 Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com