Flexible stretch-forming device and method for carrying out stretch-forming on plate by utilizing same

A flexible and sheet material technology, applied in the field of flexible drawing devices, can solve the problems of poor drawing precision, achieve the effects of improving forming precision, improving plasticity, and reducing deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

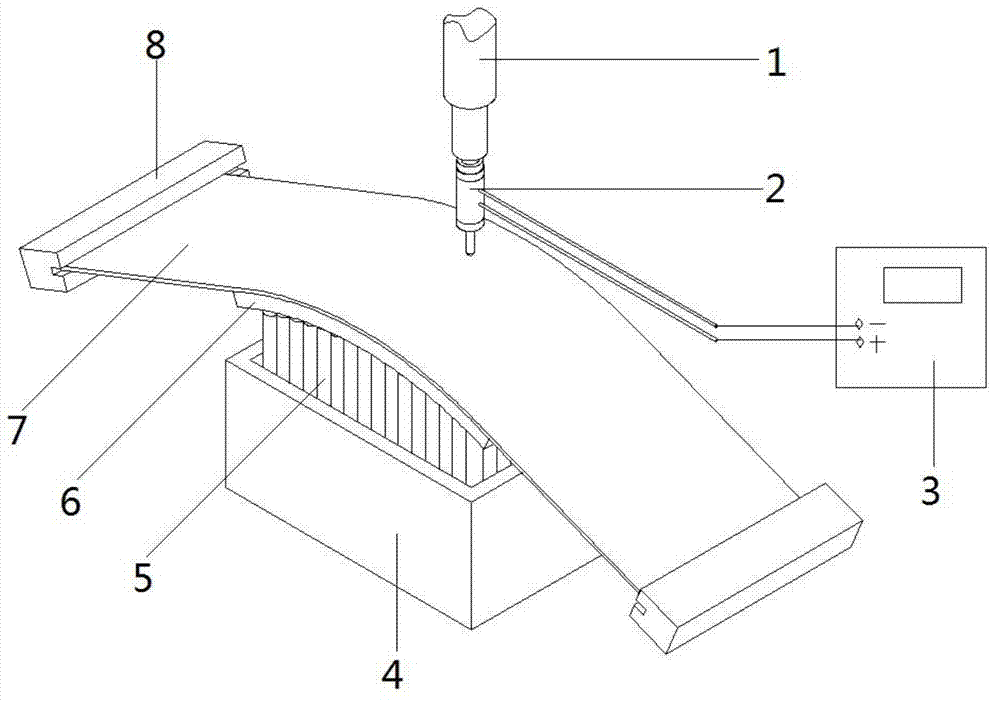

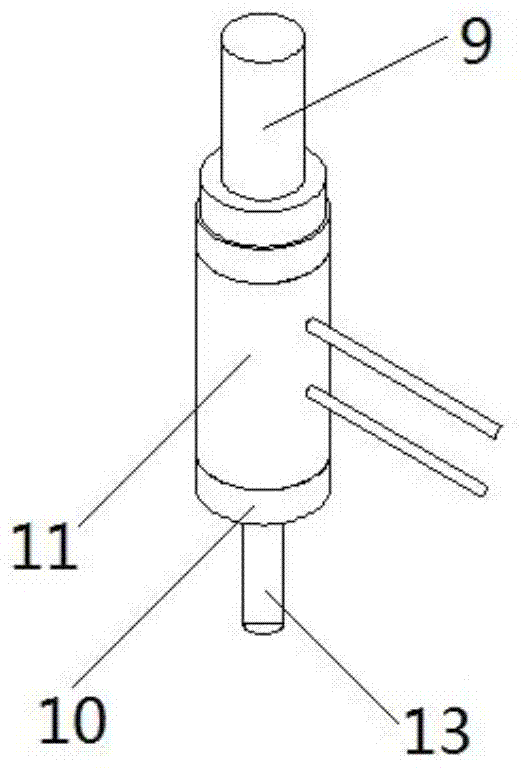

[0027] refer to figure 1 -5. This embodiment is used for electromagnetic induction heating assisted flexible drawing of 2024 aluminum alloy sheet material with a size of 2000mm×260mm and a thickness of 2mm, including an industrial robot 1 of a forming device, a heating forming head 2, a power supply 3, and a multi-point mold 4 , nail post 5, polyurethane elastic pad 6, stretching machine jaw 8 and standard parts such as bolts.

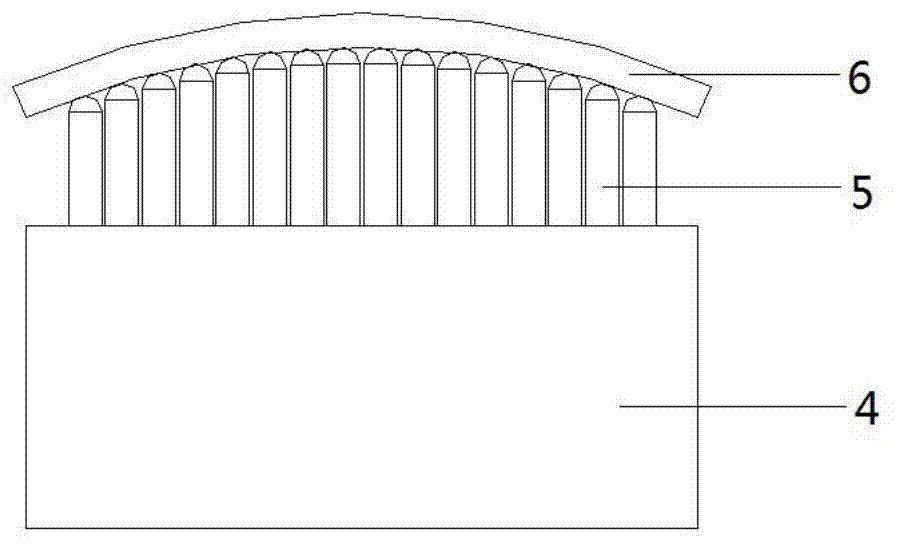

[0028] The nail column 5 of the multi-point mold is installed on the base of the multi-point mold 4, the polyurethane elastic pad 6 is positioned above the multi-point mold nail column 5, and the lower surface of the polyurethane elastic pad 6 and the nail head of the multi-point mold nail column 5 form Laying discrete curved surfaces, the sheet material 7 is located above the polyurethane elastic pad 6, the lower surface of the sheet material 7 is bonded to the upper surface of the polyurethane elastic pad 6, the jaws 8 of the drawing machine are resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com