Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Improve productivity and quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

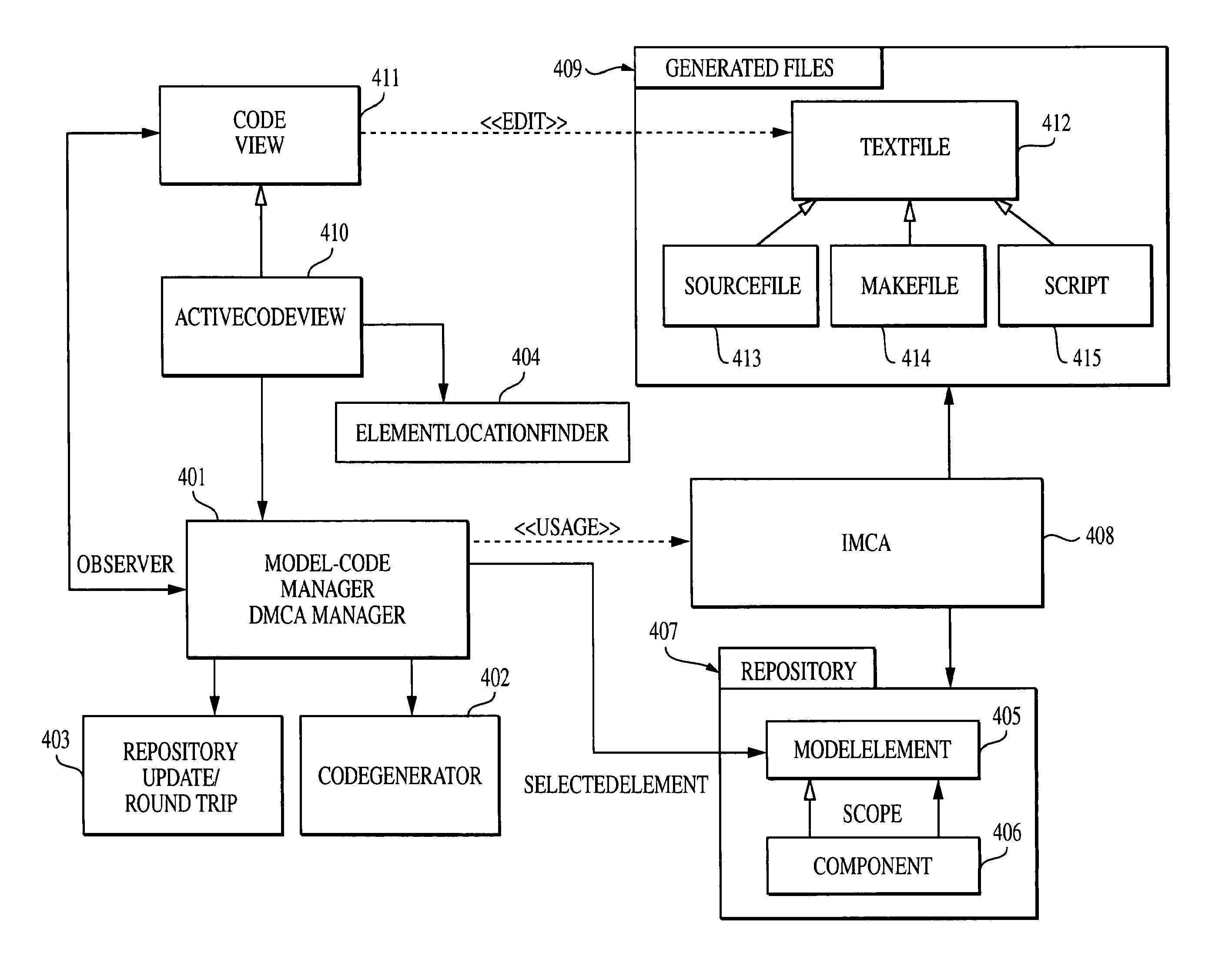

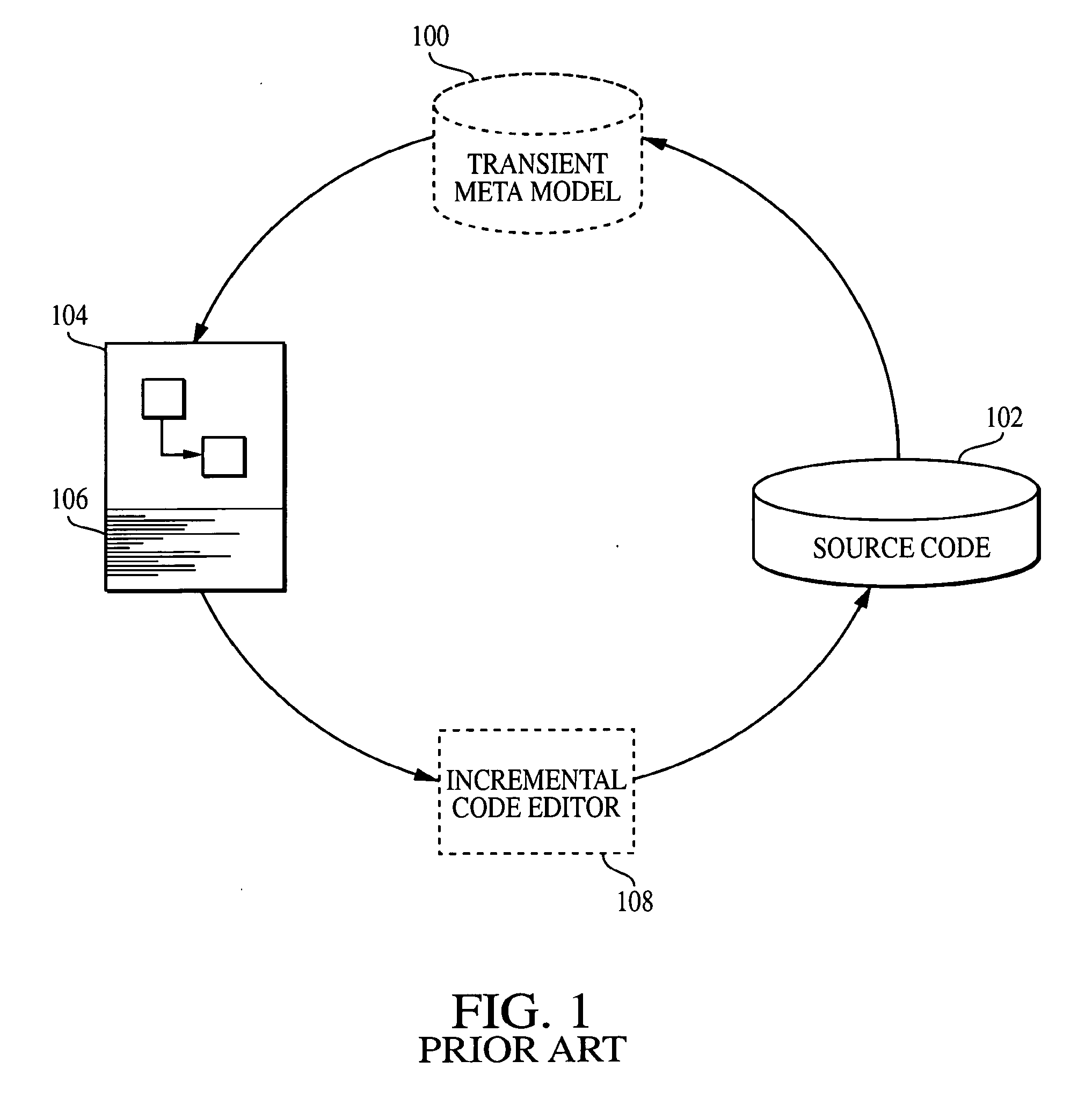

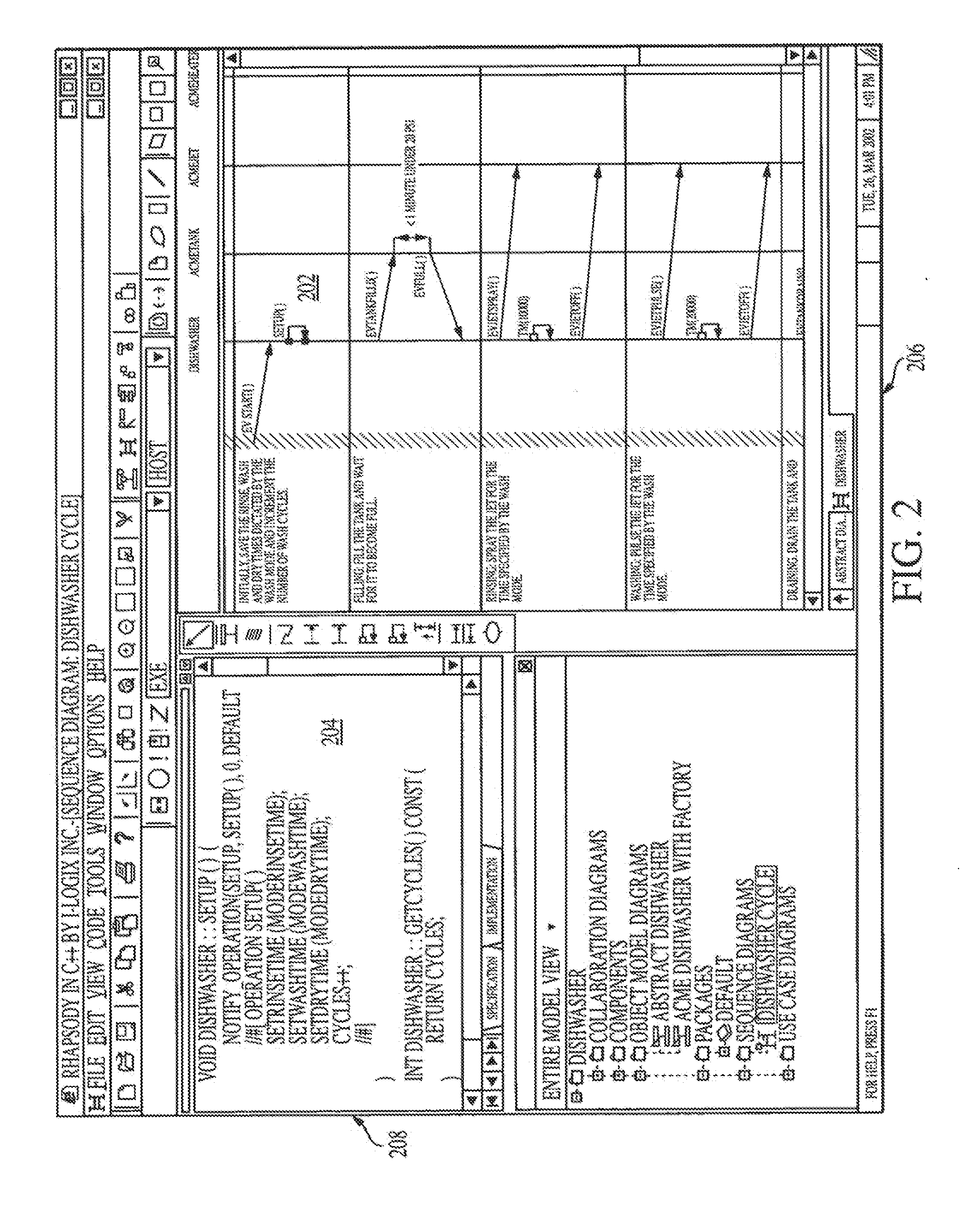

System, Method and Medium for Providing Dynamic Model-Code Associativity

InactiveUS20070209031A1Improve productivity and qualityMinimizes (or eliminates) inconsistenciesSoftware designVisual/graphical programmingDynamic modelsSource code

A system, method and medium associates source code with a plurality of elements of a model representing the source code. Portions of computer code are associated with one or more of the model elements. The source code is modified to correspond to one or more modified model elements, and at least a portion of the source code that has been modified can optionally be displayed.

Owner:TELELOGIC NORTH AMERICA

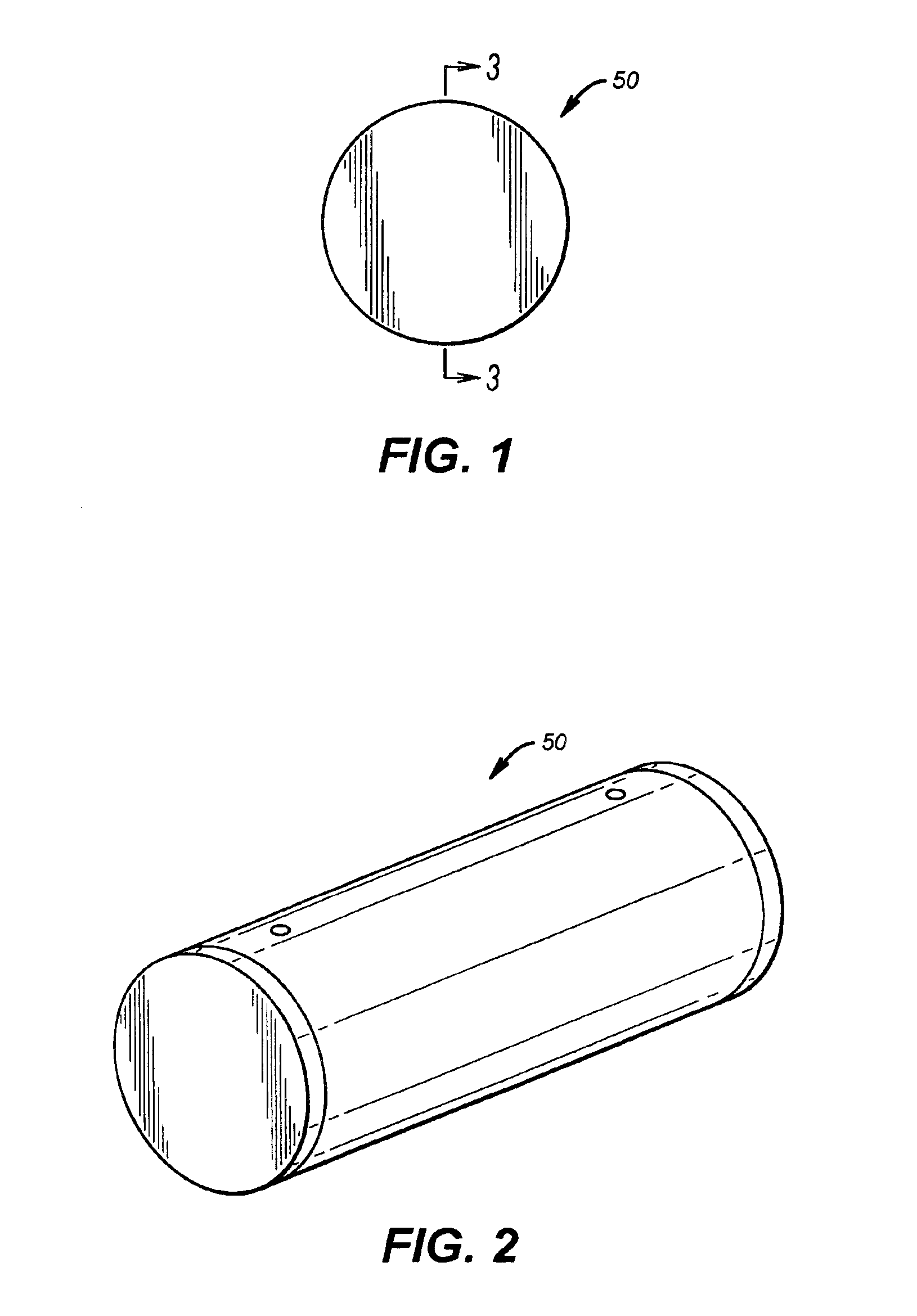

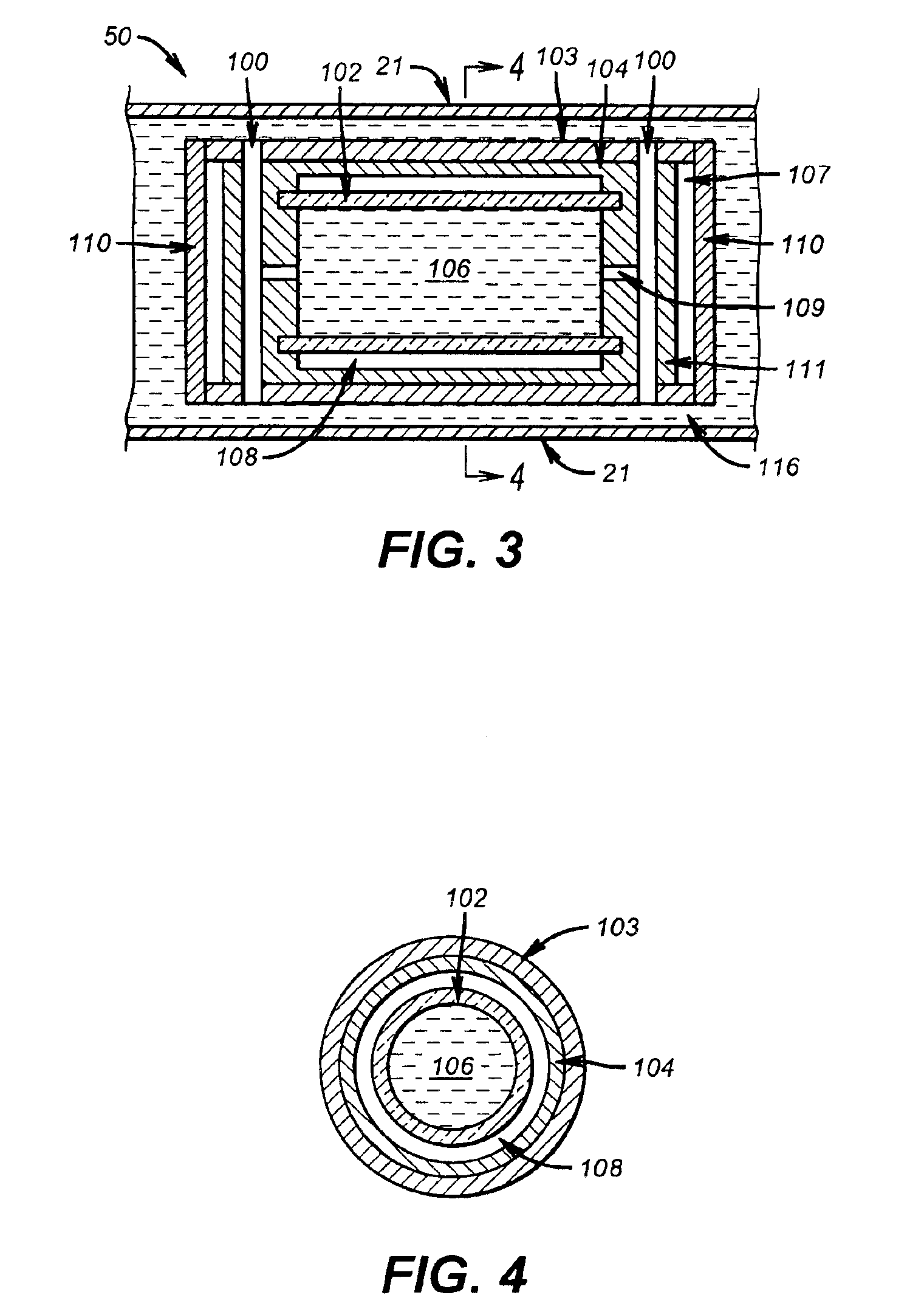

Gel-filled seismic streamer cable

InactiveUS6879546B2Improve productivity and qualitySusceptible to physical damagePiezoelectric/electrostrictive transducersSeismic signal receiversHydrophoneData acquisition

A gel-filled seismic streamer containing a hydrophone housing which isolates a hydrophone element from shear waves and mechanical forces but sensitive to pressure waves. In one embodiment, the gel-filled streamers contains a hydrophone housing with an air pocket at each end for isolating a pressure sensitive hydrophone element from mechanical noise generated by cable movement during seismic data acquisition operations. The hydrophone housing further provides and a protective case to isolate a pressure-sensitive hydrophone element from shear waves. An inlet formed in the protective hydrophone housing enables pressure waves to be communicated to the pressure sensitive hydrophone element inside of the housing. An alternative hydrophone housing for deployment inside of a streamer is also disclosed which fixably positions a positioning hydrophone or seismic hydrophone within the housing using rubber supports.

Owner:WESTERNGECO LLC

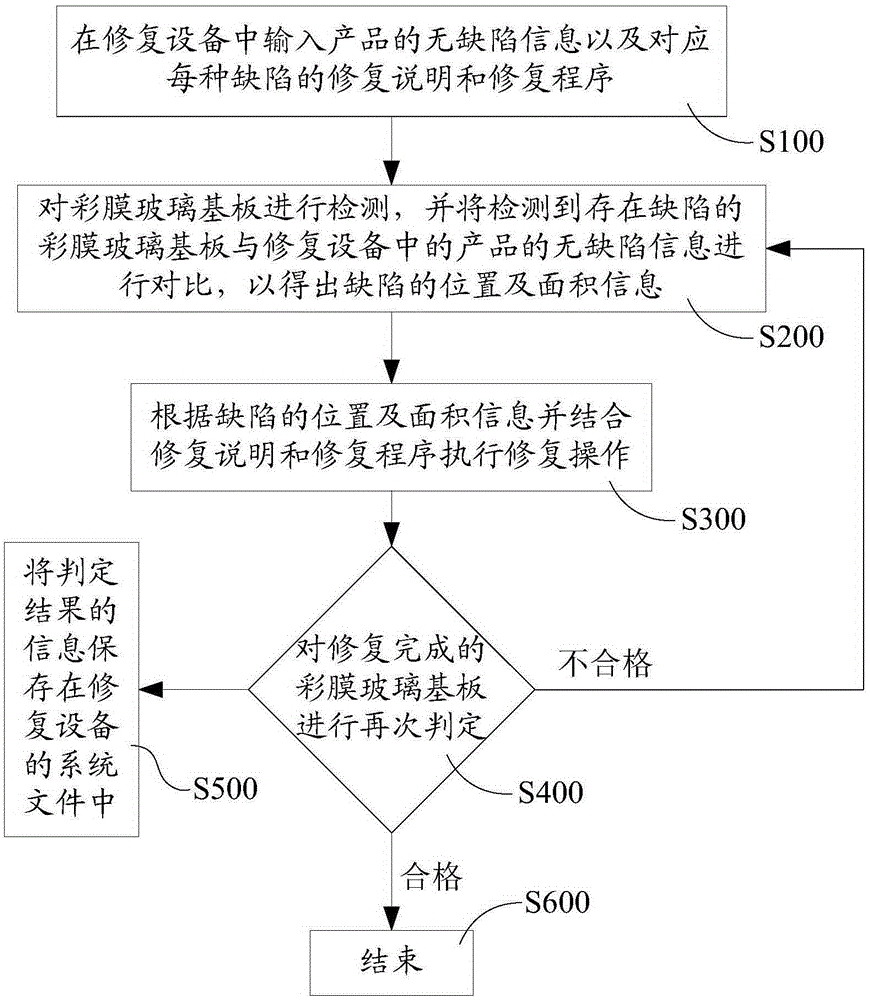

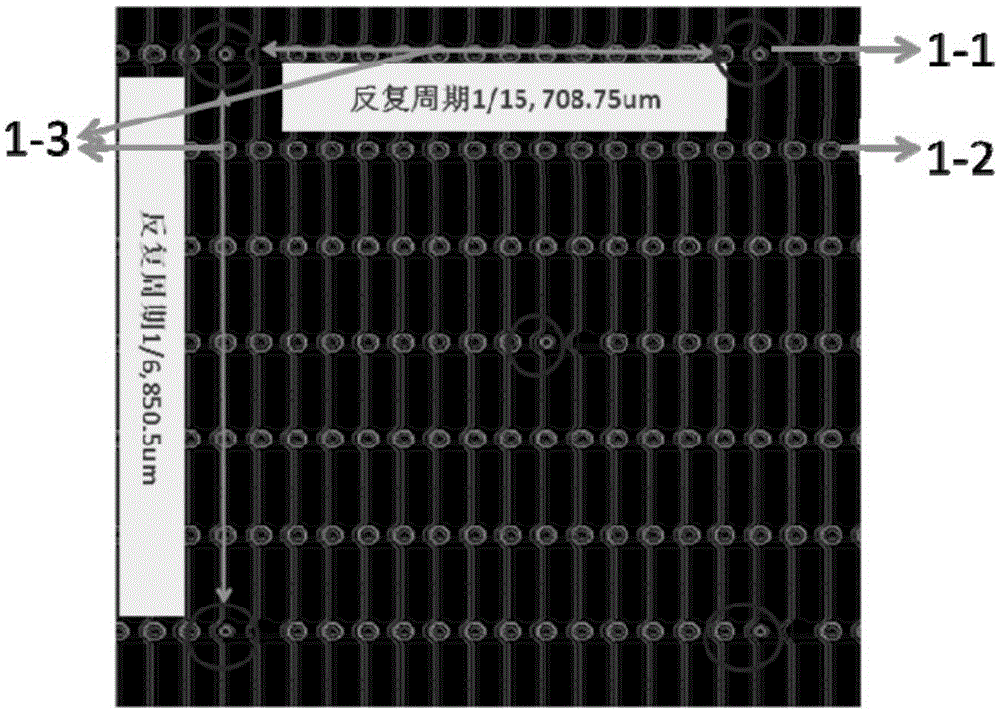

Detection and repair method and system for TFT-LCD color film glass substrates

ActiveCN105242423AReduce labor costsImprove productivity and qualityNon-linear opticsColor filmRepair method

The invention provides a detection and repair method and system for TFT-LCD color film glass substrates. The method includes the steps that zero defect information of the products and repair instructions and repair procedures corresponding to all defects are input into a repair device; the color film glass substrates are detected, and color film glass substrates detected to have defects are compared with the zero defect information, in the repair device, of the products to obtain position and area information of the defects; repair operation is performed according to the position and area information of the defects in combination with the repair instructions and the repair procedures. According to the detection and repair method and system for the TFT-LCD color film glass substrates, the TFT-LCD color film glass substrates can be automatically detected and repaired through the repair device; compared with a traditional manual detection judgment and grinding repair method, the labor cost is greatly lowered, the quality and production efficiency of the products can be improved, and the quality stability of the products can be guaranteed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

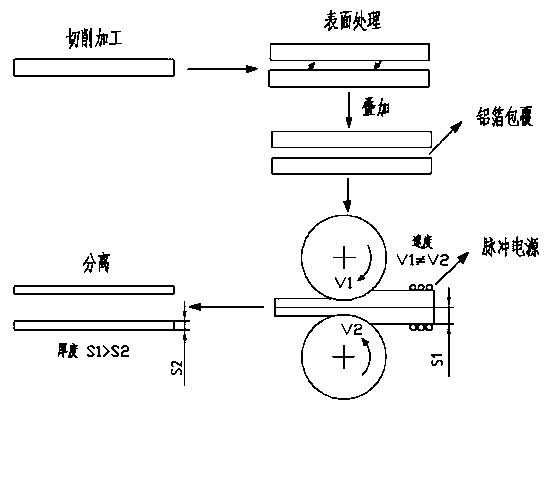

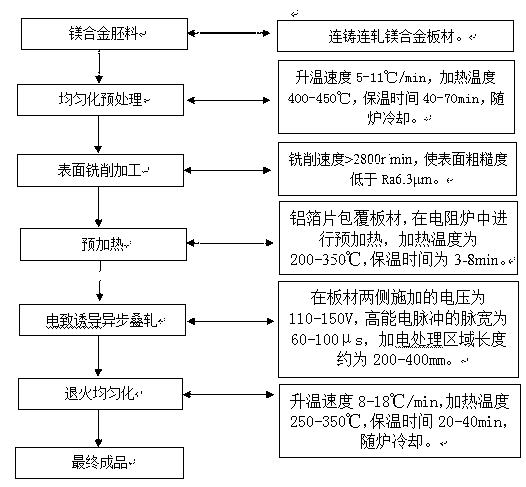

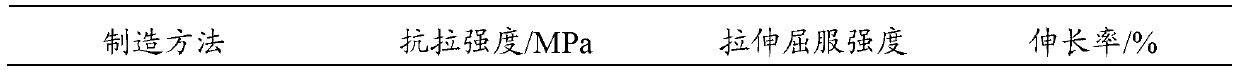

Severe plastic deformation technology of magnesium alloy board

ActiveCN103276328AImprove productivity and qualityReduce weightMetal rolling arrangementsSurface finishingMagnesium alloy

The invention relates to a severe plastic deformation technology of a magnesium alloy board. The technology comprises the following steps of: pretreating the magnesium alloy board; carrying out homogenization treatment on the magnesium alloy board; carrying out surface finishing on the magnesium alloy board; cleaning the magnesium alloy board; preheating the magnesium alloy board; carrying out pack rolling deformation on the magnesium alloy board; putting the magnesium alloy board into a rolling mill, and carrying out asynchronous pack rolling deformation on the magnesium alloy board; and carrying out annealing treatment on the magnesium alloy board. The magnesium alloy board processed by the technology has the advantages of being simple in technology, high in production efficiency, good in mechanical property and good in product quality.

Owner:UNIV OF JINAN

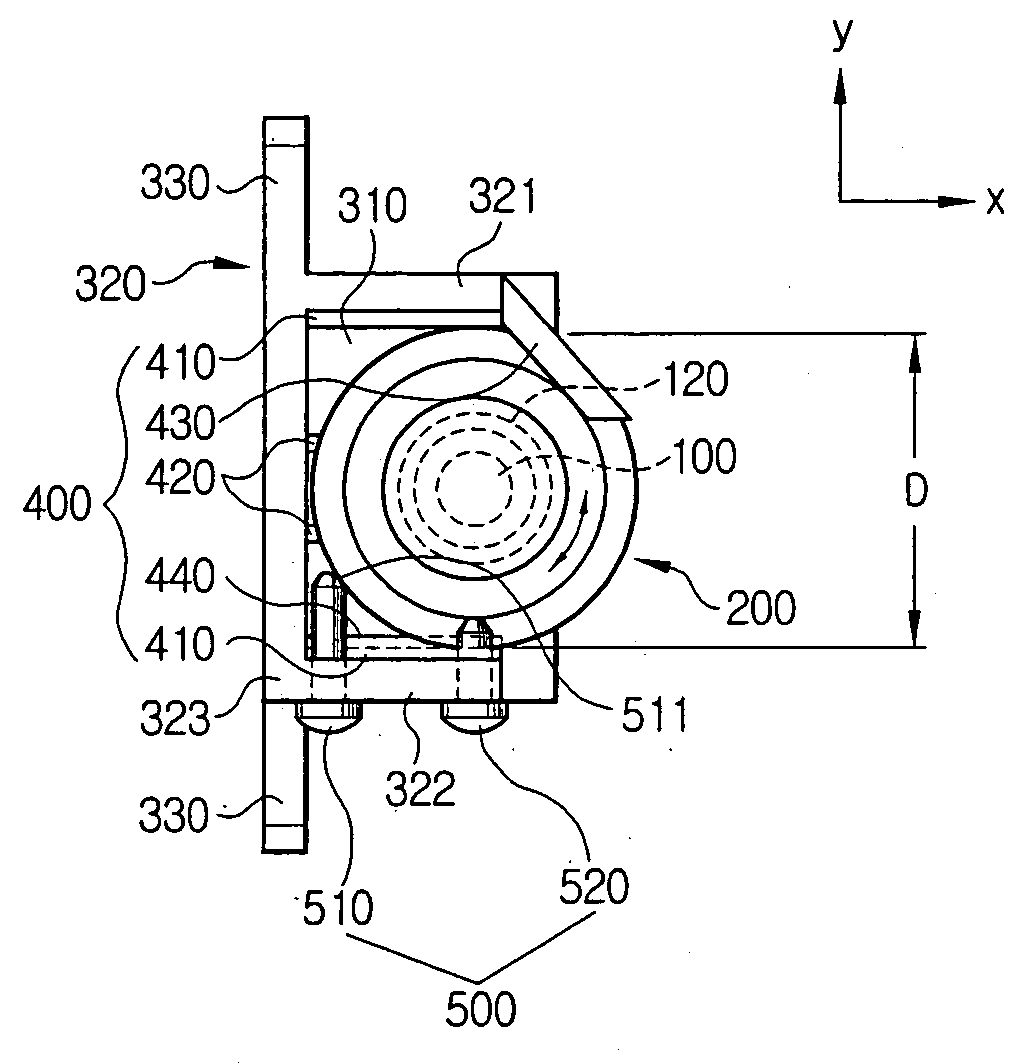

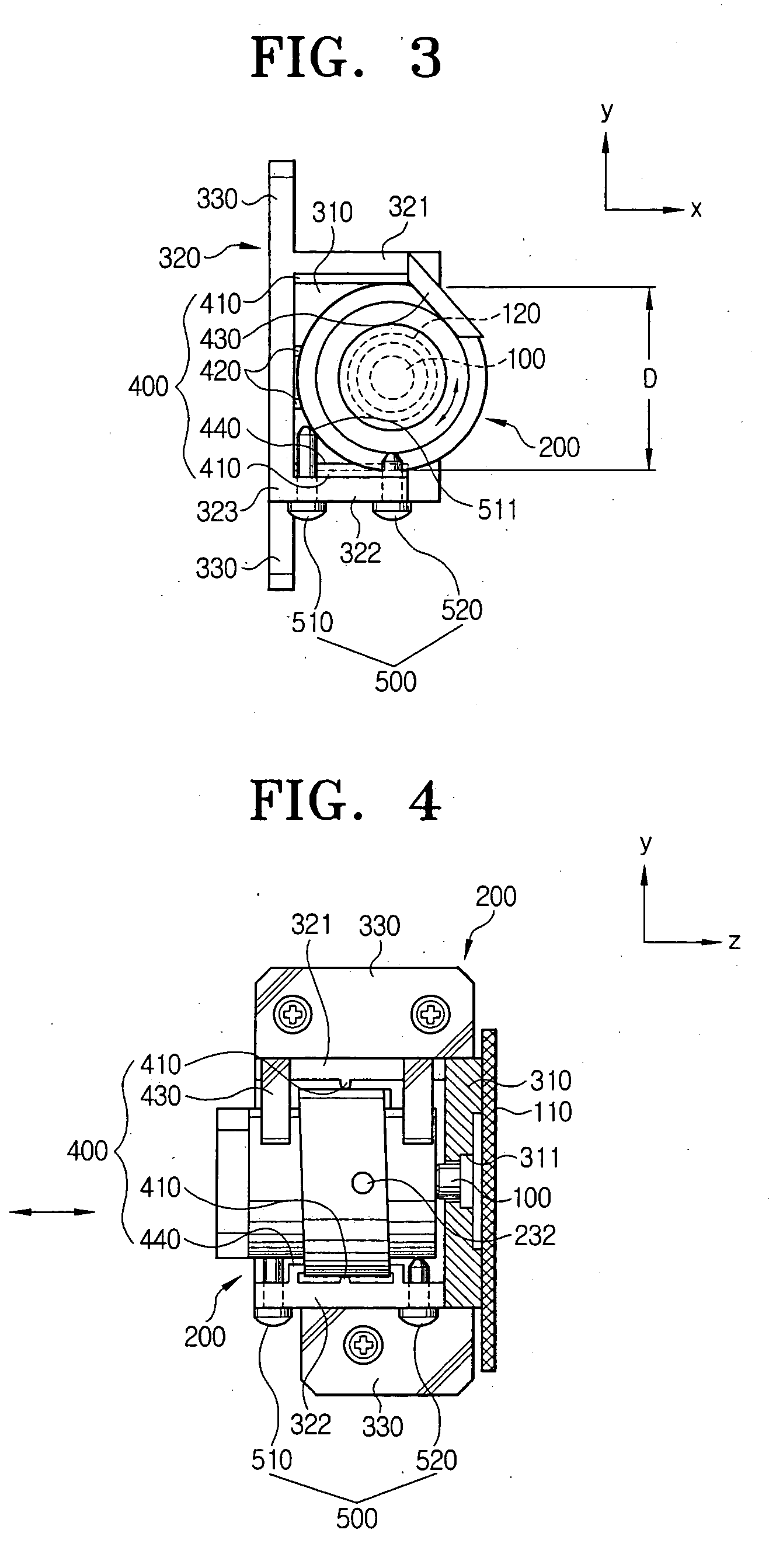

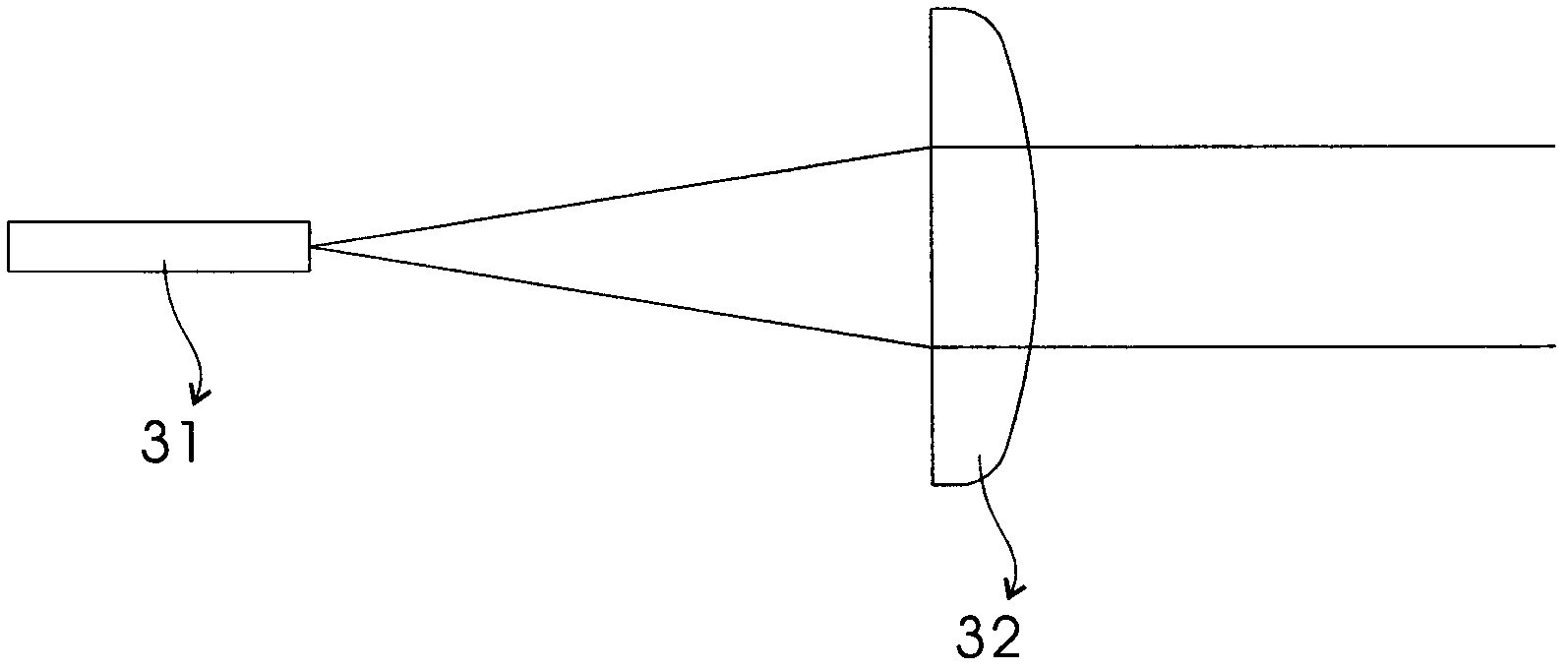

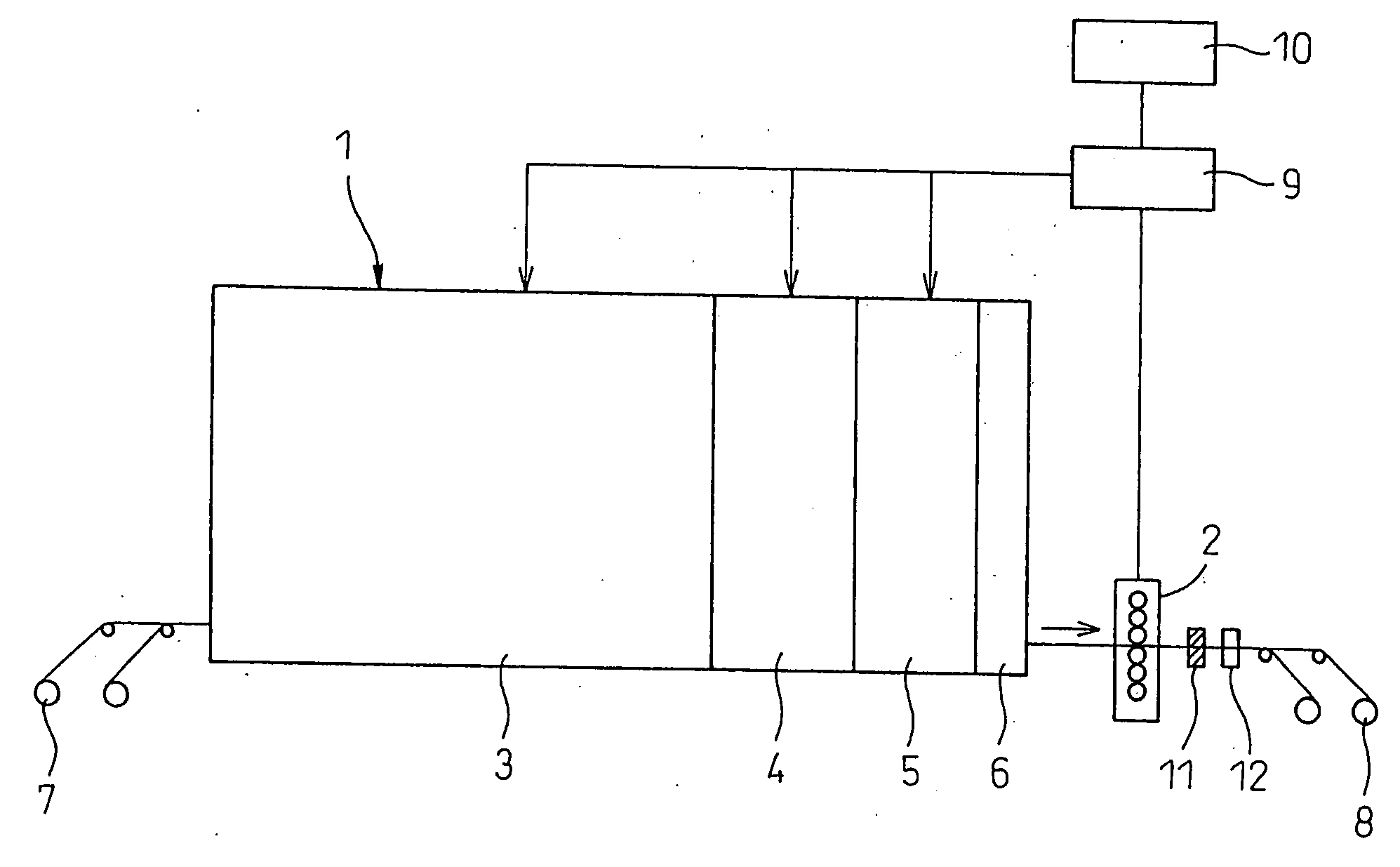

Laser beam generating apparatus for a laser scanning unit

InactiveUS20060092997A1Increase productivityQuality improvementLaser detailsElectrographic process apparatusProduction rateOptical axis

A laser beam generating apparatus of a laser scanning unit, including: a laser diode; a collimate lens for converting a laser beam emitted from the laser diode to a parallel light; a collimate lens holder for disposing the collimate lens on an optical axis of the laser beam; a base for mounting the laser diode and the collimate lens holder thereon; and a supporting means formed on the base to provisionally fix the collimate lens holder. Since a dedicated implement complements an ultraviolet (UV) bond to provisionally fix the collimate lens holder in the calibration position, assembling errors can be prevented although the UV bond changes in volume while being hardened, thereby improving productivity and quality of goods.

Owner:SAMSUNG ELECTRONICS CO LTD

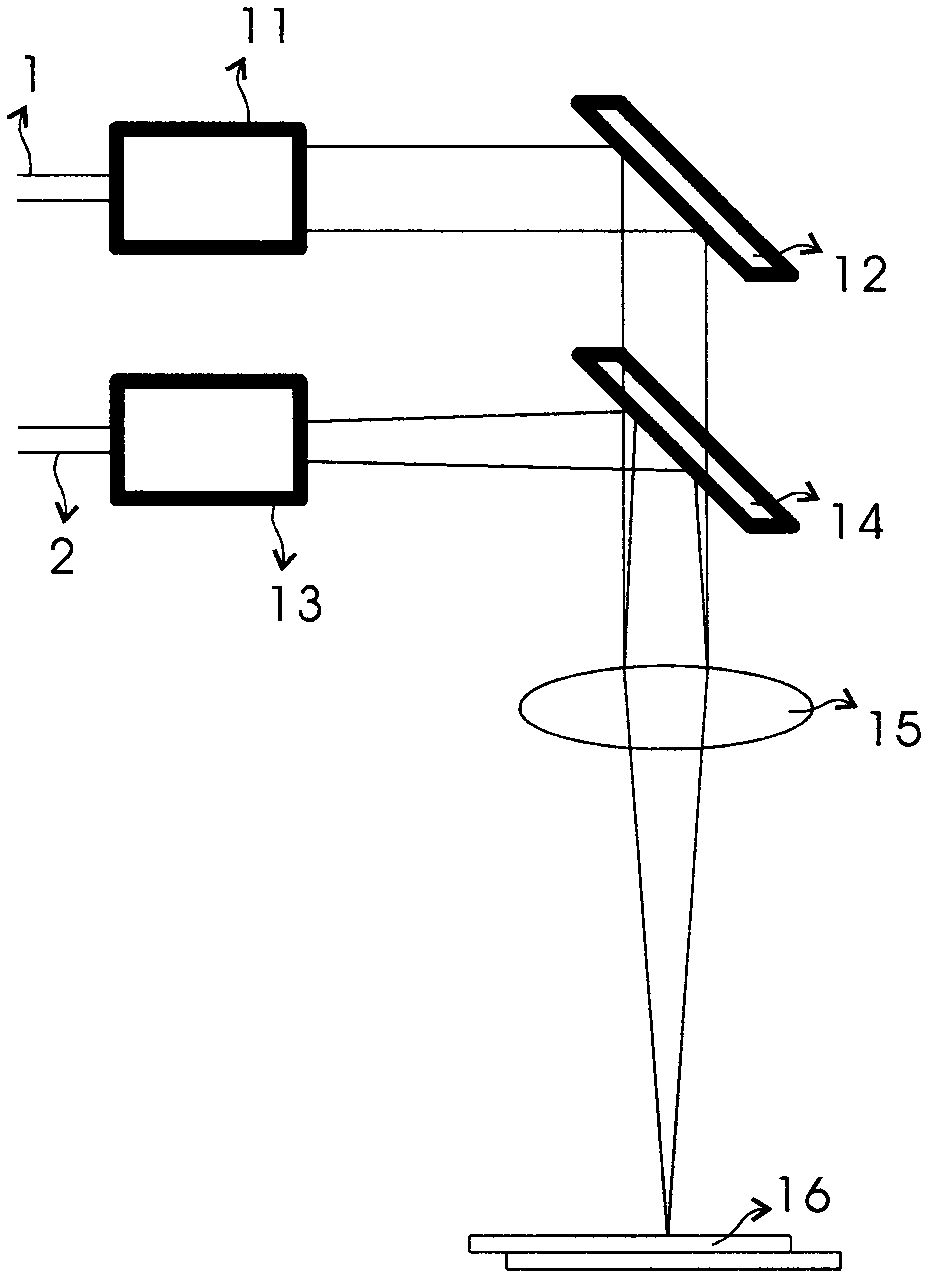

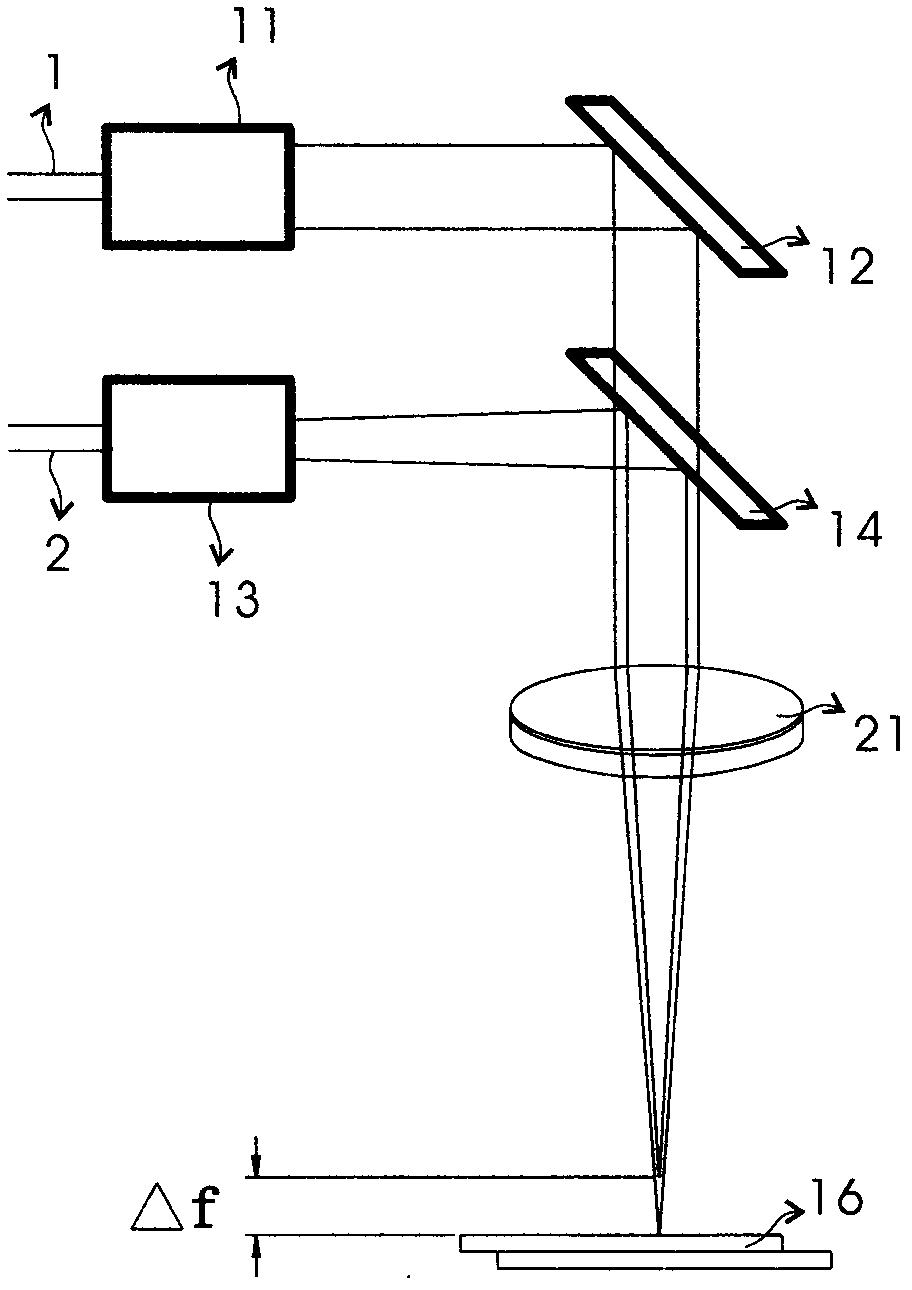

Double beam coupling device

InactiveCN102508362AImprove productivity and qualityOvercome difficultiesLaser beam welding apparatusOptical elementsPhysicsOptoelectronics

The invention discloses a double beam coupling device, which includes a collimation system used for collimating Nd:YAG laser and enabling the collimated laser beam to form a beam of parallel light, a first 45-degree reflector used for reflecting and changing the transmission direction of the Nd:YAG laser, a beam expanding system used for expanding the Nd:YAG frequency-doubled laser and obtaining light beams with different divergence angles, a second 45-degree reflector used for changing the transmission direction of the Nd:YAG frequency-doubled laser through the Nd:YAG laser and reflection, and a focusing system used for coupling and focusing the Nd:YAG laser and the Nd:YAG frequency-doubled laser to one position. The device overcomes the difficulty in welding processing by adopting the single Nd:YAG laser, and greatly improves the welding efficiency and the welding quality.

Owner:SHENZHEN GDLASER TECH CO LTD

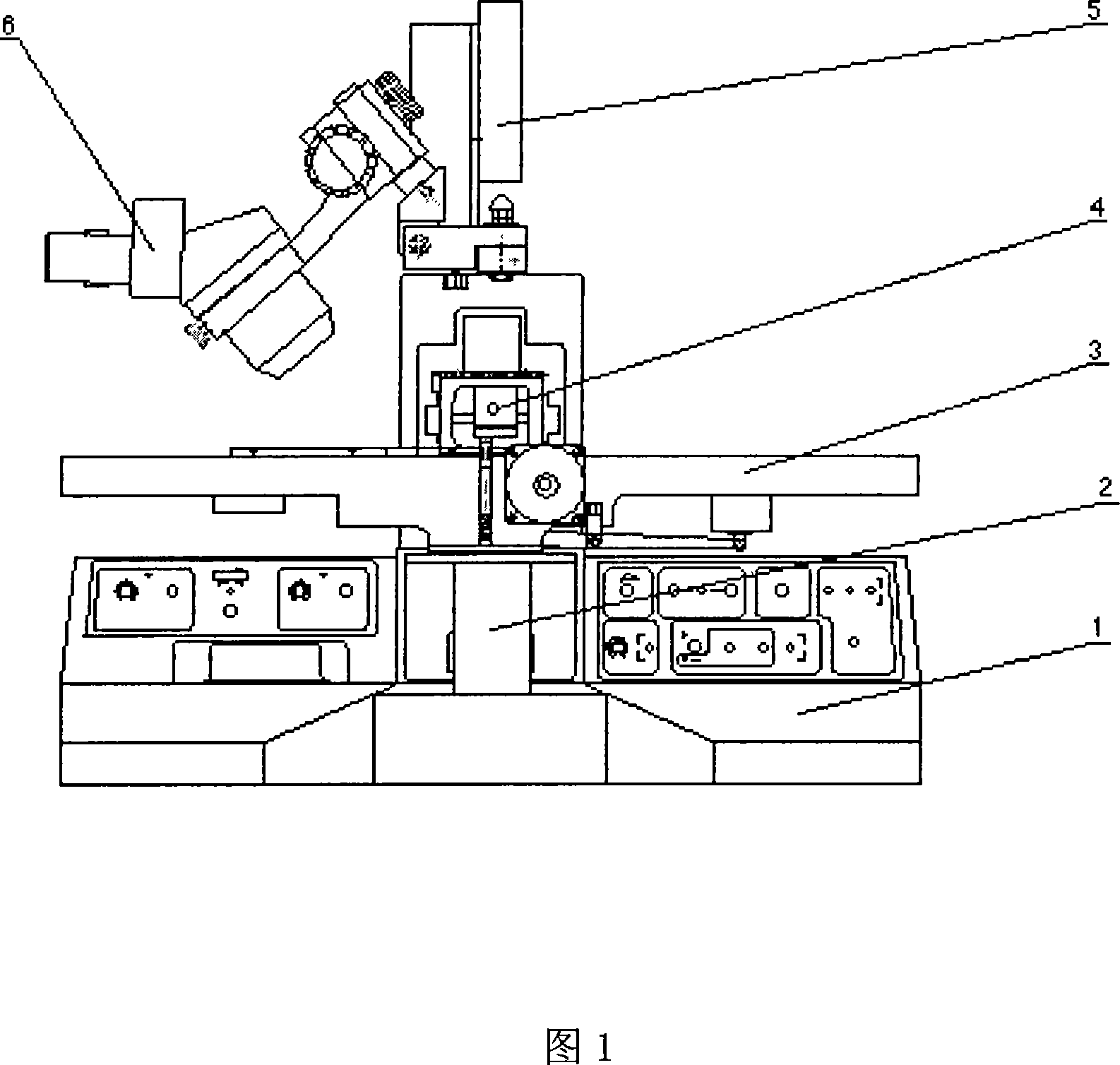

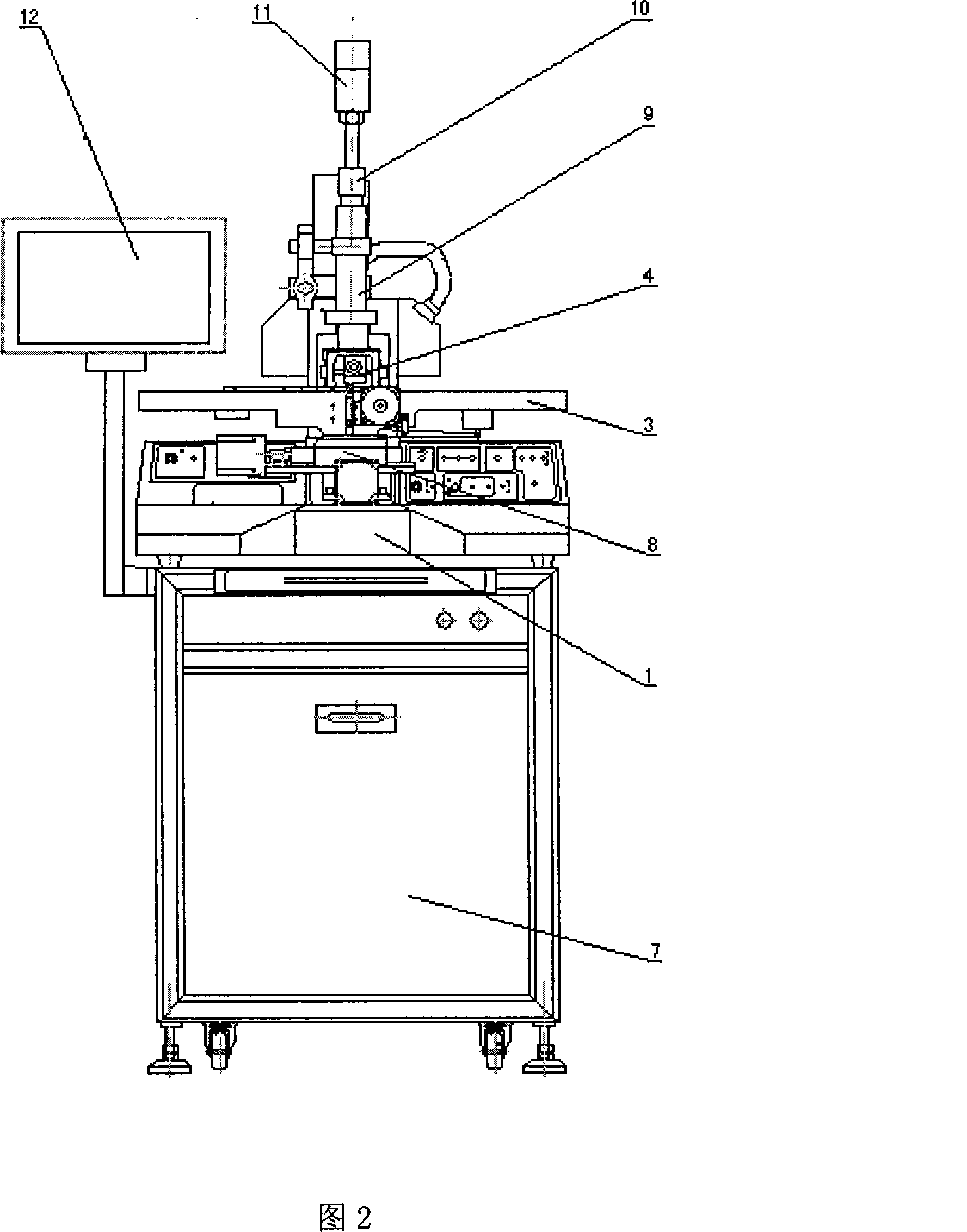

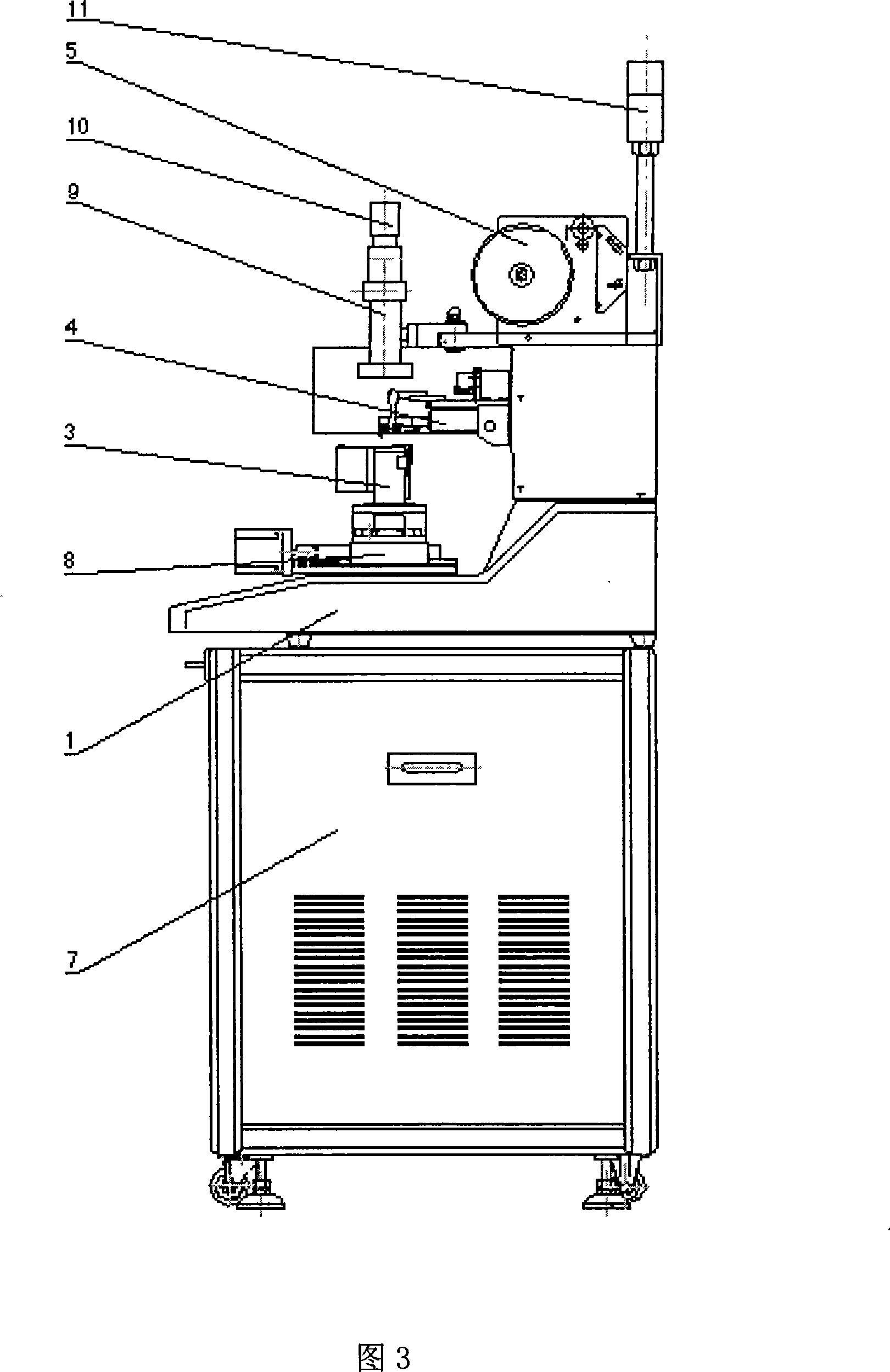

An automatic operation system of inner leading bonding device of semiconductor device

InactiveCN101217125AImprove productivity and qualityEnsure Stability and ConsistencySolid-state devicesSemiconductor/solid-state device manufacturingAutomatic controlMovement control

The invention relates to an automatic operating system of welding equipment of lead wires in a semiconductor device, which pertains to the improvement of microelectronic encapsulation equipment from manual to automatic operation. The invention removes a clamp base, a microscope and increases an X-Y two-dimensional electric control platform, a lens, a CCD, a main case, a warning light and a display on the basis of an original manual machine table, the automatic displacement of a clamp or a welding head is realized by the X-Y two-dimensional electric control platform and a step motion control card in the main case, the CCD, the lens and an image collection card in the main case are arranged above the welding head to realize the automatic identification of the chip, and the automatic control of the welding is realized by a main control computer in the main case, so as to become the equipment for automatic welding. The invention can improve the product quality and the production efficiency, ensure the consistency and stability of the welding wires, save the human resources and reduce the labor intensity. The invention can greatly improve the application range and using value of a welding wire machine. The invention is high-tech microelectronic production equipment which integrates precision machinery, automatic control, image identification, computer application, ultrasonic welding and other various fields.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI +1

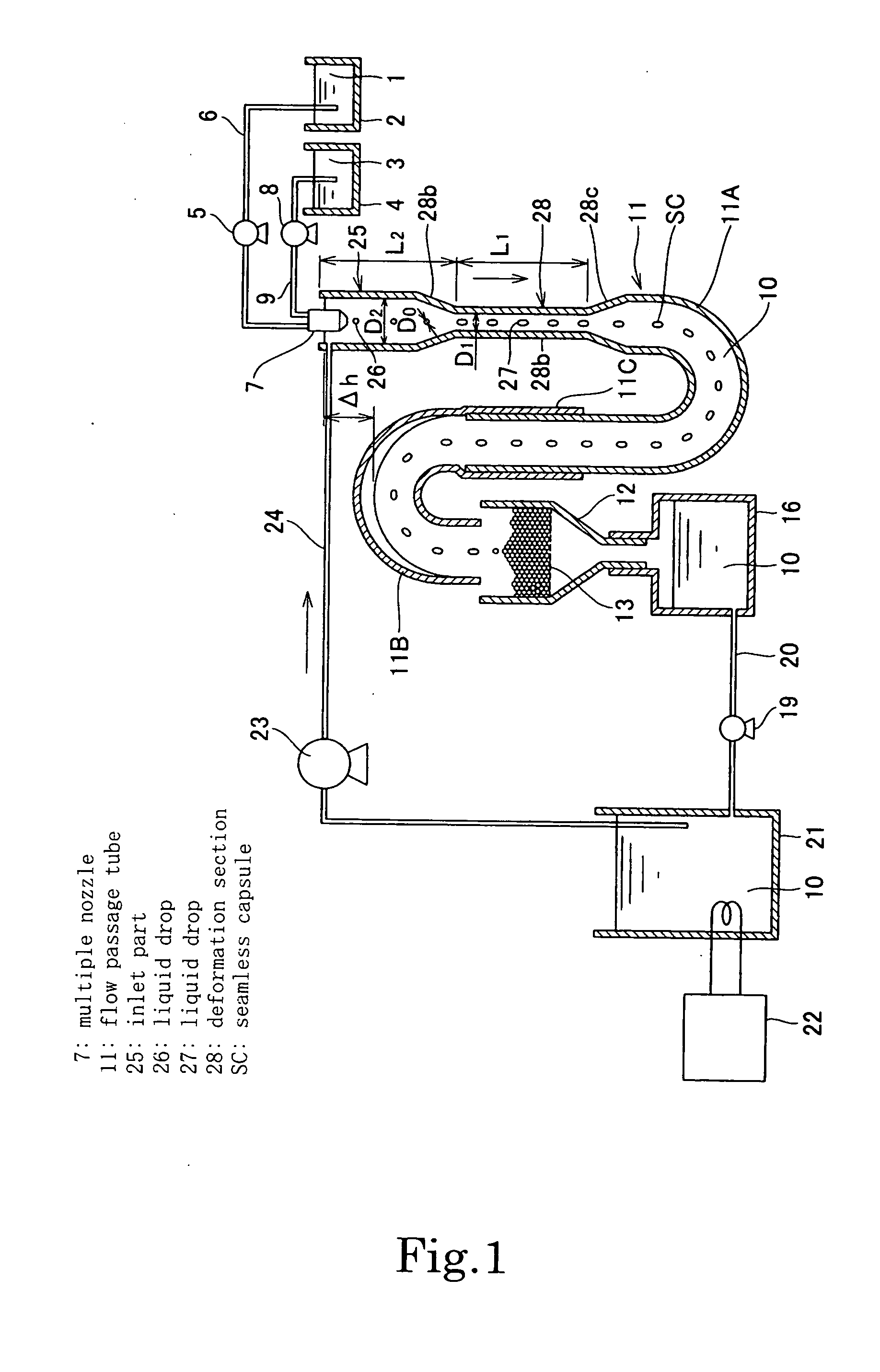

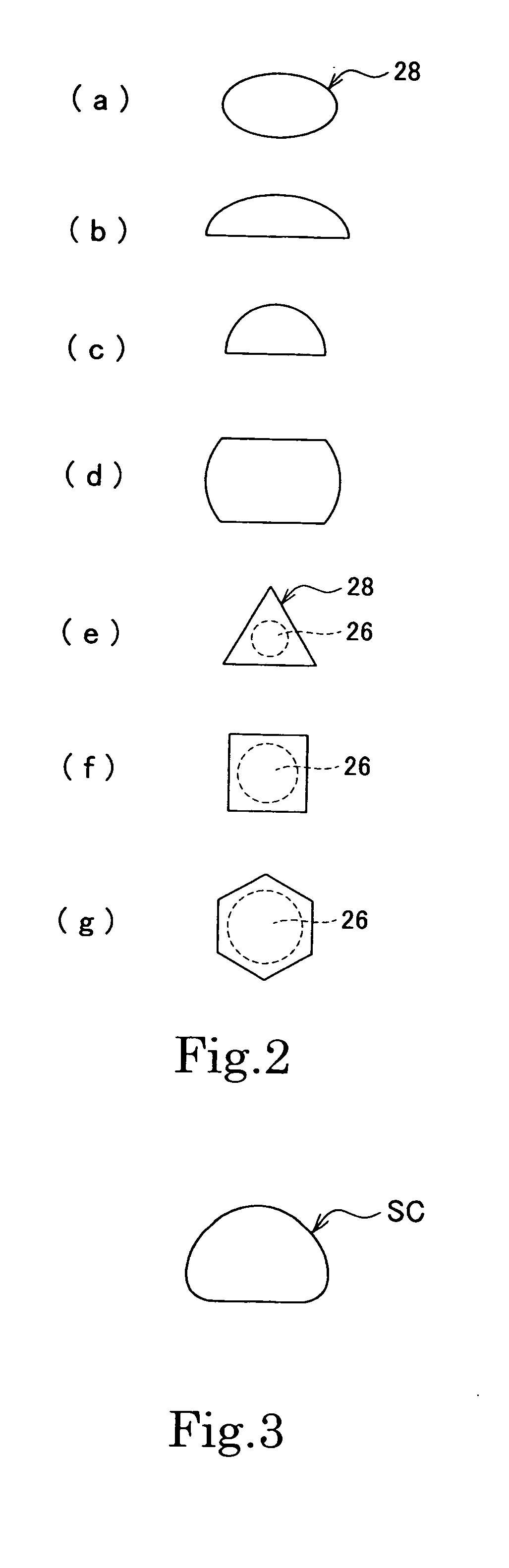

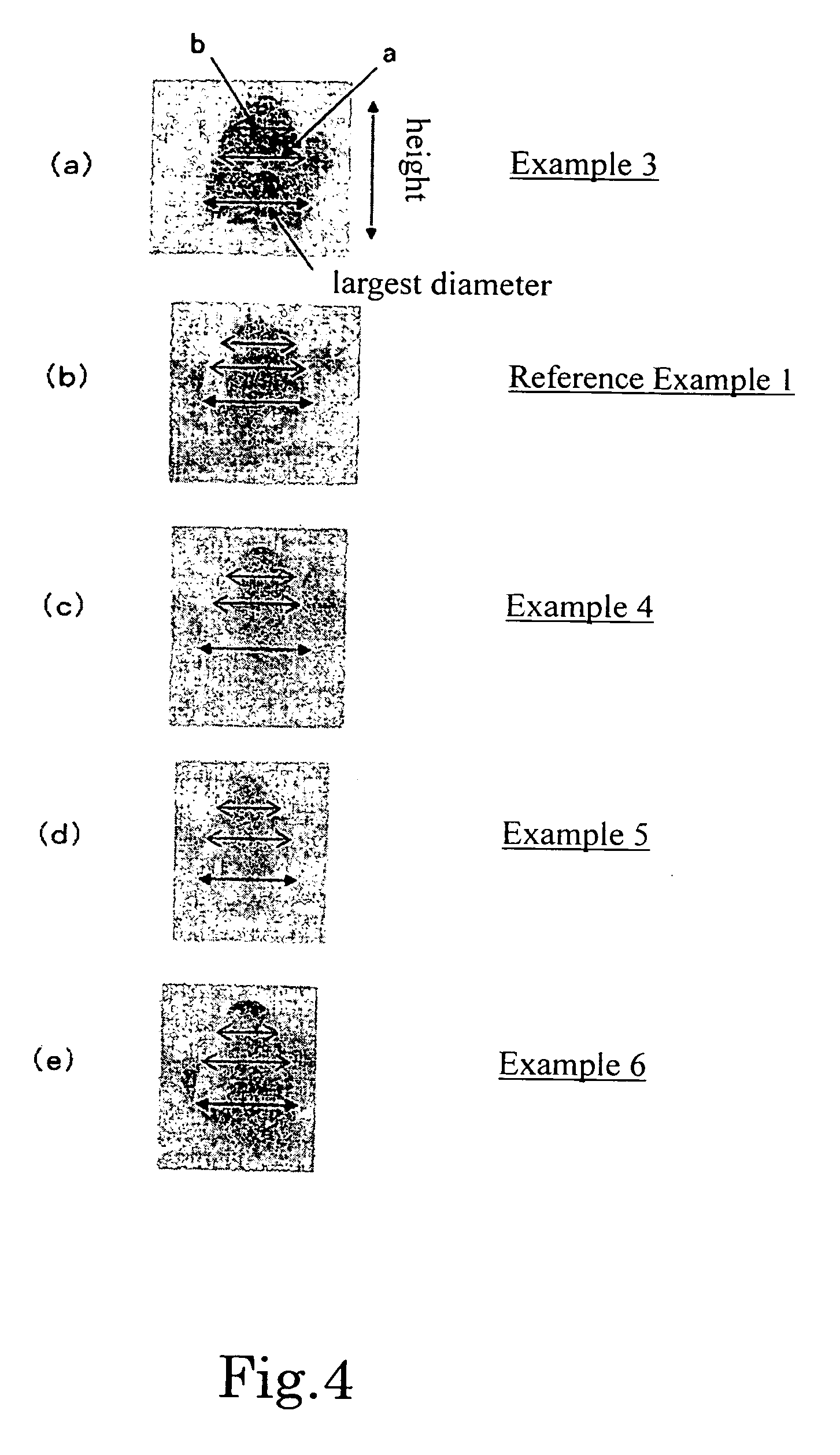

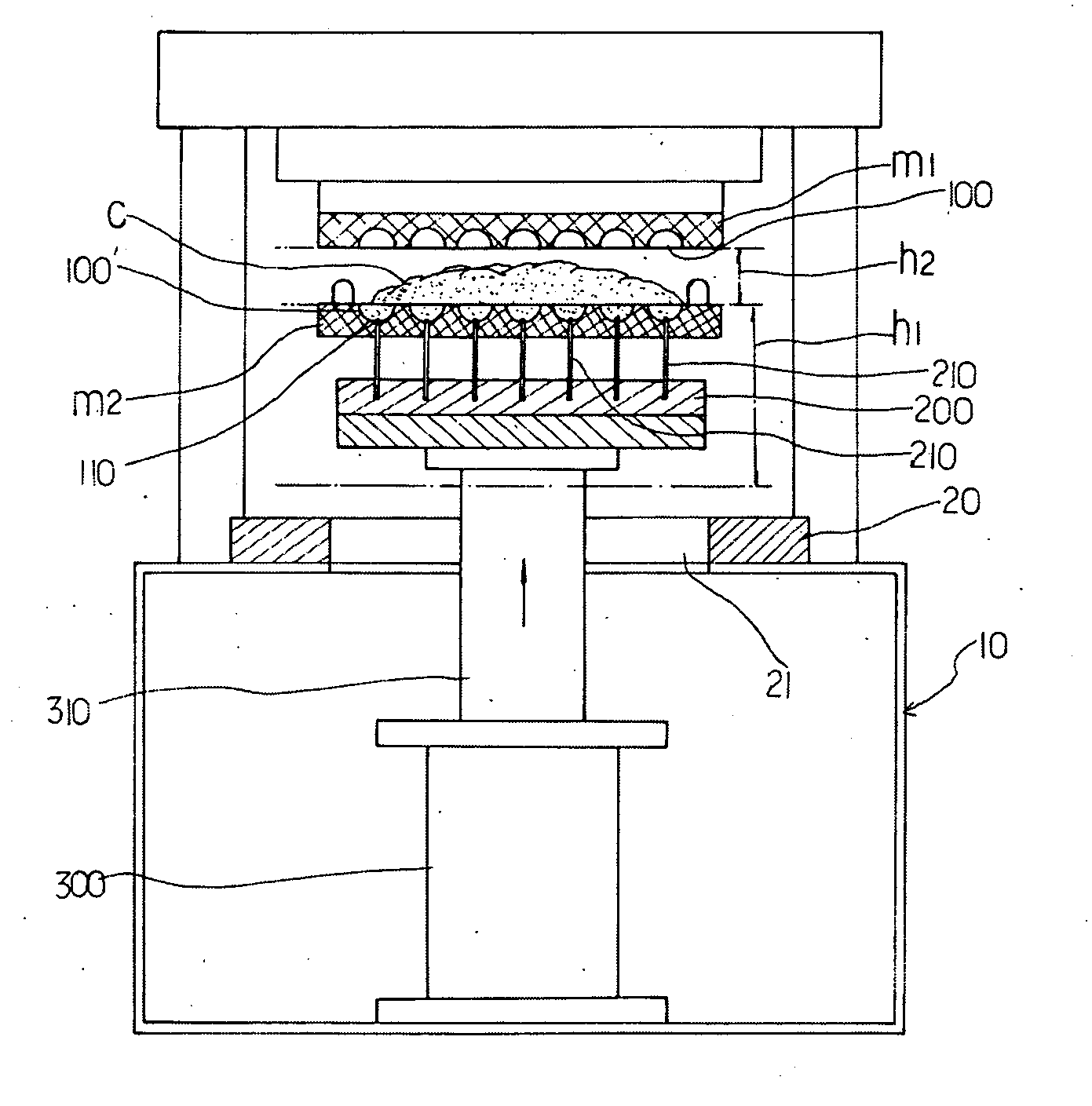

Seamless capsule manufacturing method, seamless capsule manufacturing device and seamless capsule

InactiveUS20070082045A1Improve productivity and qualityQuality improvementGranulation by liquid drop formationCapsule deliveryProduction rateEngineering

A seamless capsule manufacturing device comprises a multiple nozzle 7 for ejecting liquid drops into hardening liquid 10 and a flow passage tube 11 for containing hardening liquid 10. The flow passage tube 11 has a deformation section 28 that includes an inlet part 25 and a formation tube part 28b showing a cross sectional area smaller than the inlet part 25. The liquid drops ejected from the multiple nozzle 7 into the hardening liquid 10 are once made to become spherical liquid drops 26 in a sol state at the inlet part 25. The liquid drops 26b are introduced from the inlet part 25 into the deformation section 28 while they are still in a sol state. As hardening liquid 10 is introduced from the inlet part 25 into the formation tube part 28b, its flow rate is changed and the liquid drops 26 are deformed due to the change in the flow rate to produce nonspherical seamless capsules SC. With this arrangement, it is possible to provide a method and a device for manufacturing high quality nonspherical seamless capsules with an enhanced level of productivity without requiring cumbersome parameter defining operations and delicate control operations.

Owner:FREUNT IND

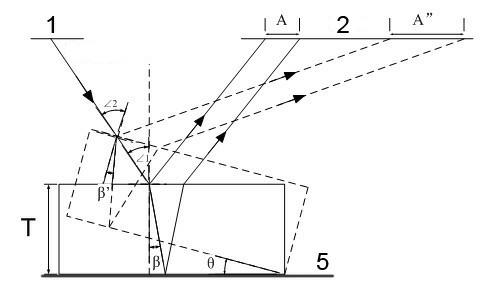

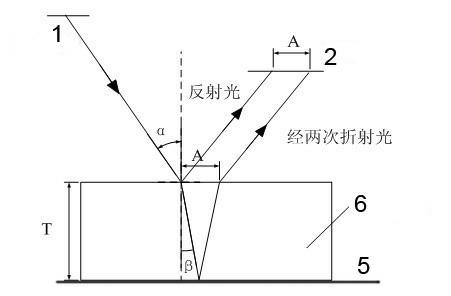

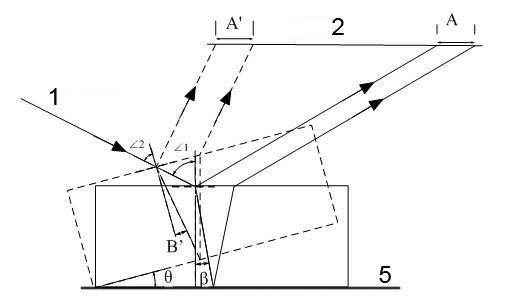

Method for measuring thickness of rigid transparent material with laser

InactiveCN102095381AImprove productivity and qualityAccurate measurementUsing optical meansPhysicsImage analysis

The invention provides a method for measuring the thickness of a rigid transparent material with laser. The method comprises the following steps of: 1) adjusting the position of a laser source and a vertical distance from the laser source to a roll gang, and adjusting the horizontal and the vertical distances between the laser source and a sensor so that light spots can be generated on the sensor after the laser illuminates a material to be measured; 2) when the material to be measured passes through a measuring system, detecting that the material to be measured is in a thickness measurement state, by the sensor; 3) after the laser source emits laser beams to illuminate the material to be measured, forming ribbon-shape light spots on the sensor after optical conduction, collecting a light spot image by an image acquisition card, and transmitting the image to a processor for image analysis; and 4) analyzing the light spot image on the sensor by the processor to obtain the width A of the light spots, and calculating the thickness of the measured material according to the following calculation formula in the specification. In the invention, the thickness of the measured material can be measured accurately without stopping of the production process, the measured material can not be damaged due to adoption of a contactless measurement method, and the quality of the product and the production efficiency are improved.

Owner:GUANGDONG FUSHAN GLASS MACHINERY +1

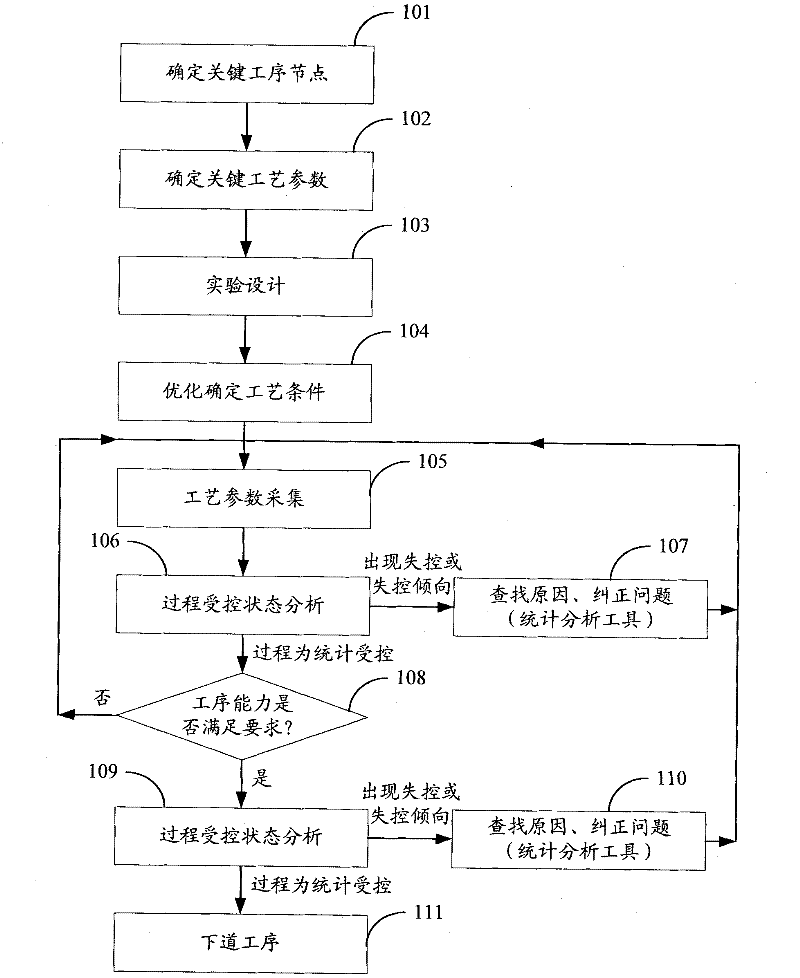

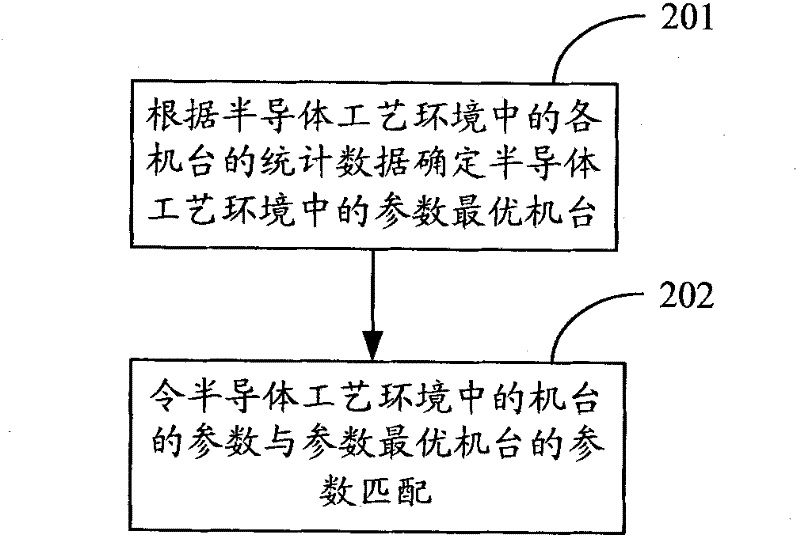

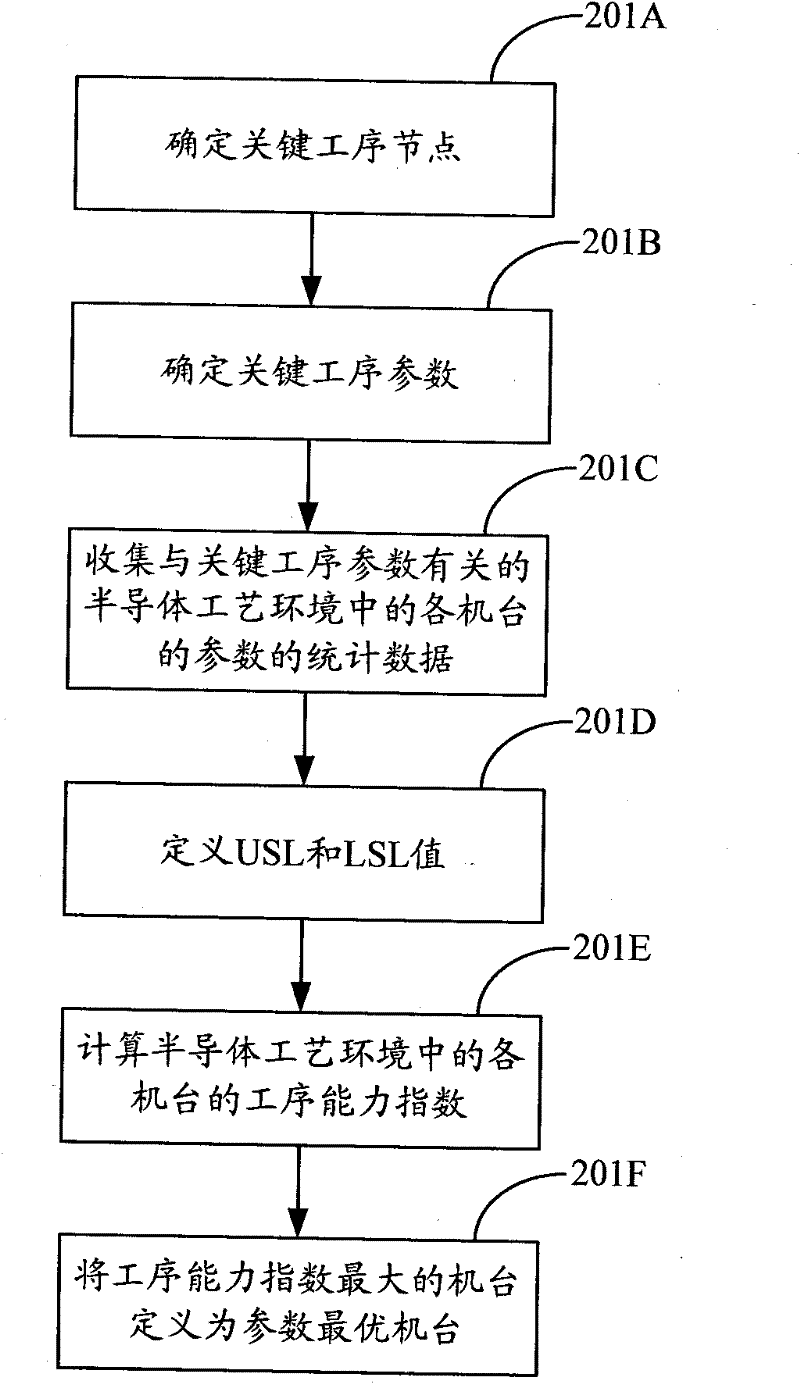

Method for optimally adjusting console parameters in semiconductor technology

ActiveCN102194655AImprove productivity and qualityReduce manufacturing costSemiconductor/solid-state device manufacturingSemiconductorSemiconductor technology

The invention discloses a method for optimally adjusting console parameters in a semiconductor technology. The method comprises the following steps of: according to statistic data of parameters of each console in a semiconductor technical environment, determining the console with the optimal parameters in the semiconductor technical environment; and enabling the parameters of the consoles in the semiconductor technical environment to match the parameters of the console with the optimal parameters. By the method, the problem that in the prior art, the console with the optimal parameters in thesemiconductor technical environment cannot be effectively and reliably searched and determined is effectively solved; and by searching and determining the console with the optimal parameters in the semiconductor technical environment effectively and reliably and regulating the parameters of the other consoles in the semiconductor technical environment according to the parameters of the console with the optimal parameters and a matching and determining standard, the quality of the produced product and the production efficiency are greatly improved and the production cost is greatly reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

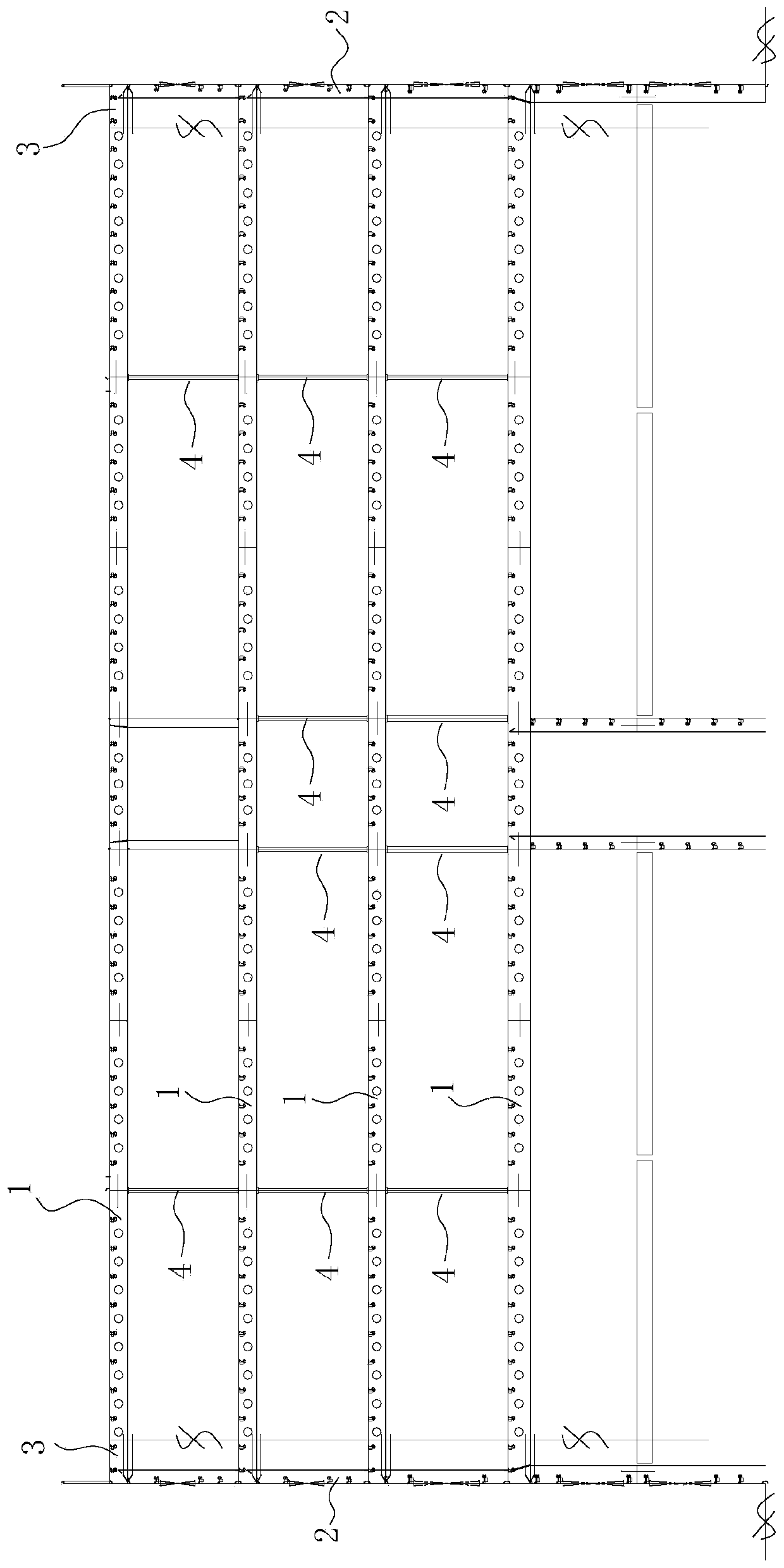

Manufacturing method for superstructure block of roll-on-roll passenger ship

InactiveCN109850067AImprove productivity and qualityShorten the timeVessel partsAssembly lineMarine engineering

The invention discloses a manufacturing method for a superstructure block of a roll-on-roll passenger ship. The method includes that following steps: step S100, dividing the superstructure block intoa plurality of deck subblocks and outer plate subblocks on both left and right sides; step S200, manufacturing the deck subblocks, providing plates required for the deck subblocks, carrying out automatic marking, assembling and cutting the remaining amount on the plates on a thin plate plane subblock assembly line, to form a deck surface at one time, and installing longitudinal bones and T-shapedmaterials on the deck surface, to form the deck subblocks; step S300, manufacturing the outer plate subblocks, providing plates required for the outer plate subblocks, carrying out automatic marking,assembling and cutting the remaining amount on the plates on the thin plate plane subblock assembly line, to form the outer plates at one time, and installing longitudinal bones and T-shaped materialson the outer plates, to form the outer plate subblocks; step S400: lifting the deck subblocks in the middle from bottom to top in the assembly stage of the superstructure block, and then lifting theouter plate subblocks on the left and right sides. Each subblock of the superstructure block of the roll-on-roll passenger ship is simple to manufacture, reasonable in subblock division and short in construction period.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

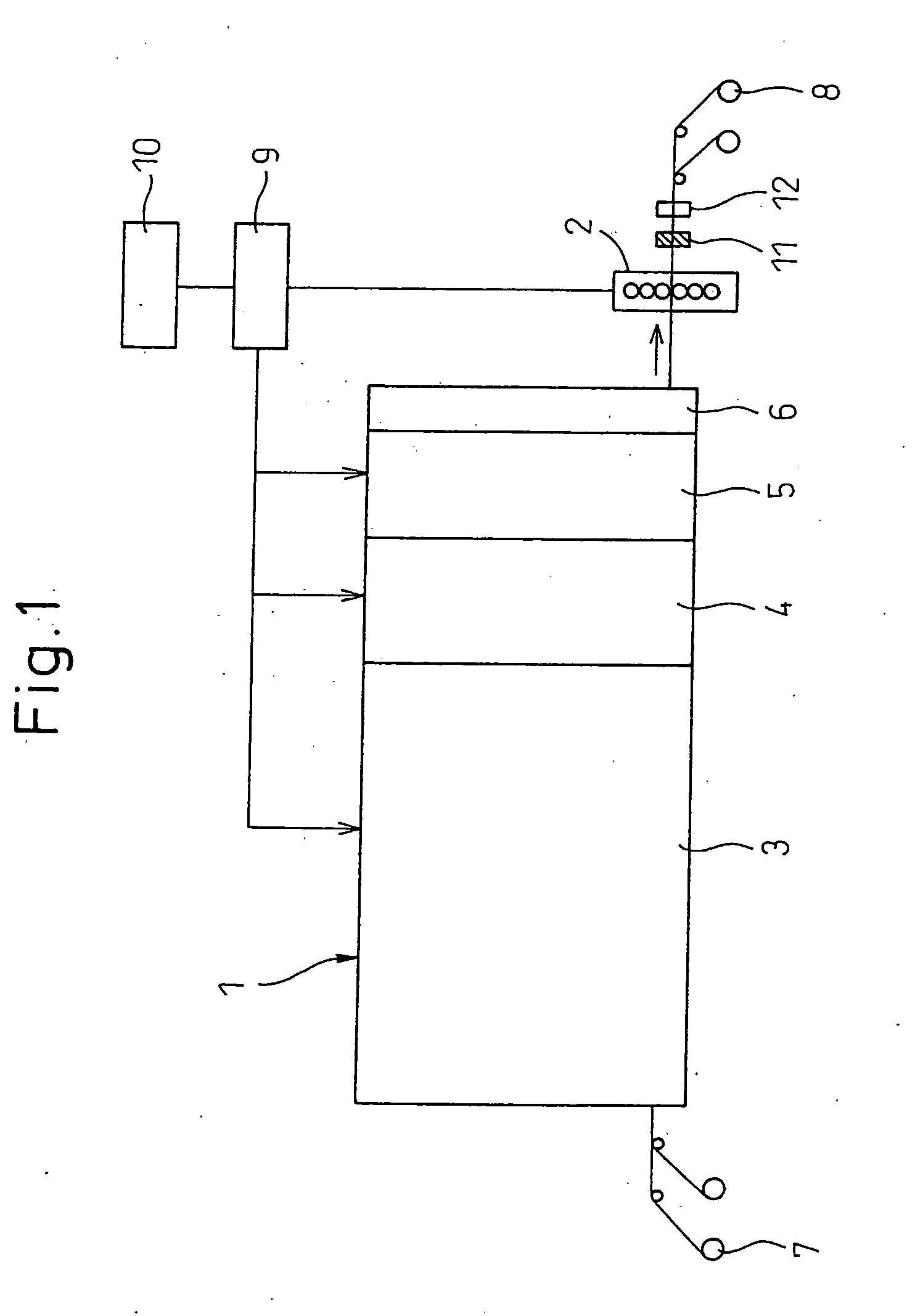

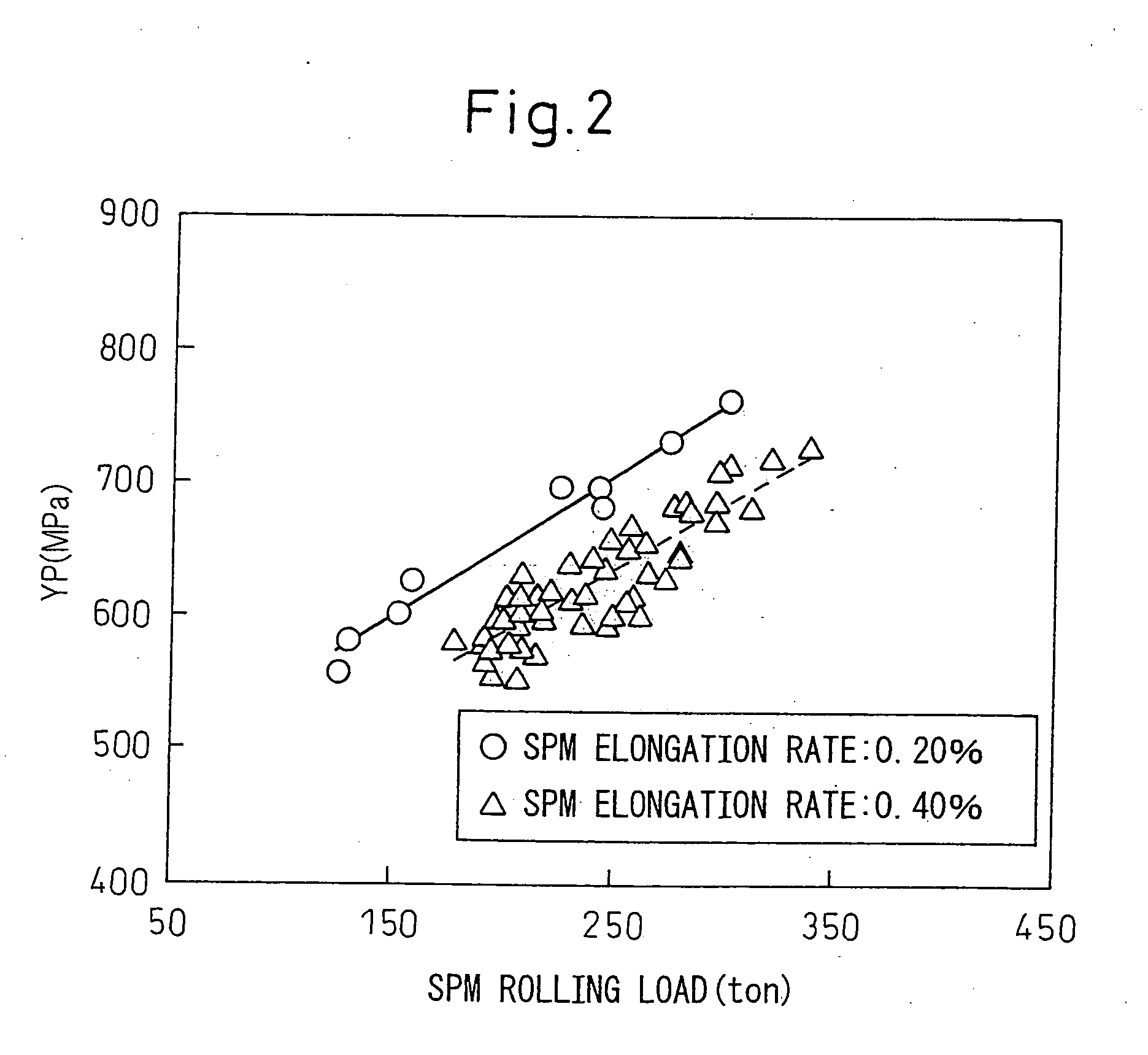

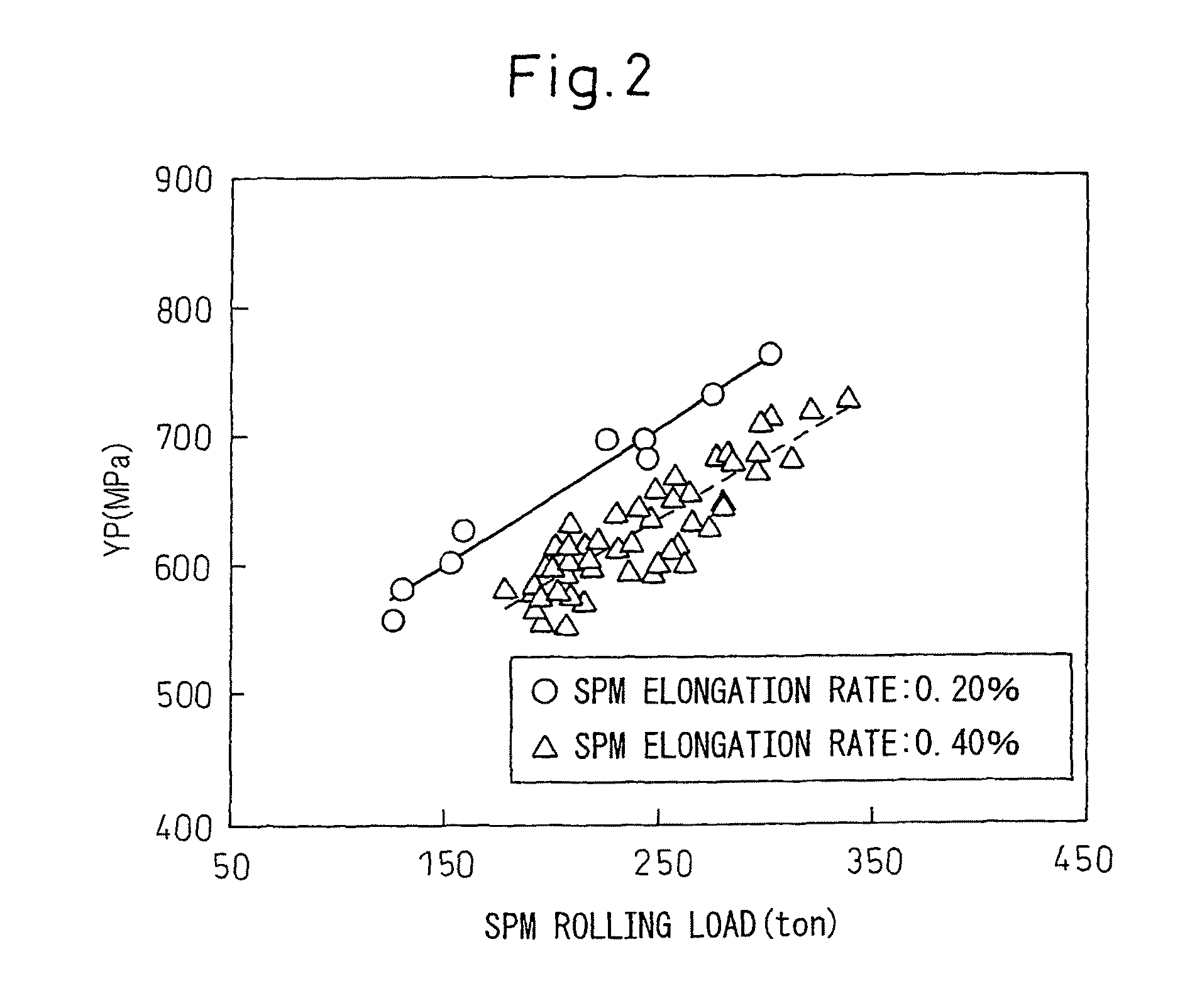

Method for provision and utilization of material information rerding steel sheet for shipping

The present invention provides a method for obtaining material information regarding steel sheet for shipping over the entire length of the steel sheet for shipping without spending too much time and effort, providing detailed material information in large volumes to a user through a computer and network, and having the user utilize the same.Specifically, it estimates the mechanical properties of temper rolled steel sheet based on the actual rolling data in a skinpass mill installed at the exit side of the continuous annealing line or galvanization facility and provides the estimated mechanical properties through the host computer and network to the user of the steel sheet.The user can use the estimated material information so as to remove the parts defective in mechanical properties or change the press forming conditions of the steel sheet.Further, the user can feed back information to the steel sheet manufacturer.

Owner:NIPPON STEEL CORP

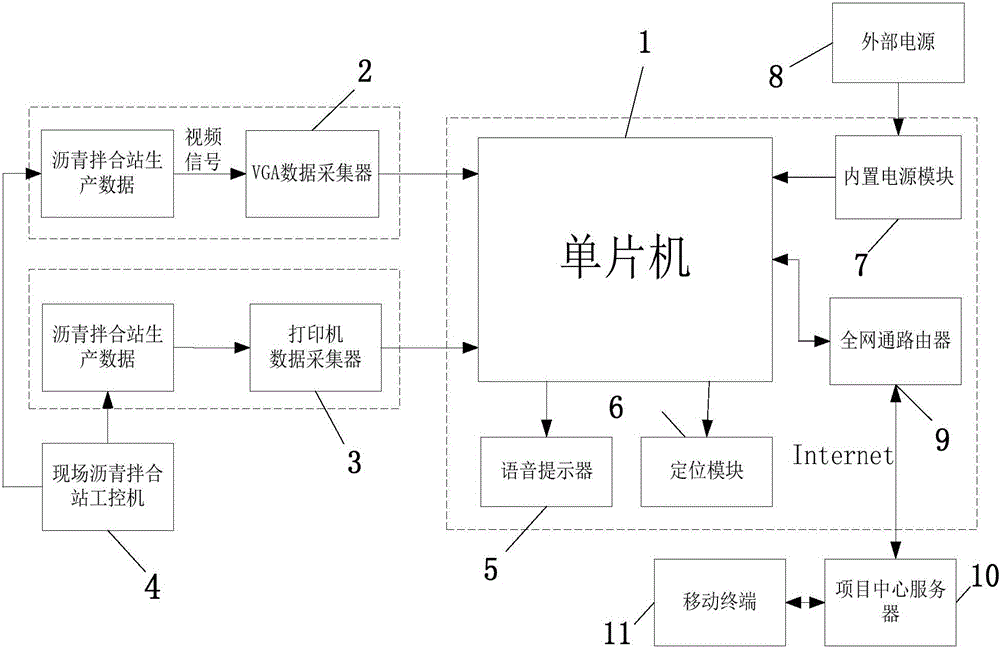

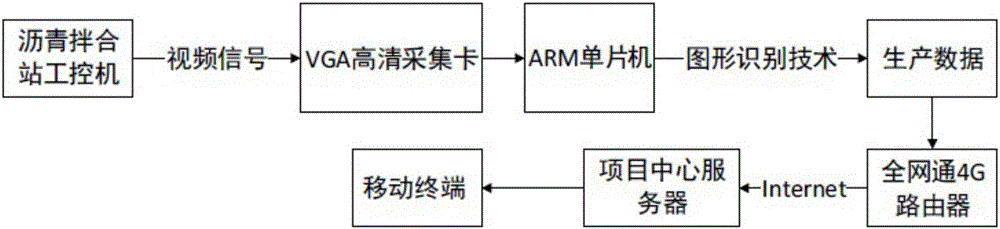

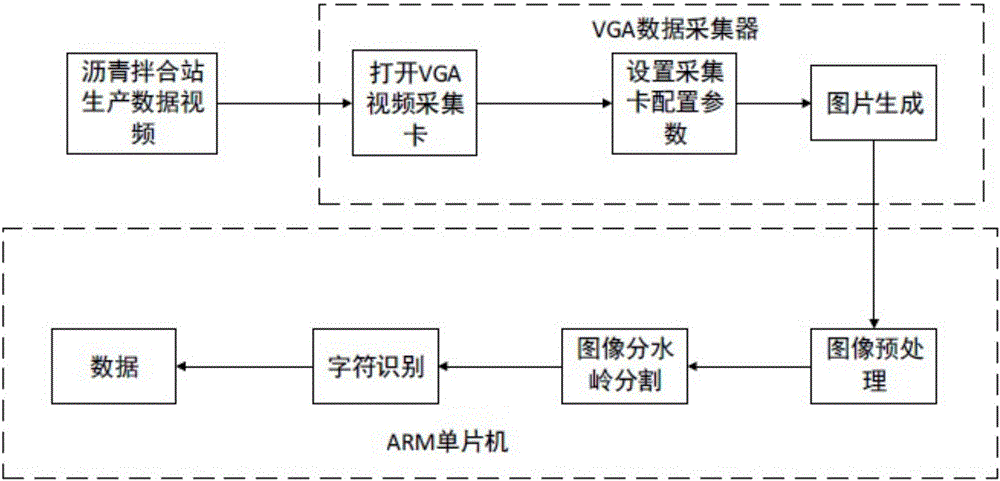

Asphalt mixing station monitoring and management system based on IoT technology

InactiveCN105700442ARealize real-time monitoringImprove productivity and qualityProgramme controlComputer controlMonitoring dataData collector

The invention provides an asphalt mixing station monitoring and management system based on IoT technology including a single-chip microprocessor connected with a field asphalt mixing station industrial machine through a VGA data collector and a printing machine data collector separately. The single-chip microprocessor is connected with a voice prompt module, a positioning module and a built-in power source module. The production data of the asphalt mixing station collected by the single-chip microprocessor is connected to a project center server through a router via Internet. The project center server is in bidirectional connection with a mobile terminal used for inquiring monitoring data and capable of sending request signals. According to the invention, a VGA high-definition collection card in the VGA data collector can collect real time images containing production data of the field asphalt mixing station industrial machine at special time intervals, so that real time monitoring on asphalt production process is realized, voice alarm can be given for unqualified data, the production efficiency and quality of the mixing station can be improved; and at the same time, the monitoring data can be inquired through the mobile terminal at any time.

Owner:CHANGAN UNIV

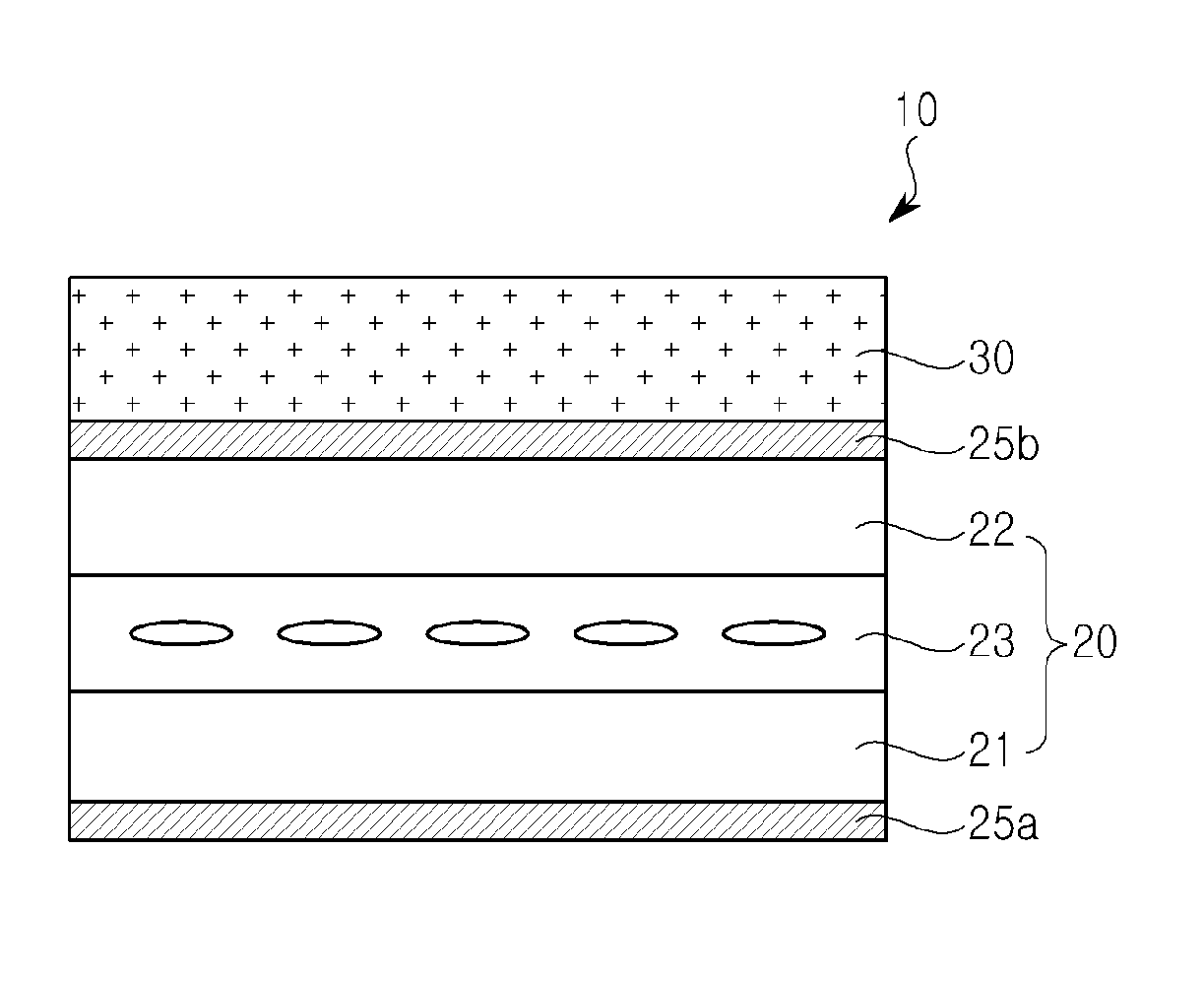

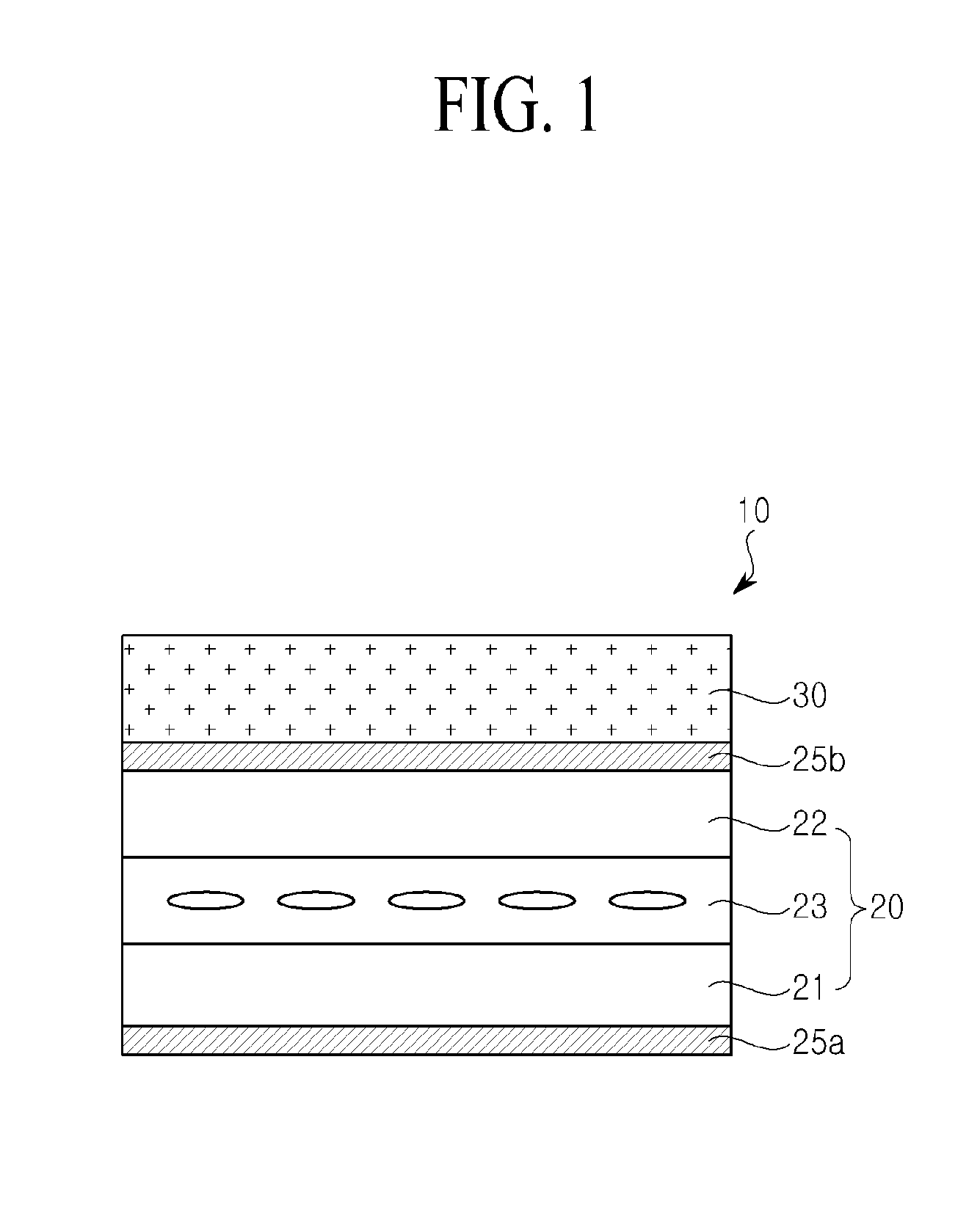

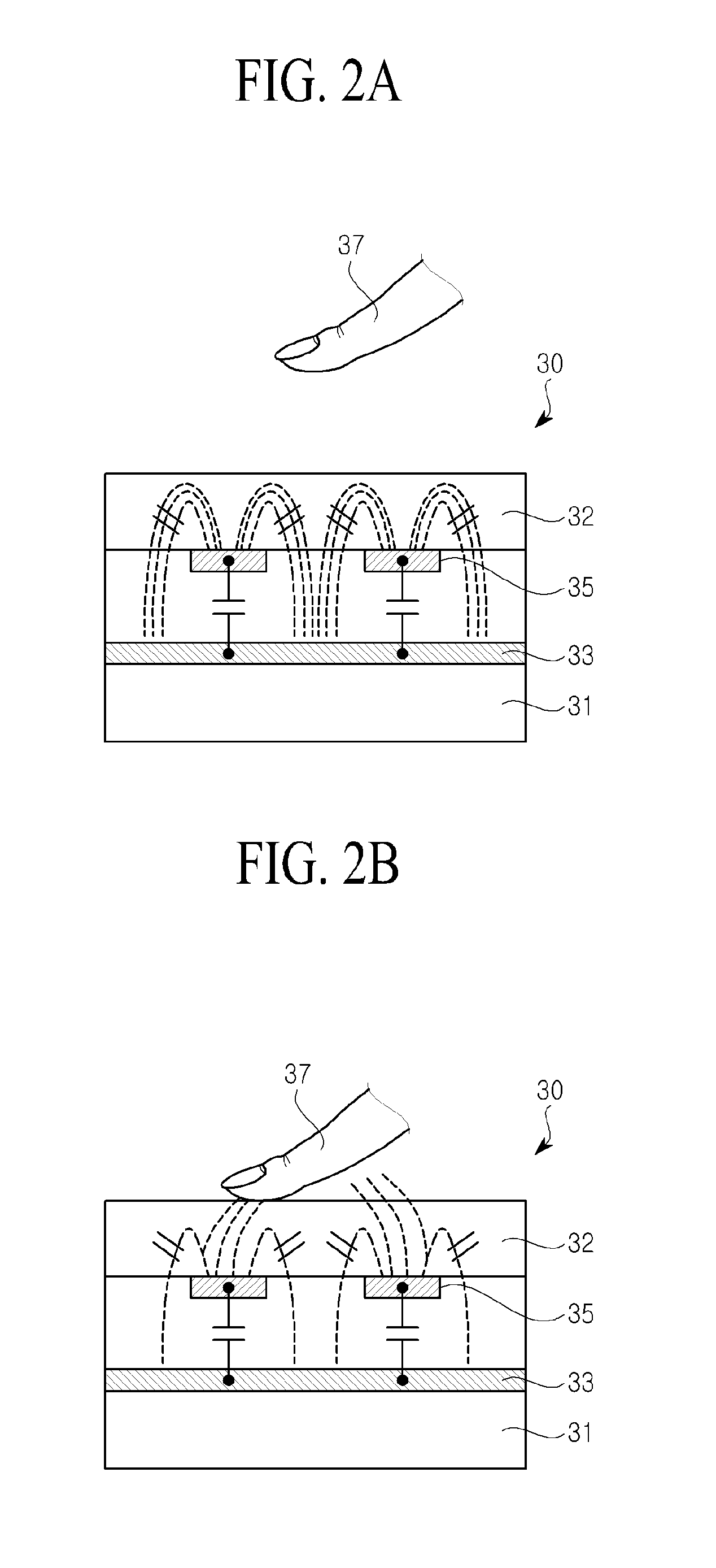

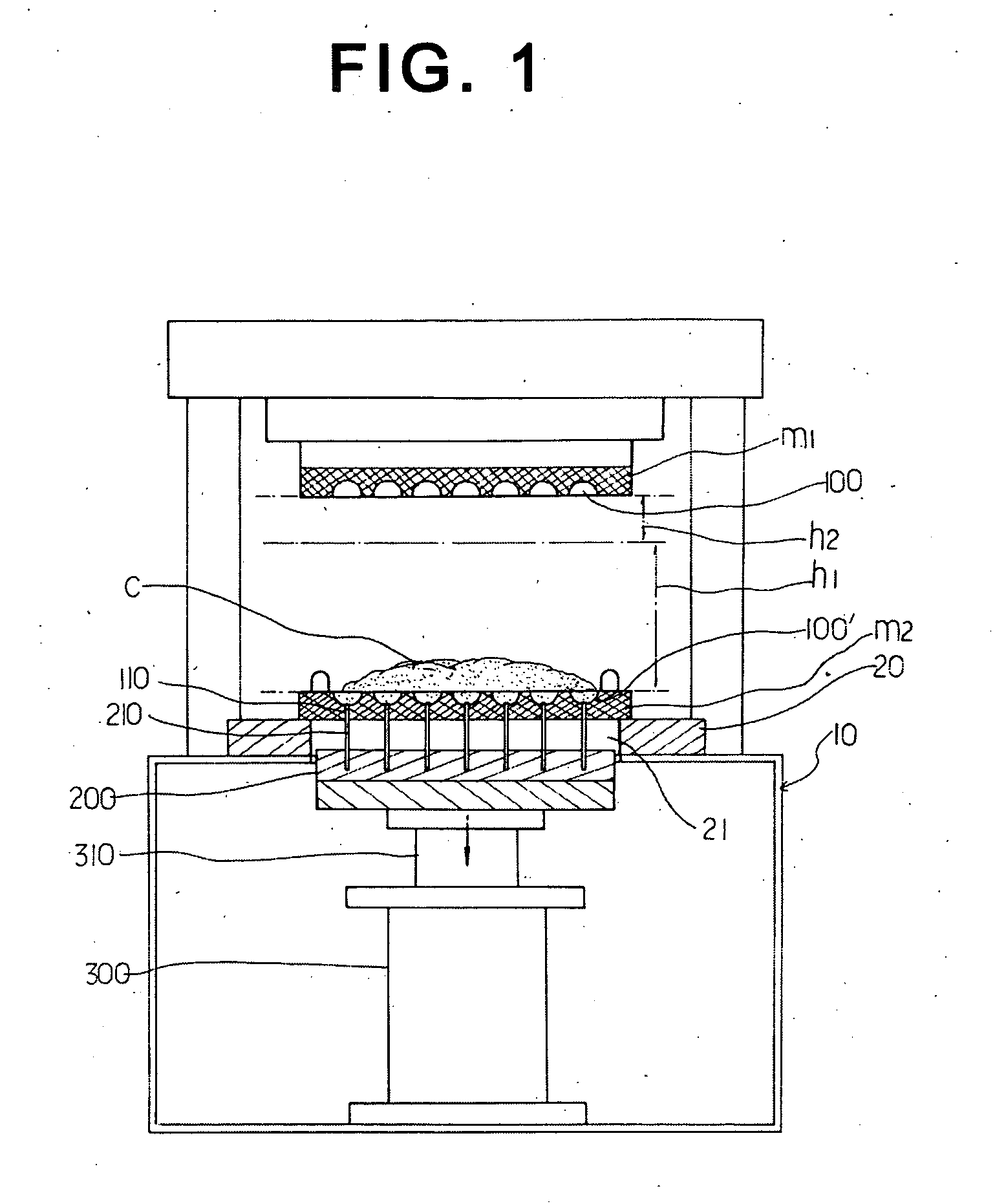

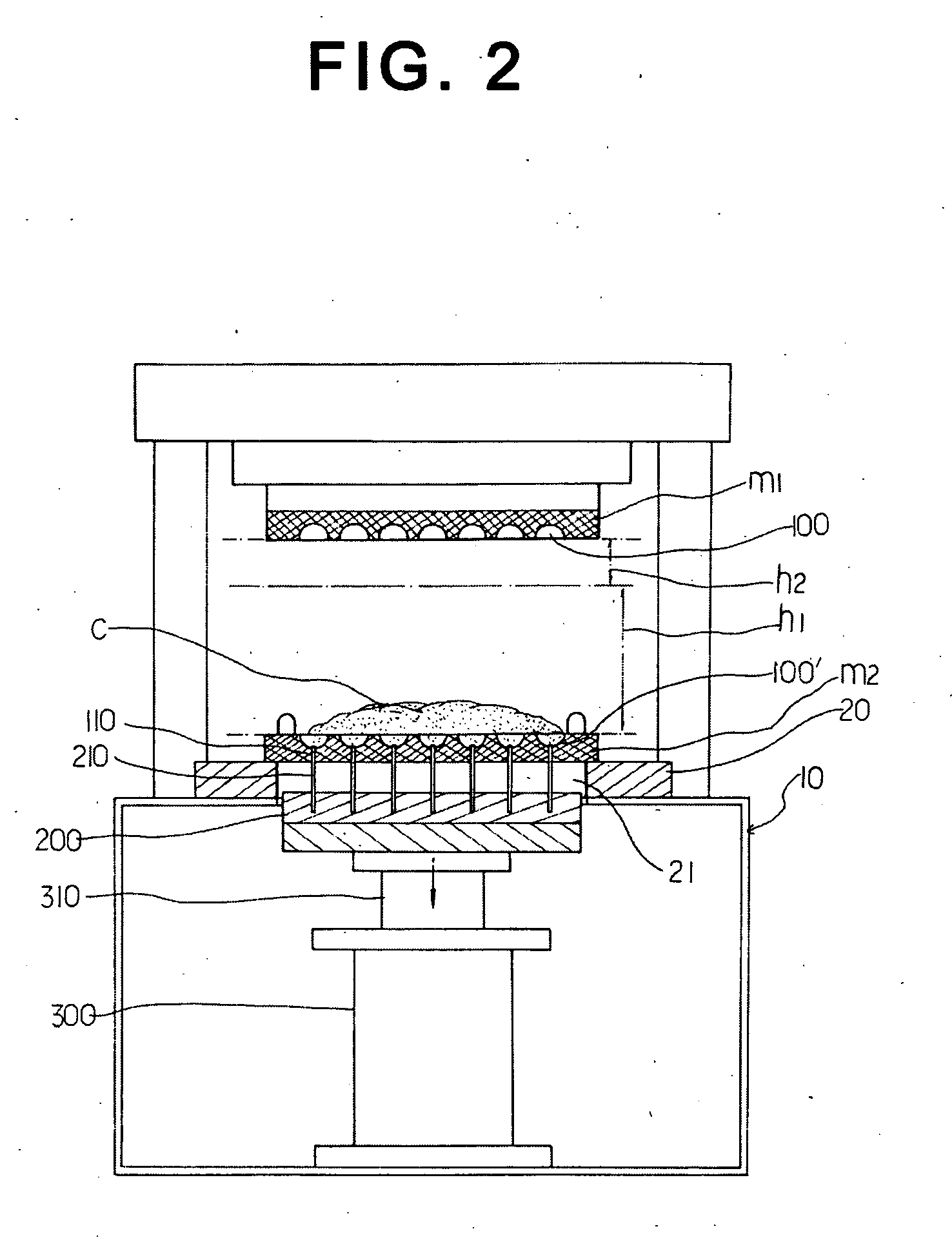

Automatic bonding system for liquid crystal display device and automatic bonding method using the same

ActiveUS20140182780A1Reduce the presence of air bubblesIncrease hardening rateLamination plant layoutMechanical working/deformationLiquid-crystal displayEngineering

Disclosed is an automatic bonding system for an LCD device. The automatic bonding system includes a bonding unit configured to perform a process of bonding a first substrate to a second substrate, a first substrate supply unit configured to include an inverting arm and supply the first substrate to the bonding unit, a second substrate supply unit configured to include an adhesive resin coating unit and supply the second substrate to the bonding unit, a pre-hardening unit configured to perform a process of pre-hardening an adhesive resin that adheres the first and second substrates, and a hardening unit configured to perform a process of hardening the adhesive resin that adheres the first and second substrates. A gap between the first and second substrates bonded to each other by the bonding unit is a bonding gap controlled by a gap variable control stage.

Owner:LG DISPLAY CO LTD

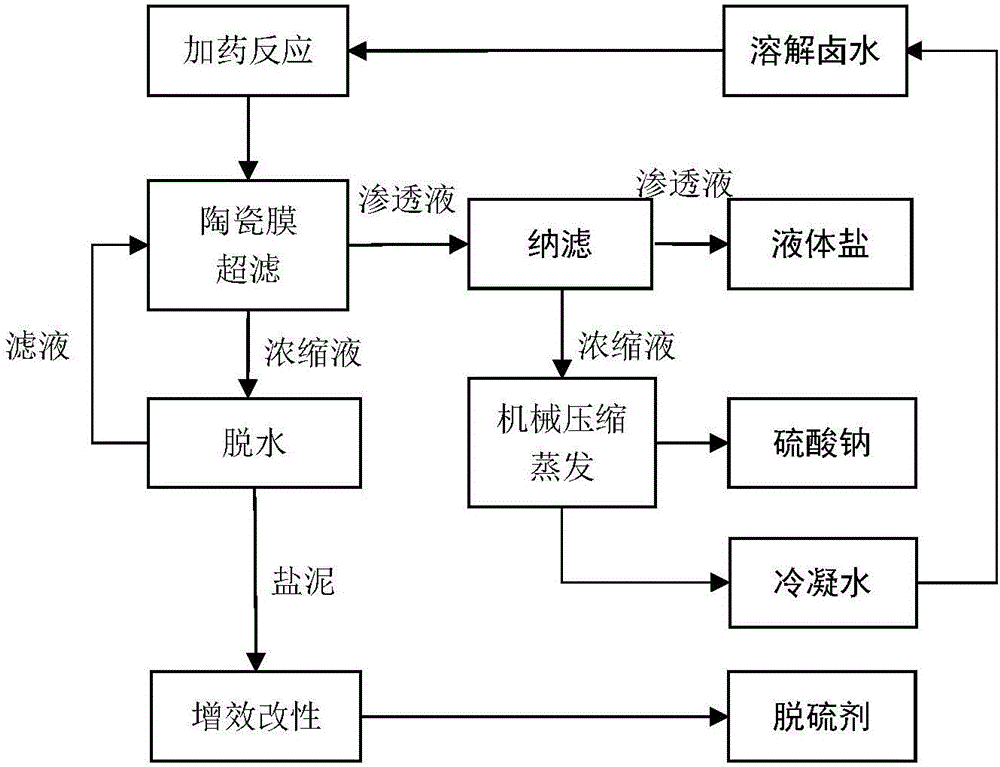

Double-membrane liquid salt refining zero-emission production technology

ActiveCN106495187AAchieve reuseReduce energy consumptionAlkali metal chloridesAlkali metal sulfites/sulfatesSuspended particlesSlurry

The invention discloses a double-membrane liquid salt refining zero-emission production technology. The technology comprises the following steps: dissolving mineral salt with water to obtain dissolved bittern, and adding a medicament to remove calcium and magnesium ions; removing suspended particles in the system by pottery membrane microfiltration, and letting a ultrafiltration penetrating fluid enter a nanofiltration unit; letting a ultrafiltration concentrate enter a dehydration unit to obtain solid salt slurry, and letting a filtrate return the ultrafiltration unit; modifying the obtained solid salt slurry to prepare a desulfurizer; preparing a liquid salt product from a nanofiltration penetrating fluid which is a sodium chloride solution with low content of impurities; and carrying out evaporative crystallization on a nanofiltration concentrate to obtain an industrial sodium sulfate product, and letting a evaporated condensate return to be used as mineral salt dissolving water. According to the invention, the two-membrane method of ceramic membrane and nanofiltration membrane is used for brine refining, and removal of calcium and magnesium ions, sulfate removal and membrane separation are highly integrated. By modification and activation of solid waste salt slurry, the waste is changed into a valuable thing. The salt slurry is used as a desulfurizer. Thus, reutilization of resources is realized. The technology of the invention has good economic, environmental and social benefits.

Owner:NANJING UNIV OF TECH +1

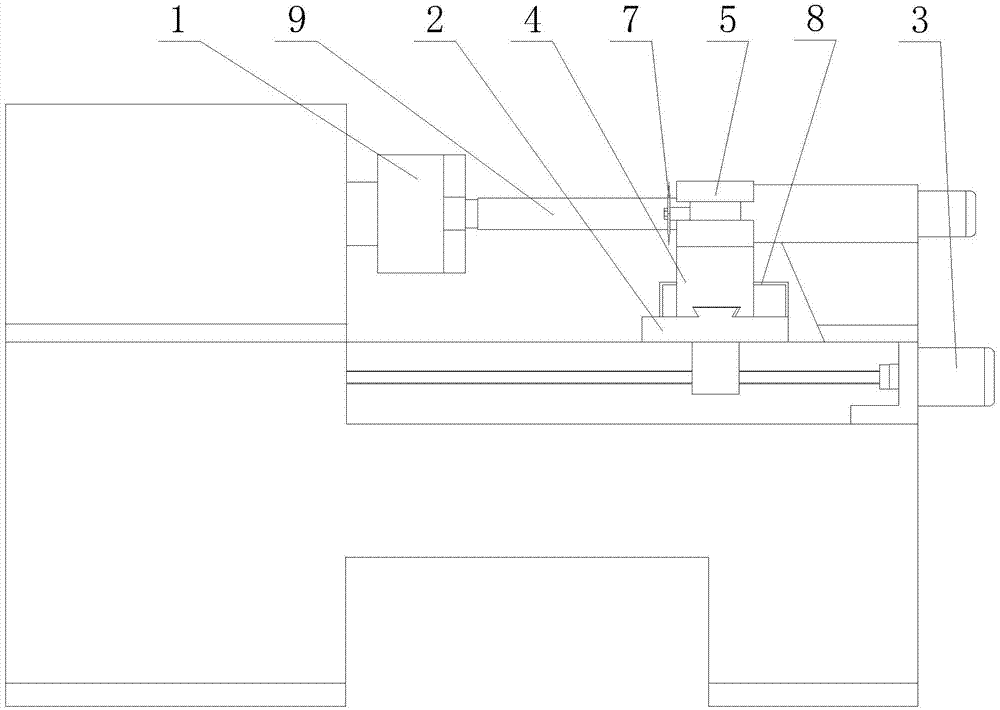

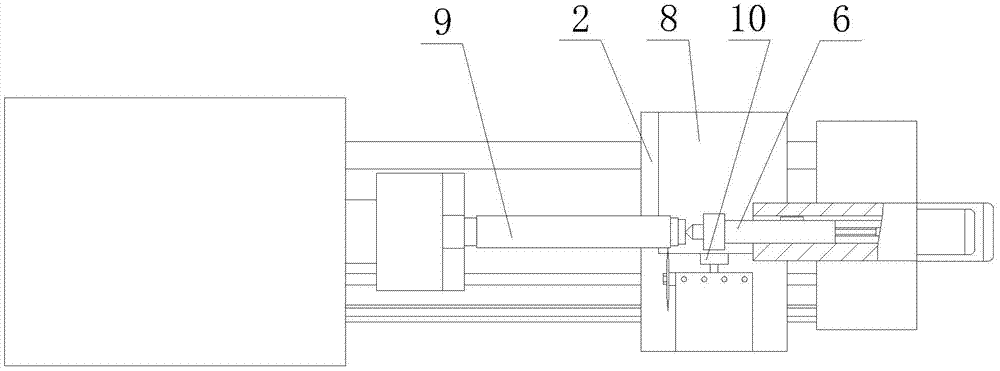

Special numerical control lathe

InactiveCN104741629AImprove productivity and qualityReduce labor intensityAutomatic/semiautomatic turning machinesEngineeringMechanical engineering

Owner:汤子仁

Method for provision and utilization of material information regarding steel sheet for shipping

ActiveUS8296081B2Less effortLess timePlug gaugesData processing applicationsEngineeringContinuous annealing

The present invention provides a method for obtaining material information regarding steel sheet for shipping over the entire length of the steel sheet for shipping without spending too much time and effort, providing detailed material information in large volumes to a user through a computer and network, and having the user utilize the same. Specifically, it estimates the mechanical properties of temper rolled steel sheet based on the actual rolling data in a skinpass mill installed at the exit side of the continuous annealing line or galvanization facility and provides the estimated mechanical properties through the host computer and network to the user of the steel sheet. The user can use the estimated material information so as to remove the parts defective in mechanical properties or change the press forming conditions of the steel sheet. Further, the user can feed back information to the steel sheet manufacturer.

Owner:NIPPON STEEL CORP

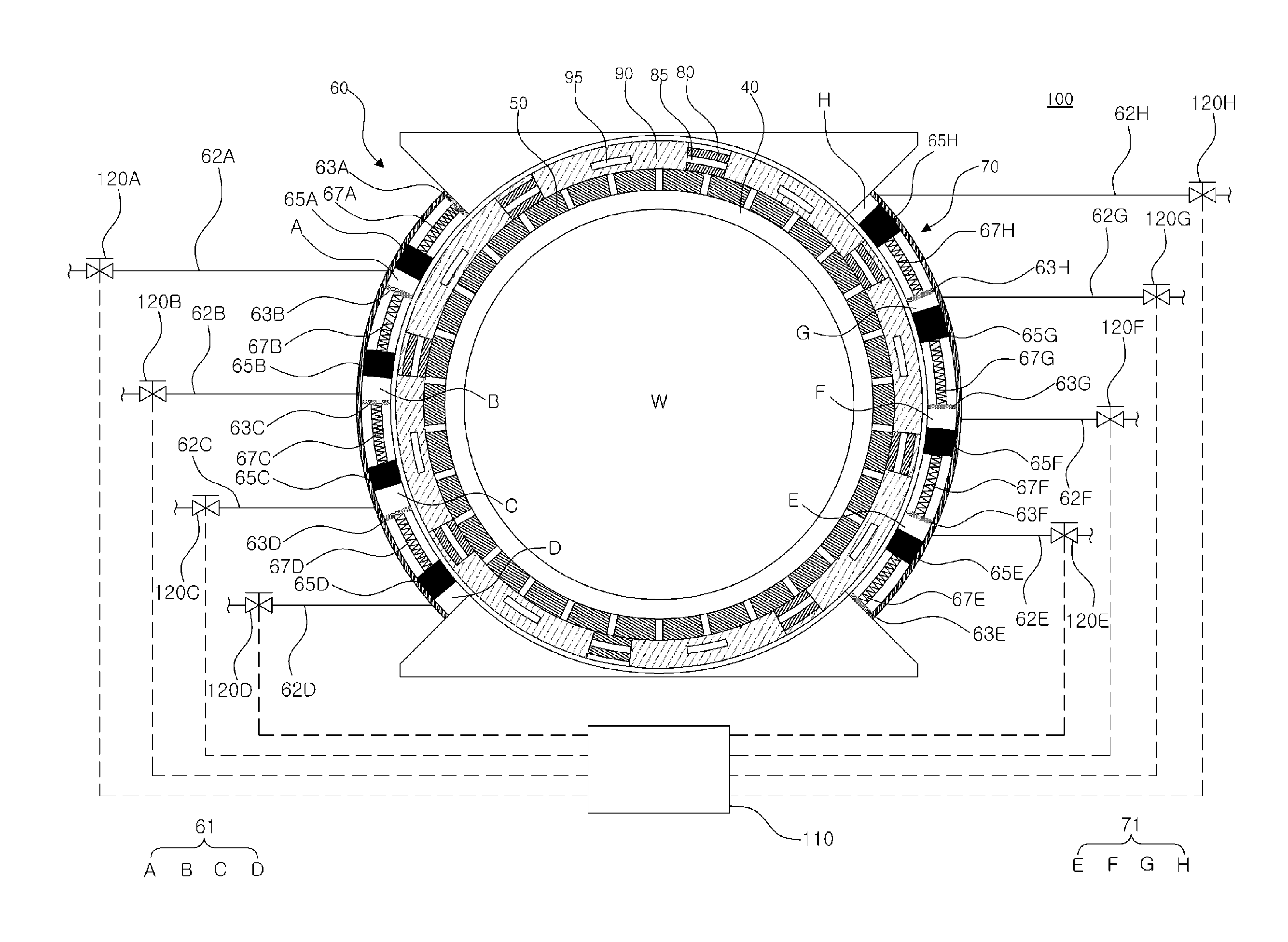

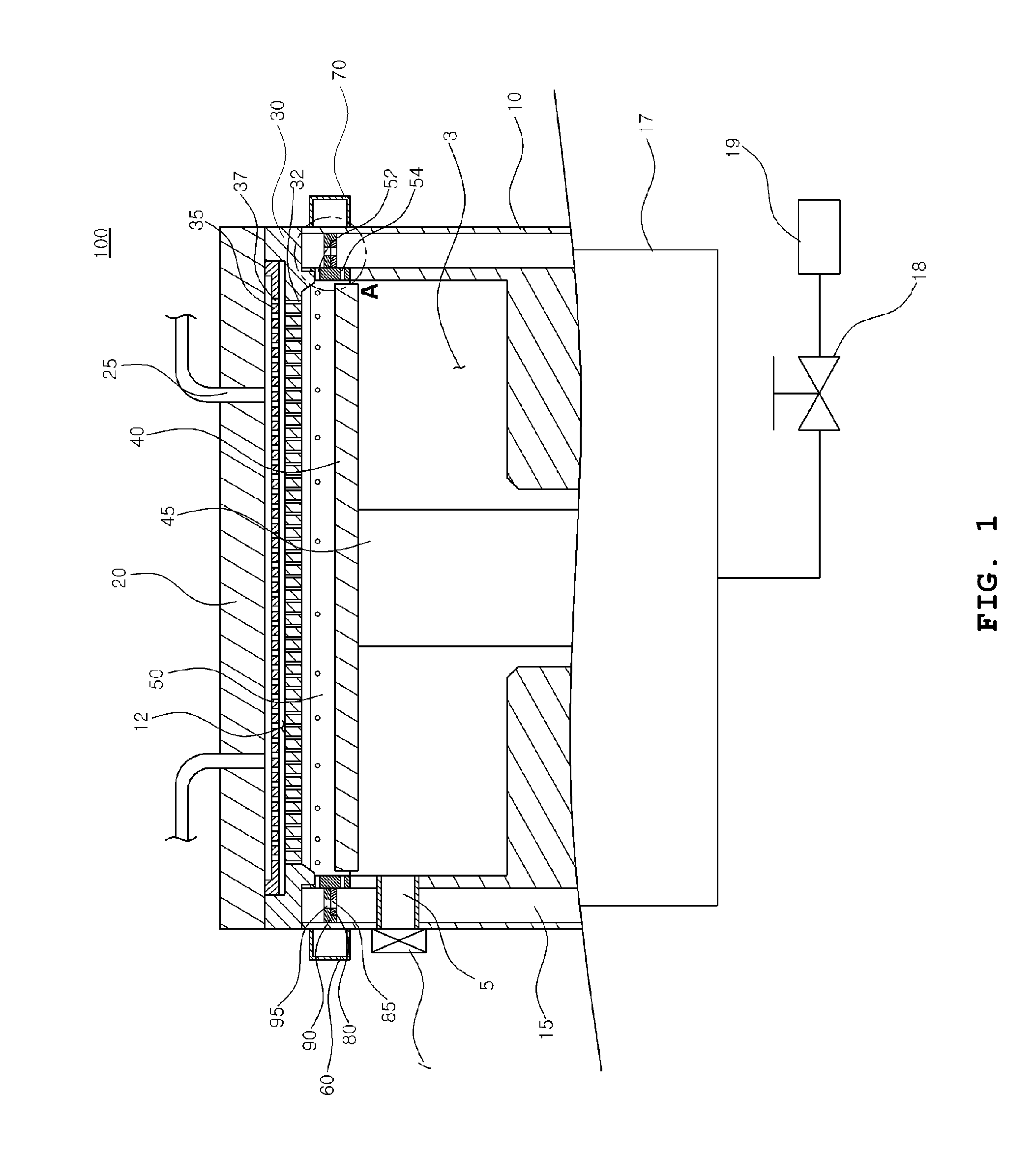

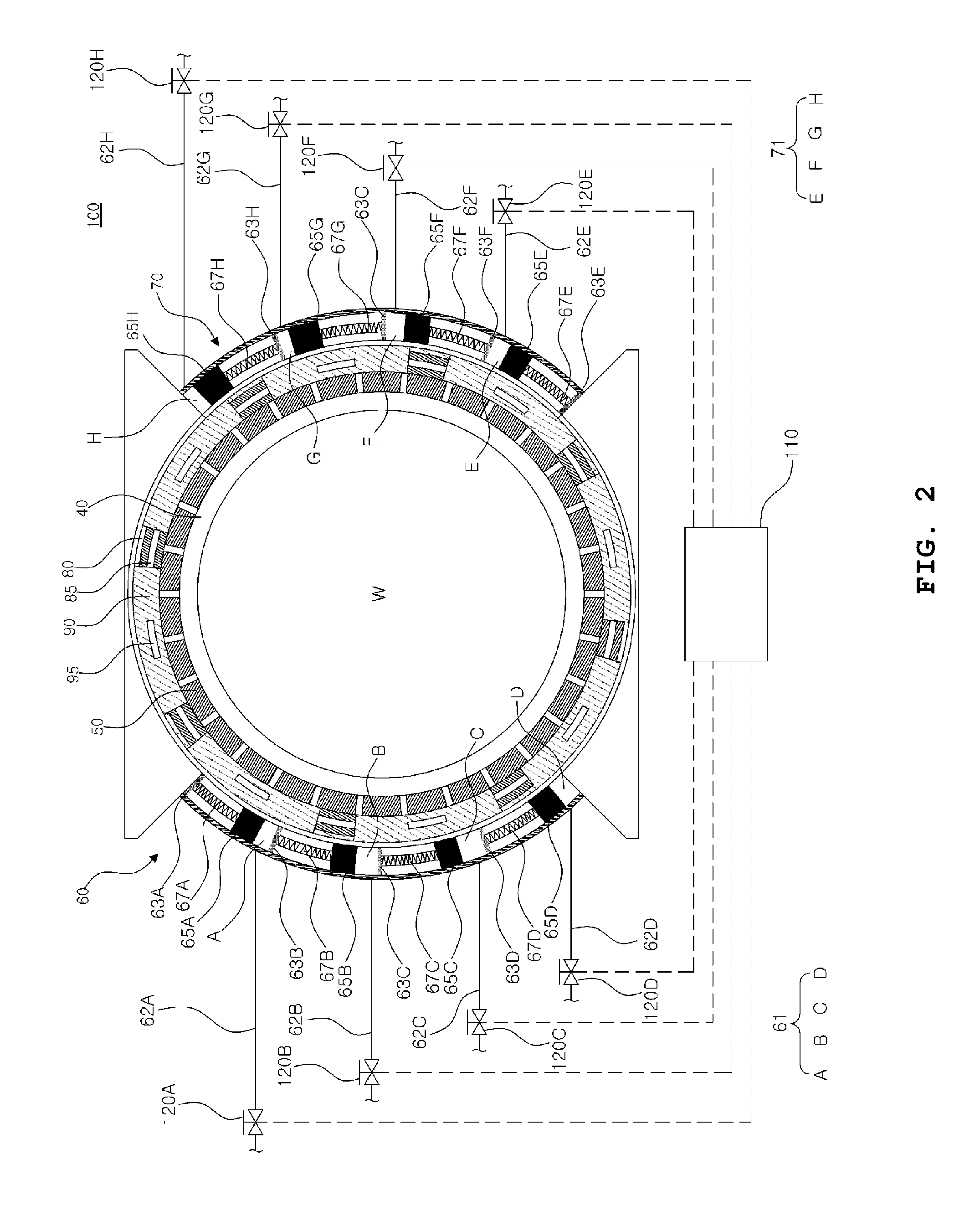

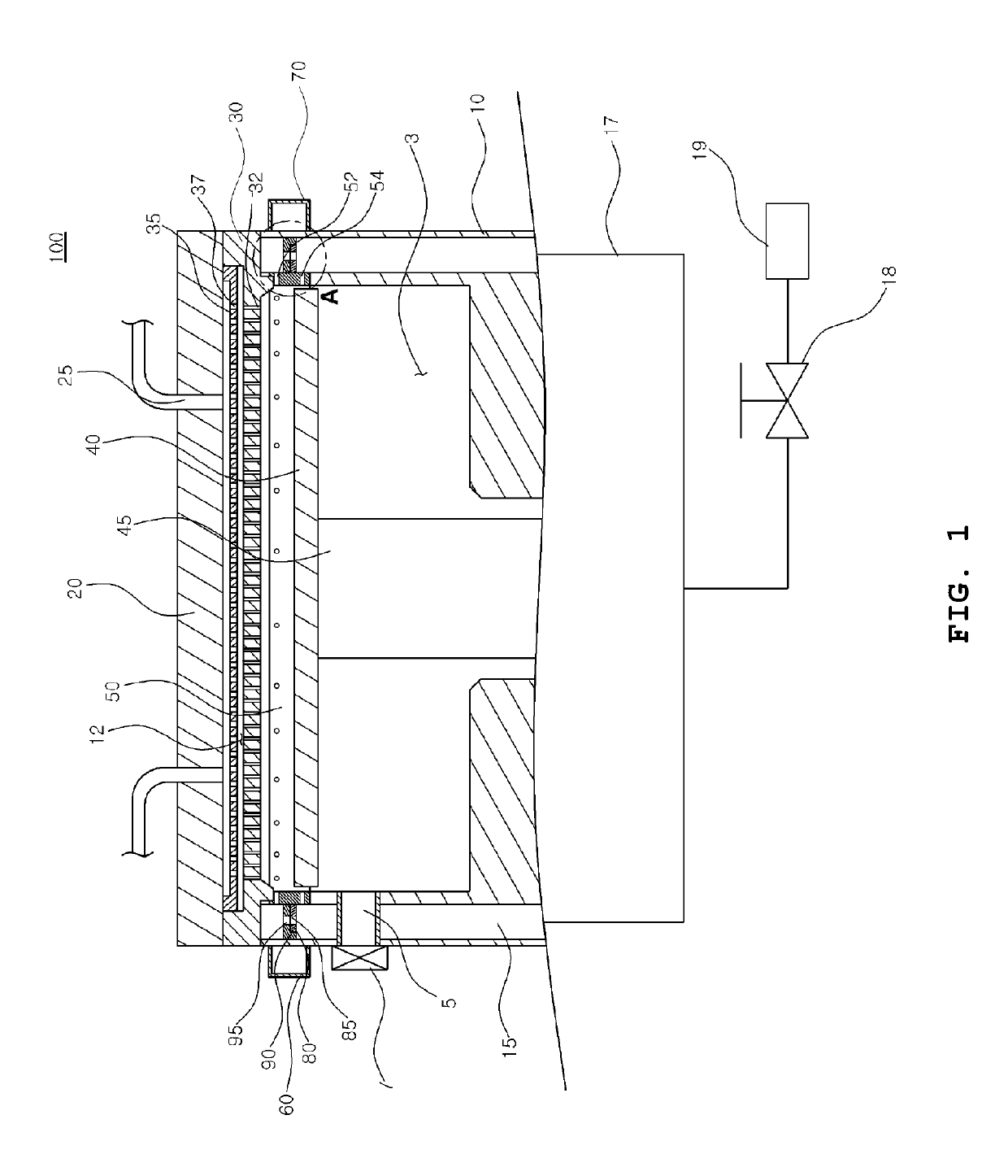

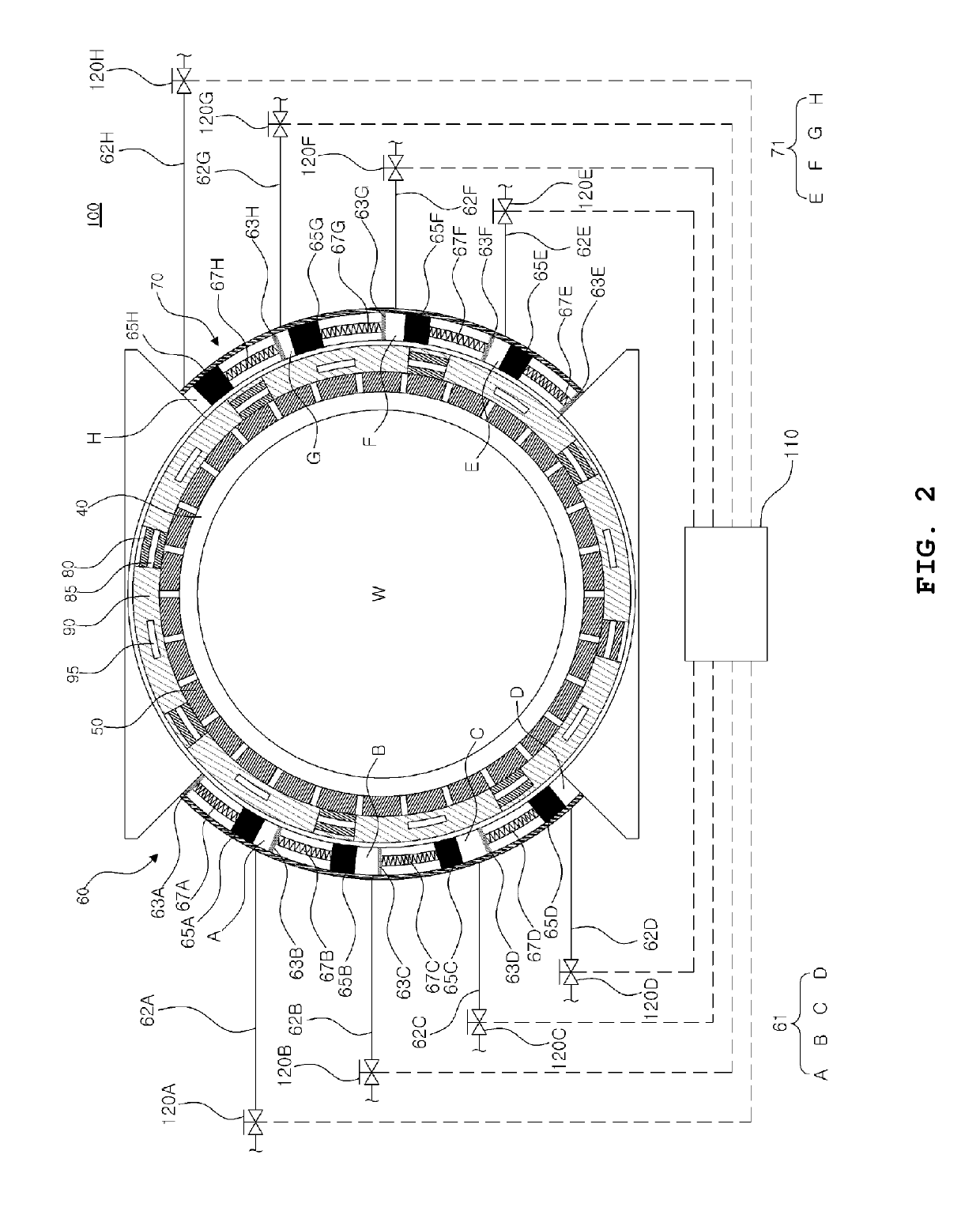

Substrate processing device

ActiveUS20160289834A1Increase productivityQuality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

Provided is an apparatus for processing a substrate. The apparatus includes a chamber providing an inner space in which a process with respect to the substrate is performed, a susceptor disposed in the inner space and on which the substrate is placed, a fixing plate disposed in an exhaust port disposed in a sidewall of the chamber along a circumference of the susceptor, the fixing plate having a plurality of through-holes, and at least one sliding plate disposed on an upper or lower portion of the fixing plate to rotate with respect to a center of the susceptor, the at least one sliding plate selectively opening and closing the through-holes.

Owner:EUGENE TECH CO LTD

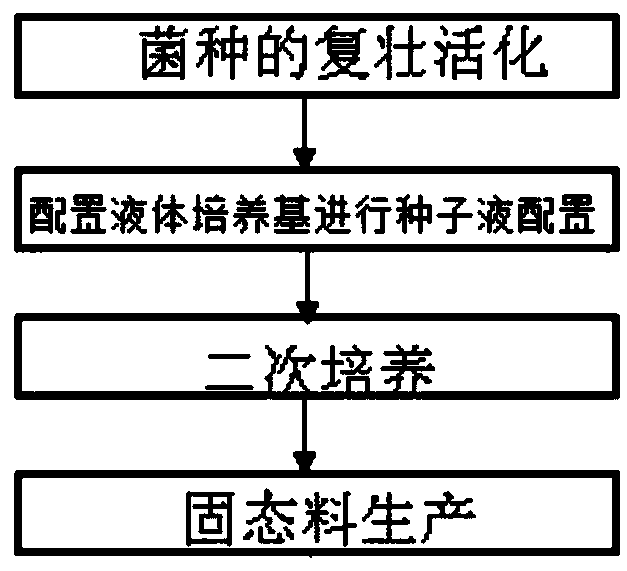

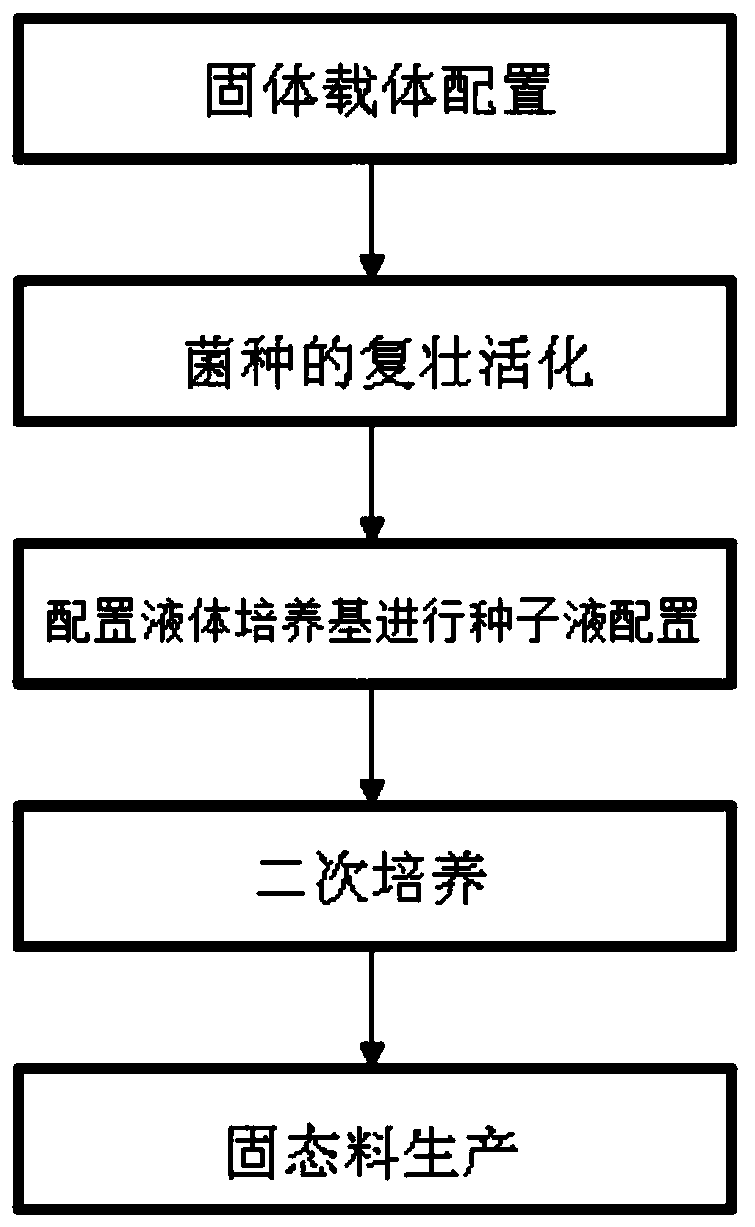

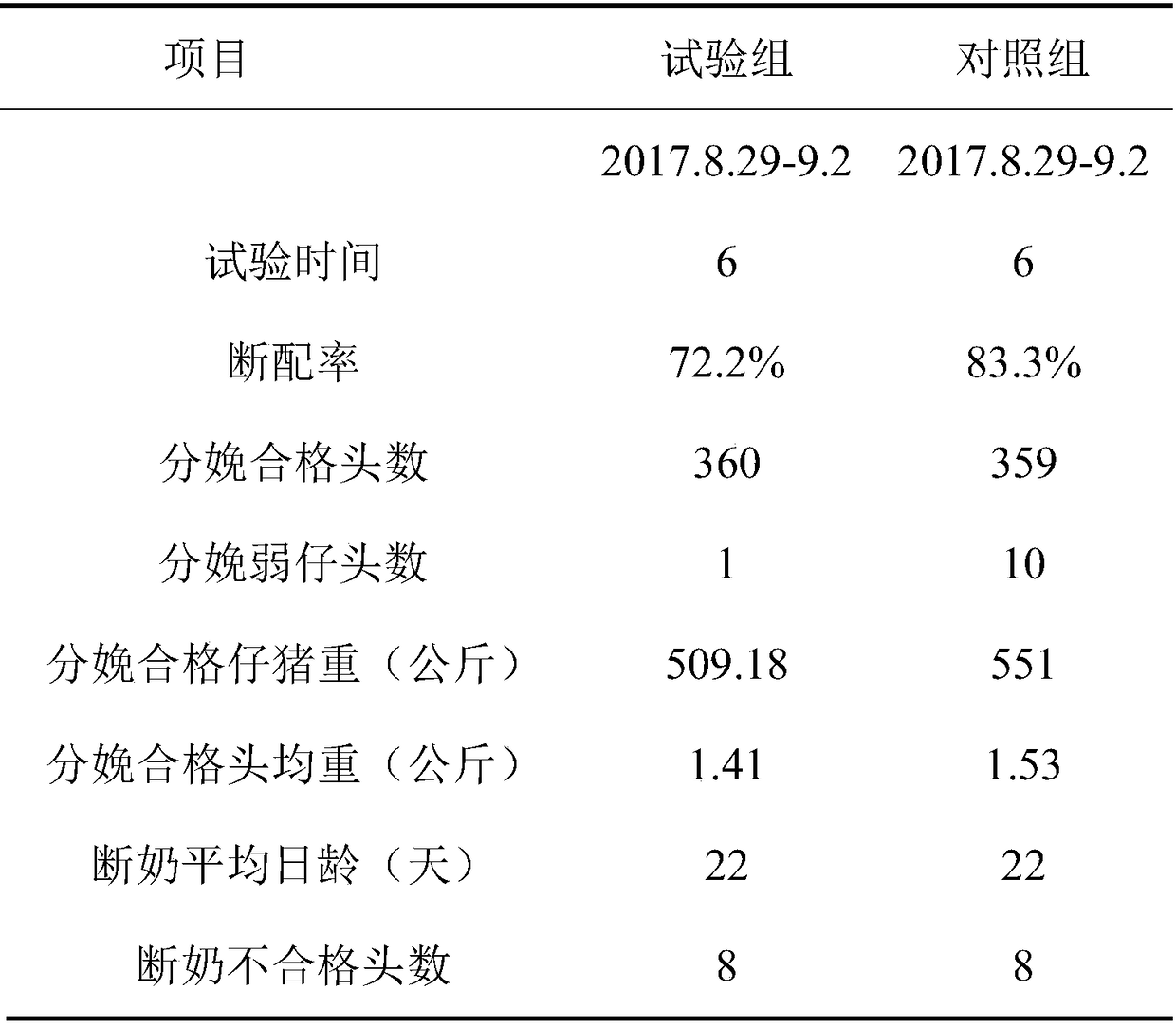

Method for mixed fermentation of probiotics containing bacillus coagulans

InactiveCN109439560AIncrease contentImprove palatabilityFungiBacteriaSaccharomyces cerevisiaeBacillus coagulans

The invention relates to a method for mixed fermentation of probiotics containing bacillus coagulans. The method comprises the following four steps: rejuvenation and activation of a culture, seed solution configuration of a configured liquid medium, secondary culture and solid material production. On the one hand, a processing and production technology is simple, a production process is standard,the production efficiency and quality can be improved effectively, the production cost is reduced, on the other hand, the bacillus coagulans, saccharomyces cerevisiae and lactobacillus bulgaricus arefermented in a mixed manner creatively, the content and palatability of lactic acid are greatly improved, PH of a fermented finished product is between 4.0 and 4.5, and the content of the bacillus coagulans is greater than or equal to 109 CFU / mL; the content of the saccharomyces cerevisiae is greater than or equal to 108 CFU / mL; and the content of lactic acid bacteria is greater than or equal to 108 CFU / mL.

Owner:焦作恒辉牧业有限公司

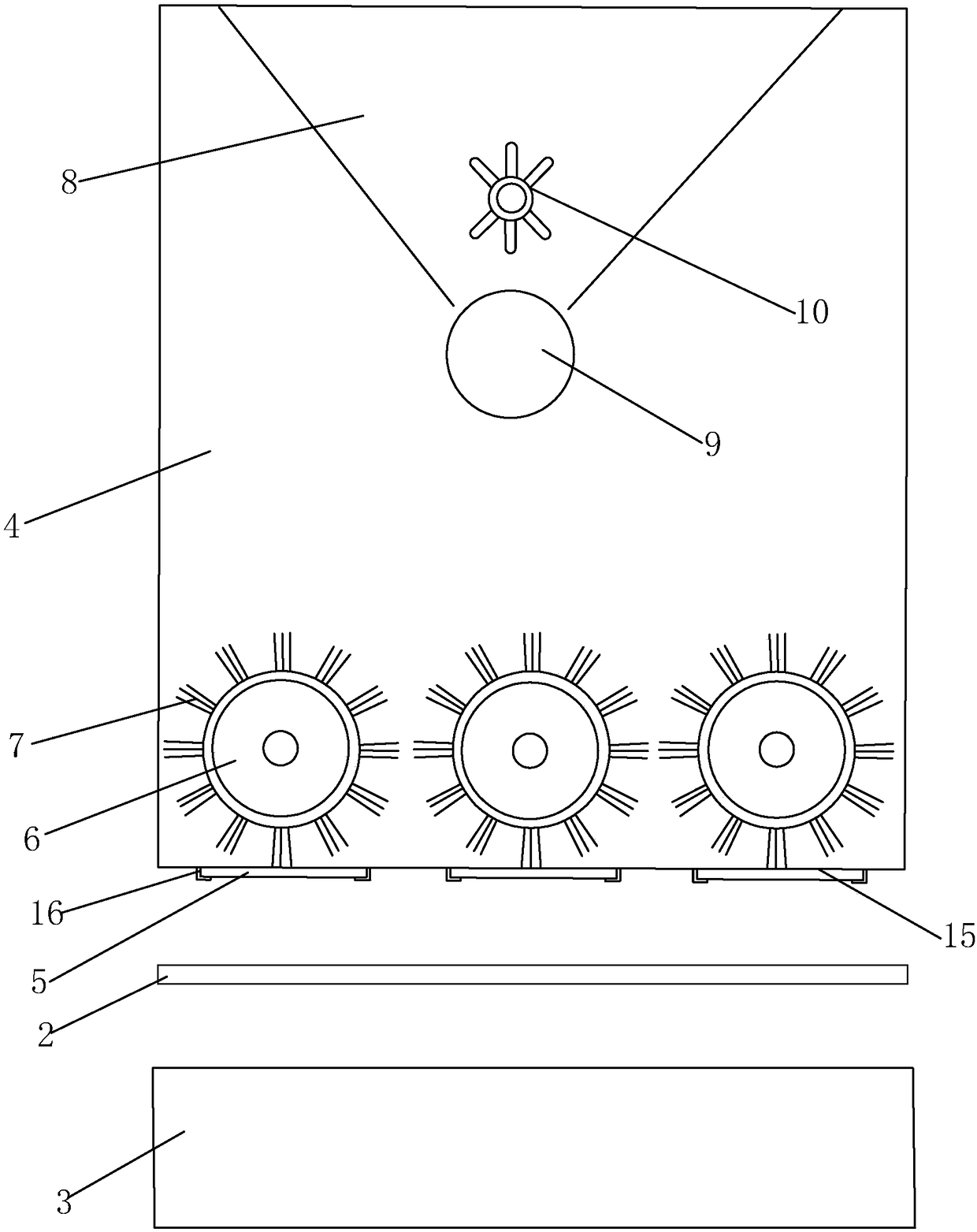

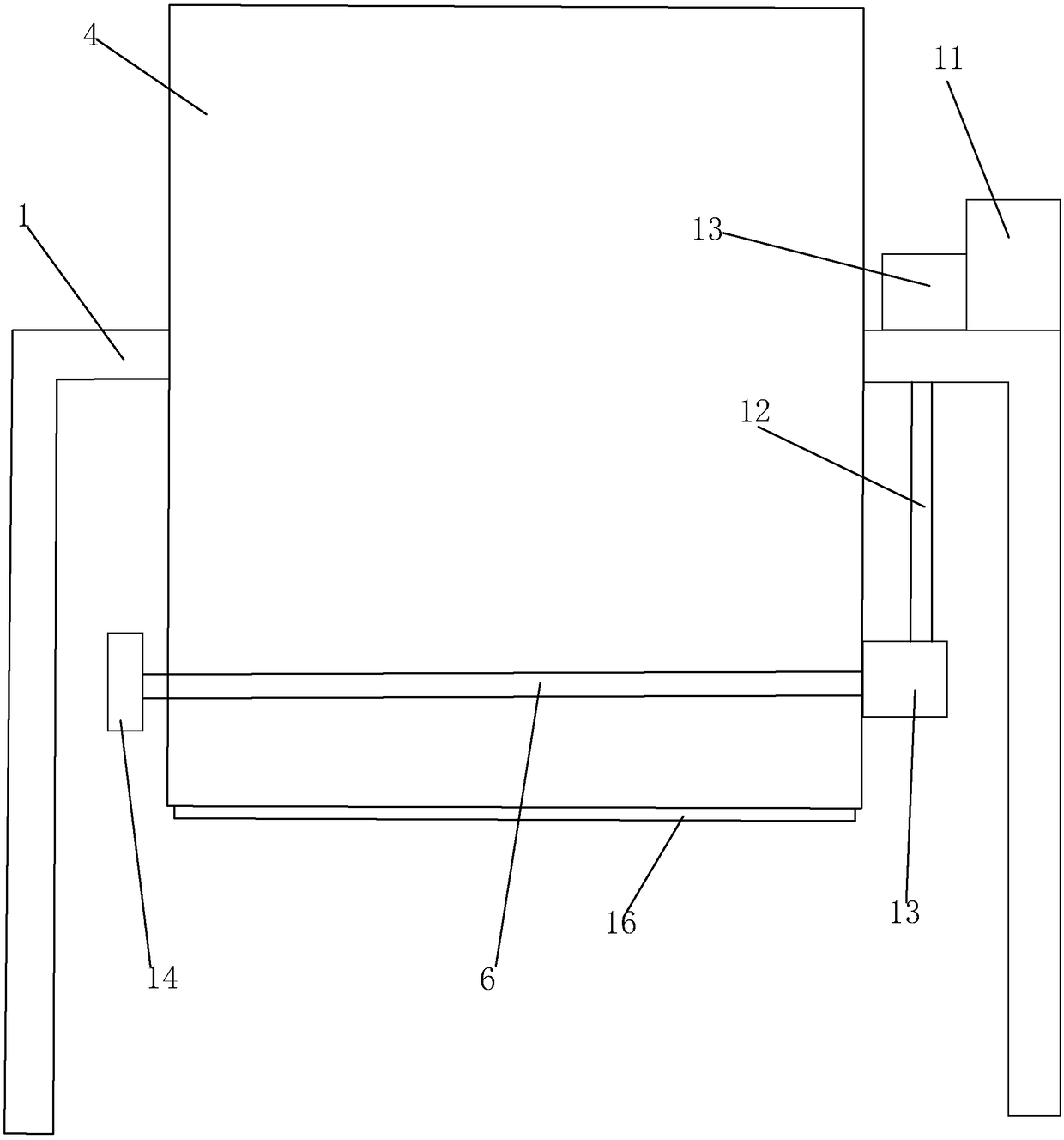

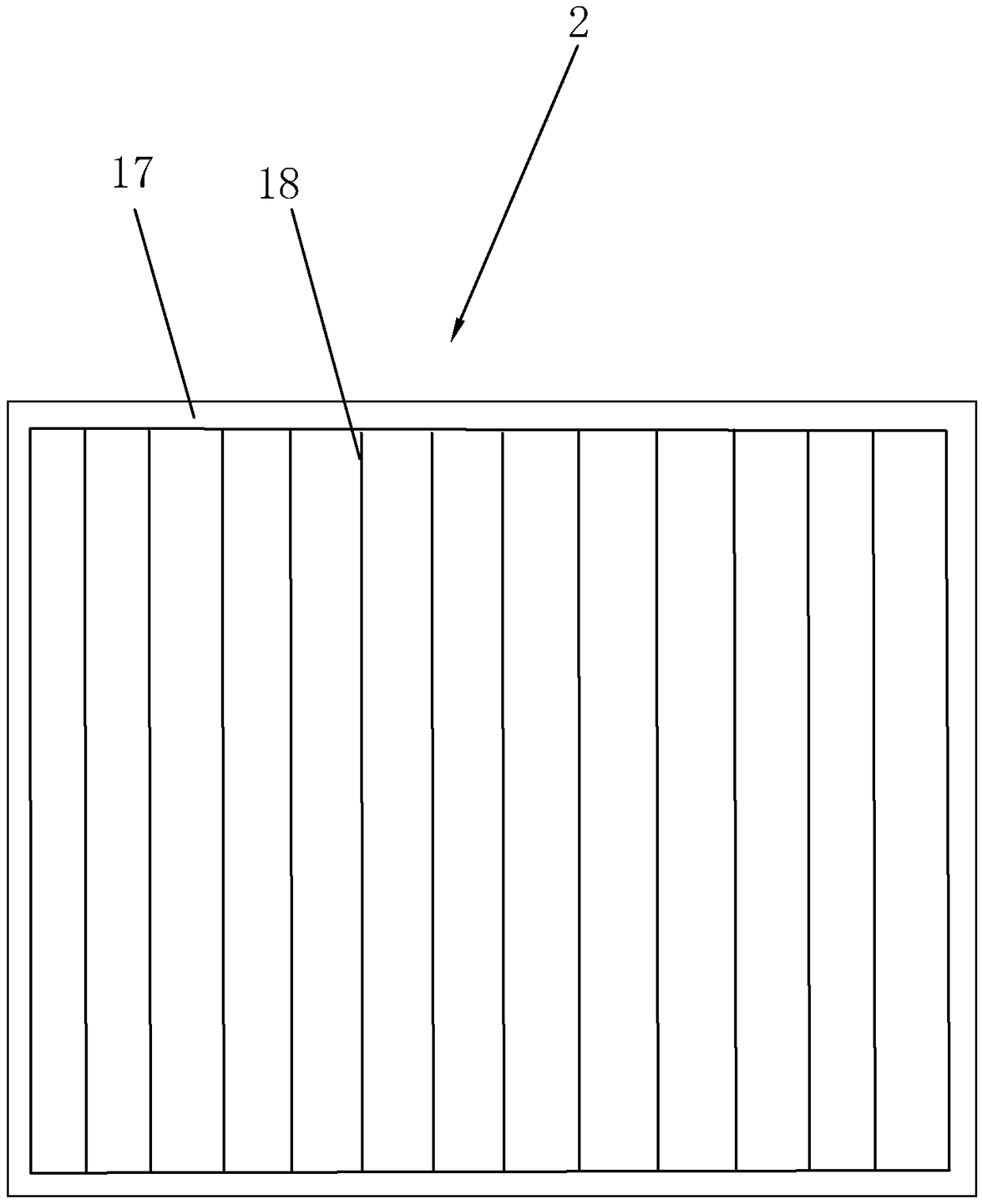

Automatic stone side line grinding and polishing machine with quick head switching device

ActiveCN102699786AImprove productivity and qualityPrevent looseningEdge grinding machinesGrinding drivesMotor driveEngineering

The invention discloses an automatic stone side line grinding and polishing machine with a quick head switching device. The machine comprises a gear box and a swing mechanism which are connected with each other, wherein a spindle head part is arranged on the other side of the swing mechanism; the swing mechanism drives the spindle head part to move to grind and polish a stone; the spindle head part comprises a spindle head bracket, and a servo motor and a support which are fixed on the spindle head part; the output end of the servo motor is connected with a screw rod nut mechanism for adjusting the longitudinal movement of a cutter according to the shape of a stone side line; the servo motor drives the screw rod nut mechanism to move; a spindle motor is fixedly arranged on the support and connected with a spindle; the other end of the spindle is connected with the quick head switching device; the cutter is arranged on the quick head switching device in a matched mode; the support longitudinally moves along a groove on the spindle head bracket under the action of the screw rod nut mechanism; the spindle motor is fixed on the support and drives the spindle to rotate, so that the cutter is driven to rotate; the cutter can be quickly switched among a chamfering cutting head, a grinding head and a polishing head; and the chamfering cutting, grinding and polishing of the stone side line can be finished at one station after a workpiece is loaded.

Owner:YUNFU KETE MACHINERY

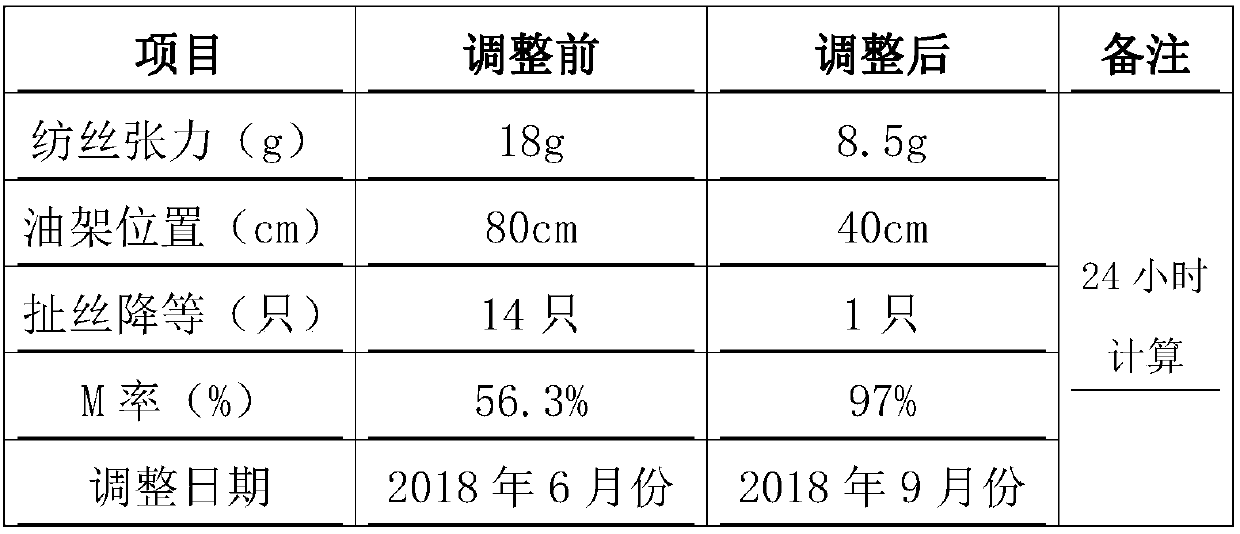

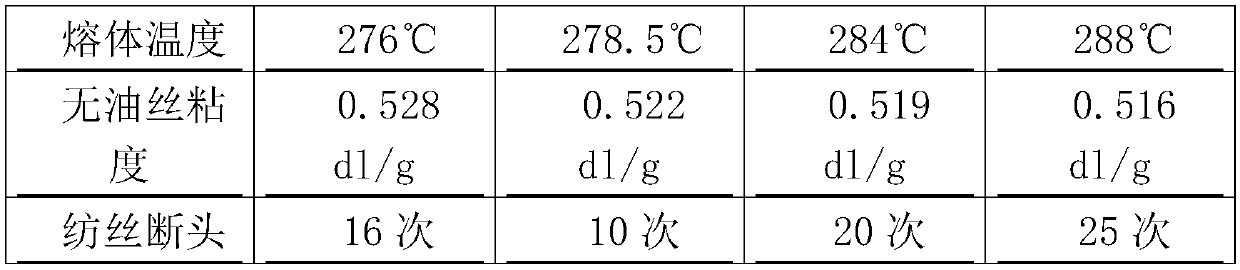

Production process of energy-saving and environmentally-friendly direct-spinning FDY fine-denier cationic polyester filament

ActiveCN109629022AImprove productivity and qualityEnergy savingNew-spun product collectionArtificial thread manufacturing machinesChemistryDyeing

The invention discloses a production process of an energy-saving and environmentally-friendly direct-spinning FDY fine-denier cationic polyester filament. The process flow comprises the steps of polymerization three-cylinder flow->melt distributor->booster pump->melt transport->cooler->static mixer->melt distribution valve->spinning box->metering pump melt extrusion->spinning assembly->ring blowing drum->cooling forming->magnetic ring->oil nozzle oiling->spinning shaft->yarn guide->GR0 ->first heat roll->second heat roller->third heat roller->fourth heat roller->fifth heat roller->GR1->GR2->main network->GR3->yarn guide->broken wire detector ->winder->fully automatic doffer->sky rail transportation->dyeing and classification->quality inspection packaging->stereo warehouse automatic storage. The production process of the energy-saving and environmentally-friendly direct-spinning FDY fine-denier cationic polyester filament not only achieves energy saving and environmental protection, butalso guarantees spinning quality.

Owner:TONGKUN GRP

Substrate processing device

ActiveUS10287687B2Improve productivity and qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

Provided is an apparatus for processing a substrate. The apparatus includes a chamber providing an inner space in which a process with respect to the substrate is performed, a susceptor disposed in the inner space and on which the substrate is placed, a fixing plate disposed in an exhaust port disposed in a sidewall of the chamber along a circumference of the susceptor, the fixing plate having a plurality of through-holes, and at least one sliding plate disposed on an upper or lower portion of the fixing plate to rotate with respect to a center of the susceptor, the at least one sliding plate selectively opening and closing the through-holes.

Owner:EUGENE TECH CO LTD

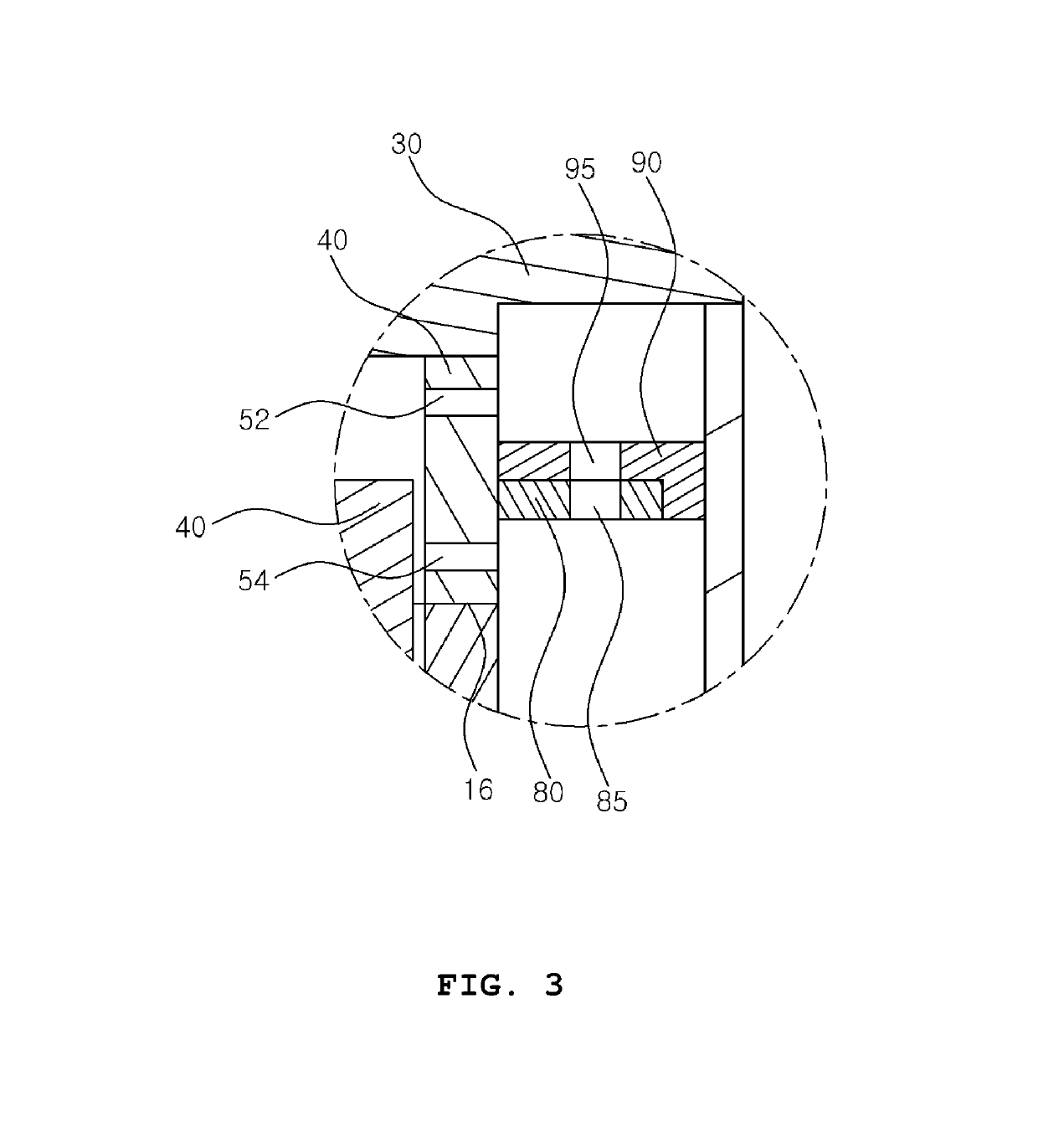

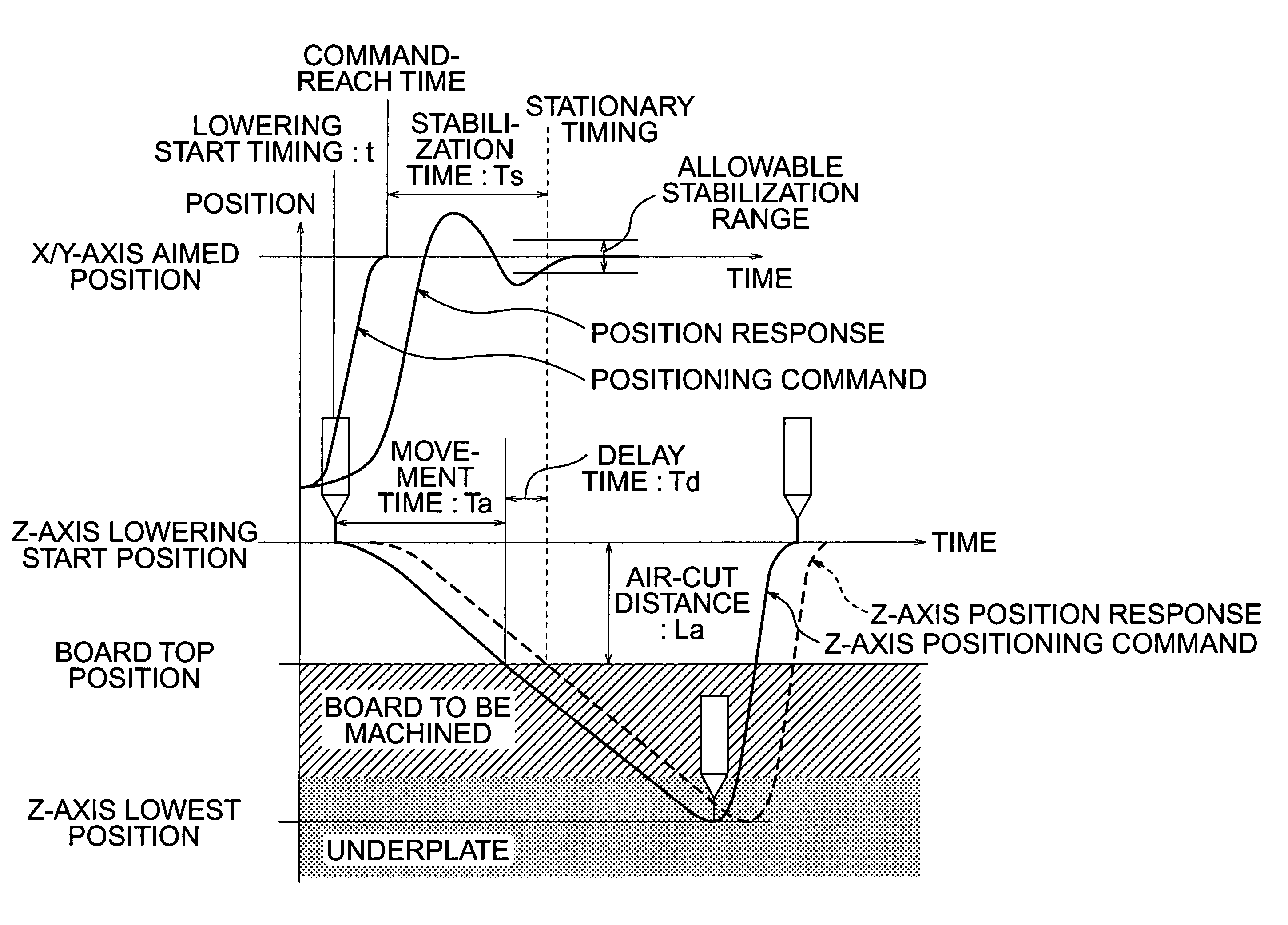

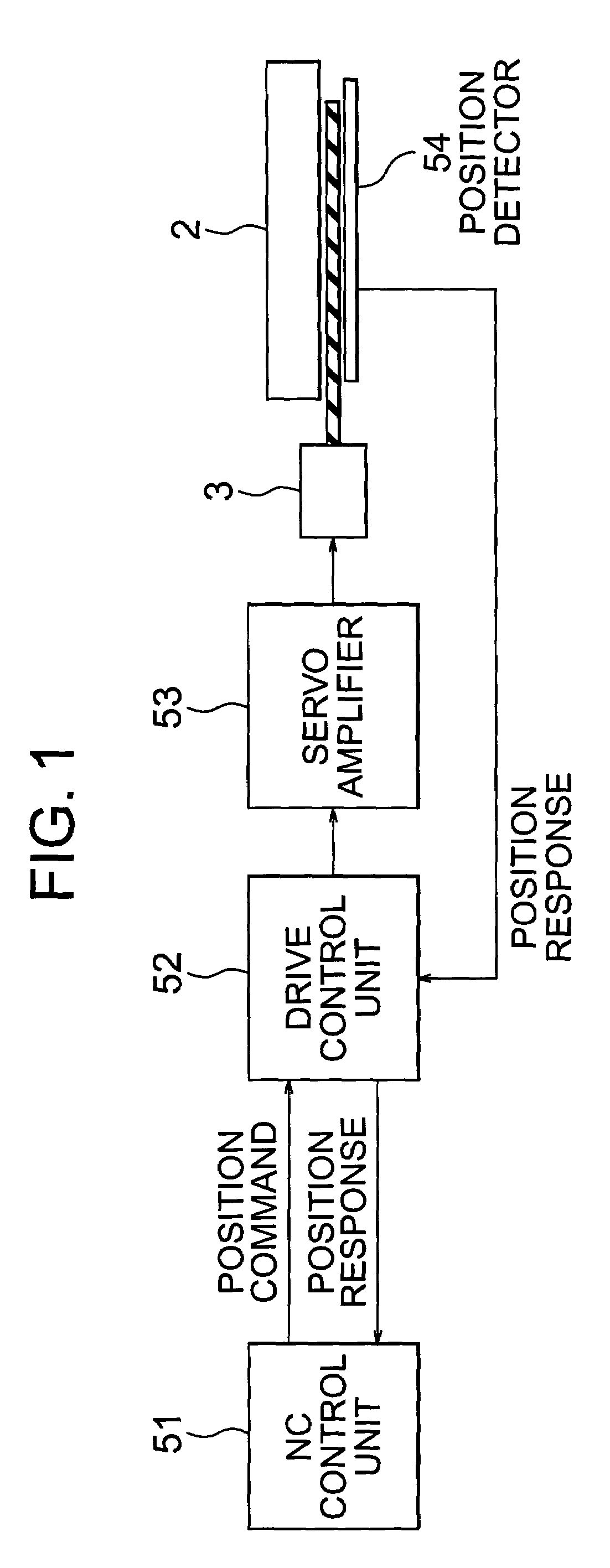

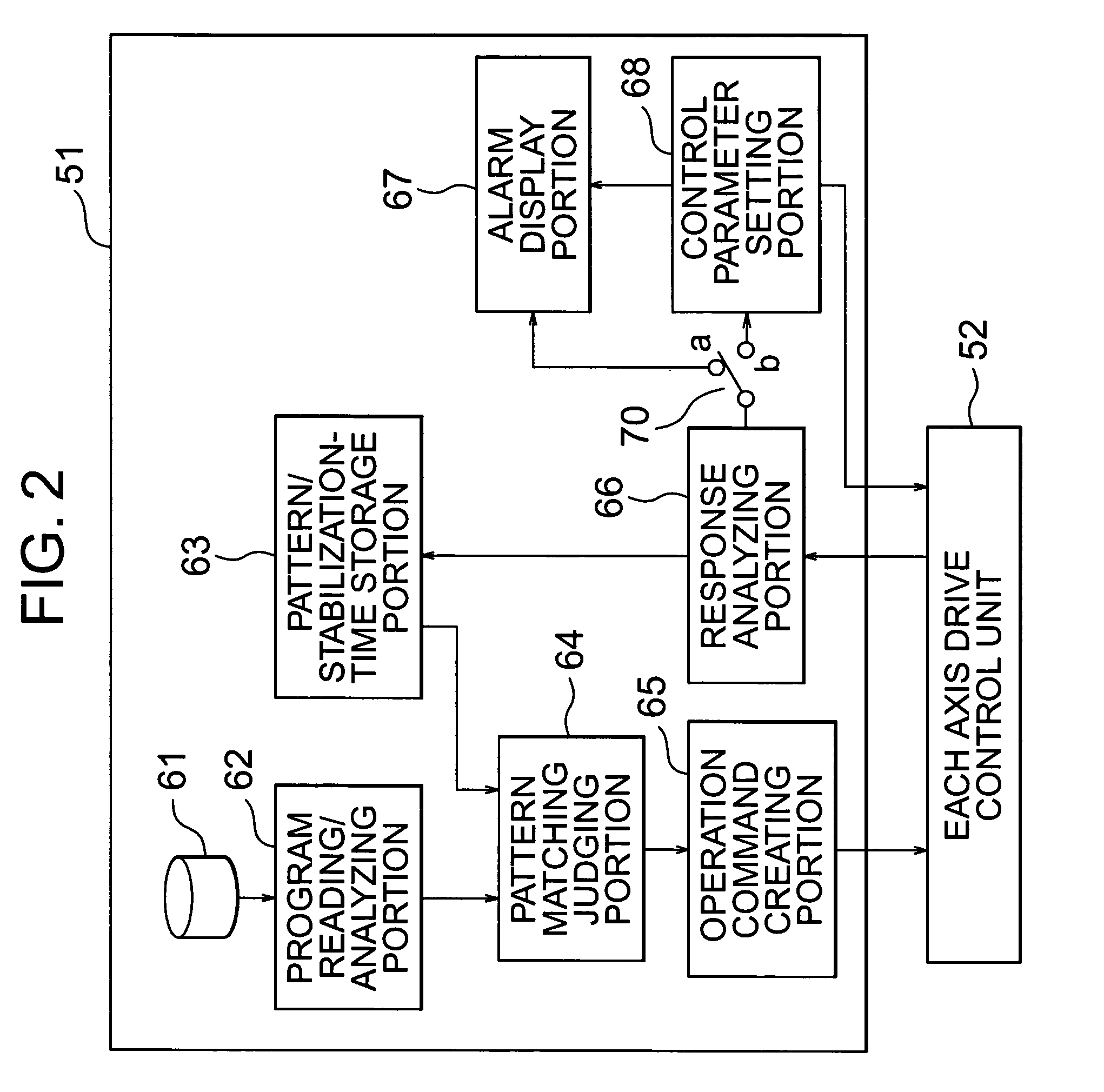

Machining method and machining apparatus

ActiveUS7130715B2Improve work and productivityImprove productivity and qualityProgramme controlAutomatic control devicesPosition responseTime of arrival

In a machining method and a machining apparatus, prior to machining, an NC control unit makes an X-axis drive unit move a table based on examination conditions specified in advance. Thus, the NC control unit obtains a stabilization time required from the command-reach time of a poisoning command and till the stabilization of position response of the table within a predetermined allowable range. Likewise, for moving a drill in a Y-axis direction, the NC control unit obtains a stabilization time required till the stabilization of position response within a predetermined allowable range. At the time of machining, the drill is moved in a Z-axis direction to cut into a printed wiring board as soon as the obtained stabilization time has passed.

Owner:HITACHI SEIKO LTD

Flocking machine

InactiveCN109365232AIncreased villi ionizationImprove productivity and qualityLiquid surface applicatorsCoatingsEngineeringBristle

The invention relates to the technical field of flocking equipment, in particular to a flocking machine. According to the technical scheme, the flocking machine is characterized by comprising a rack,a velvet falling device, an ionization plate and a transporting platform, the velvet falling device is arranged on the rack and located above the transporting platform, and the ionization plate is horizontally arranged between the velvet falling device and the transporting platform, the velvet falling device comprises a metering assembly, a velvet brushing box, brushing rollers rotationally connected into the velvet brushing box, mesh sieves arranged on the bottom of the velvet brushing box and a drive assembly driving the brush rollers to rotate, the metering assembly is connected to the upper side of the velvet brushing box, each brushing roller comprises a velvet brushing shaft and bristle arranged on the velvet brushing shaft, the velvet brushing shaft is electrically connected with anelectrostatic generator, and the velvet brushing box is made of tempered glass. The flocking machine has the advantages of improving the flocking efficiency and quality.

Owner:东莞市诚嘉隆植绒制品有限公司

Method and apparatus for manufacturing imitation pearl beads

InactiveUS20050230865A1Quality improvementReduce contentConfectioneryWood working apparatusComposite materialLearning Imitation

The present invention relates to a method and apparatus for manufacturing imitation pearl beads with / without holes for use in ornaments and accessories. To manufacture the imitation pearl beads, an upper mold having a semicircular recess is fixed at the upper portion of the body of the apparatus, and a lower mold also having a semicircular recess is installed below the upper mold in such a manner that the lower mold descends or ascend. As the lower mold and the upper mold meet, urea resin powder in the recesses is melted and beads are molded through primary and secondary molding processes.

Owner:RHEE YOUNG NAM +1

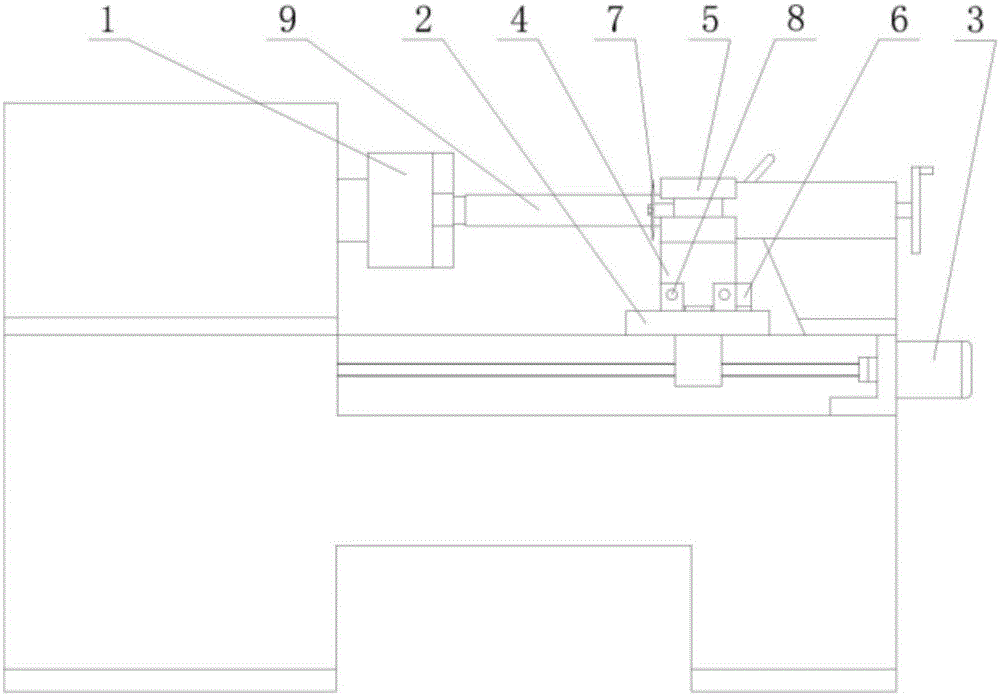

Special-purpose numerically controlled lathe

InactiveCN105149615AImprove productivity and qualityReduce labor intensityAutomatic/semiautomatic turning machinesEngineeringKnife holder

The invention discloses a special-purpose numerically controlled lathe which comprises a control system and a lathe body. A spindle box and a tailstock are fixed to be lathe body, the tailstock is located on the right side of the spindle box, a rotating center is arranged at the left end of the tailstock, a chuck is arranged at the right end of a rotating spindle of the spindle box, a Z-direction sliding rail is arranged on the lathe body, a large carriage capable of performing slippage on the Z-direction sliding rail is arranged between the spindle box and the tailstock and is driven by a Z-direction driving mechanism arranged under the large carriage, a small carriage for performing slidable feeding in the X-direction is arranged on the large carriage, a tool rest for clamping a tool is fixed to the small carriage, and the small carriage is driven by an X-direction driving mechanism. An adhesive tape jumbo roll is cut through the special-purpose numerically controlled lathe, the quality and production efficiency of adhesive tape products can be remarkably improved, the labor intensity of an operator can be reduced, and the production cost of an enterprise can be reduced, and the profit of the enterprise can be improved.

Owner:CHONGQING DACHENG GRACE NC TECH CO LTD

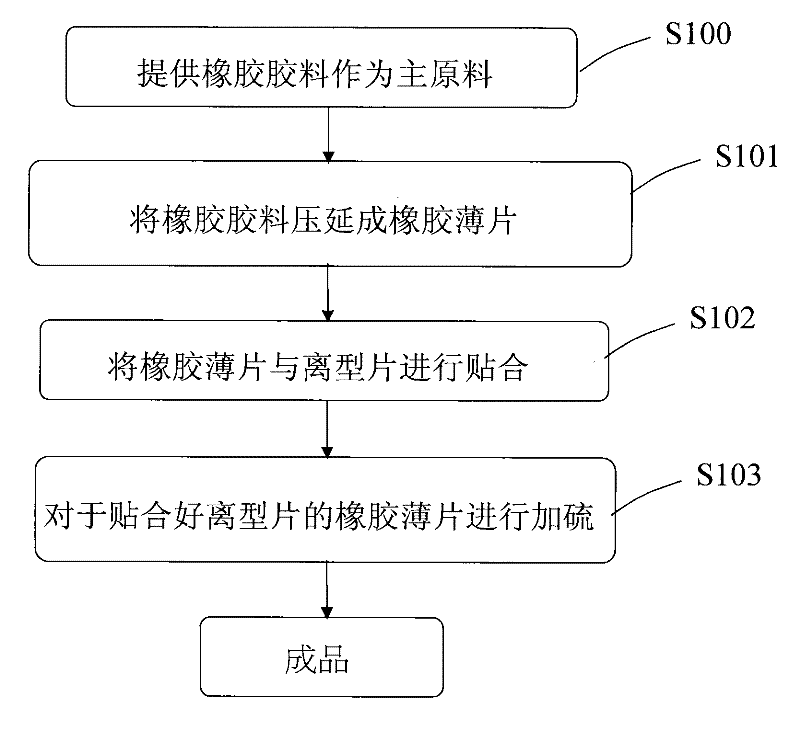

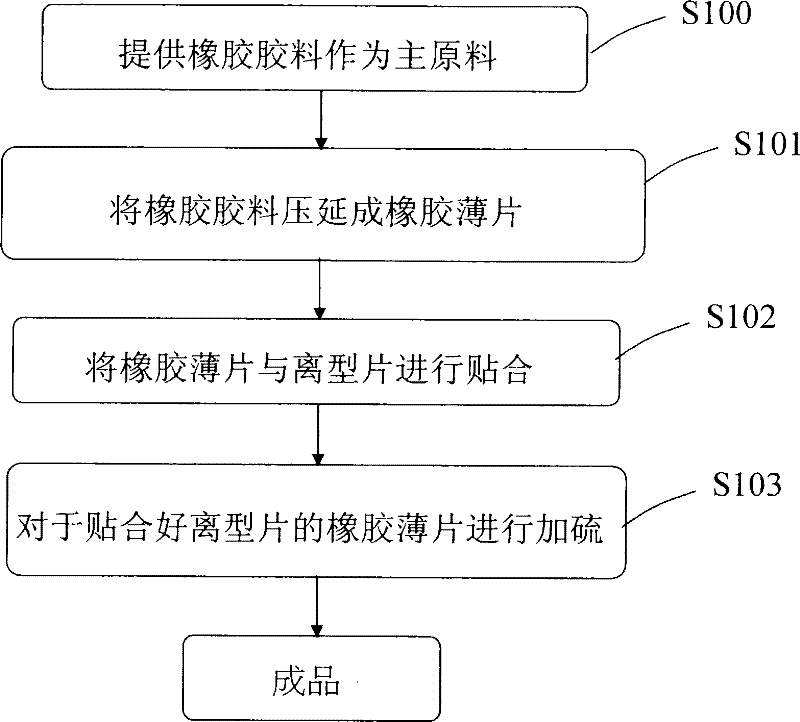

Continuous production method for rubber oil boom

The invention discloses a continuous production method for a rubber oil boom. The method comprises the following steps of: calendaring a rubber material into rubber sheets by using a calendar; jointing in a way of clamping at least one release sheet between every two layers of rubber sheets; and conveying into a sulphureting device for sulphureting to produce a rubber sheet for a required hollow and inflatable rubber oil boom. The production method has a simple production process and low cost, and is very suitable for continuous high-speed mass production; and the problem of solvent volatilization is solved, the yield and quality of the oil boom are increased greatly, and the industrial competitiveness of the oil boom can be further increased.

Owner:FORMOSAN RUBBER GRP

Preparation method of fermented feed additive containing sweet wormwood powder and chrysanthemum powder

InactiveCN109452448ASimple production processImprove productivity and qualityFungiBacteriaFood additiveBacillus aryabhattai

The invention relates to a preparation method of a fermented feed additive containing sweet wormwood powder and chrysanthemum powder. The method comprises five steps: solid carrier preparation, strainrejuvenation and activation, liquid culture medium preparation and seed liquid preparation, secondary culturing, and solid material production. On the one hand, the method is simple in processing andproduction process and standard in production process, and can effectively improve production efficiency and quality and reduce production cost; and on the other hand, the method creatively carries out mixed fermentation modification operation on the components such as the sweet wormwood powder and the chrysanthemum powder and a bacterial liquid formed by traditional bacillus coagulans, saccharomyces cerevisiae and lactobacillus bulgaricus, thereby greatly improving the lactic acid content and palatability. The pH value of the fermented finished product is 4.0-4.5, the content of bacillus coagulans is 10<9> CFU / mL or above, the content of saccharomyces cerevisiae is 10<8> CFU / mL or above, and the content of lactic acid bacteria is 10<8> CFU / mL or above.

Owner:焦作恒辉牧业有限公司

Semiautomatic magnetic core coil winding spot welding machine and winding spot welding method thereof

InactiveCN106563897AImprove productivity and qualityReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesMagnetic coreWinding machine

Owner:SHANGHAI JIUJUN ELECTRONICS SCI & TECH

Intelligent production program transmission system

InactiveCN113031541AImprove productivity and qualityAvoid poor communicationTotal factory controlProgramme total factory controlService layerApplication software

An intelligent production program transmission system disclosed by the present invention comprises an equipment layer, a networking module and a service layer, the networking module comprises a communication module, an edge acquisition computer and a switch, the communication module comprises a communication board card and an IO parallel card, the service layer comprises a server and a personal terminal, the personal terminal is in communication connection with the server, the application software comprises textile equipment programming application software, the textile equipment programming application software is used for generating a knitting program file, and the knitting program file is stored in a server of a research and development system in communication connection with the programming host; According to the scheme, the production program can be set and debugged in the server side according to the types of the socks and process requirements, remote setting and modulation of the program are achieved, non-sensitive connection of process modulation is achieved by updating data to the spinning equipment, and the production efficiency and quality of the socks are remarkably improved.

Owner:浙江富安莱科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com