An automatic operation system of inner leading bonding device of semiconductor device

A technology of welding equipment and operating system, which is applied in the improvement field of microelectronic packaging equipment from manual to automatic, which can solve the problems of high human resources and labor intensity, unstable work efficiency, inconsistent product performance, etc., and reduce labor intensity , Improve the scope of application and use value, and ensure the effect of consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

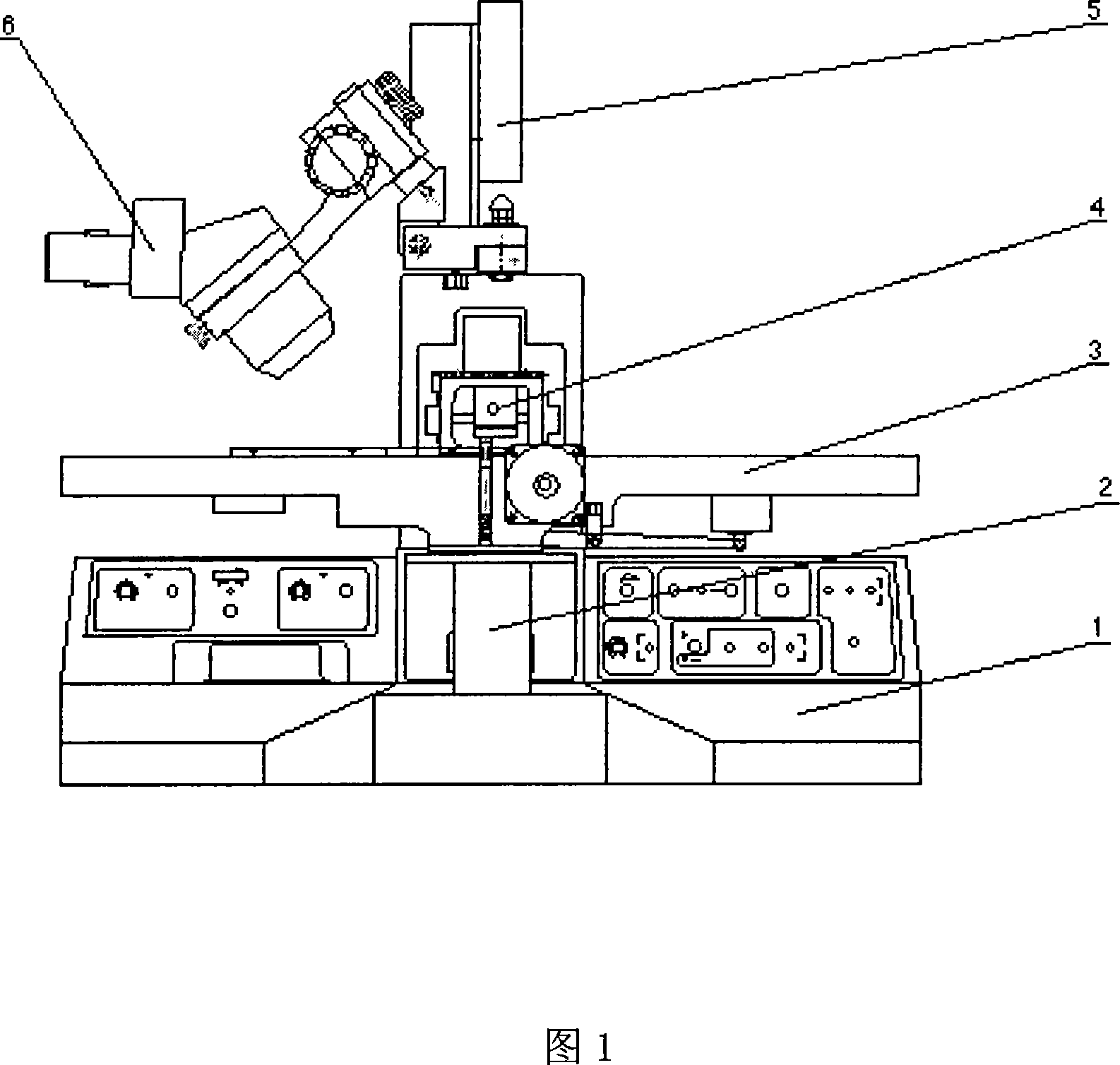

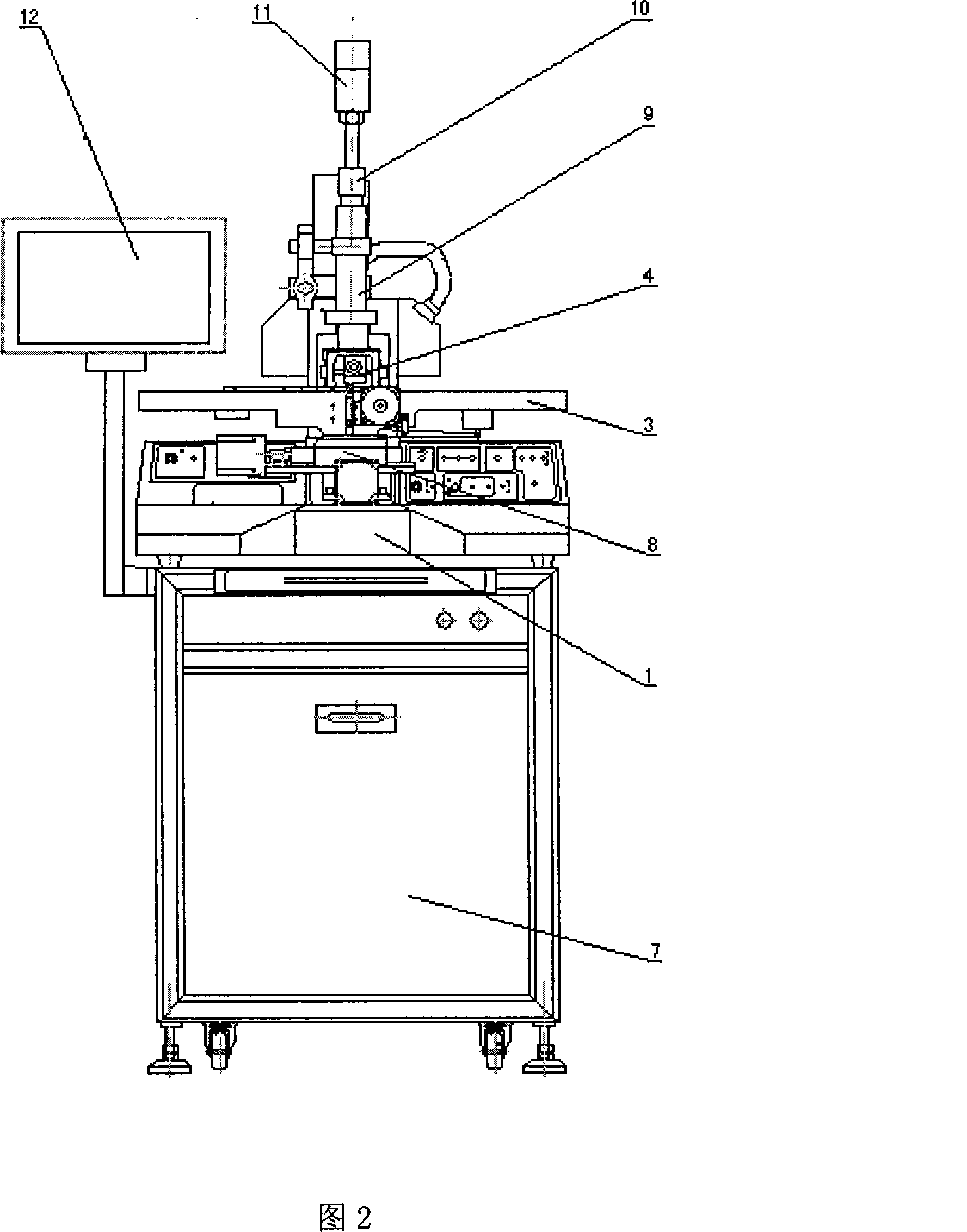

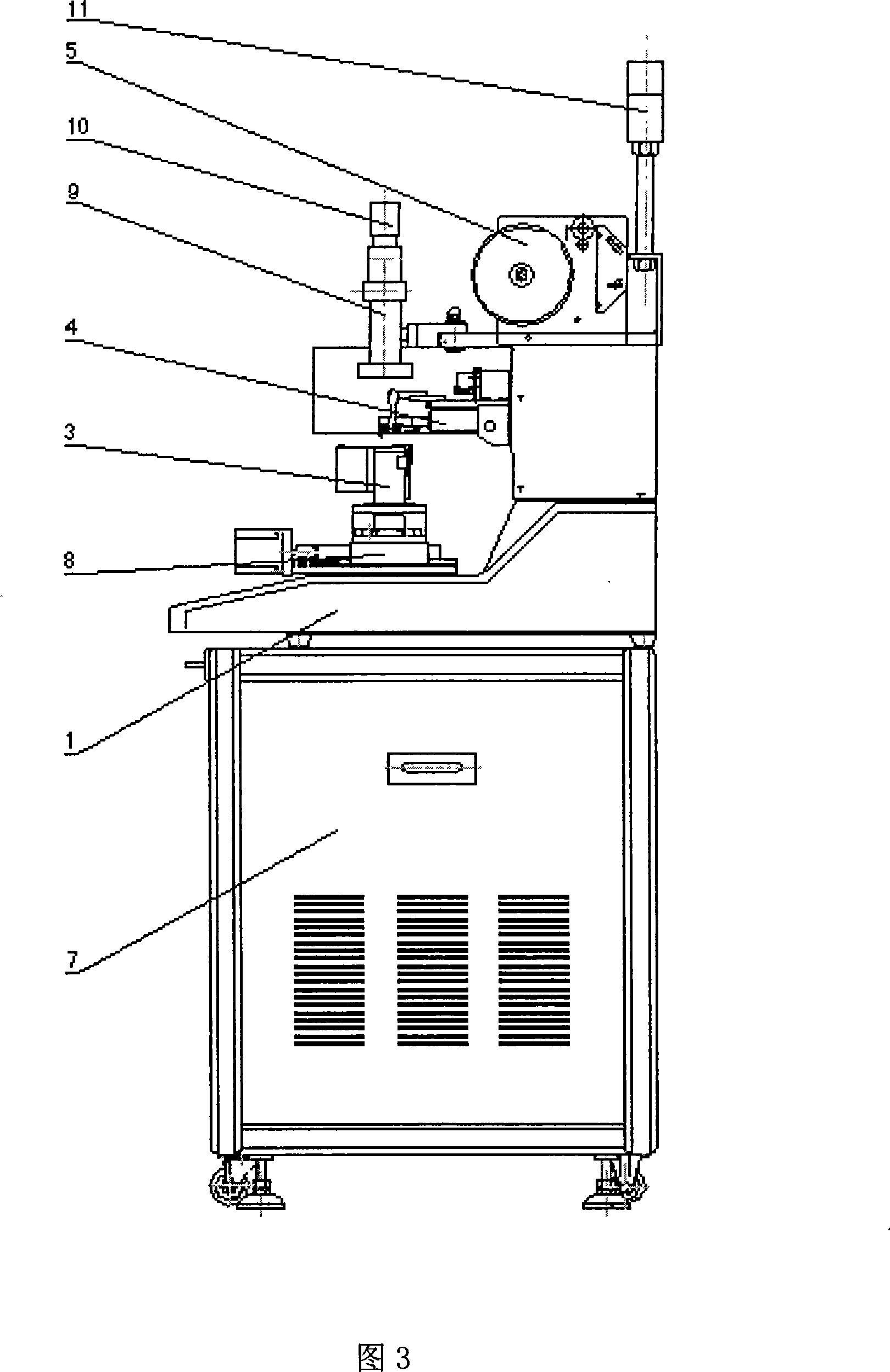

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings. Taking the manual ultrasonic aluminum wire pressure welding machine as an example, the original manual ultrasonic aluminum wire pressure welding machine solder joint alignment is to use a microscope to observe with human eyes, and the operator keeps staring at the welder. In this area, the damage to human eyes is very large. Because of misoperation when people are tired or inattentive, resulting in a high product rejection rate and a decline in product quality. The improved model removes the microscope 6 on the original welding machine, and replaces it with the lens 9, CCD 10, and the image acquisition card in the main box 7 to jointly realize the image acquisition of the chip, and automatically identify the position of the chip through software processing. Manpower is liberated and product quality is improved.

[0018] The displacement of the fixture on the original m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com