Method for measuring thickness of rigid transparent material with laser

A technology of laser thickness measurement and transparent materials, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems affecting production efficiency and achieve the effect of improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

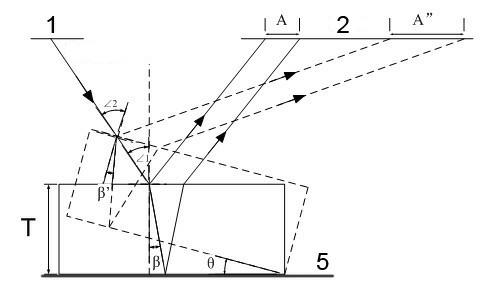

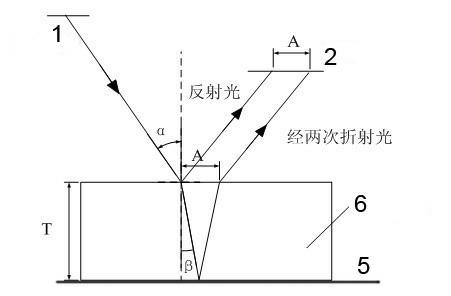

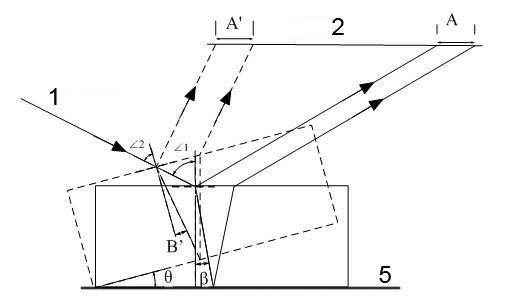

[0022] Such as figure 1 As shown, after the position of the laser light source 1 is fixed, the incident angle of the laser beam is a constant value, the material refraction angle It varies according to the difference in material composition, but the same material for a certain value. Suppose the refractive index of the material 6 to be tested is K, the thickness of the material is T, and the horizontal distance between the two bundles of parallel rays reflected and refracted on the upper and lower surfaces of the material is A. For the convenience of calculation, the laser incident angle is adjusted as . Then the calculation method of the material thickness T at this time is as follows:

[0023] ;

[0024] ;

[0025] (1)

[0026] in:

[0027]

[0028] From equation (1), it can be seen that the thickness T of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com