Double beam coupling device

A dual-beam coupling and laser technology, applied in optics, optical components, laser welding equipment, etc., can solve the problems of high price and inability to obtain welding effects, improve production efficiency and quality, improve welding efficiency and welding quality, overcome difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

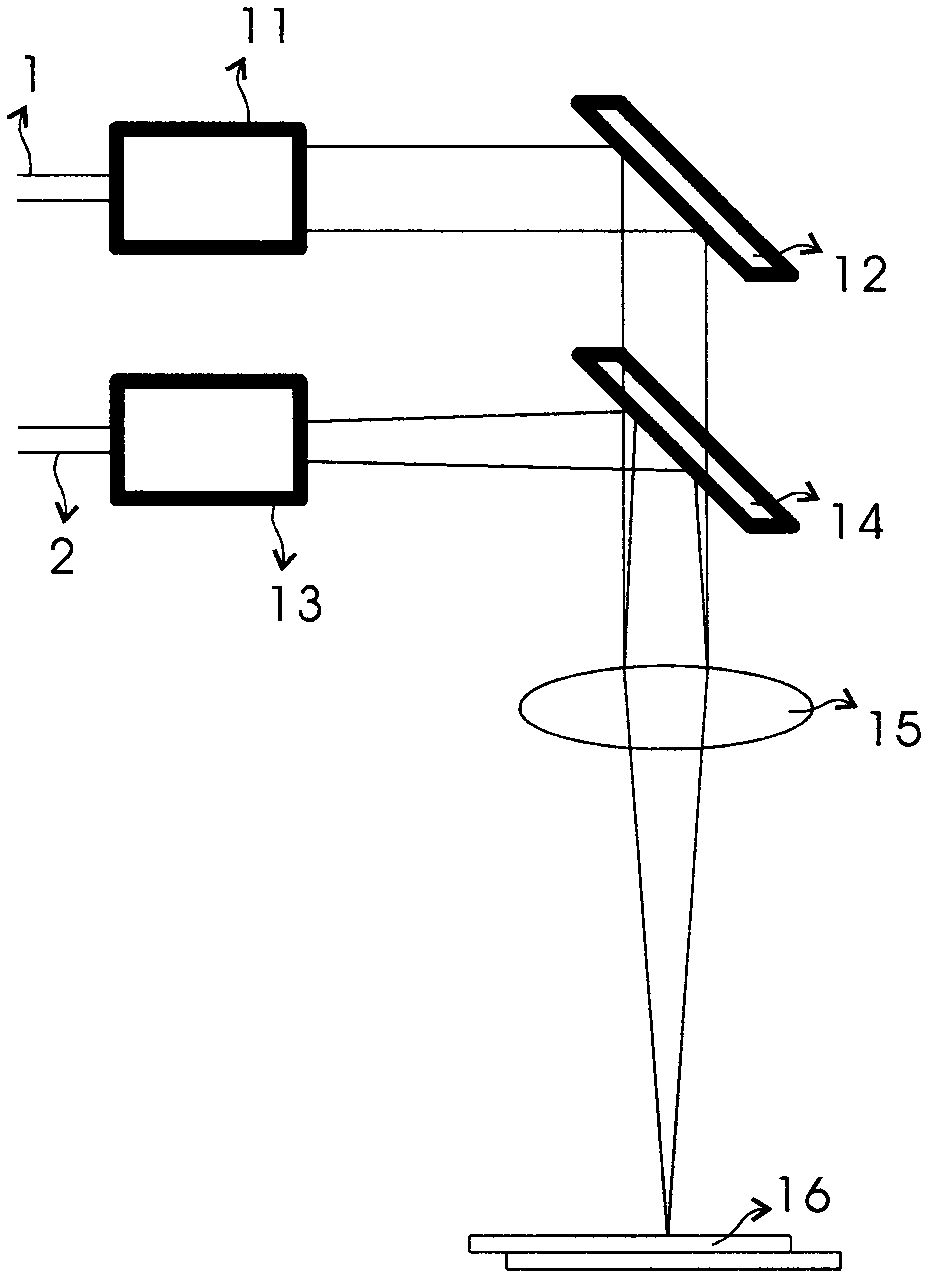

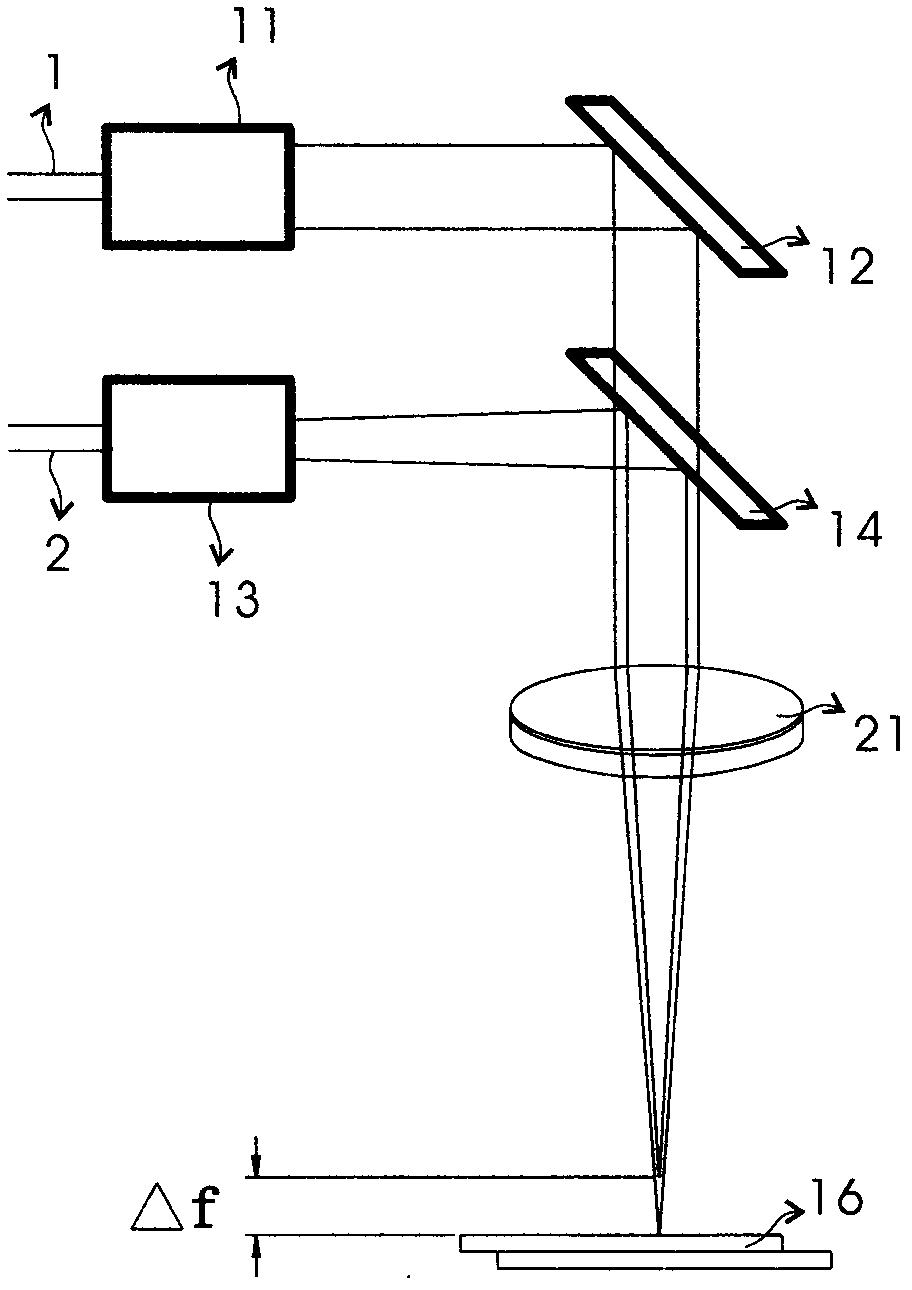

[0015] figure 1 It is a simplified schematic diagram of a device for coupling and focusing two laser beams with different wavelengths according to an embodiment of the present invention. The coupling device includes: a collimation system 11, which collimates the Nd:YAG laser beam 1 into a nearly parallel laser beam; a first 45-degree reflector 12, which is used to reflect the Nd:YAG laser beam 1 with little loss, so that it can be transmitted The direction is changed by 90 degrees; the beam expander system 13 expands the frequency-doubled laser beam 2 of Nd:YAG into a beam with a certain divergence angle; the second 45-degree reflector 14 is used to pass the Nd:YAG laser beam 1 with little loss , and reflect the frequency-doubled laser beam 2 of Nd:YAG with small loss, so that the transmission direction of the frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com