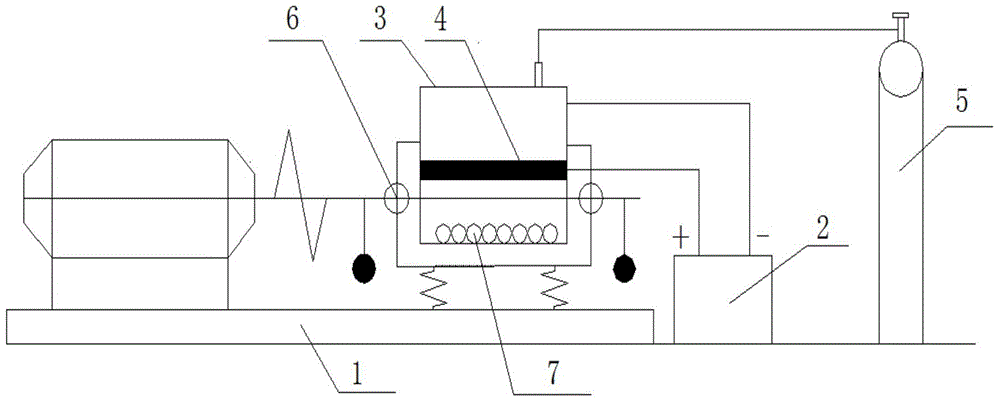

Application method of cold field plasma discharge assisted high energy ball milled powder and plasma assisted high energy ball milling device

A plasma, high-energy ball milling technology, applied in the field of machinery manufacturing and powder metallurgy, can solve the problems of heavy pollution, high energy consumption of mechanical alloying, low efficiency, etc., to accelerate the refinement and promote the alloying process, efficient ball milling, avoid burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Step 1. Use the inner copper core and the outer polytetrafluoroethylene to form the electrode rod. The fastening end and the outer layer of polytetrafluoroethylene insulation use threaded cooperation, and the discharge end adopts a polished rod structure (abandon the threaded structure), and in The gap between the electrode layer and PTFE is fully filled with heat-resistant glue to avoid the existence of air, and the top of the electrode adopts a spherical structure to match the outer insulating medium. Install the electrode rod in a 4L ball mill jar, and fill the ball mill jar with grinding balls and powder to be processed, and place the dielectric barrier discharge electrode rod at the center of the ball mill jar, so that the electrode rod is in contact with the ball mill and the powder to be processed , and then use the end cap of the ball mill jar for sealing and fixing. Among them, the diameter of the electrode rod is 25mm, the grinding ball is made of hard alloy m...

Embodiment 2

[0092] Step 1, step 2, same as example 1;

[0093] Step 3, same as example 1, but the rotating speed of ball mill adopts 960rpm.

[0094] The results show that the service life of the electrode rod can reach about 30 hours.

Embodiment 3

[0096] Step 1, the same as Example 1, but the volume of the ball mill is 0.15L, the diameter of the electrode rod is 20mm, and the grinding ball is made of stainless steel;

[0097] Step 2, same as example 1;

[0098] Step 3 is the same as Example 1, but the discharge current is 1.0A, and the speed of the ball mill is 960rpm.

[0099] The results show that the service life of the electrode rod can reach about 35 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com