Calibration method and device of centering precision of side guide plates of finishing mill

A technology of a calibration device and a calibration method, which is applied in the field of hot rolling, can solve problems such as inaccurate calibration of side guide plates, and achieve the effects of improving the stability of tail throwing, ensuring calibration accuracy and avoiding rolling accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

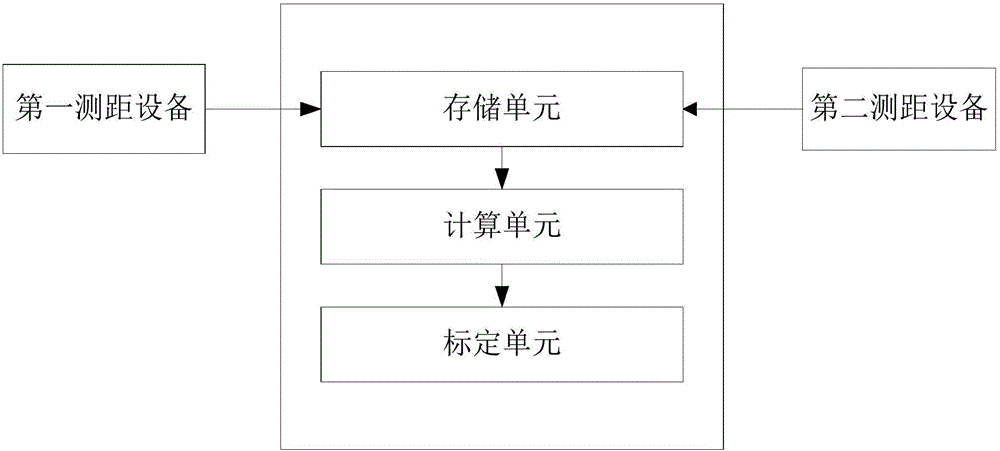

[0026] The embodiment of the present invention solves the problem of inaccurate calibration of the side guide plate in the prior art by providing a calibration method and device for the centering accuracy of the finish rolling side guide plate, and realizes accurate calibration of the opposite side guide plate.

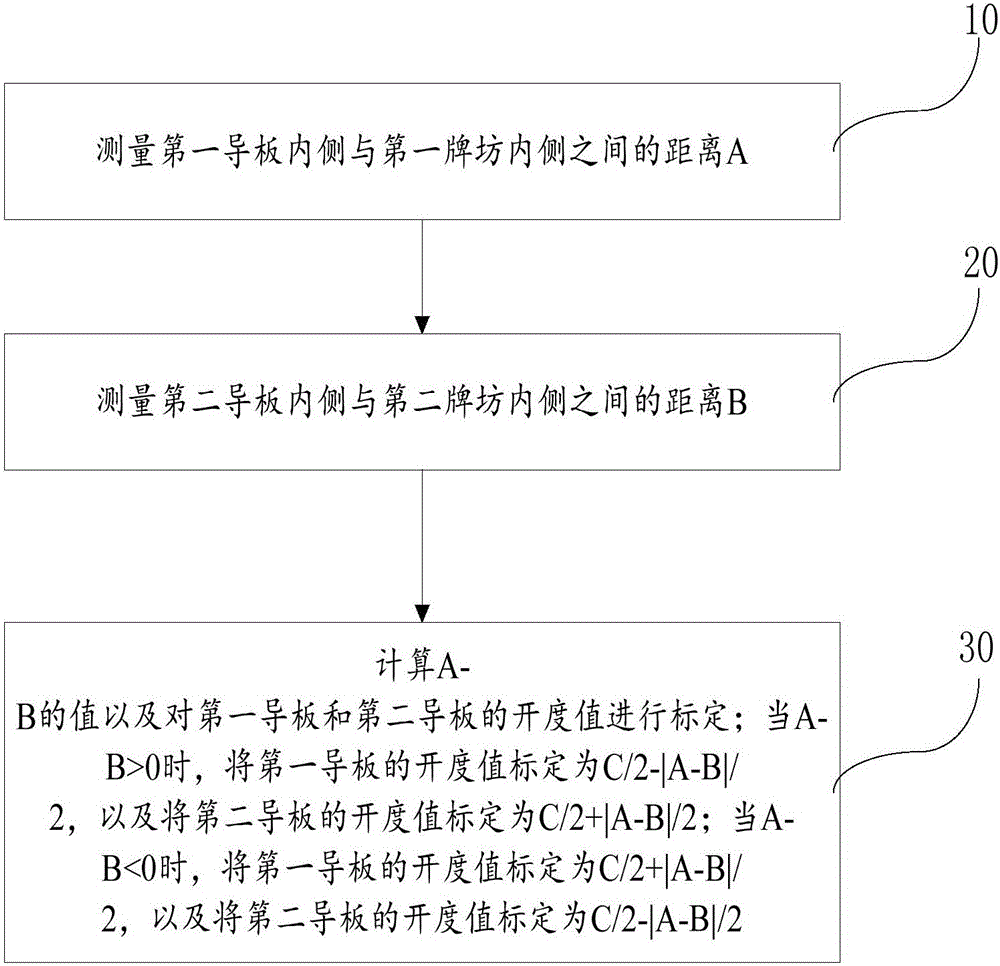

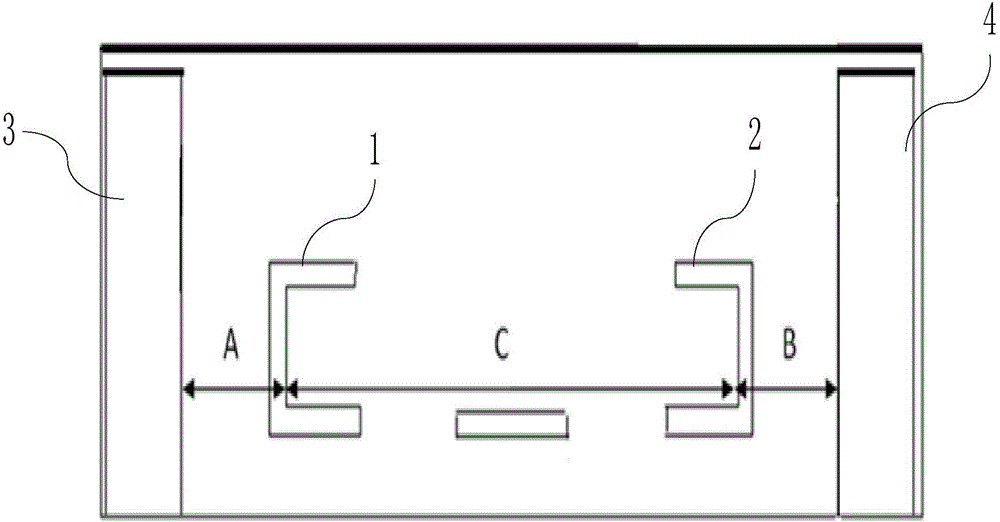

[0027] The embodiment of the present invention provides a method for calibrating the centering accuracy of the side guide plate of the finishing mill, see figure 2 The side guide plate of the finishing mill includes a first archway 3, a second archway 4, a first guide plate 1 and a second guide plate 2 oppositely arranged, and the first guide plate 1 and the second guide plate 2 are located between the first archway 3 and the second archway 4 between. see figure 1 and figure 2 , the calibration method of the centering accuracy of the side guide plate of the finishing mill includes:

[0028] Step 10, measure the distance A between the inner side of the first guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com