Compact chuck type universal mill

A universal rolling mill and chuck-type technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of affecting side roll change, inconvenient roll change, heavy equipment weight, etc., and achieves improvement Overall rigidity and control accuracy, saving time for changing rolls, and increasing operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

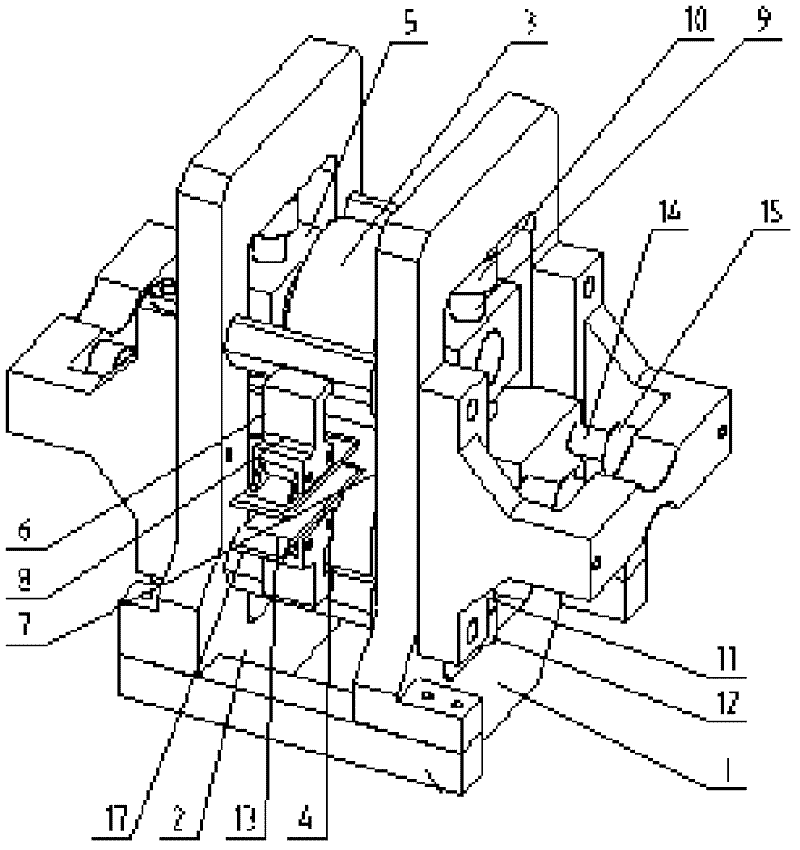

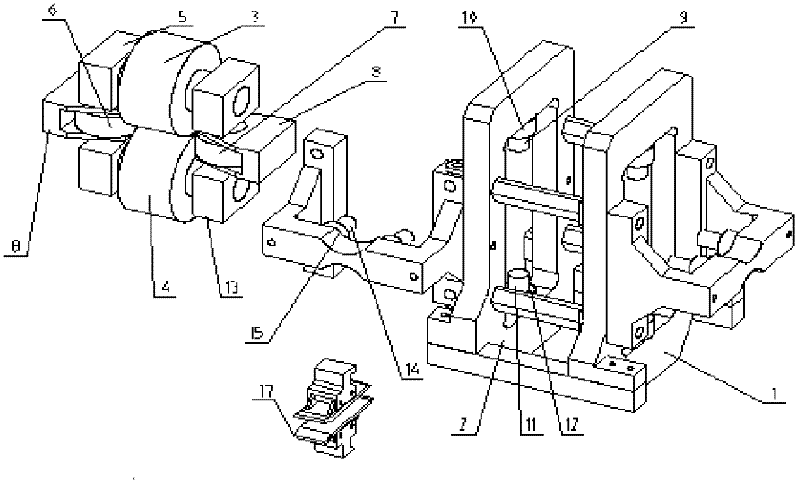

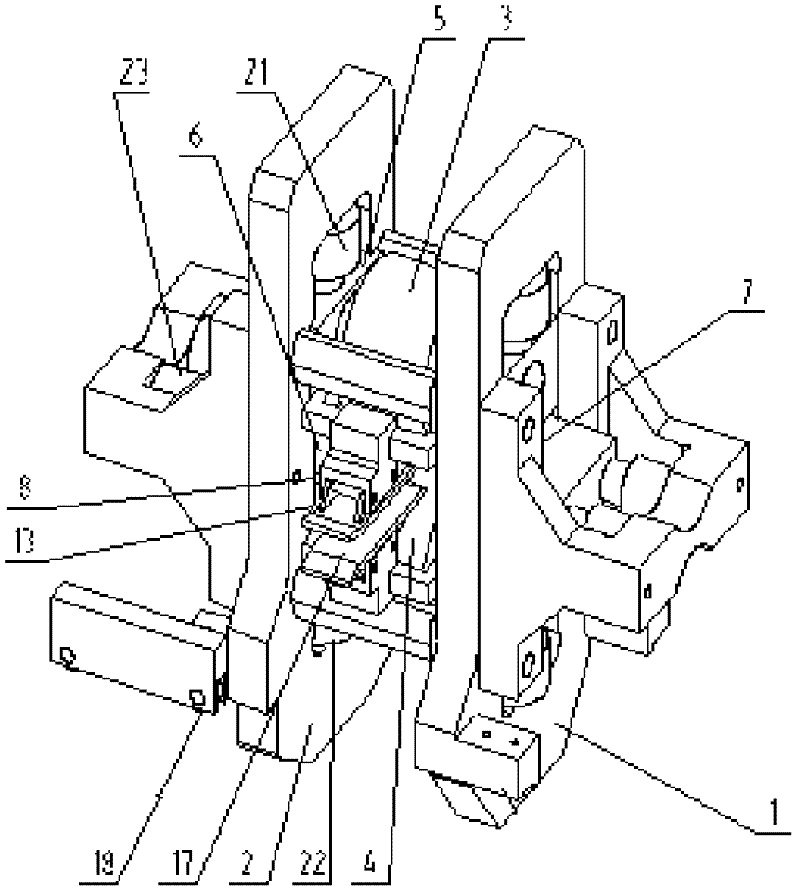

[0019] Such as image 3 , Figure 4 As shown, a kind of compact chuck type universal rolling mill of the present invention comprises frame 1,2, roll system, guide device 17, and wherein roll system comprises horizontal roll 3,4, bearing housing 5,13, vertical roll 6, 7. The vertical roller box 8, 16, the upper horizontal roller 3 is installed on the upper horizontal roller bearing seat 5, the lower horizontal roller 4 is installed on the lower horizontal roller bearing seat 13, and the bearing seats 5, 13 are embedded in the transmission side frame 1 and the operation side In the window of the frame 2, the vertical roll 6 on the operation side is located in the vertical roll box 8 on the operation side, the vertical roll 7 on the transmission side is located in the vertical roll box 16 on the transmission side, and the vertical roll boxes 8 and 16 are located in the bearing housing of the upper horizontal roll 5 and the lower horizontal bearing seat 13, the operating side v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com