Design method based on machine vision inspection centring control device

A technology for machine vision detection and control devices, applied in measuring devices, guiding/positioning/alignment devices, optical devices, etc. issues of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

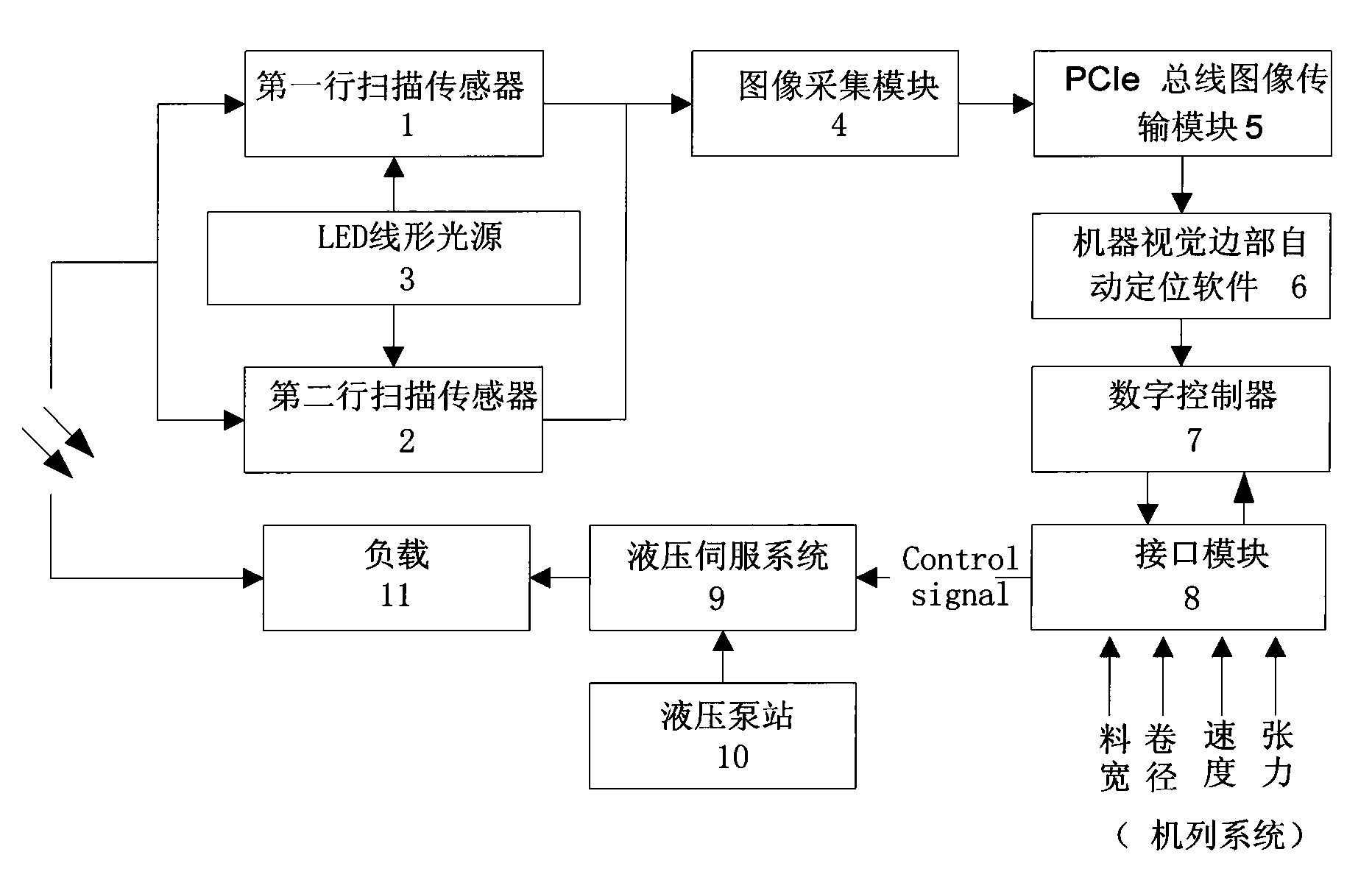

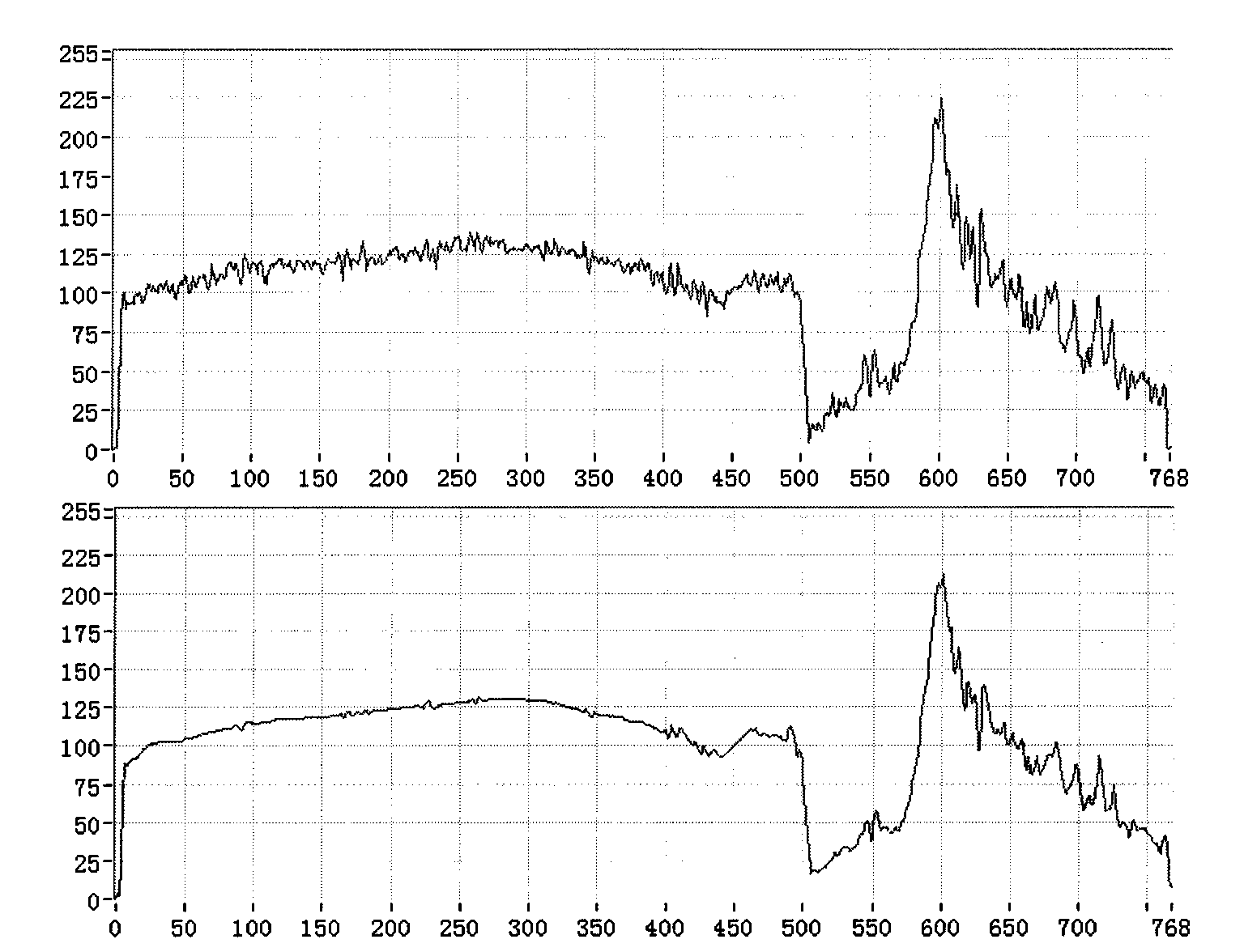

[0028] According to the process, the strip position measurement is divided into two processes. One is to overcome the problem of cylindrical distortion in the video collection method through synchronous linear acquisition of both sides; Adaptive recognition and tracking of the edge of the material; in addition, the vertical range of a detection can be customized due to the use of the first-scan technology, which overcomes the instability of the detection signal caused by the edge crack caused by simple line scanning, and overcomes the traditional video The size of the acquired image is fixed and the refresh cycle is low. In terms of implementation, virtual instrument software technology is used, and flexible and powerful computer software is used to replace some hardware of traditional instruments, so that intelligent detection algorithms can be realized in applications, especially the application of computers in the device directly participates in the generation and measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com