Vertical ring rolling mill capable of realizing on-line measurement control

A measurement control and ring rolling mill technology, applied in metal rolling, manufacturing tools, length measuring devices, etc., can solve the problems of low precision forgings, large consumption of raw materials, inability to achieve online control, etc. High forming accuracy and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

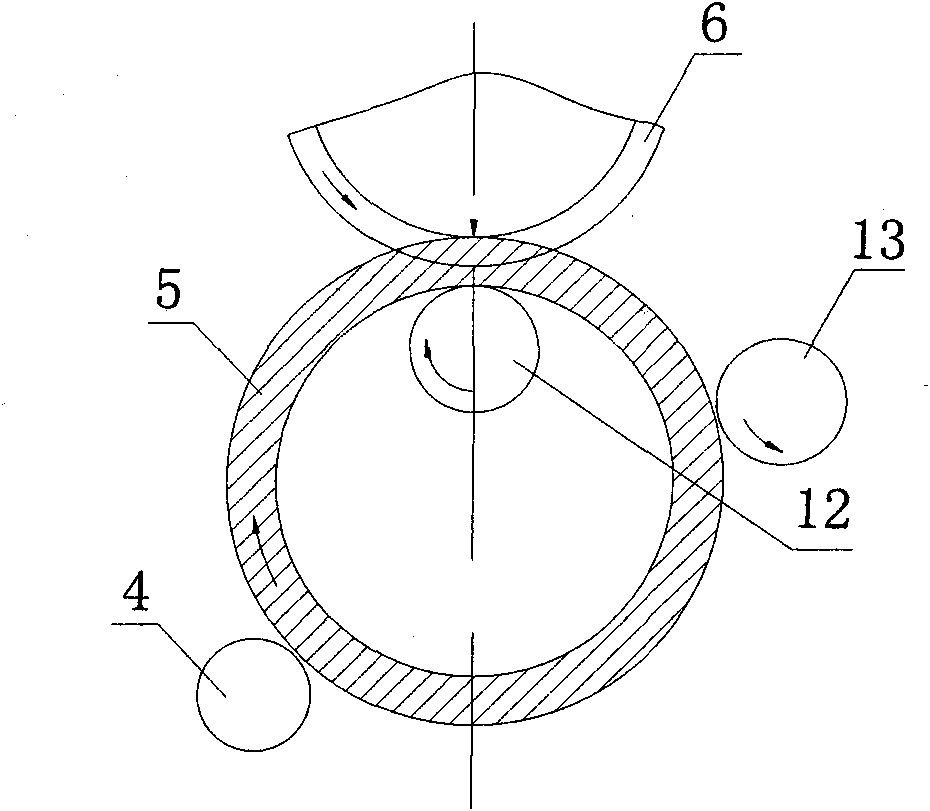

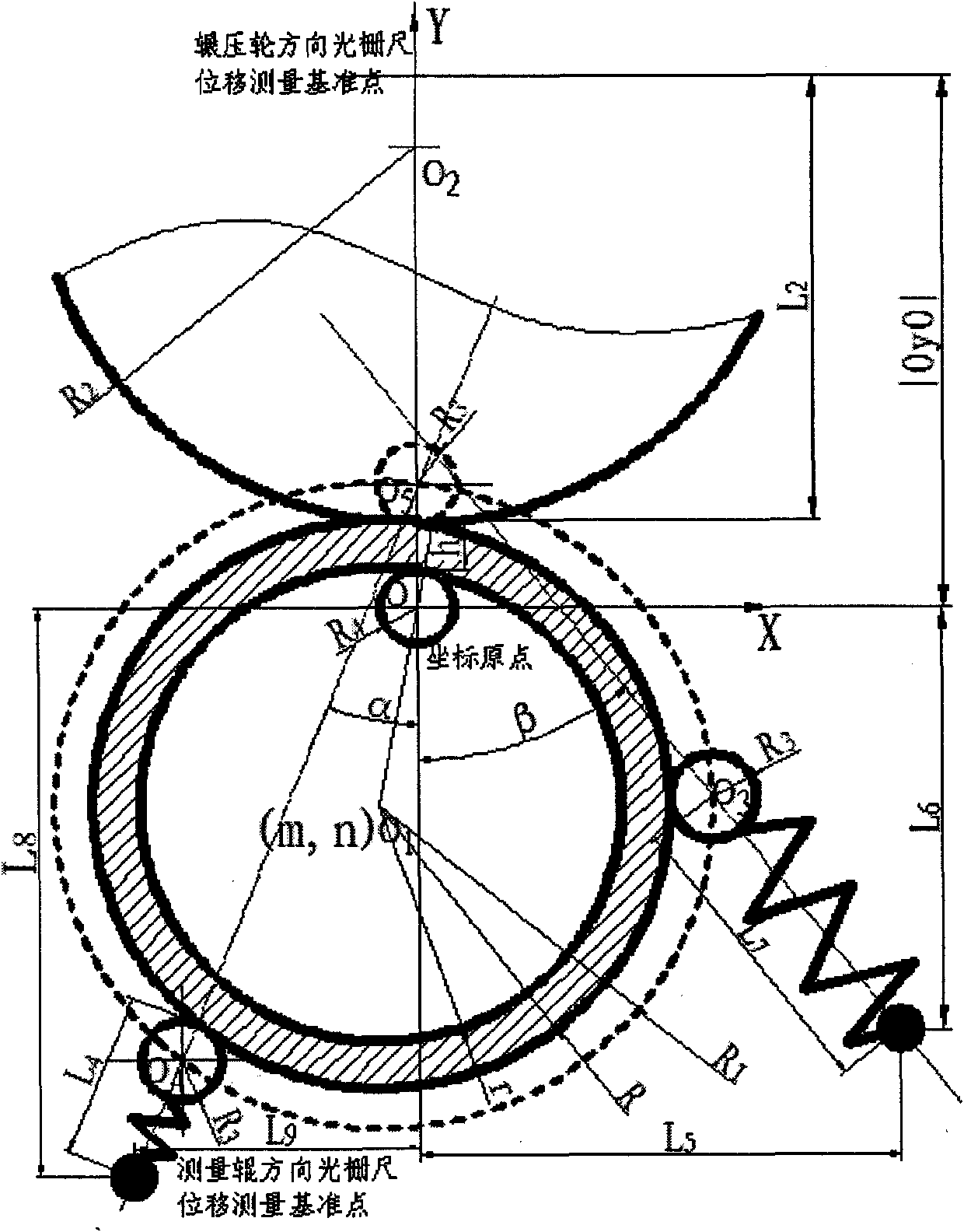

[0032] Such as Figure 4 , Figure 5 As shown, the vertical ring rolling machine that can realize online measurement control includes frame 3, rolling wheel mechanism, measuring roller mechanism, guide roller mechanism, core roller mechanism, unloading device 14 and on-line measurement control device, measuring roller The centerline of the mechanism is at an angle of 50-60° to the vertical centerline of the machine tool, the centerline of the guide roller mechanism is at an angle of 60-70° to the vertical centerline of the machine tool, and the measuring roller 4 of the measuring roller mechanism is located at the core roller of the core roller mechanism 12 below the left ( Figure 4The left side is left, the right side is right), the guide roller 13 of the guide roller mechanism is located on the right side of the core roller 12 of the core roller mechanism, and the rolling wheel 6 of the rolling wheel mechanism is located directly above the core roller 12 of the core roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com