Method for preparing composite wear-resistant foreplate

A kind of technology of guide plate and alloy powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

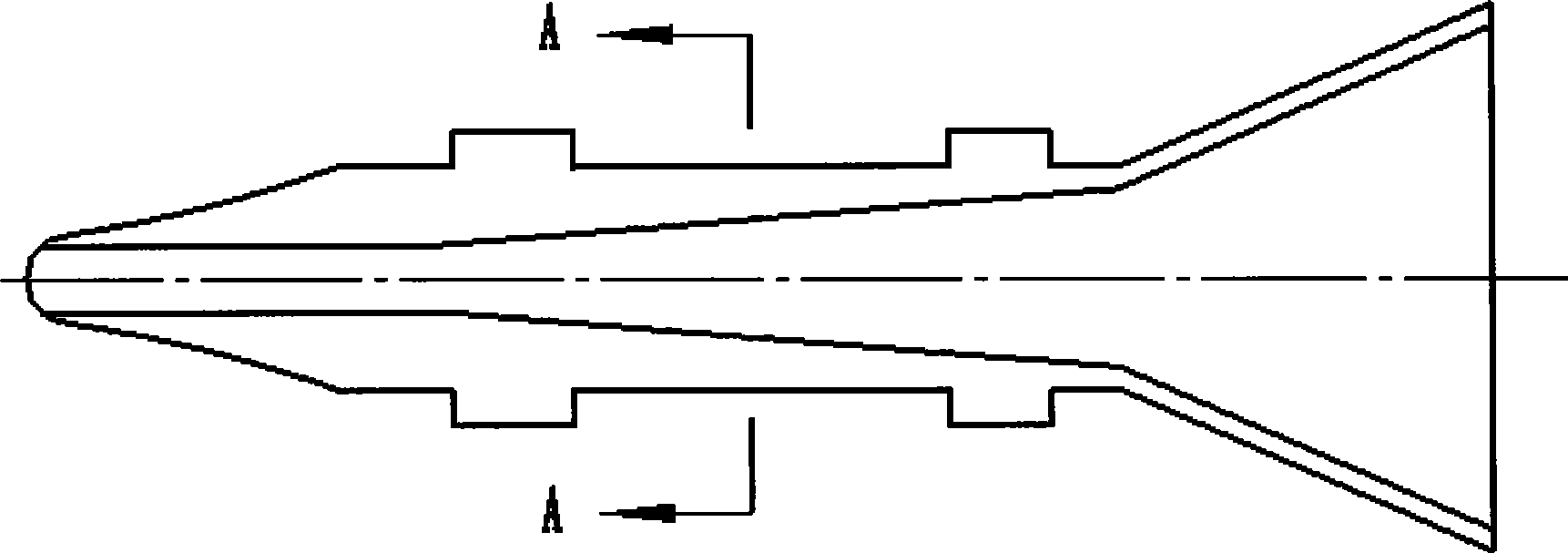

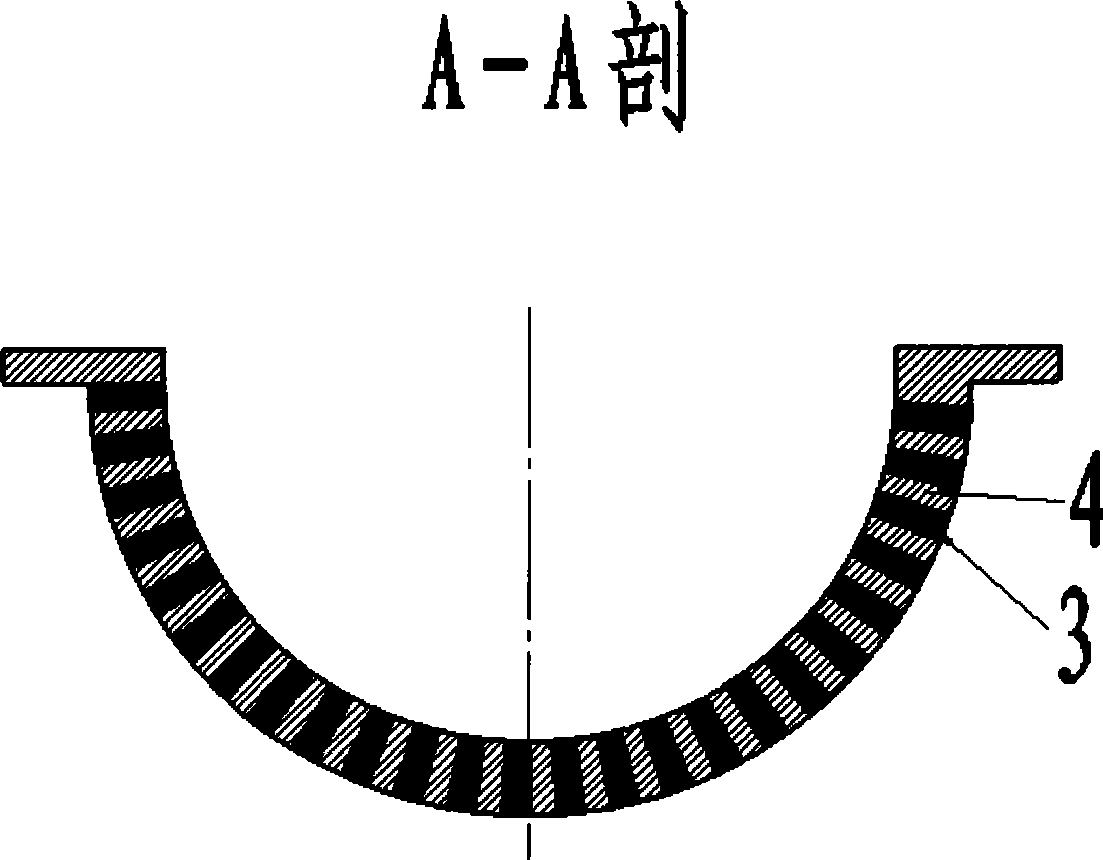

[0024] Example 1: Preparation of a rod-shaped composite wear-resistant guide plate with high chromium alloy as the hard phase and A3 steel as the matrix

[0025] 1. Use 3mm diameter alloy powder core rod 1 to bundle into bundles. The alloy powder loaded in alloy powder core rod 1 is high-carbon ferrochromium powder with a particle size of 100-150 mesh and cut to the same thickness as the guide plate. high;

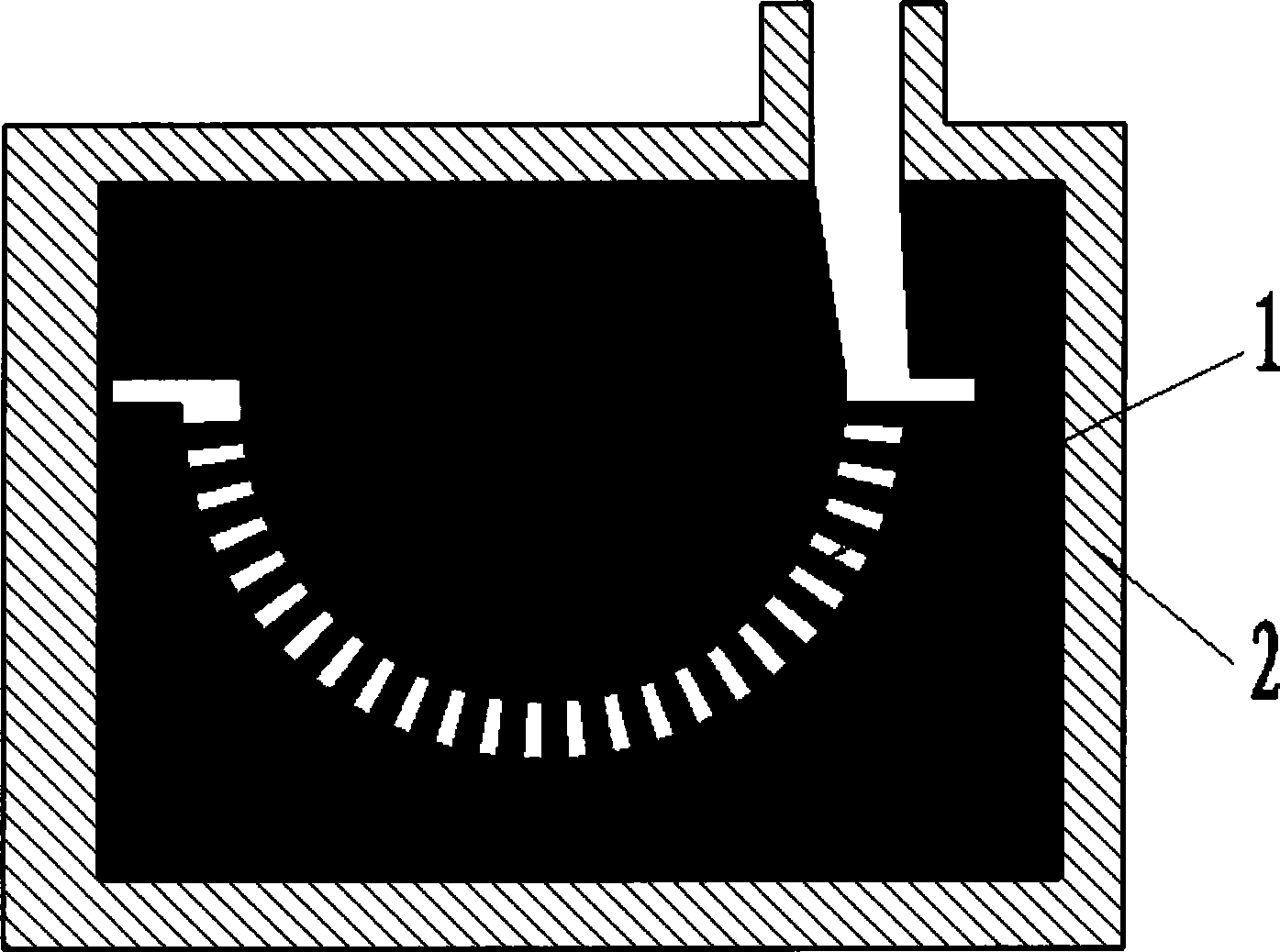

[0026] 2. Use resin sand to make guide plate mold 2 according to the casting process requirements;

[0027] 3. Arrange the bundle of alloy powder core rods in the cavity of the casting mold 2 of the wear-resistant guide plate according to the ratio of 50% of the volume of the wear-resistant guide plate;

[0028] 4. Select A3 steel as the base metal 3. After smelting and melting in an intermediate frequency furnace, it reaches 1600°C and is released from the furnace. The molten steel is poured into the cavity of the guide plate mold 2 until it is full;

[0029] 5. Cool at...

Embodiment 2

[0031] Example 2: Preparation of a rod-shaped composite wear-resistant guide plate with tungsten carbide as the hard phase and A3 steel as the matrix

[0032] 1. Select alloy powder core rod 1 with a diameter of 5 mm to make a bundle. The alloy powder loaded in alloy powder core rod 1 is tungsten carbide alloy powder with a particle size of 150 mesh, which is cut to the same length as the thickness of the guide plate;

[0033] 2. Use resin sand to make guide plate mold 2 according to the casting process requirements;

[0034] 3. The alloy powder core rod 1 is preset in the mold cavity of the wear-resistant guide plate according to the ratio of 40% of the volume of the wear-resistant guide plate;

[0035] 4. Select A3 steel as the base metal 3. After smelting and melting in an intermediate frequency furnace, it reaches 1600°C and is released from the furnace. The molten steel is poured into the cavity of the guide plate mold 2 until it is full;

[0036] 5. Cool at room tempera...

Embodiment 3

[0037] Example 3: Preparation of a rod-shaped composite wear-resistant guide plate with tungsten carbide as the hard phase and high manganese steel as the matrix

[0038] 1. Use 3mm diameter alloy powder core rod 1 to make bundles. The alloy powder loaded in alloy powder core rod 1 is tungsten carbide alloy powder, with a particle size of 50-80 mesh, and cut to the same length as the thickness of the guide plate. ;

[0039] 2. Use resin sand to make guide plate mold 2 according to the casting process requirements;

[0040] 3. The alloy powder core bar 1 is preset in the mold cavity of the wear-resistant guide plate according to the ratio of 60% of the volume of the wear-resistant guide plate;

[0041] 4. Select high manganese steel Mn13 as the base metal 3. After smelting and melting in an intermediate frequency furnace, it reaches 1650°C and is released from the furnace. The molten steel is poured into the cavity of the guide plate mold 2 until it is full;

[0042] 5. Cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com