Method suitable for width measurement and centering of rough rolling slab in hot rolling mill

A technology for slab and rough rolling, applied in the field of computer control of steel rolling, can solve problems such as unsolvable problems, and achieve the effects of avoiding malfunction, ensuring rolling quality and equipment safety, and enhancing equipment performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

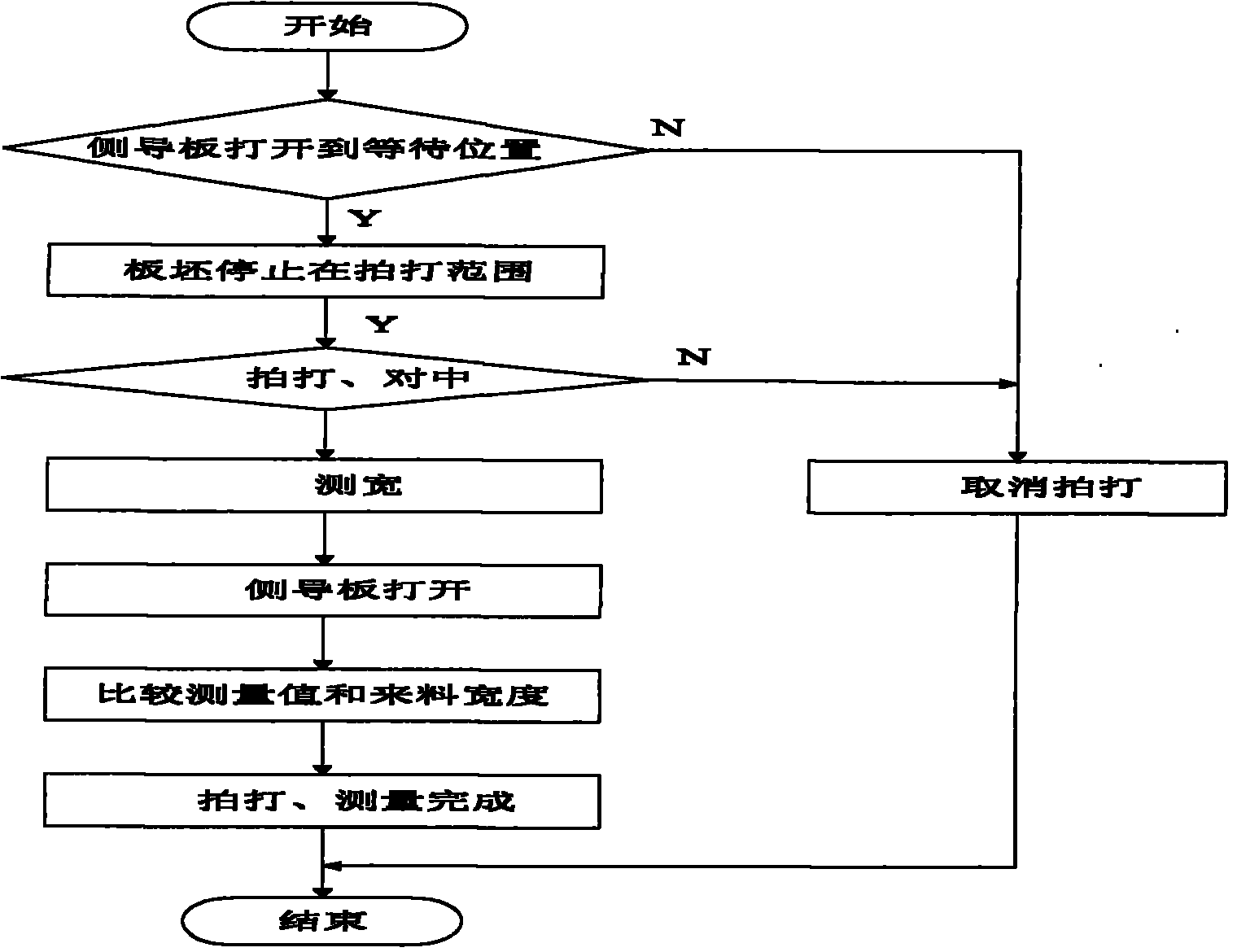

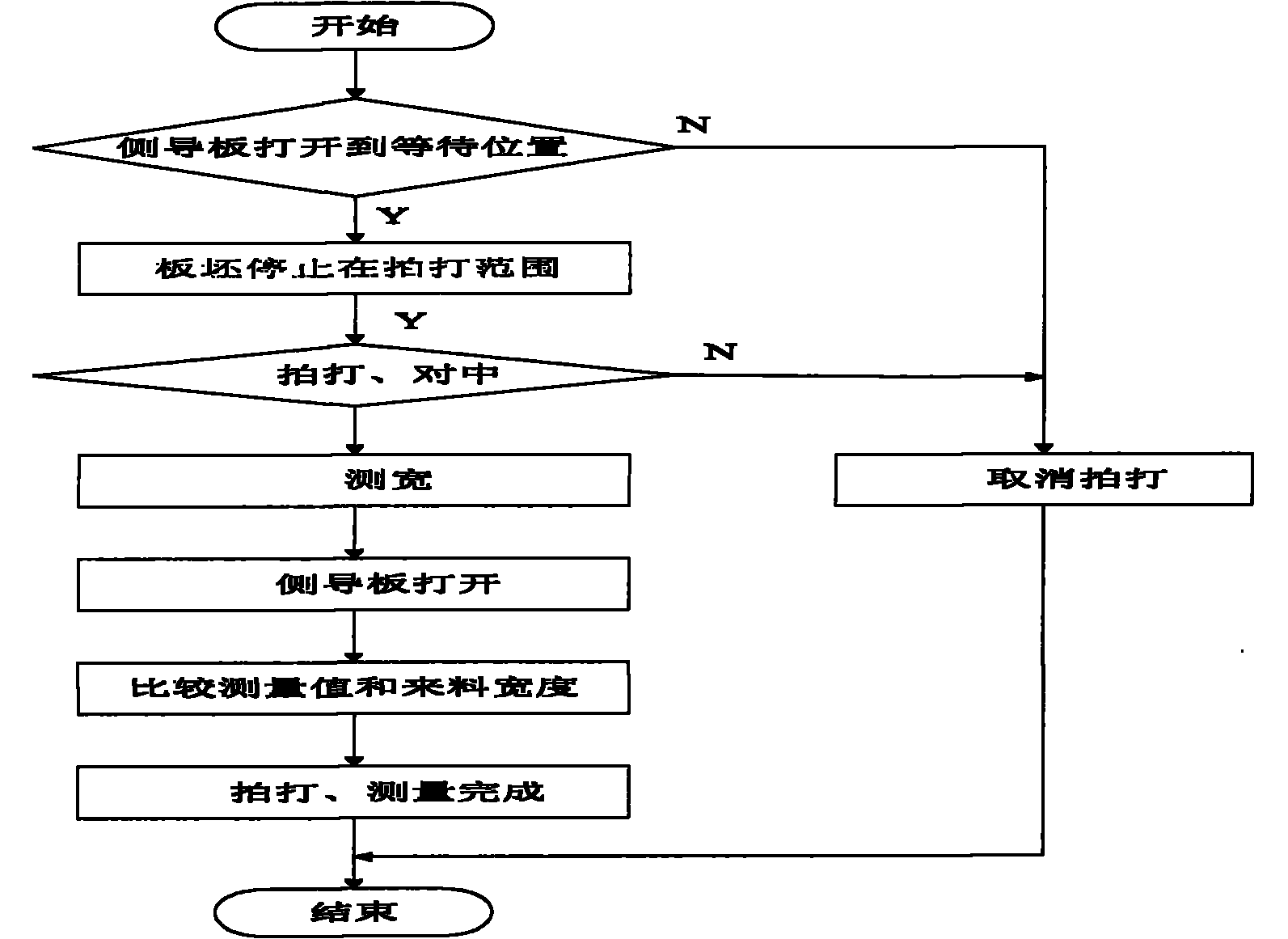

[0021] In this embodiment, the existing rolling mills with computer-controlled left and right guide plates are retrofitted. Pressure sensors whose signal lines are input to the computer are installed on the inner sides of the left and right guide plates, and the computer controls the side guide plates according to the steps after the transformation. , The specific control process is shown in Figure 1.

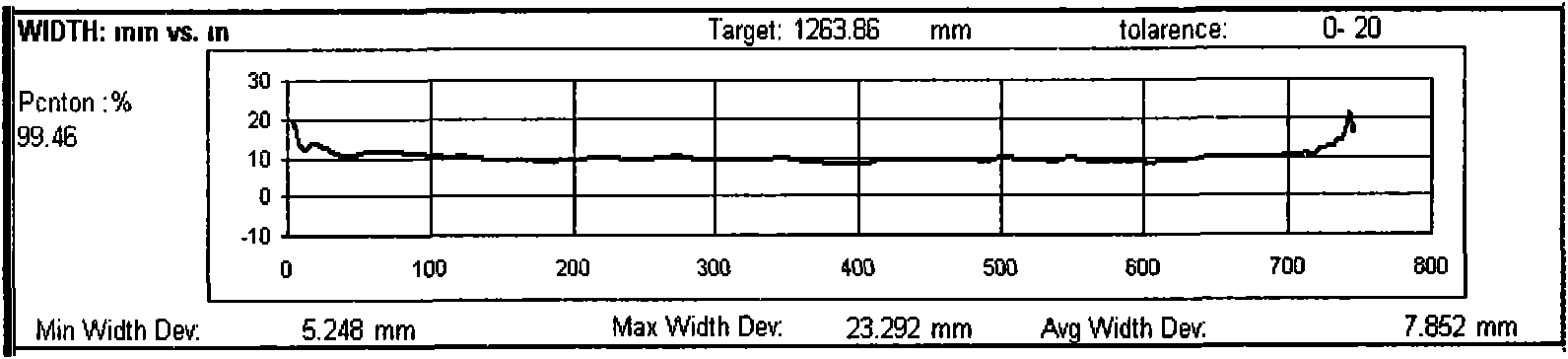

[0022] In actual operation, there are 2 steel coils. The ID of the coils are 82376030100 and 8243630600 respectively. The steel grades are SPHC. The original width of the slab is 1250mm. The actual measured width is about 1242.5mm, and the required width of the finished product is 1250mm. The actual firing temperature of the slab is 1160℃ and 1174℃. The original thermal width data of the slab predicted by the model is 1271.6mm and 1272.0mm. 82436030600 uses the method of the present invention, while 82376030100 does not use the present invention, as a comparison. The control step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com