Oil-water separation composite filter material and preparation method thereof

A filter material, oil-water separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., to achieve the effect of low cost, good engineering application prospects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

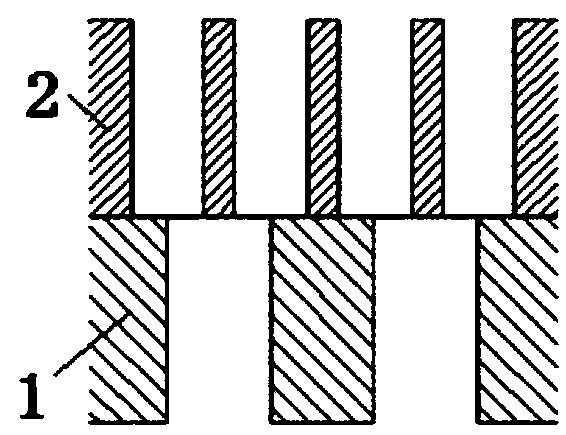

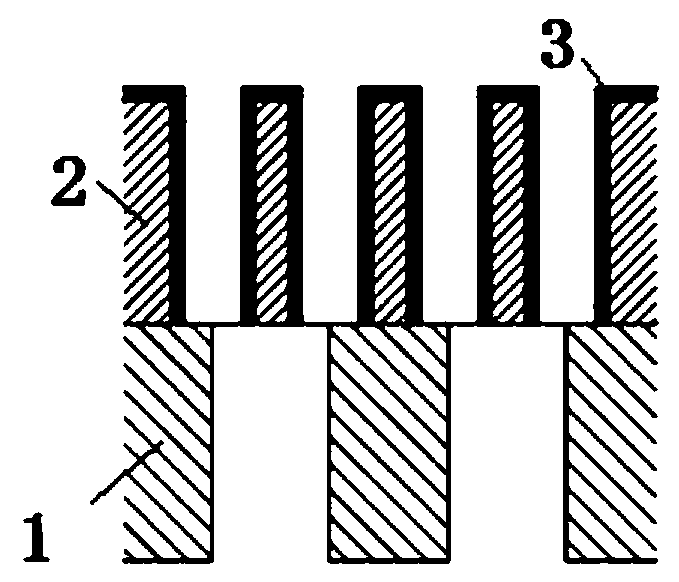

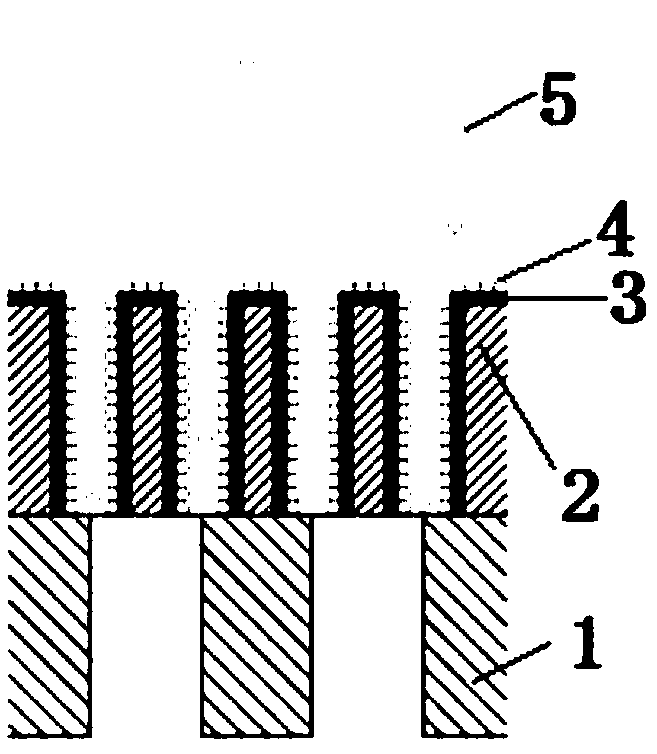

[0031] The preparation method of the oil-water separation composite filter material among the present invention comprises the following steps:

[0032] Step 1: Prepare support material and base filter material

[0033] Choose a metal or other material filter screen with a good rigidity and a pore size of 0.5-10mm as the supporting material, with a thickness of 0.5-10mm, and a metal or other material filter screen with a pore size of 5-300μm as the base filter material, with a thickness of 0.1- 0.5mm, by means of sintering or mechanical fixation, the base filter material is placed on the surface of the support material to form a composite structure.

[0034] Step 2: The surface of the base filter material is evenly coated with the adhesive material by means of spraying or dipping, with a thickness of 10-150 μm, preferably 10-50 μm for dipping, and 50-150 μm for spraying. When a curing agent is added to the adhesive material, after the curing agent is added and stirred evenly, ...

Embodiment 1

[0040] A high-strength refined steel mesh with a thickness of 1 mm and a pore diameter of 2 mm was selected as the supporting material, a metal felt with a pore diameter of 10 μm and a thickness of 100 μm was used as the base filter material, and hydrophobic silica microspheres with a particle size of 500 nm were used as the surface shape. Surface modified particles (nanoparticles). The two support materials and the base filter material are sintered to form a composite filter screen. Immerse the composite filter in the fluorocarbon resin for 20 minutes and take it out. Immediately after taking it out (within 1 minute), hang it in the suspension space of silica microspheres. After the fluorocarbon resin is dry and solidified, take it out and blow off the excess particles on the surface. After being taken out of the confined space, it is completely solidified to form an oil-water separation composite filter material with special wettability. The prepared oil-water separation co...

Embodiment 2

[0042] A metal filter with a thickness of 0.5mm and a pore size of 1mm is used as the supporting material; a metal microporous filter material with a pore size of 10μm and a thickness of 100μm is used as the base filter material, and a composite structural network is formed by pressing and sintering. Immerse the composite filter in the silicone resin for 20 minutes, take it out and hang it in the suspension space of silica microspheres with a particle size of 500nm, take it out after 10 minutes and solidify at room temperature to form an oil-water separation composite with special wettability filter material. The prepared above-mentioned oil-water separation composite filter material is used for the separation of oil-water mixture (diesel oil and water are mixed and stirred at a ratio of 1:10 to form an oil-water mixture), and a separation effect higher than 99% can be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com