Powder recovering and treating device applied to metal powder spraying

A metal powder, recycling technology, applied in the direction of spraying equipment, etc., can solve the problems of difficult material reuse, waste of metal powder coatings, etc., to achieve the effect of reducing floor space, increasing comfort, and avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

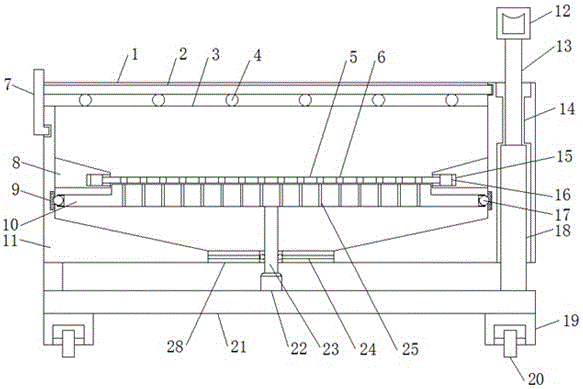

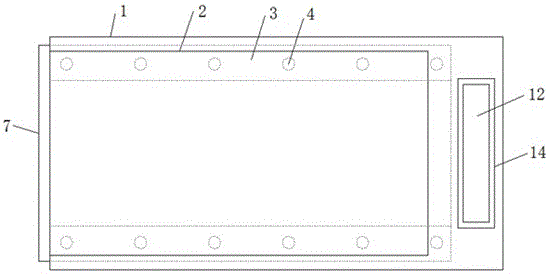

[0026] refer to Figure 1-5 , a powder recycling and processing device that uses metal powder spraying, including a device body 1, the device body 1 is a cavity structure, an opening is provided on the top side of the device body 1, and a first chute 3 is connected to both sides of the opening, There is a baffle 2 arranged horizontally in the opening, and two groups of first rolling balls 4 arranged in a straight line are arranged at the bottom of the baffle 2, and the first rolling balls 4 are slidingly connected with the first chute 3, and the baffle 2 is far away from the device. One side of the body 1 is provided with a vertical clamping plate 7, and the inner walls of both sides of the device body 1 are provided with a fixed block 8, and the side where the two fixed blocks 8 are close to each other is provided with a card slot 15, and the card slot 15 There is a screen plate 5 arranged horizontally between them, the screen plate 5 is provided with a plurality of first scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com