Preparation method of polydopamine modified imidazolyl nano particle composite nanofiltration membrane

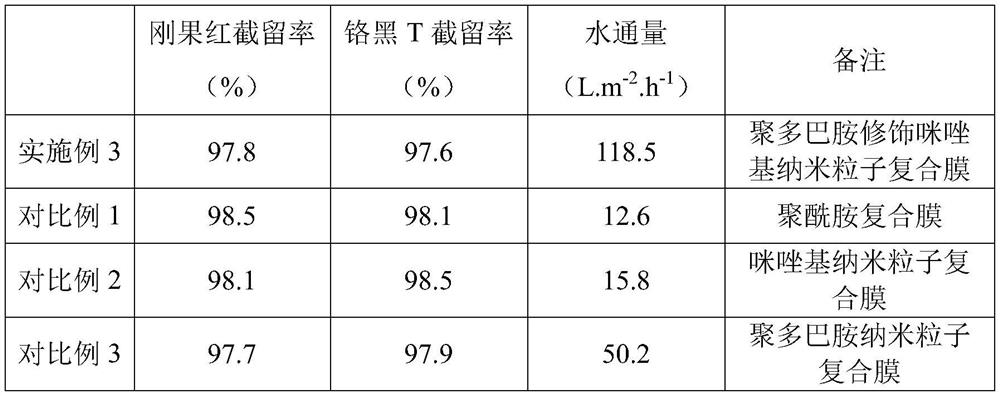

A composite nanofiltration membrane and nanoparticle technology, applied in the field of membrane separation, can solve the problems of limited scale production and application, difficult control of membrane structure and performance, complex synthesis and dispersion stability methods, etc., and achieve good pollution resistance, The effect of performance optimization and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

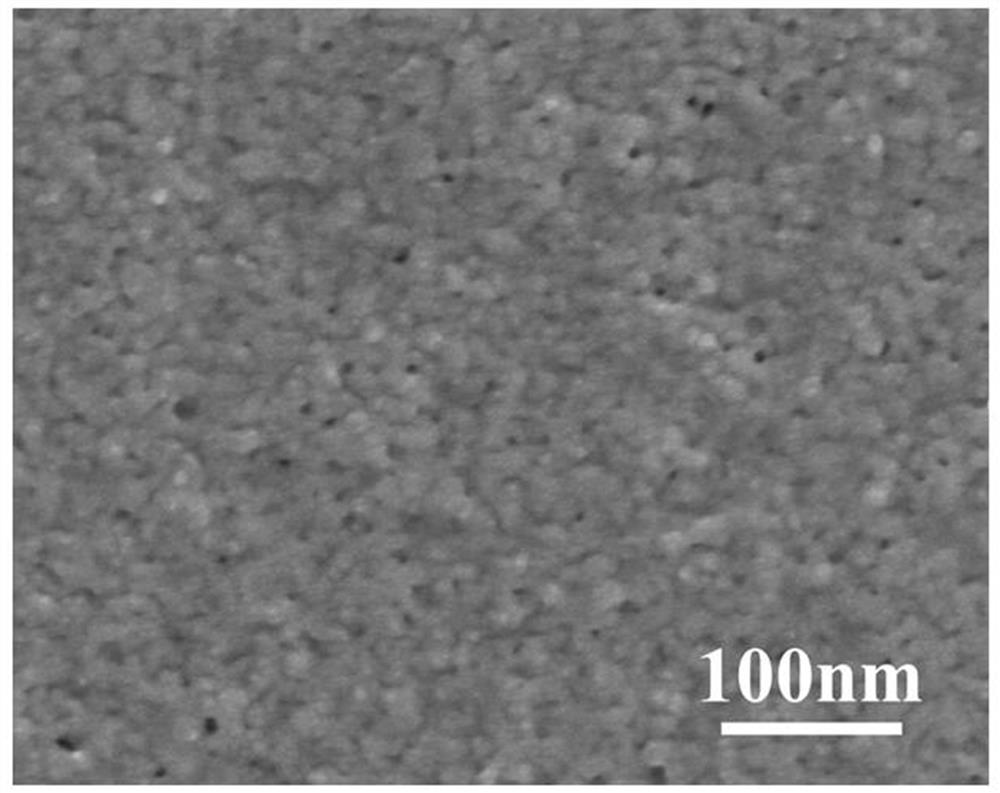

Image

Examples

preparation example Construction

[0023] The preparation method of the polydopamine-modified imidazole-based nanoparticle composite nanofiltration membrane described in this embodiment comprises the following steps:

[0024] 1) Dissolve 0.02-0.5 parts by mass of aromatic polyamine monomer molecules in 100 parts by mass of acidic aqueous solution, and then add 0.02-0.2 parts by mass of aldehyde compounds and 0.2-0.6 parts by mass of dicarbonyl compounds to the above-mentioned Mix evenly in an acidic aqueous solution, polycondense at 60-120°C for 1-72 hours, centrifuge, wash with deionized water, and freeze-dry to obtain imidazole-based nanoparticle powder;

[0025] 2) Dispersing 0.01 to 0.5 parts by mass of imidazole-based nanoparticles in 100 parts by mass of an alkaline aqueous solution, then adding 0.005 to 1.0 parts by mass of dopamine, and passing oxygen into it for oxidative polymerization to obtain polydopamine-modified imidazole-based nanoparticles aqueous dispersion;

[0026] 3) Dip-coat the surface o...

Embodiment 1

[0028]0.02g 2,4,6-tris(4-aminophenyl)-1,3,5-triazine was dissolved in 100g mass percent concentration of 10% glacial acetic acid aqueous solution, then 0.02g formaldehyde and 0.2g acetone The aldehyde was added to the above-mentioned glacial acetic acid aqueous solution and mixed evenly, polycondensed at 60°C for 72 hours, centrifuged at 5000 rpm for 40 minutes, washed with deionized water, and freeze-dried to obtain imidazole-based nanoparticle powder; then 0.01g The above-mentioned organic nanoparticles are dispersed in 100 g of an aqueous sodium hydroxide solution with a concentration of 0.001% by mass, 0.005 g of dopamine is added, and oxygen is passed through to oxidize and polymerize at 15° C. for 24 hours to obtain an aqueous dispersion of polydopamine-modified imidazole-based nanoparticles;

[0029] Dip-coat the surface of the polysulfone ultrafiltration membrane in the aqueous dispersion of the above-mentioned polydopamine-modified imidazole-based nanoparticles for 0.5...

Embodiment 2

[0032] 0.5g 2,4,6-tris(4-aminophenyl)-1,3,5-triazine was dissolved in 100g mass percent concentration of 50% glacial acetic acid aqueous solution, then 0.2g formaldehyde and 0.6g acetone The aldehyde was added to the above-mentioned glacial acetic acid aqueous solution and mixed evenly, polycondensed at 120°C for 1 hour, centrifuged at 8000 rpm for 20 minutes, washed with deionized water, and freeze-dried to obtain imidazole-based nanoparticle powder; then 0.5g The above-mentioned organic nanoparticles were dispersed in 100 g of an aqueous sodium hydroxide solution with a concentration of 0.01% by mass, 1.0 g of dopamine was added, oxygen was passed through and oxidatively polymerized at 35° C. for 1 hour to obtain an aqueous dispersion of polydopamine-modified imidazole-based nanoparticles;

[0033] The surface of the polysulfone ultrafiltration membrane was dip-coated in the aqueous dispersion of the above-mentioned polydopamine-modified imidazole-based nanoparticles for 4 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com