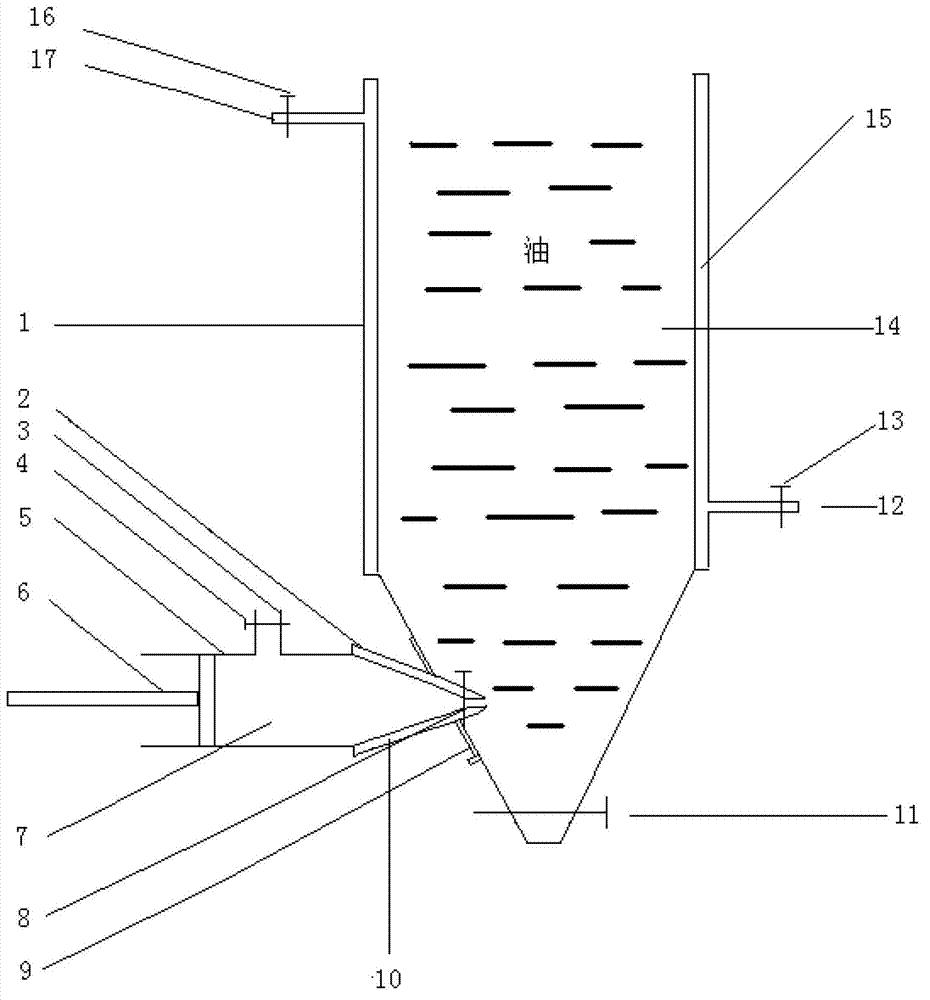

Method and device for preparing porous ceramic micro beads

A technology of porous ceramics and microbeads, which is applied in the direction of ceramic molding machines and manufacturing tools, which can solve the problems of difficult preparation of ceramic hollow microbeads, and achieve the effects of rich internal cavities, light weight, and good thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

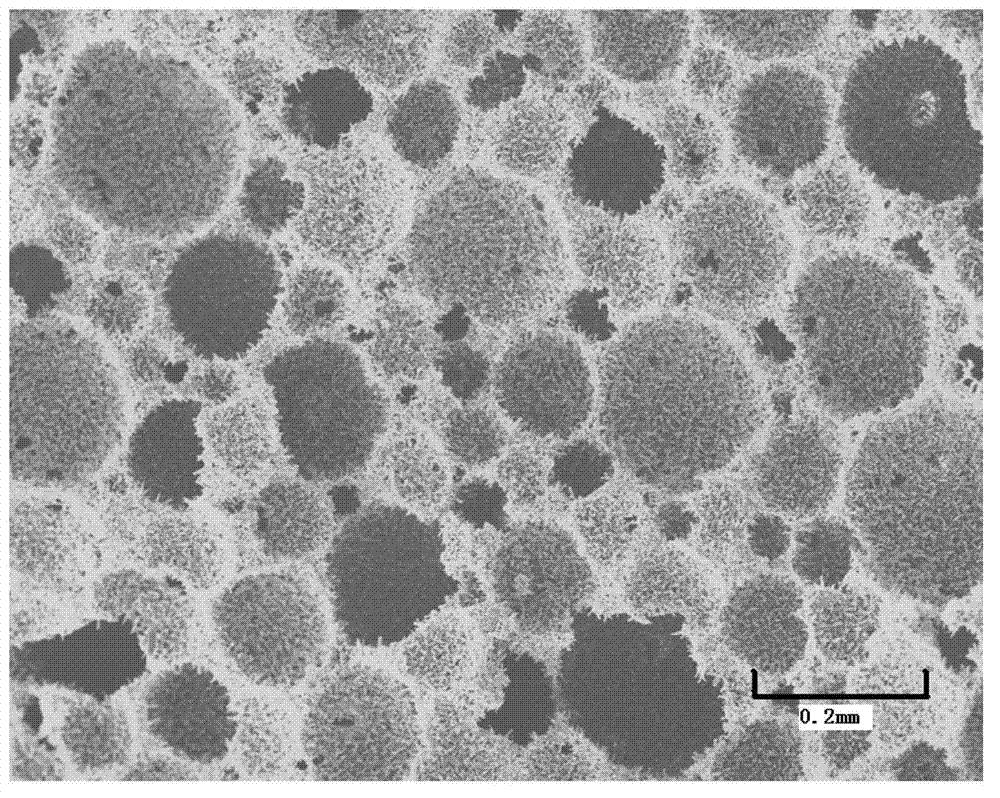

[0040] Preparation of alumina porous ceramic beads

[0041] α-Al 2 O 3 The high-purity powder raw material provided for Henan Jiyuan Aluminum Company, with a purity of greater than 99.99% and an average particle size of 2.35μm. Dissolve 3wt% acrylamide monomer and 0.2wt% crosslinking agent methylene bisacrylamide in 96.8wt% water to make a premixed solution; add alumina powder and ammonium citrate to 100ml of premixed solution for dispersion Alumina ceramic suspension with 28% solid phase volume fraction is made by ball milling for 24 hours, that is, the volume of alumina accounts for 28% of the total volume of the slurry after adding alumina powder, and the addition of ammonium citrate is oxidation 2wt% of aluminum powder. Add 80μl of the initiator ammonium persulfate with a concentration of 1%, 40μl of the catalyst tetramethylethylenediamine with a concentration of 2%, and 3ml of the foaming agent valeric acid with a concentration of 0.02mol / l into the suspension, stirring rap...

Embodiment 2

[0043] Preparation of zirconia porous ceramic beads

[0044] ZrO 2 The powder raw material provided for the Nuclear Energy Technology Design and Research Institute has an average particle size of 0.25μm. Take acrylamide monomer solution, add ammonium citrate and tetramethylammonium hydroxide solution as dispersant, the mass ratio is monomer solution: ammonium citrate: tetramethylammonium hydroxide solution=98:1:3; The concentration of acrylamide in the body solution is 15wt%, and the methylenebisacrylamide is 0.50wt%. Join ZrO 2 The powder is configured into a zirconia suspension with a solid phase volume fraction of 36 vol% and ball milled for 18 hours. Add 0.2ml of the initiator ammonium persulfate with a concentration of 0.5%, 0.1ml of the catalyst tetramethylethylenediamine with a concentration of 0.25%, and 3wt.% zirconia foaming agent butyric acid into the suspension, and stir quickly to make it The foaming is complete, thereby preparing an ultra-stable zirconia foam slur...

Embodiment 3

[0046] Preparation of silicon nitride porous ceramic beads

[0047] Si 3 N 4 It is a commercially available commercial powder with an average particle size of 0.48μm. Mix and dissolve 54.4wt% water, 45wt% hydroxyethyl acrylate and 0.6wt% methylene bisacrylamide to prepare a premixed liquid. Silicon nitride powder is added to the mixture to form a 55vol% silicon nitride slurry, that is, the volume of silicon nitride accounts for 55% of the total volume of the slurry after adding silicon nitride, and ammonium citrate is added as a dispersant, ammonium citrate The added amount is 1% of the mass of the powder, ball milled for 15 hours to make a silicon nitride ceramic suspension. Then 0.4ml of the catalyst tetramethylethylenediamine and 0.2ml of the initiator ammonium persulfate concentration of 10% aqueous solution were added to the slurry, while adding 2wt% (based on the mass of silicon nitride powder) The short-chain amphiphilic propyl gallate was used as a foaming agent, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com