Method for synthesizing Bi0.5Na0.5TiO3 spheroidal particles by microwave hydrothermal method

A microwave hydrothermal method and spherical particle technology are applied in the preparation field of microwave hydrothermal synthesis of BNT single-diameter spherical particles, which can solve problems such as steps of increasing cost and purification, and reaction time restricting industrial production, etc. The effect of reduced production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

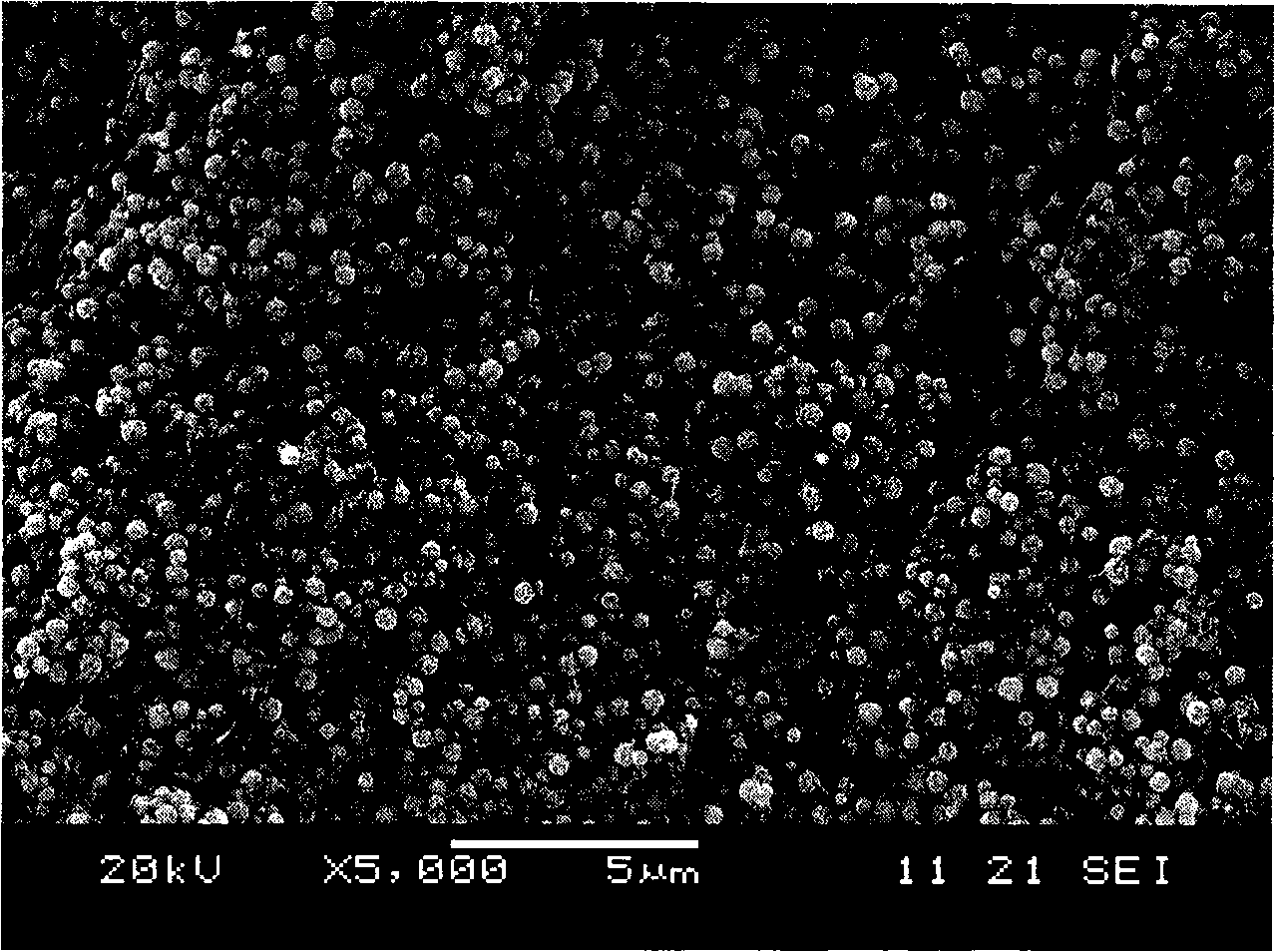

[0022] Weigh 3.359g Bi(BO 3 ) 3 ·5H 2 O was dissolved in 50 mL of deionized water, and then 3.5 mL of Ti(OC 4 h 9 ) 4 , stirring to form a mixed solution (solution A), control [Ti 4+ ] / [Bi 3+ ] The molar ratio is 1.5. Weigh 16.0106g NaOH and dissolve in 50mL deionized water (solution B). Drop solution B into solution A drop by drop, stir to form a uniform mixed solution (solution C), and control [OH] in the solution after the reaction - ]=5M. Measure 10 mL of solution C into a reaction vessel, put it into a microwave hydrothermal system (PIEMEX) for microwave heating; control the synthesis temperature to 190° C., and the reaction time to 2 h. After the reaction, the precipitate was filtered and washed with deionized water until neutral. Put the precipitate into an oven and dry it at 80°C to obtain a spherical ultrafine BNT powder with a single particle size.

[0023] Take a little BNT powder and place it in 30ml ethanol, and ultrasonically disperse it in an ultrason...

Embodiment 2

[0026] Weigh 2.5192g Bi(BO 3 ) 3 ·5H 2 O was dissolved in 50 mL of deionized water, and then 3.5 mL of Ti(OC 4 h 9 ) 4 , stirring to form a mixed solution (solution A), control [Ti 4+ ] / [Bi 3+ ] The molar ratio is 2. Weigh 6.7375g NaOH and dissolve in 50mL deionized water (Solution B). Drop solution B into solution A drop by drop, stir to form a uniform mixed solution (solution C), and control [OH] in the solution after the reaction - ]=1M. Measure 10 mL of solution C into a reaction vessel, and put it into a microwave hydrothermal system for microwave heating. The synthesis temperature was controlled to be 140° C., and the reaction time was 6 h.

[0027] Other steps are the same as described in Example 1. The SEI of the obtained BNT powder is as follows image 3 shown.

Embodiment 3

[0029] Weigh 2.675g Bi(BO 3 ) 3 ·5H 2 O was dissolved in 50 mL of deionized water, and 1.2 mL of TiCl was added dropwise into it 4 , stirring to form a mixed solution (solution A), control [Ti 4+ ] / [Bi 3+ ] The molar ratio is 2. Weigh 6.8964g NaOH and dissolve in 50mL deionized water (Solution B). Drop solution B into solution A drop by drop, stir to form a uniform mixed solution (solution C), and control [OH] in the solution after the reaction- ]=1M. Measure 10 mL of solution C into a reaction vessel, and put it into a microwave hydrothermal system for microwave heating. The synthesis temperature was controlled at 190° C., and the reaction time was 2 h.

[0030] Other steps are the same as described in Example 1. The SEI of the obtained BNT powder is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com