Preparation method of modified volcanic slag filter material and its application

A technology of volcanic slag and modification, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the complex process of treating phenol wastewater, difficult operation of filter material modification, and high cost of adsorbents and other problems, to achieve the effect of low metal leaching toxicity, expensive solution cost, and water treatment cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] First, sieve the volcanic slag through sieves with apertures of 1.5 mm and 1.0 mm respectively, rinse it repeatedly with tap water, and dry it in an oven at 110°C. After drying, take out the volcanic slag at 0.1mol L -1 Pretreated in dilute hydrochloric acid solution, soaked for 24 hours, washed with distilled water until neutral, dried in an oven at 110°C, taken out and cooled to complete pretreatment; then soaked 50g of pretreated volcanic slag in 80mL 2.5mol L -1 FeCl 3 After soaking in the solution for 20 minutes, place the volcanic slag in an oven at 110°C for drying, and finally place the volcanic slag in a muffle furnace at 400°C for 4 hours, then take it out and cool it at room temperature. The above steps are repeated several times until the surface of the modified volcanic slag is no longer wet, and the preparation of the modified volcanic slag filter material is completed.

[0038] figure 1 Scanning electron micrograph of the modified volcanic slag filter...

Embodiment 2

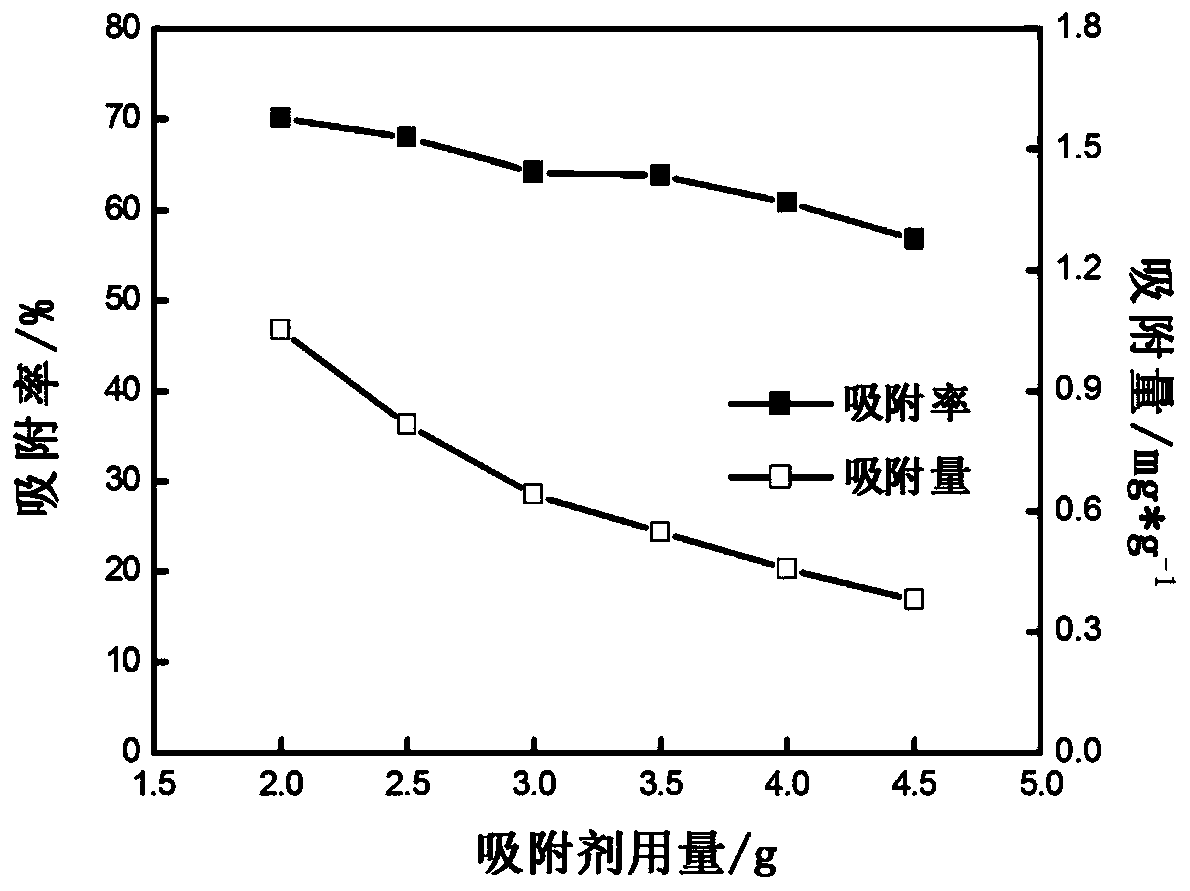

[0040] The modified volcanic slag filter material that prepares with embodiment 1 is adsorbent, gets 100ml30mg L -1 The simulated phenol wastewater was placed in six 250mL Erlenmeyer flasks, and the pH value was adjusted to 7, and 2.0g, 2.5g, 3.0g, 3.5g, 4.0g, 4.5g of iron-coated modified volcanic slag were added in different amounts. Oscillate with an oscillator at a constant speed for 2.5 hours at 30°C, take it out, let it stand for 10 minutes, and filter it. Take the filtered solution and measure its absorbance by a TU-1901 double-beam ultraviolet-visible spectrophotometer.

[0041] figure 2 For the influence figure of the consumption of the modified volcanic slag filter material that embodiment 1 prepares to the phenol simulated wastewater adsorption treatment effect; figure 2 As shown, when the amount of iron-coated modified volcanic slag filter material is 2.0g, the removal rate and adsorption capacity of phenol are high, so the optimal amount of adsorbent should be 2.0...

Embodiment 3

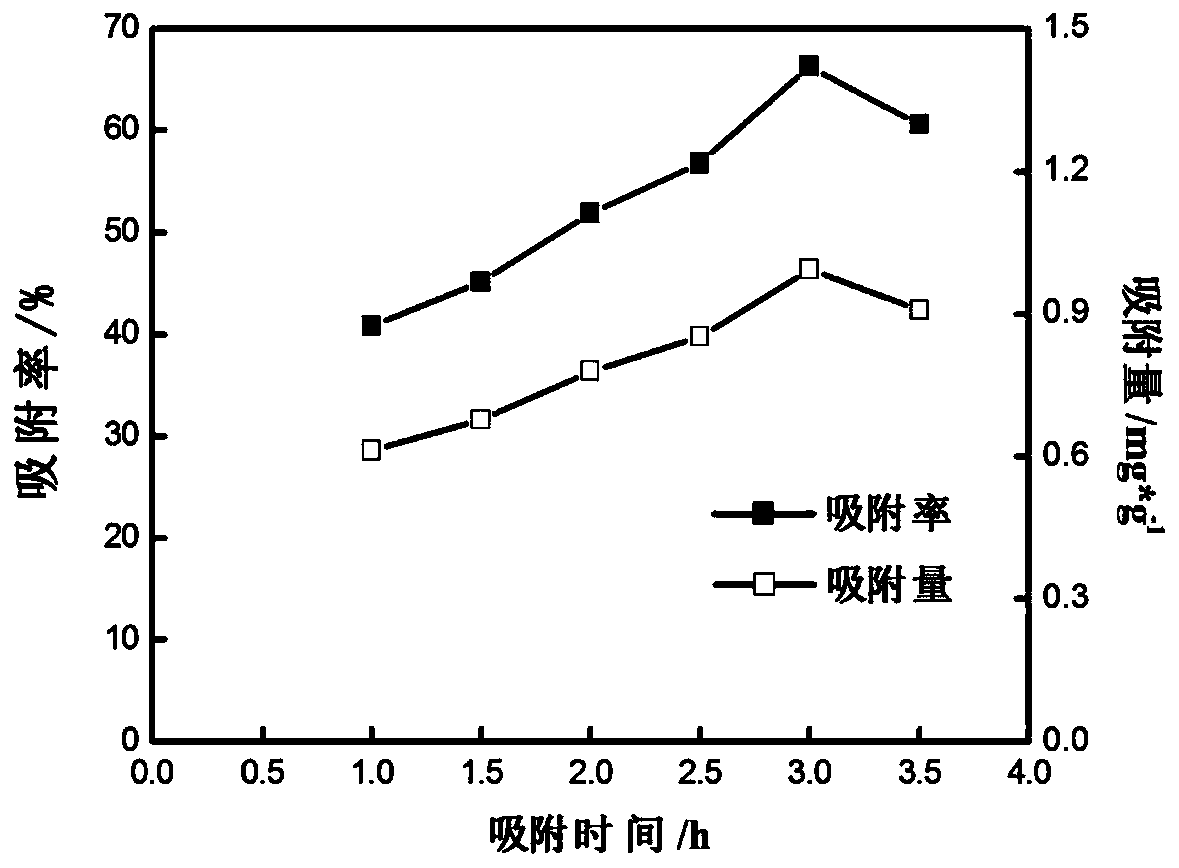

[0043] The modified volcanic slag filter material that prepares with embodiment 1 is adsorbent, gets 100ml30mg L -1 The simulated phenol wastewater was placed in six 250mL conical flasks, the pH value was adjusted to 7, and then 2.0g of iron-coated modified volcanic slag was added, and shaken at a constant speed for 1.0h, 1.5h, and 2.0h with an oscillator at 30°C. , 2.5h, 3.0h, and 3.5h, take it out, let it stand for 10min, and then filter. Take the filtered solution and measure its absorbance by a TU-1901 double-beam ultraviolet-visible spectrophotometer.

[0044] image 3 For the modified volcanic slag filter material adsorption phenol simulated waste water time that embodiment 1 prepares influence figure on adsorption treatment effect; image 3 As shown, with the extension of the adsorption time, the removal rate and adsorption capacity of the adsorbent to phenol gradually increased at first, and showed a downward trend after 3.0 h. When the adsorption time was 3.0h, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com