Inorganic/organic mutually doped hydrophobic polyimide aerogel and preparation method thereof

A polyimide and inorganic gel technology, which is applied in the fields of inorganic/organic inter-doped hydrophobic polyimide aerogel and green preparation, and can solve the problems of reduced performance and difficult molding of modified aerogel materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

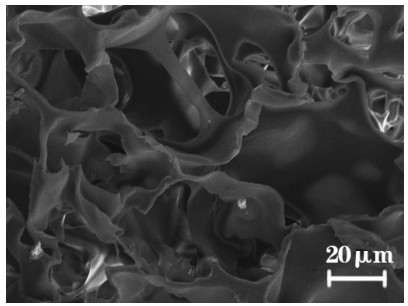

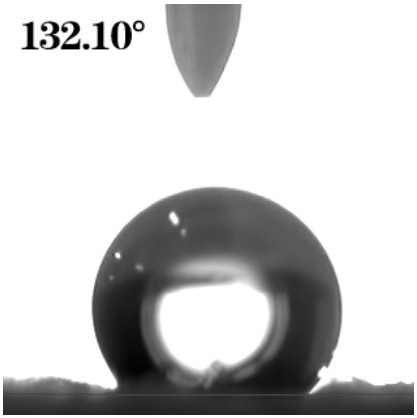

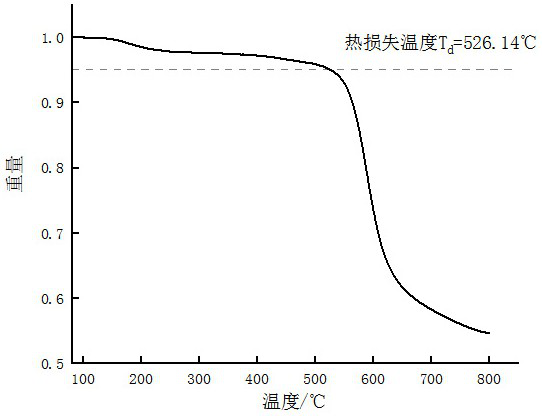

Image

Examples

Embodiment 1

[0041] This embodiment provides an inorganic / organic doped hydrophobic polyimide gas gel and a green preparation method comprising the steps of:

[0042] 1) Preparation of the polyamic acid solution: 2.436 g of 4,4'-diaminophenylene ether and 2.436 g of 3,4'-di amino diphenyl ether were dissolved in 80 ml N, N-dimethyl. Among the acetamide, 5.128 g of 1,2,4,5-xenobhenic tetramethrhalate is slowly added to the solution to be stabilized. The mixture was stirred for 3 hours to obtain and pale yellow transparent viscous polyamic acid solution.

[0043] 2) Preparation of the polyamic acid precursor: Under 5 ° C, the light yellow transparent viscous polyamic acid solution was mixed with 2.46 g of triethylamine and stirred for 1.5 hours to give a transparent viscous uniform polyamic acid precursor. Sketch. The polyamic acid precursor sol was slowly put into 1 L of deionized water to obtain a white polyamic acid precursor precipitate, and the precipitate was washed five times to its org...

Embodiment 2

[0052] This embodiment provides an inorganic / organic-doped hydrophobic polyimide gas gel and a green preparation method, and the preparation process is substantially the same as in Example 1, and only the carbon quantum point is not added to compare. Includes the following steps:

[0053] 1) Preparation of the polyamic acid solution: 2.436 g of 4,4'-diaminophenylene ether and 2.436 g of 3,4'-di amino diphenyl ether were dissolved in 80 ml N, N-dimethyl. Among the acetamide, 5.128 g of 1,2,4,5-xenobhenic tetramethrhalate is slowly added to the solution to be stabilized. The mixture was stirred for 3 hours to obtain and pale yellow transparent viscous polyamic acid solution.

[0054] 2) Preparation of the polyamic acid precursor: Under 5 ° C, the light yellow transparent viscous polyamic acid solution was mixed with 2.46 g of triethylamine and stirred for 1.5 hours to give a transparent viscous uniform polyamic acid precursor. Sketch. The polyamic acid precursor sol was slowly put...

Embodiment 3

[0059] This embodiment provides a polyimide gas gel and a green preparation method, and the preparation process is substantially the same as in Example 1, and only the cobalt iron oxide inorganic gel is added as the following steps:

[0060] 1) Preparation of the polyamic acid solution: 2.436 g of 4,4'-diaminophenylene ether and 2.436 g of 3,4'-di amino diphenyl ether were dissolved in 80 ml N, N-dimethyl. Among the acetamide, 5.128 g of 1,2,4,5-xenobhenic tetramethrhalate is slowly added to the solution to be stabilized. The mixture was stirred for 3 hours to obtain and pale yellow transparent viscous polyamic acid solution.

[0061] 2) Preparation of the polyamic acid precursor: Under 5 ° C, the light yellow transparent viscous polyamic acid solution was mixed with 2.46 g of triethylamine and stirred for 1.5 hours to give a transparent viscous uniform polyamic acid precursor. Sketch. The polyamic acid precursor sol was slowly put into 1 L of deionized water to obtain a white pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com