Method for preparing super thermal isolation polymer materials from polymer nanometer hollow capsules

A technology for the preparation of polymer materials and capsules, which is applied in the preparation of microcapsule preparations and microspheres, can solve the problems of inability to obtain nanoporous foam materials and porous materials, and achieve simple preparation processes, good mechanical strength, and high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method step of described melamine formaldehyde resin is as follows:

[0057] 1) Weighing 40-70 parts by weight of formaldehyde, adding triethylamine or sodium hydroxide solution dropwise to adjust the pH to 7.8-8.5. Then add 10-30 parts by weight of melamine to formaldehyde, and react at 60-85° C. for 15-40 minutes.

[0058] 2) Add 15-40 parts by weight of methanol to the reactant, adjust the pH to 4.0-6.5 with hydrochloric acid, react at 40-60° C. for 30-60 minutes, and end the reaction to obtain melamine formaldehyde resin for use. The mass percentage content of the melamine formaldehyde resin is 30-50%.

[0059] The preparation method step of described urea-formaldehyde resin is as follows:

[0060] Take formaldehyde and urea at a molar ratio of 1.05-2.0, and divide the urea into three batches; first, adjust the pH value to 7.5-8.5 with sodium hydroxide, add the first batch of urea, heat up to 80-95°C, and keep warm for 20-40min. Use ammonium chlor...

Embodiment 1

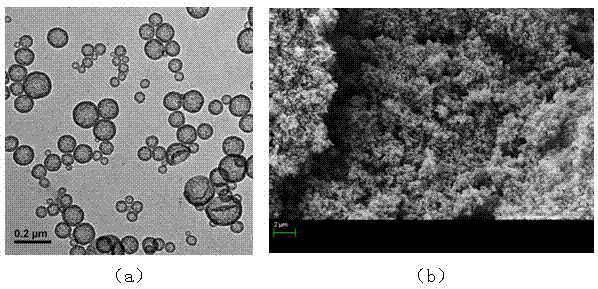

[0064] (1) Preparation of polymer nanocapsules:

[0065] 1) Mix 7 grams of methacrylic acid, 6 grams of methyl methacrylate, 0.3 grams of 4,4-azo-bis(4-cyanovaleric acid) and 2 grams of dodecyl-3-carbonitrile Trithio valeric acid was dissolved in 50 grams of dioxane solvent, and polymerized at 90° C. for 6 hours to obtain an amphiphilic macromolecular reversible addition scission chain transfer reagent. The structural formula is as follows:

[0066]

[0067] 2) 0.6 gram of the above-mentioned amphiphilic macromolecular reversible addition chain scission chain transfer reagent and 80 grams of deionized water are formulated into an aqueous solution as the water phase, and 1 gram of glycidyl methacrylate, 9 grams of p-vinylbenzene , 0.15 g of azobisisobutyronitrile and 10 g of paraffin oil phase and mixed uniformly, and prepared under the action of a high shear field by an ultrasonic pulverizer to obtain a miniemulsion.

[0068] 3) Move the mini-emulsion to the reactor, stop...

Embodiment 2~4

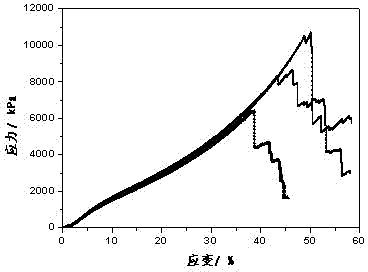

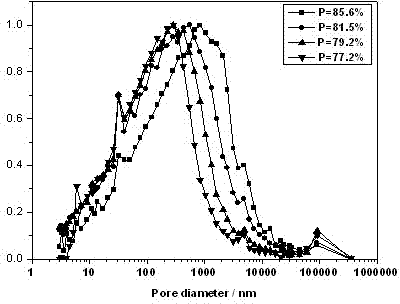

[0078] Examples 2-4 are the same as Example 1 except that the solid content of the nanocapsule emulsion is different. The solid contents of the nanocapsule emulsions used in Examples 2 to 4 were 20%, 25%, and 45%, respectively, and the specific property parameters of the prepared polymer nanoporous materials are shown in Table 2. From Table 2, it can be found that although the pore size distribution of the polymeric porous material is very wide, from nanometer to micron, by adjusting the solid content of the gelled emulsion, its average pore size (volume average) can be reduced to the order of nanometers, Such as image 3 shown. Since the heat transfer of nanopores is affected by the Knudsen Effect, the thermal conductivity of the gas phase can be significantly reduced. Although the porosity decreases, the thermal conductivity of the solid part will increase, but the results show that within a certain range, the polymer porous material shows a trend of decreasing thermal con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com