Process for producing porous object and porous object obtained by the same

A manufacturing method and technology of porous bodies, applied in the field of porous bodies, can solve the problems of small pore size, difficulty in achieving a wide range of pore size, and difficulty in ensuring uniform pore distribution of porous bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The water content in the mixed solution was changed to produce a porous body, and the control of the pore size was confirmed.

[0054] A lactide-caprolactone copolymer (P(LA / CL=50 / 50)) with a composition ratio (molar ratio) of L-lactide and ε-caprolactone of 50:50, 1,4- Dioxane and water were mixed to prepare 29 kinds of mixed solutions with different water contents. In addition, the mixing ratio (mass ratio) of (P(LA / CL=50 / 50)) and 1,4-dioxane is a certain value (4:96), and the mixing ratio of water in the aforementioned mixed solution (containing water rate) changed to 1, 2, 4, 6, 8, 8.25, 8.5, 8.75, 9, 9.25, 9.5, 9.75, 10, 10.25, 10.5, 10.75, 11, 11.25, 11.5, 11.75, 12, 12.25, 12.5, 12.75, 13, 14, 16, 18, 20% by mass. Then, these mixed solutions (20 g) were supplied to stainless steel petri dishes (diameter 5 cm, depth 1.5 cm, the same below).

[0055] Place the aforementioned stainless steel Petri dish on a cooling rack (at room temperature) in a freeze dryer (tr...

Embodiment 2

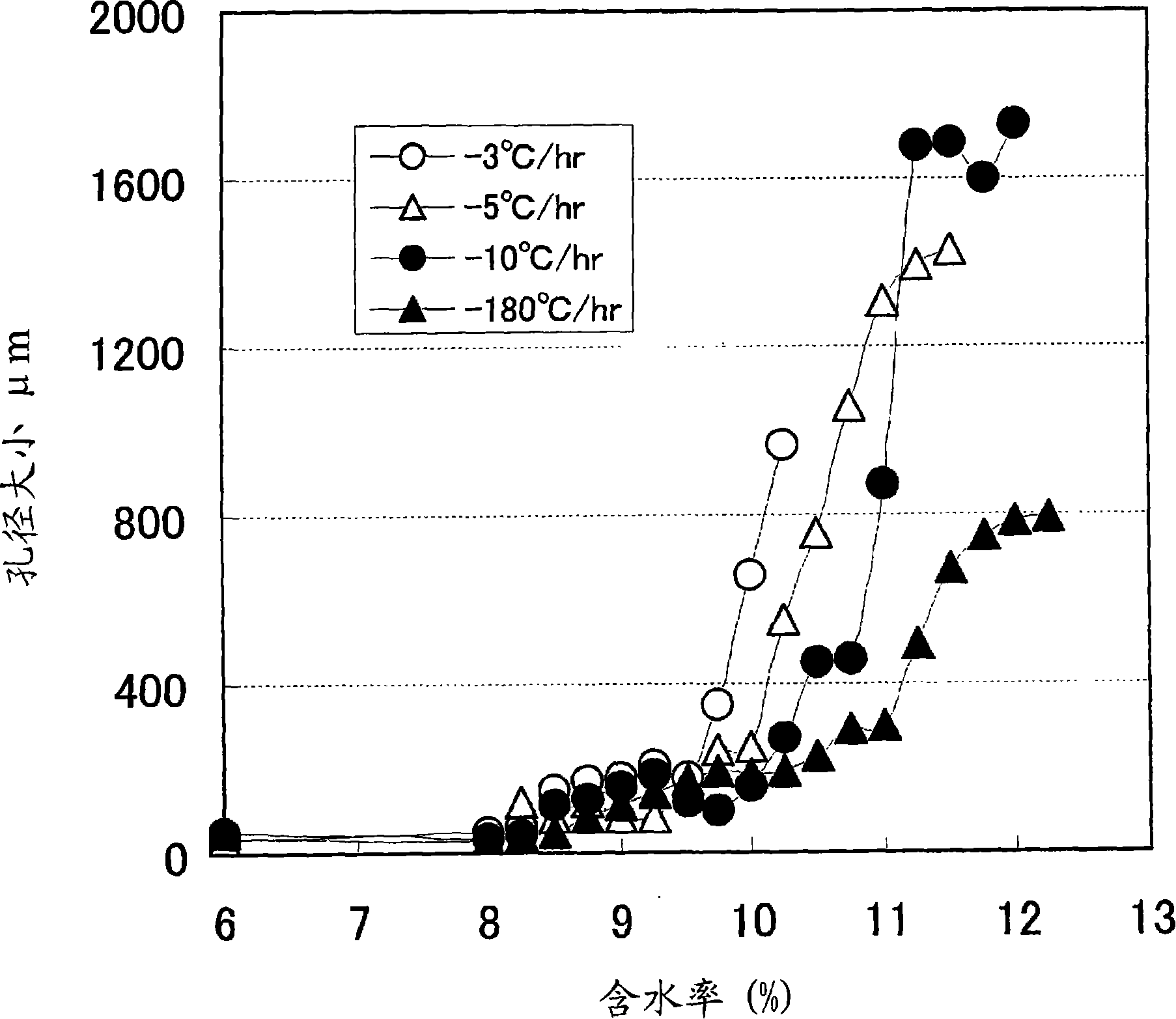

[0065] The cooling rate was changed to make a porous body, and the control of the pore size was confirmed.

[0066] In addition to using P (LA / CL=51 / 49) in which the composition ratio of L-lactide and ε-caprolactone is 51:49, the same operation as in the aforementioned Example 1 was used to prepare a variety of different water contents. The solutions were mixed, and the aforementioned mixed solutions (20 g) were supplied to stainless steel petri dishes, respectively. Then, the aforementioned stainless steel culture dish was placed on a cooling rack of a freeze dryer (trade name TF 5-85ATANCS: manufactured by Takara Seisakusho), and the temperature of the cooling rack was lowered to 10°C (required time 25 minutes) and left for 60 minutes. After standing, the cooling rack was cooled to -50°C at a predetermined rate (180°C / hr, 10°C / hr, 5°C / hr, 3°C / hr), and treated at -50°C for 180 minutes. Then, at the same time as the cooling treatment was completed, the temperature in the free...

Embodiment 3

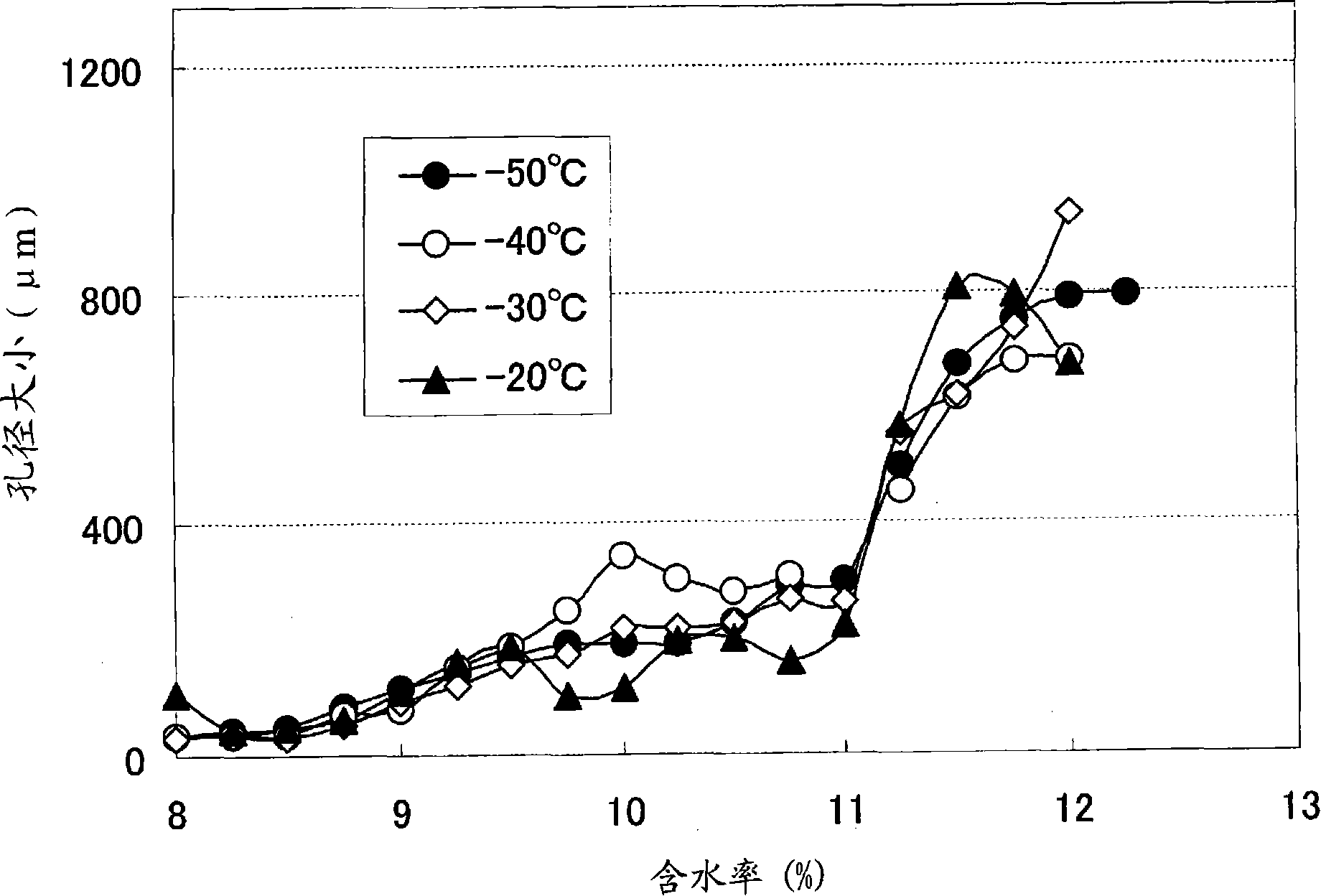

[0069] Investigate the effect of changes in freezing temperature on pore size.

[0070] The cooling rate is set to 180°C / hr, and the final cooling temperature is set to a predetermined temperature (-20°C, -30°C, -40°C), except that, the same operation as the above-mentioned Example 2 is performed to prepare a porous body sample, and Pore size was determined (n=3). The relationship between the water content in the aforementioned mixed solution and the pore size of the aforementioned sample is shown in image 3 .

[0071] as it should image 3 It can be seen that when the cooling rate is 180°C / hr, the behavior of the pore size corresponding to the water content does not change greatly due to the change of the final cooling temperature, and is not affected by the aforementioned cooling temperature. From this, it can be said that as long as the cooling temperature is set at -20°C, excessive cooling is unnecessary and cost reduction can be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com