High-die-welded low-temperature container steel plate with medium thickness and high toughness and production method thereof

A low-temperature container and production method technology, applied in the field of iron and steel smelting, can solve the problems of unstable weldability, unstable impact performance, poor production performance, etc., achieve simple production process, good strength and toughness, and reduce the complexity of impact component design problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

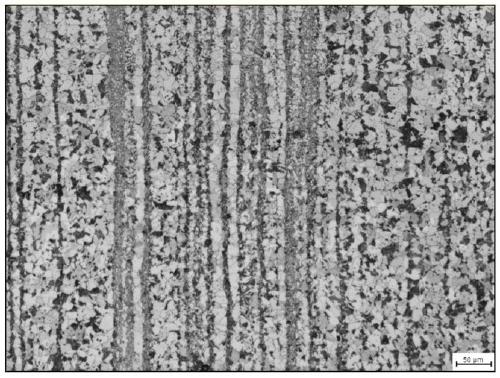

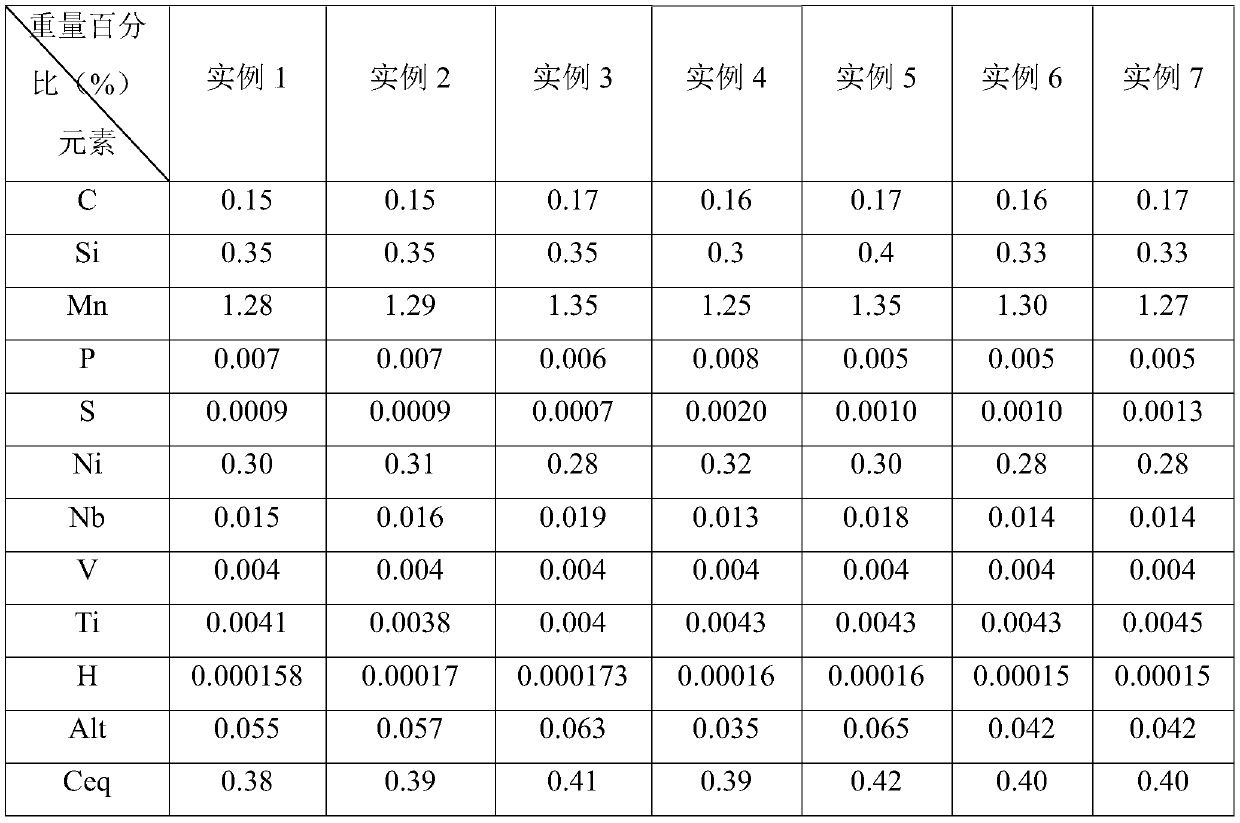

[0032] A medium-thickness, high-toughness, high-form welding low-temperature container steel plate in this embodiment, the chemical composition of the steel plate, in terms of weight percentage, includes C: 0.15%, Si: 0.35%, Mn: 1.28%, P: 0.007%, S: 0.0009%, Ni: 0.30%, Nb: 0.015%, Alt: 0.055%, Ceq: 0.38%, the balance is Fe and unavoidable impurities. The microstructure of the steel plate is ferrite + pearlite + shellfish Tensitic structure, the grain size is controlled at 10μm-12μm, and the grain size is controlled at level 9.

[0033] The production method of this container steel plate in the present embodiment is as follows:

[0034] S1. Converter steelmaking: the chemical composition of molten steel is calculated by weight percentage, including C: 0.15%, Si: 0.35%, Mn: 1.28%, P: 0.007%, S: 0.0009%, Ni: 0.30%, and Nb: 0.015%, Alt: 0.055%, Ceq: 0.38%, and the balance is Fe and unavoidable impurities.

[0035]S2. Out of the furnace and rolling: In this embodiment, a slab wit...

Embodiment 2

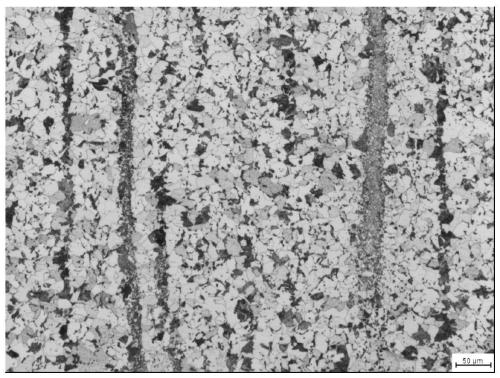

[0044] A medium-thickness, high-toughness, high-mode welded low-temperature container steel plate in this embodiment, the chemical composition of the steel plate, in terms of weight percentage, includes C: 0.15%, Si: 0.35%, Mn: 1.29%, P: 0.007%, S: 0.0009%, Ni: 0.31%, Nb: 0.016%, Alt: 0.057%, Ceq: 0.39%, and the balance is Fe and unavoidable impurities.

[0045] The production method of this container steel plate in the present embodiment is as follows:

[0046] S1. Converter steelmaking: the chemical composition of molten steel is calculated by weight percentage, including C: 0.15%, Si: 0.35%, Mn: 1.29%, P: 0.007%, S: 0.0009%, Ni: 0.31%, and Nb: 0.016%, Alt: 0.057%, Ceq: 0.39%, and the balance is Fe and unavoidable impurities.

[0047] S2, out of the furnace and rolling: In this embodiment, a slab with a thickness of 260mm is used, the temperature of the billet heating section is 1220-1240°C, the soaking temperature is 1209°C, the time of the soaking section is 56min, the bi...

Embodiment 3

[0053] A medium-thickness, high-toughness, high-mode welded low-temperature container steel plate in this embodiment, the chemical composition of the steel plate, in terms of weight percentage, includes C: 0.17%, Si: 0.35%, Mn: 1.35%, P: 0.006%, S: 0.0007%, Ni: 0.28%, Nb: 0.019%, Alt: 0.063%, Ceq: 0.41%, and the balance is Fe and unavoidable impurities.

[0054] The production method of this container steel plate in the present embodiment is as follows:

[0055] S1. Converter steelmaking: the chemical composition of molten steel is calculated by weight percentage, including C: 0.17%, Si: 0.35%, Mn: 1.35%, P: 0.006%, S: 0.0007%, Ni: 0.28%, and Nb: 0.019%, Alt: 0.063%, Ceq: 0.41%, and the balance is Fe and unavoidable impurities.

[0056] S2. Out of the furnace and rolling: In this embodiment, a slab with a thickness of 260mm is used. The temperature of the billet heating section is 1220-1240°C, the soaking temperature is 1211°C, the soaking section time is 57min, the billet is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com