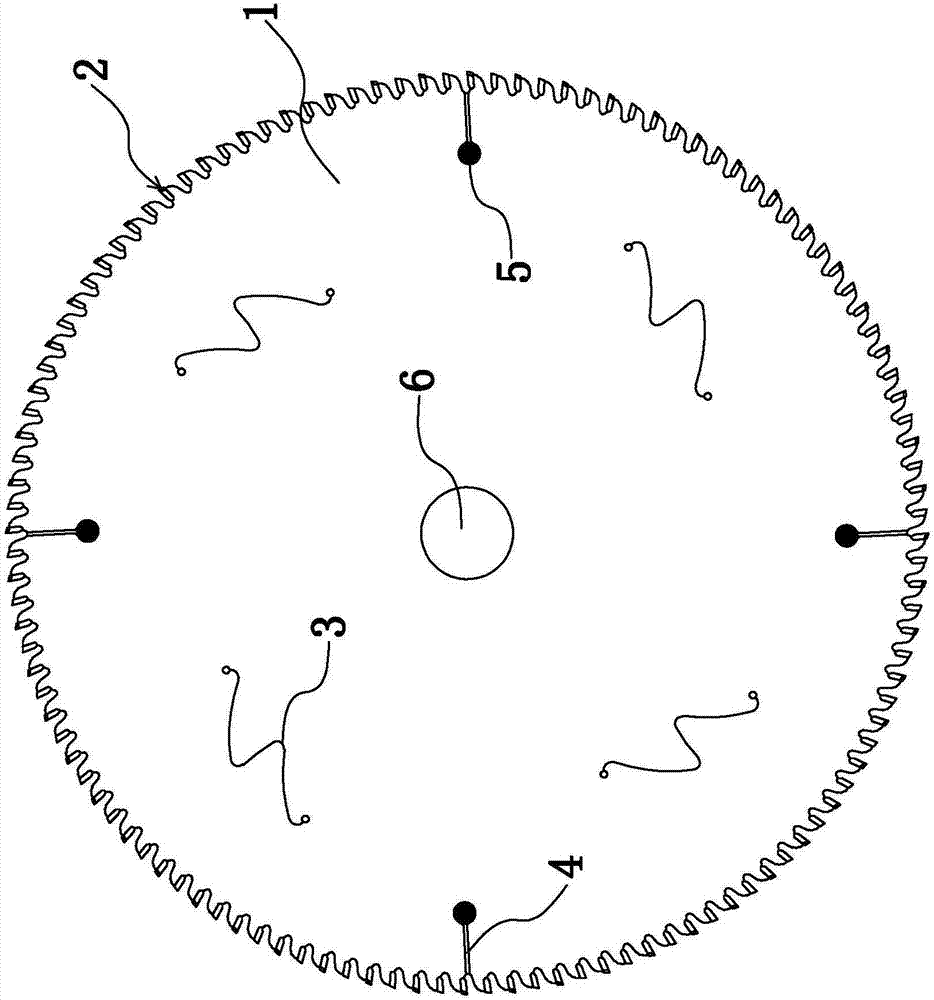

Hard alloy circular saw web

A cemented carbide, circular saw blade technology, applied in circular saws, metal sawing equipment, saw blades, etc., can solve the problems of short service life, more heat generation, cumbersome processing procedures, etc., to achieve smooth cutting surface, improve The effect of processing efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

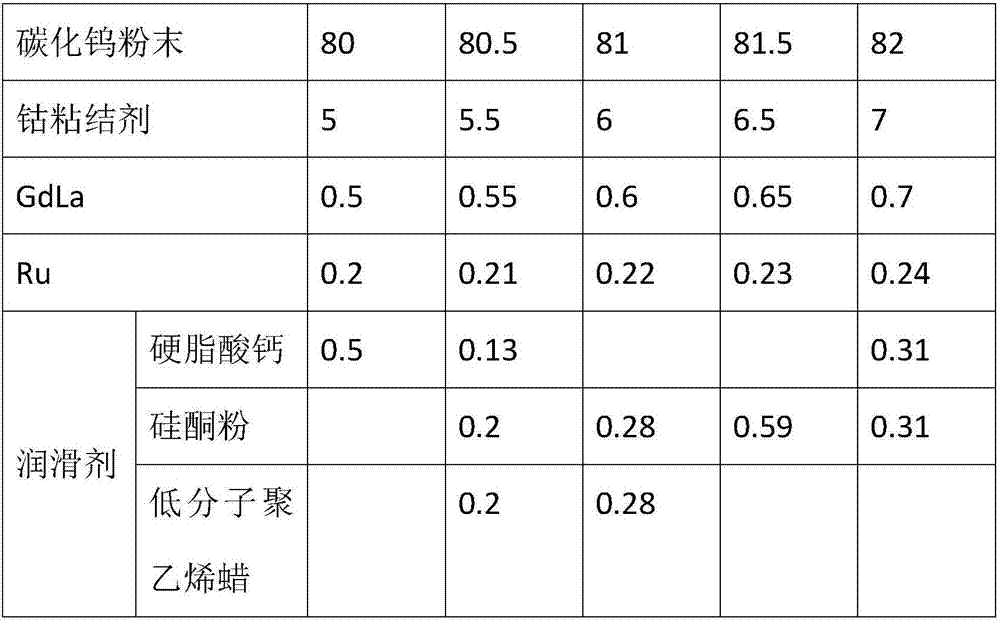

Embodiment 1

[0050] Mixing: Weigh the cemented carbide material according to the parts by weight described in Example 1 in Table 1 and add it to the ball mill, wherein the grain size of the tungsten carbide powder is 0.3 μm, and the cobalt binder contains 2% Mo and 0.2% organic bentonite, and add 200ml of ethanol to wet grind until the powder particle size is 1 μm to obtain a mixed slurry, after the mixed slurry is filtered, dry at 120°C for 40min to obtain a mixture;

[0051] Compression molding: under the condition of 40MPa, the mixture and 0.02% molding agent are put into the sawtooth mold and pressed to obtain the saw blade sawtooth blank, wherein the molding agent is polyethylene glycol;

[0052] Sintering: Quenching the saw blade substrate blank and the saw blade sawtooth blank, the quenching temperature is 820°C, and the quenching time is 5 minutes; Tempering is carried out at 380°C, and the tempering time is 5 hours. After the tempering is completed, the saw blade matrix and saw bl...

Embodiment 2

[0058] Mixing: Weigh the cemented carbide material according to the parts by weight described in Example 2 in Table 1 and add it to the ball mill, wherein the grain size of the tungsten carbide powder is 0.32 μm, and the cobalt binder contains 2.1% Mo and 0.21% organic Bentonite, and add 210ml of ethanol to wet grind until the powder particle size is 1.2μm to obtain a mixed slurry, after filtering the mixed slurry, dry it at 122°C for 41min to obtain a mixture;

[0059] Compression molding: under the condition of 42MPa, the mixture and 0.022% molding agent are dropped into the sawtooth mold and pressed to obtain the saw blade sawtooth blank, wherein the molding agent is polyethylene glycol;

[0060] Sintering: Quenching the saw blade base blank and the saw tooth blank, the quenching temperature is 823°C, and the quenching time is 5.5 minutes; after quenching, sintering is carried out in a vacuum, the sintering temperature is 1520°C, after the sintering is completed, the tempera...

Embodiment 3

[0066] Mixing: take the cemented carbide material according to the parts by weight described in Example 3 in Table 1 and add it to the ball mill, wherein the grain size of the tungsten carbide powder is 0.34 μm, and the cobalt binder contains 2.2% Mo and 0.22% organic bentonite, and add 220ml of ethanol to wet grind until the powder particle size is 1.4μm to obtain a mixed slurry, after the mixed slurry is filtered, dry at 124°C for 42min to obtain a mixture;

[0067] Compression molding: under the condition of 44MPa, the mixture and 0.024% molding agent are dropped into the sawtooth mold and compressed to obtain the saw blade sawtooth blank, wherein the molding agent is polyethylene glycol;

[0068] Sintering: Quenching the saw blade base blank and saw blade sawtooth blank, the quenching temperature is 826°C, and the quenching time is 6 minutes; Tempering is carried out under the condition of 388°C, and the tempering time is 5.4h. After the tempering is completed, the saw bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com