High-strength TBM center cutter box and preparation method

A high-strength, center-knife technology, applied in mining equipment, earthwork drilling, manufacturing tools, etc., can solve problems such as cracking, easy crushing, and low strength of the tool box, and achieve the goal of increasing strength, improving strength, and improving mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

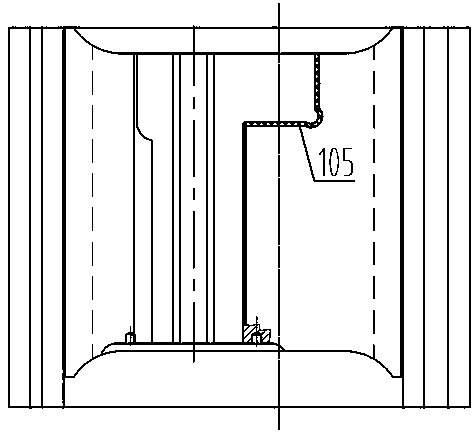

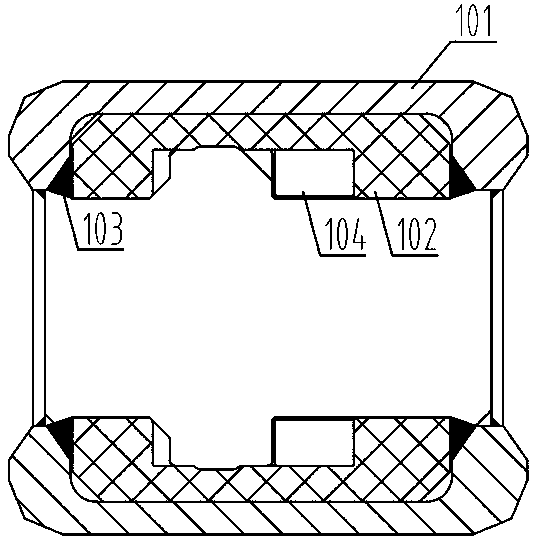

[0031] A high-strength TBM center knife box includes an outer knife box 101 and an inner knife box 102. The outer knife box 101 is made of low-alloy structural steel, and the inner knife box 102 is made of low-carbon medium-alloy structural steel.

[0032] The low-alloy structural steel material used in the outer knife box 101 includes the following components in weight percentage: C: 0.11%, Si: 0.2%, Mn: 0.38%, V: 0.07%, S: ≤0.02%, P: ≤ 0.02%, the balance is iron.

[0033] The low-carbon medium-alloy structural steel material used in the inner knife box 102 includes the following components in weight percentage: C: 0.11%, Si: 0.2%, Mn: 0.38%, Cr: 1.45%, Ni: 4.5%, W: 0.9%, V: 0.08%, Ti: 0.03%, Nb: 0.01%, S: ≤0.02%, P: ≤0.02%, and the balance is iron.

[0034] The preparation method of described high-strength TBM center cutter box, the steps are as follows:

[0035] (a) Forging the outer knife box 101 and the inner knife box 102;

[0036] (b) Stress-relief annealing treatmen...

Embodiment 2

[0043] A high-strength TBM center knife box includes an outer knife box 101 and an inner knife box 102. The outer knife box 101 is made of low-alloy structural steel, and the inner knife box 102 is made of low-carbon medium-alloy structural steel.

[0044] The low-alloy structural steel material used in the outer knife box 101 includes the following components in weight percentage: C: 0.14%, Si: 0.3%, Mn: 0.40%, V: 0.09%, S: ≤0.02%, P: ≤ 0.02%, the balance is iron.

[0045] The low-carbon medium-alloy structural steel material used in the inner knife box 102 includes the following components in weight percentage: C: 0.13%, Si: 0.3%, Mn: 0.42%, Cr: 1.50%, Ni: 4.8%, W: 1.2%, V: 0.09%, Ti: 0.04%, Nb: 0.015%, S: ≤0.02%, P: ≤0.02%, and the balance is iron.

[0046] The preparation method of described high-strength TBM center cutter box, the steps are as follows:

[0047] (a) Forging the outer knife box 101 and the inner knife box 102;

[0048] (b) Stress-relief annealing treatme...

Embodiment 3

[0055] A high-strength TBM center knife box includes an outer knife box 101 and an inner knife box 102. The outer knife box 101 is made of low-alloy structural steel, and the inner knife box 102 is made of low-carbon medium-alloy structural steel.

[0056] The low-alloy structural steel material used in the outer knife box 101 includes the following components in weight percentage: C: 0.16%, Si: 0.4%, Mn: 0.45%, V: 0.10%, S: ≤0.02%, P: ≤ 0.02%, the balance is iron.

[0057] The low-carbon medium-alloy structural steel material used in the inner knife box 102 includes the following components in weight percentage: C: 0.16%, Si: 0.35%, Mn: 0.42%, Cr: 1.55%, Ni: 5.0%, W: 1.2%, V: 0.09%, Ti: 0.05%, Nb: 0.02%, S: ≤0.02%, P: ≤0.02%, and the balance is iron.

[0058] The preparation method of described high-strength TBM center cutter box, the steps are as follows:

[0059] (a) Forging the outer knife box 101 and the inner knife box 102;

[0060] (b) Stress-relief annealing treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com