Reinforced high-pressure GIS (gas insulated switchgear) shell

An enhanced, high-pressure technology, applied in the field of GIS shells, can solve the problems of large machining allowance, welding cracks, incomplete penetration, and uneven thickness, so as to improve welding quality, reduce welding stress, and reduce weld seam differences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

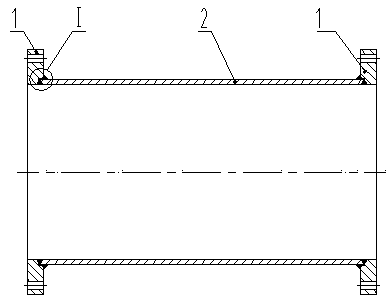

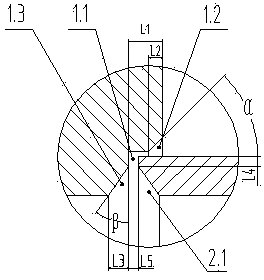

[0014] The reinforced high-pressure GIS shell shown in the accompanying drawings includes a cylinder body 2 and flanges 1 at both ends; the inner hole of the flange 1 is provided with an inner stop 1.1 on one end surface; the inner holes at both ends of the cylinder body 2 are provided with Inner bevel 2.1; Flange 1 inner stop 1.1 is set on the cylinder body 2 and fixedly connected by welding; inner stop 1.1 depth L1 is 0.9 to 1 times the wall thickness of the cylinder body 2, in this embodiment, the inner stop The depth L1 of the mouth 1.1 is 1 time of the wall thickness of the cylinder 2; the upper end surface of the internal stop 1.1 is chamfered, the chamfer angle α is 45°~55°, and the depth L2 is 0.4~0.5 times of the wall thickness of the cylinder 2, In this embodiment, the chamfering angle α is 45°, the depth L2 is 0.5 times the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com