Vehicle high strength and toughness hot-forming steel plate and preparation method thereof

A high-strength toughness, hot forming technology, applied in the field of high-strength automotive steel, can solve the problems of insufficient toughness and high strength, and achieve the effects of saving resources, good strength and toughness, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

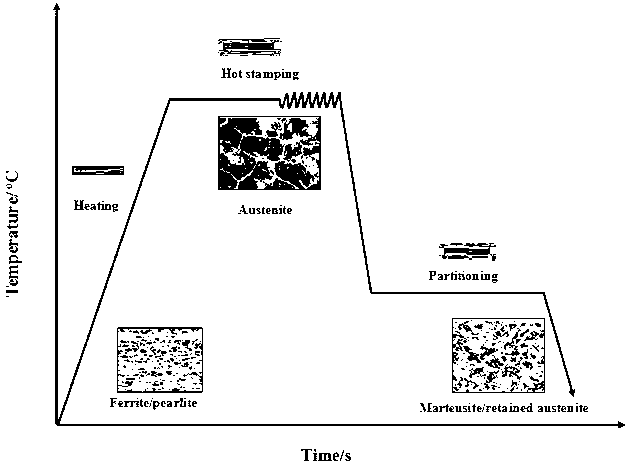

Method used

Image

Examples

Embodiment 1

[0021] A high-strength and toughness hot-formed steel plate for automobiles, its components and weight percentages are: C: 0.25%, Si: 0.90%, Mn: 1.78%, Ti: 0.022%, B: 0.0021%, S: 0.0013%, P : 0.0058%, the rest is Fe. Heat the steel to the austenitizing temperature of 880°C at a rate of 25°C / s and hold it for 5 minutes, and then heat it for 1s -1 The strain rate was hot-rolled with a strain deformation of 0.8, then quenched to 310°C at a rate of 50°C / s, isothermally held at a tempering temperature of 310°C for 5s, and finally quenched to room temperature. After testing, the tensile strength Rm of the steel is 1534MPa, and the yield strength Rp 0.2 It is 862MPa, and the total elongation is 12.8%.

Embodiment 2

[0023] A high-strength and toughness hot-formed steel plate for automobiles, its components and weight percentages are: C: 0.25%, Si: 0.90%, Mn: 1.78%, Ti: 0.022%, B: 0.001%, S: 0.0013%, P : 0.0058%, the rest is Fe. Heat the steel at a rate of 50°C / s to the austenitizing temperature of 1000°C and hold it for 2 minutes, then -1 The strain rate is 0.8 for hot rolling, then quenched to 300°C at a rate of 80°C / s, isothermally held at a tempering temperature of 300°C for 30s, and finally quenched to room temperature. After testing, the tensile strength Rm of the steel is 1633MPa, and the yield strength Rp 0.2 It is 952MPa, and the total elongation is 14.9%.

Embodiment 3

[0025] A high-strength and toughness hot-formed steel plate for automobiles, its components and weight percentages are: C: 0.30%, Si: 0.50%, Mn: 2.4%, Ti: 0.01%, B: 0.005%, S: 0.0013%, P : 0.0058%, the rest is Fe. Heat the steel to the austenitizing temperature of 850°C at a rate of 100°C / s and hold it for 30 minutes, then -1 The strain rate is 0.8 for hot rolling, then quenched to 290°C at a rate of 100°C / s, isothermally held at a tempering temperature of 290°C for 50s, and finally quenched to room temperature. After testing, the tensile strength Rm of the steel is 1696MPa, and the yield strength Rp 0.2 It is 932MPa, and the total elongation is 15.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com