Stainless steel miniature pipe welding process

A welding process and micro-tube technology, which is applied in stainless steel tube welding and stainless steel micro-tube welding fields, can solve the problems that the service life of the connection joint is lower than that of the base metal body, the tensile strength, plasticity and toughness are poor, and the labor intensity is high. Reduce connection cost and labor intensity, good plasticity and toughness, fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

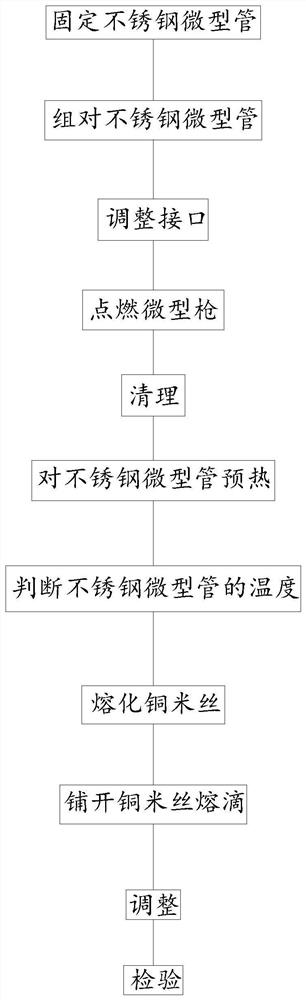

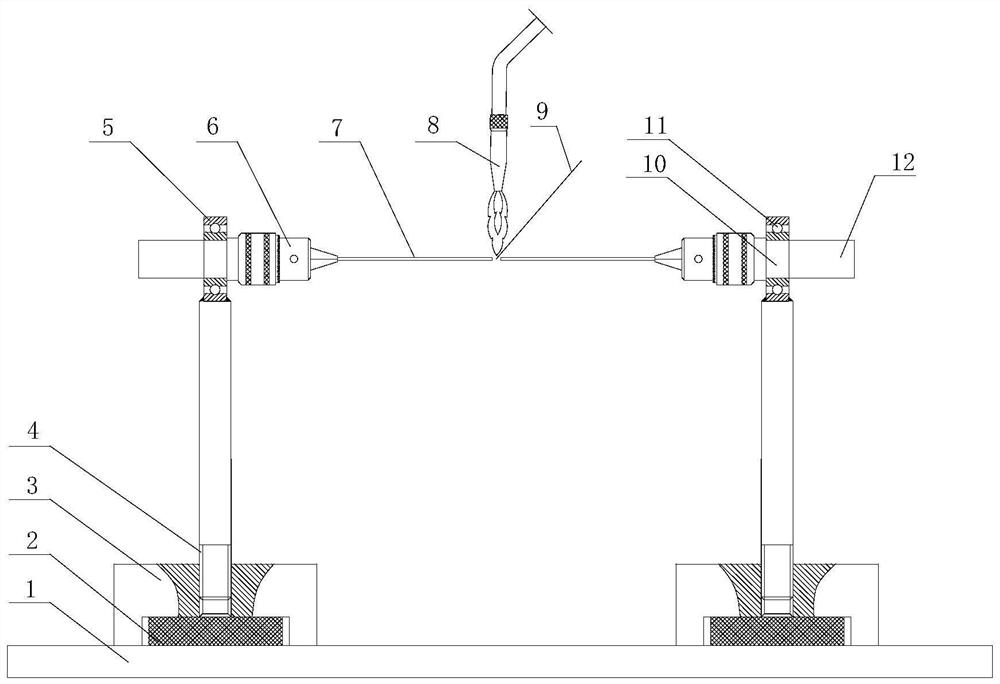

[0033] Such as Figure 1-2 Described, a stainless steel microtube 7 welding process, comprises the following steps:

[0034] Step S1: fixing the stainless steel micro-tube 7, respectively fixing the two stainless steel micro-tubes 7 to be welded on the welding equipment, which is convenient for assembly, adjustment, welding and grinding;

[0035] Step S2: Assembling the stainless steel microtubes 7 so that the two stainless steel microtubes 7 to be welded are located on the same straight line;

[0036] Step S3: adjust the interface, adjust the interface of the stainless steel microtube 7 to be welded to ensure that there is no misalignment, and the gap is within the expansion coefficient of the stainless steel microtube 7;

[0037] Step S4: igniting the miniature welding torch 8, igniting the miniature welding torch 8 and adjusting the flame so that the flame of the miniature welding torch 8 is a neutral flame, and testing the flame core temperature of the miniature welding t...

Embodiment 2

[0047] Such as Figure 1-2 , on the basis of above-mentioned embodiment 1 common welding equipment, a kind of stainless steel microtube 7 welding process comprises the following steps:

[0048] Step S1: fixing the stainless steel micro-tube 7, respectively fixing the two stainless steel micro-tubes 7 to be welded on the welding equipment, which is convenient for assembly, adjustment, welding and grinding;

[0049] Step S2: Assembling the stainless steel microtubes 7 so that the two stainless steel microtubes 7 to be welded are located on the same straight line;

[0050] Step S3: adjust the interface, adjust the interface of the stainless steel microtube 7 to be welded to ensure that there is no misalignment, and the gap is within the expansion coefficient of the stainless steel microtube 7;

[0051] Step S4: igniting the miniature welding torch 8, igniting the miniature welding torch 8 and adjusting the flame so that the flame of the miniature welding torch 8 is a neutral flame...

Embodiment 3

[0060] Such as Figure 1-2 , on the basis of above-mentioned embodiment 1 common welding equipment, a kind of stainless steel microtube 7 welding process comprises the following steps:

[0061] Step S1: fixing the stainless steel micro-tube 7, respectively fixing the two stainless steel micro-tubes 7 to be welded on the welding equipment, which is convenient for assembly, adjustment, welding and grinding;

[0062] Step S2: Assembling the stainless steel microtubes 7 so that the two stainless steel microtubes 7 to be welded are located on the same straight line;

[0063] Step S3: adjust the interface, adjust the interface of the stainless steel microtube 7 to be welded to ensure that there is no misalignment, and the gap is within the expansion coefficient of the stainless steel microtube 7;

[0064] Step S4: ignite the miniature welding torch 8, ignite the miniature welding torch 8 and adjust the flame so that the flame of the miniature welding torch 8 is a neutral flame, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com