Method for connecting carbon fiber reinforced aluminum-based composite with metal

A technology for strengthening aluminum matrix and composite materials, applied in the field of composite materials and metals, it can solve the problems of severe interface reaction, deterioration of base material performance, and high heating temperature, and achieve the effect of good connection quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

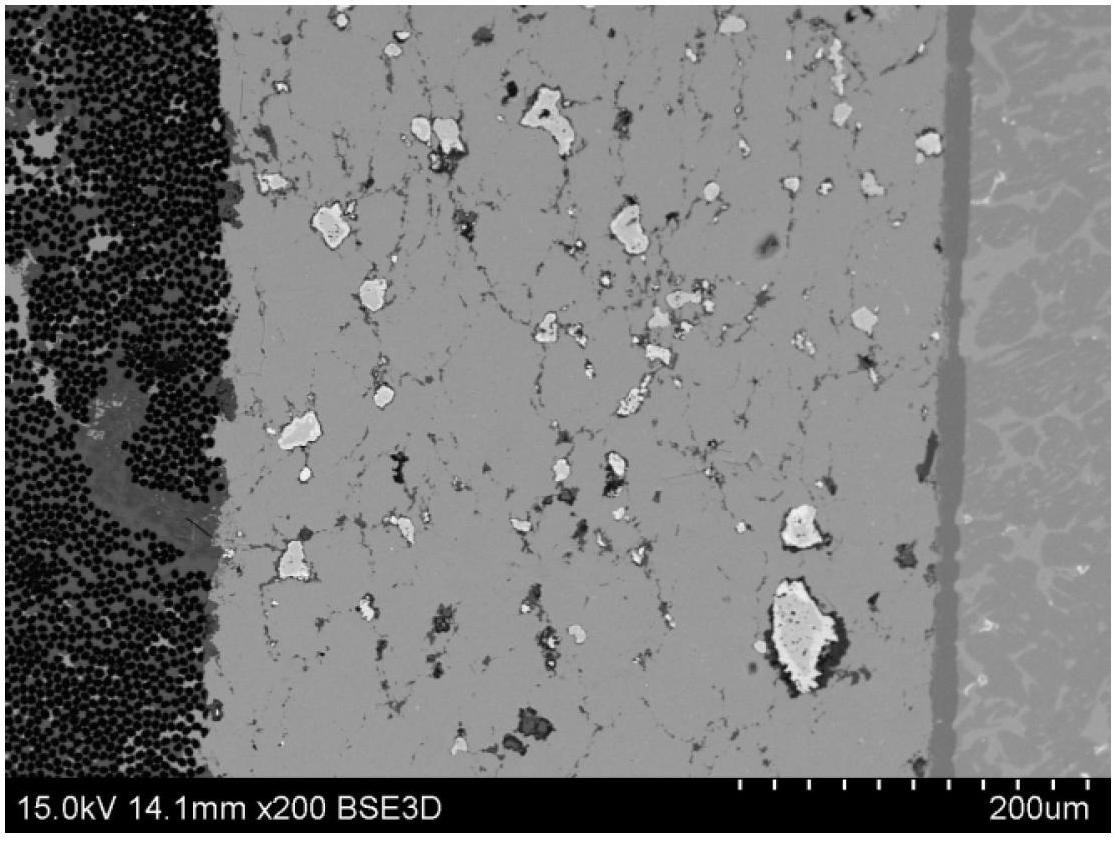

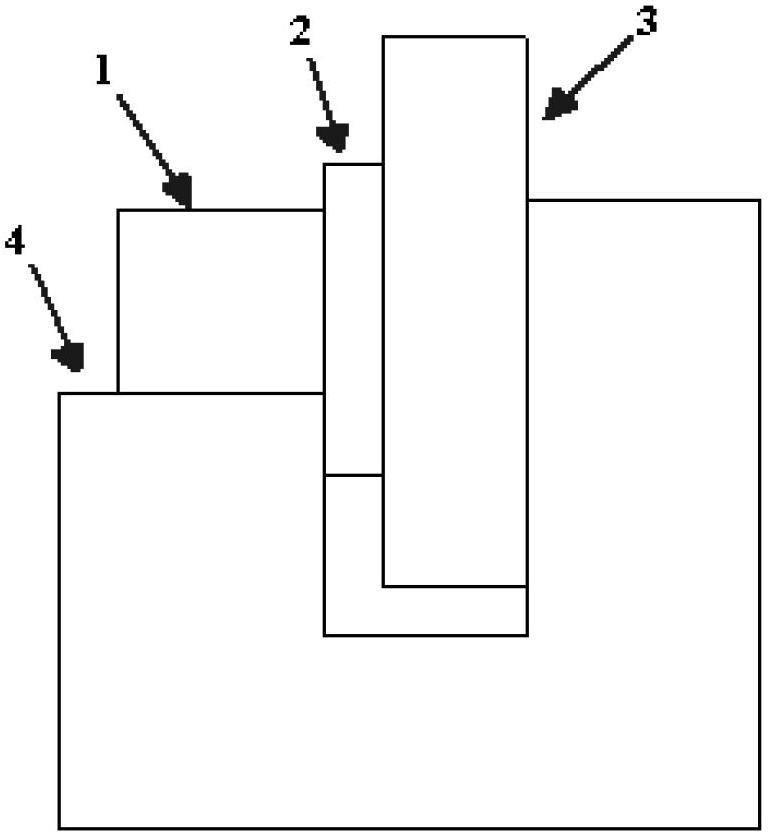

[0012] Specific embodiment one: a kind of method of connecting carbon fiber reinforced aluminum matrix composite material and metal of this embodiment is carried out according to the following steps: 1, the aluminum powder of 54~58 parts by weight, the nickel powder of 8~10 parts Powder and 33~37 parts of copper oxide powder are mixed evenly, placed in the ball mill tank, and the ball is put into the ball at a mass ratio of 5:1. Under the condition of argon protection, the Speed ball milling for 2-3 hours to obtain mixed powder; 2. Press the mixed powder obtained in step 1 into an intermediate laminated compact with a relative density of 60%-80% and a thickness of 1-3mm, and seal it for storage; 3. The intermediate laminated blank is placed between the carbon fiber reinforced aluminum matrix composite material and the metal to assemble a "sandwich" assembly, and then the assembly is clamped and placed in a vacuum furnace, and heated to 500°C under a pressure of 5MPa , and ke...

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment differs from Embodiment 1 in that: the aluminum powder in step 1 is 325-1000 mesh, the nickel powder is 325-1000 mesh, and the copper oxide powder is 325-1000 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that the relative density described in step 2 is the relative density measured at 20°C. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com