Automatic welding line for LED tube

A technology of LED tube and welding line, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of shortening the service life of LED tube, affecting the appearance of LED tube, and inability to connect with plastic shell, etc. Good effect, high degree of automation, guaranteed appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

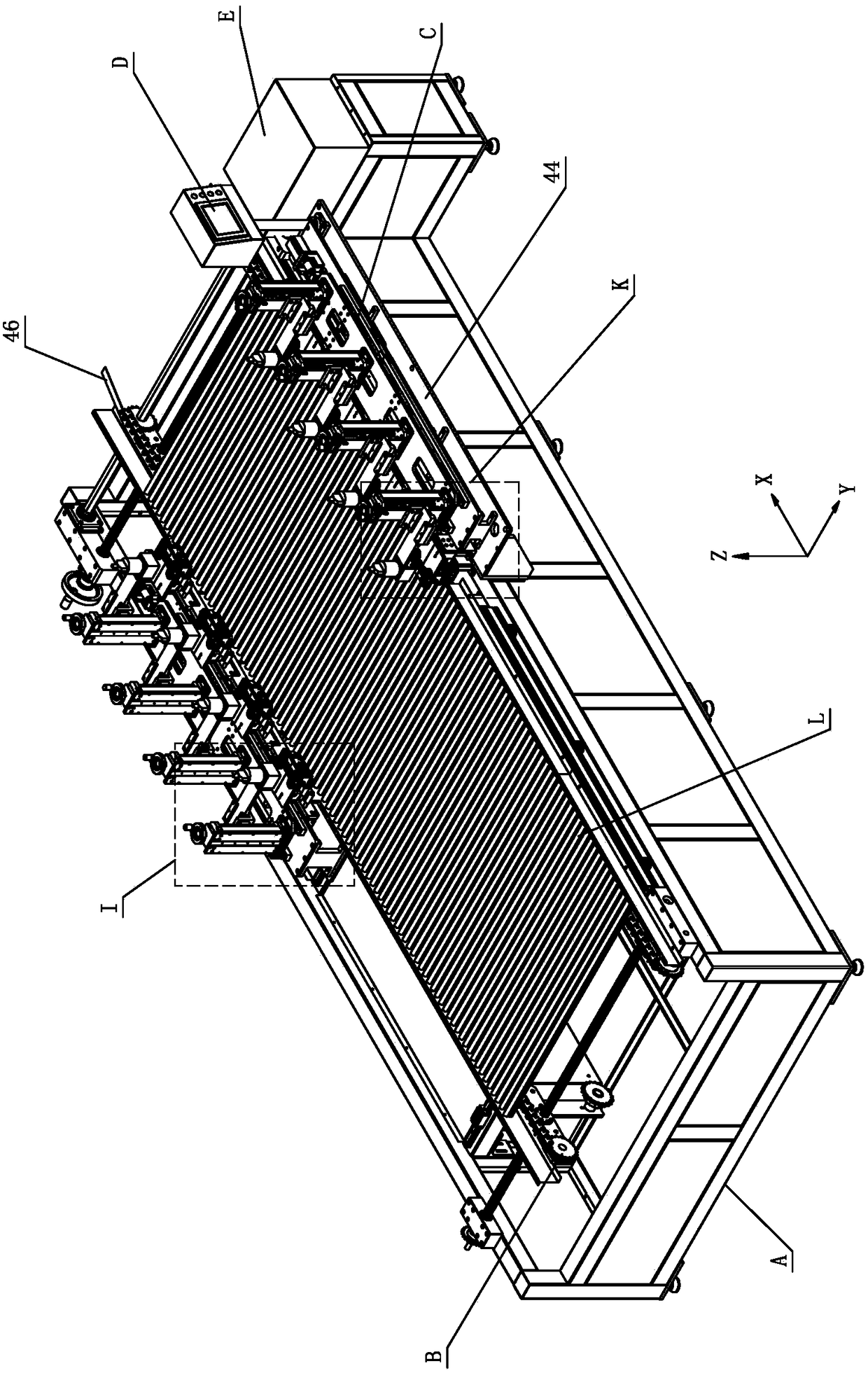

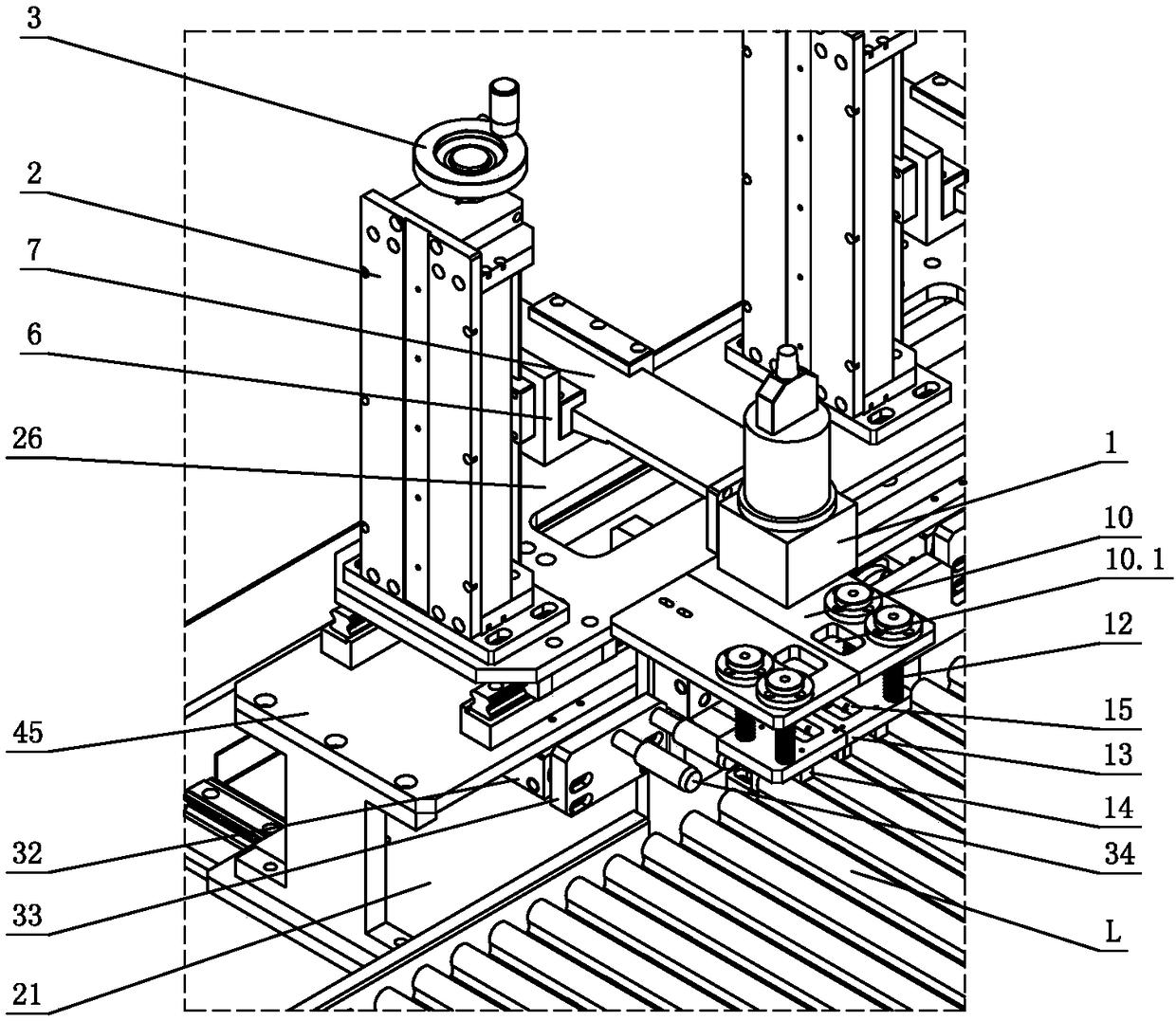

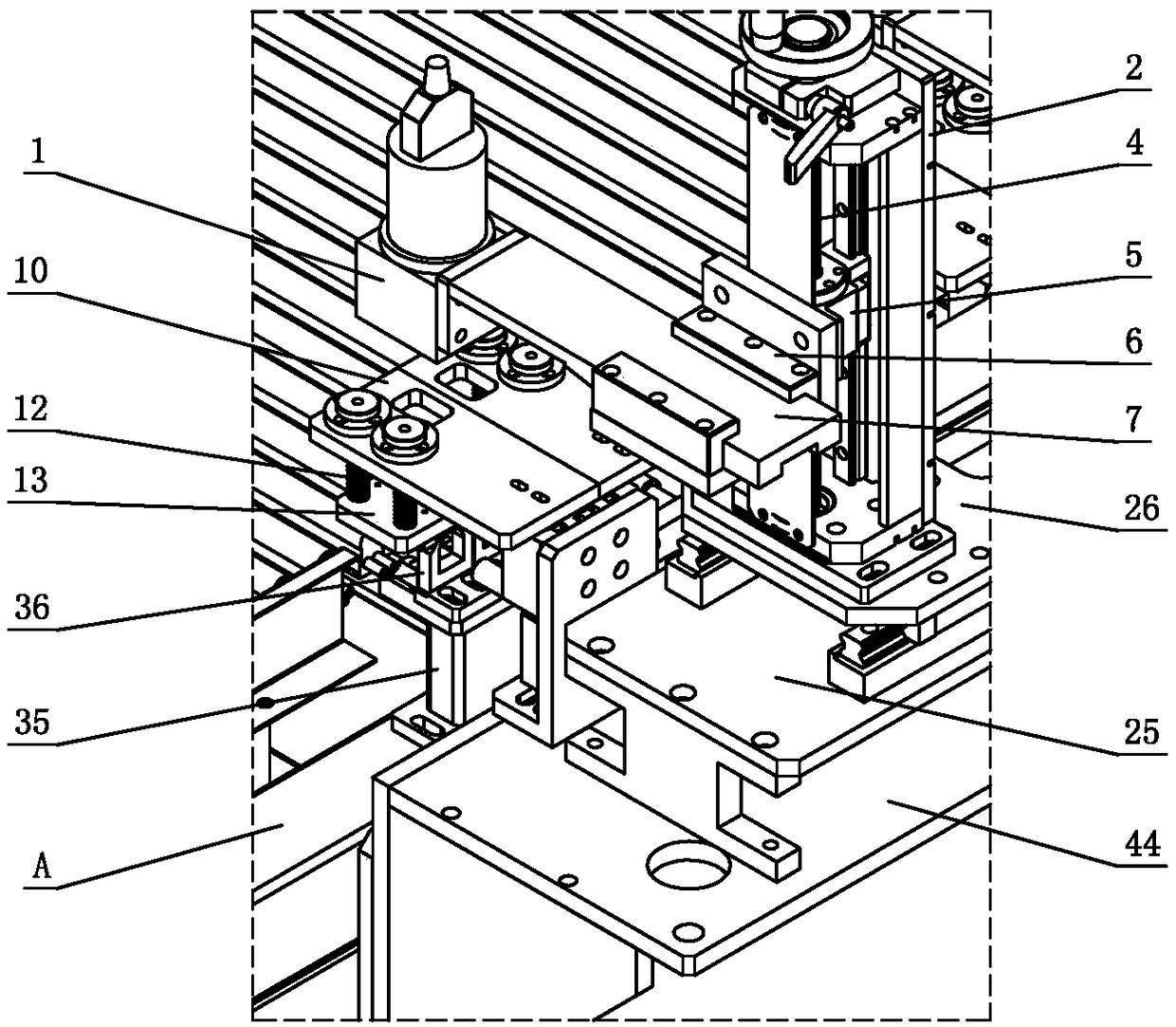

[0033] see Figure 1-Figure 14 , the LED tube automatic welding line, including the tube transmission assembly B and laser welding assembly C installed on the frame A, the tube transmission assembly B is used to transmit several LED tubes L at the same time, laser welding Assembly C is used to weld the first welding position L1 at one end of the LED tube L and the second welding position L2 at the other end (see Figure 13 and Figure 14 ). The starting end of the lamp conveying assembly B is the loading station, the middle of the conveying is the welding station, and the end of the conveying is the unloading station; when working, the worker stands on the side of the lamp conveying assembly B in the feeding station Or both sides of the LED tube L are loaded; the laser welding assembly C is located on the welding station; the end of the frame A is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com