Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Reduce quenching stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength strapping steel with tensile strength over 1,100 MPa and manufacturing method thereof

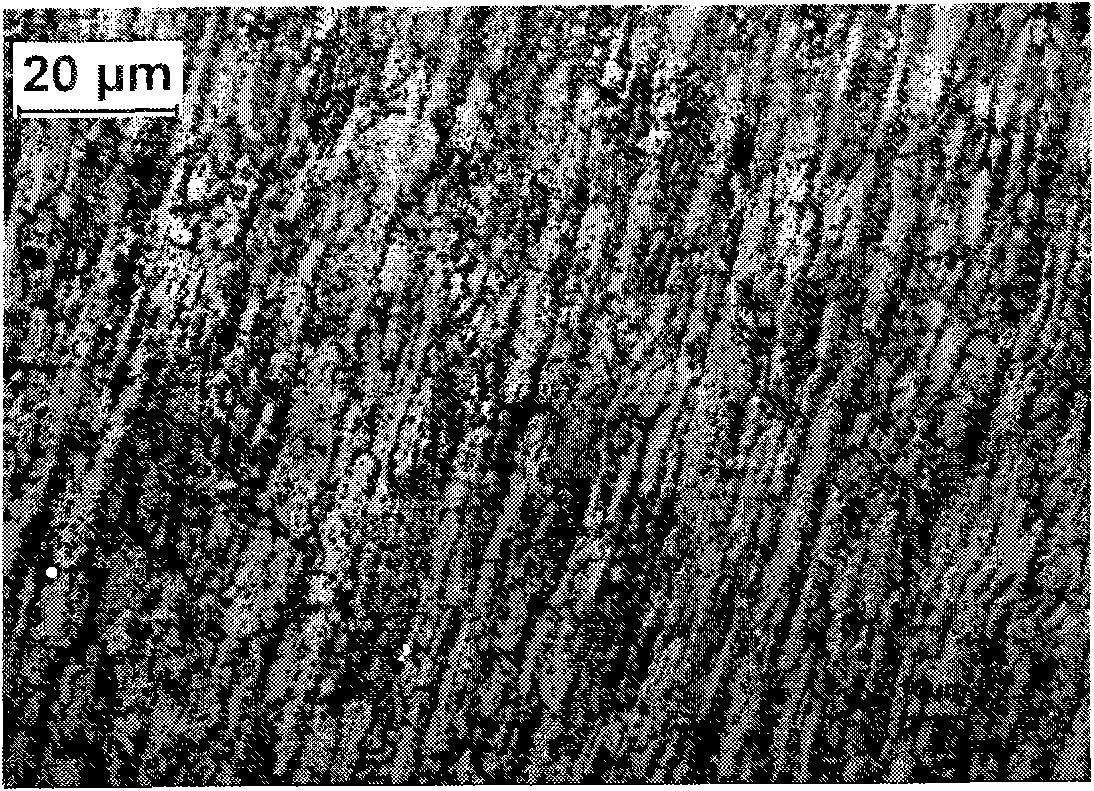

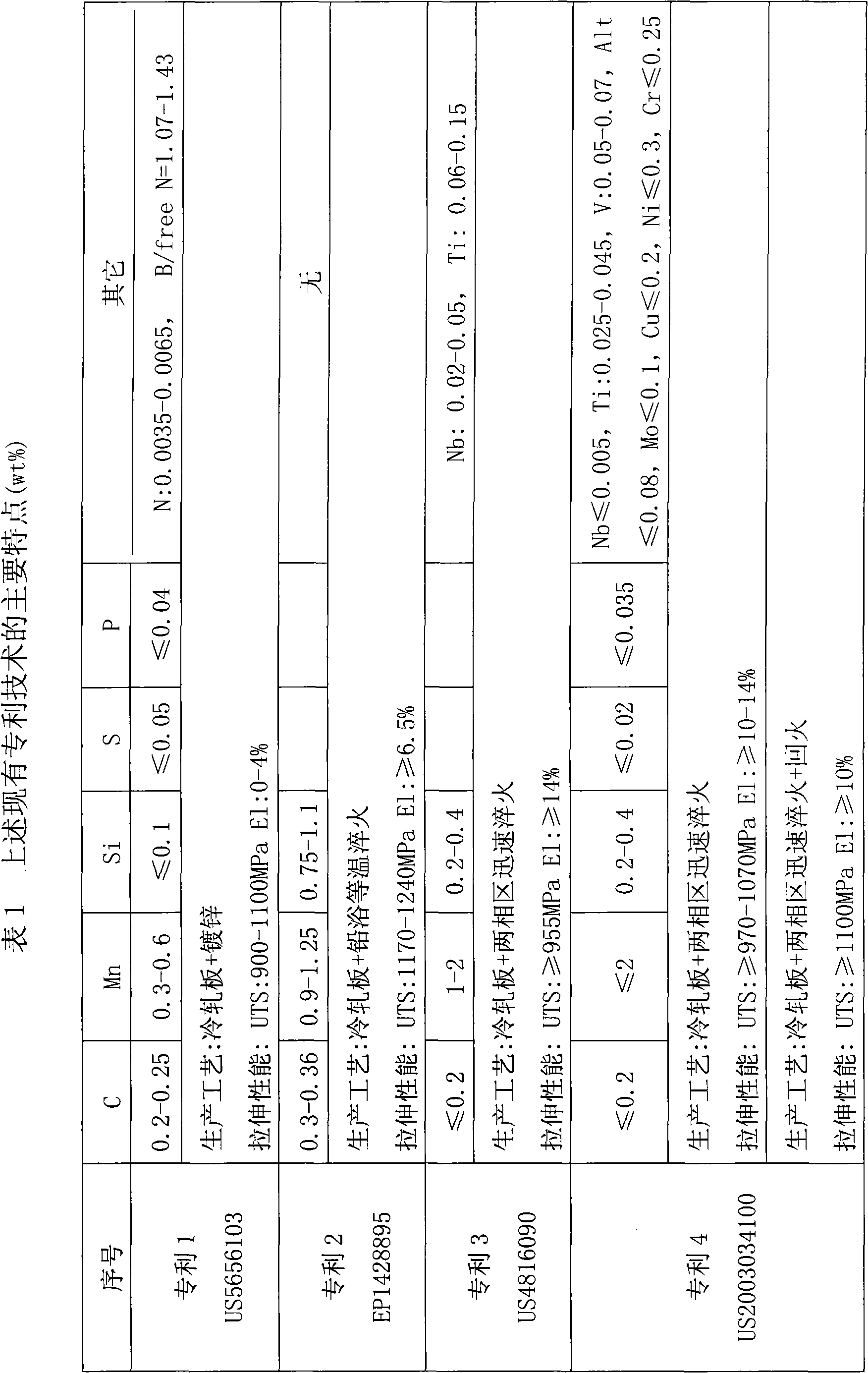

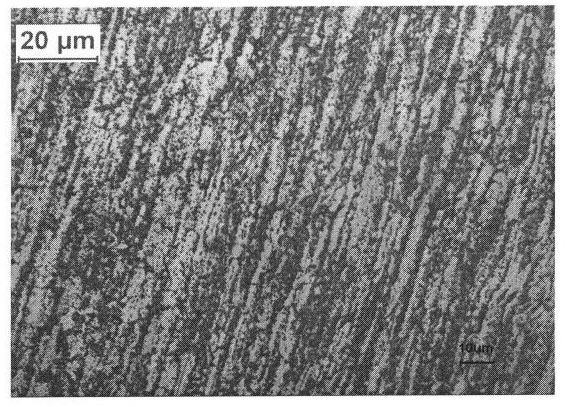

The invention discloses high strength strapping steel with tensile strength over 1,100 MPa and a manufacturing method thereof. The high strength strapping steel comprises the following components in percentage by weight: 0.25 to 0.35 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steel smelting process, hot rolling process, cold rolling process and ferrite-austenite two-phase region quick quenching and annealing heat treatment process for smelting pure steel while controlling the state of impurities. The method can realize the excellent combination of strength and plasticity, realizes the clean production of the high-strength strapping steel which has a tensile strength over 1,100MPa and an elongation over 10 percent, and has the advantages of easy-to-implement production operation, high production efficiency, low production cost, light environmental pollution. Thus, the method has a good application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

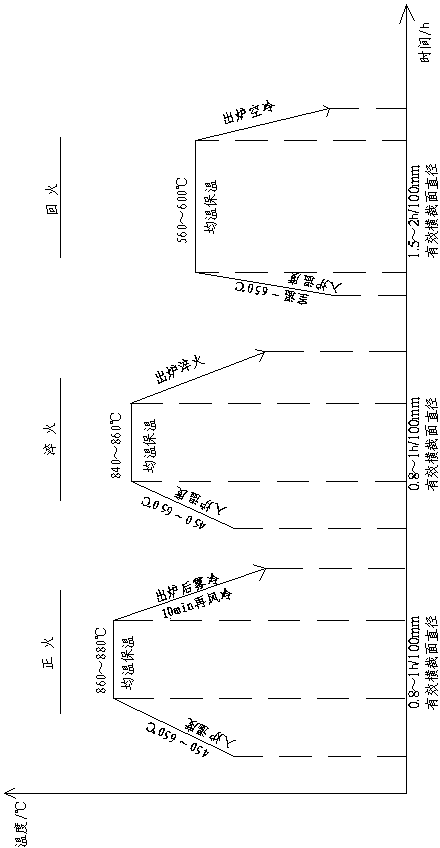

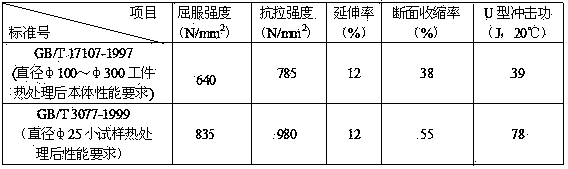

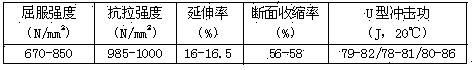

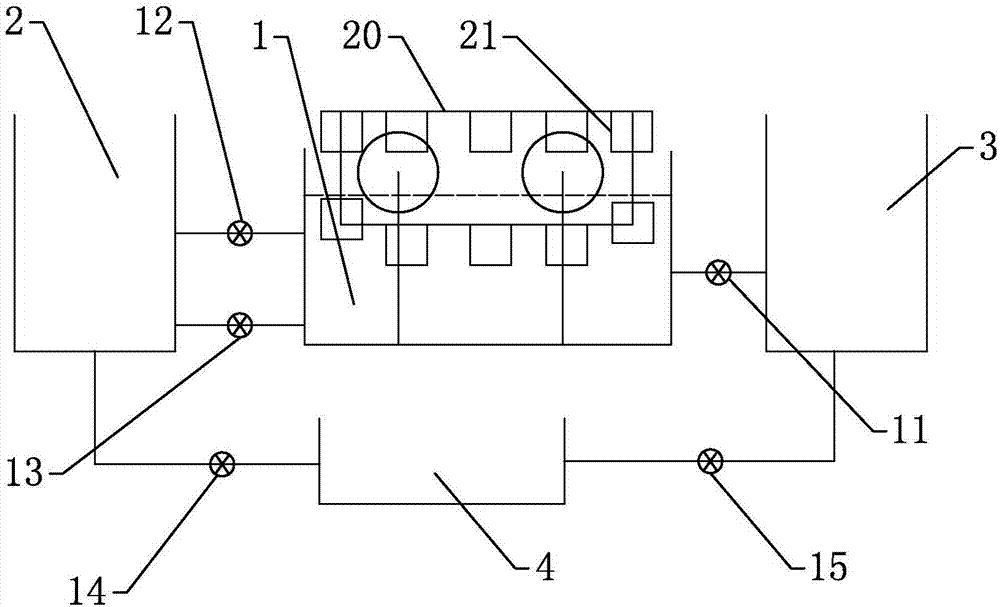

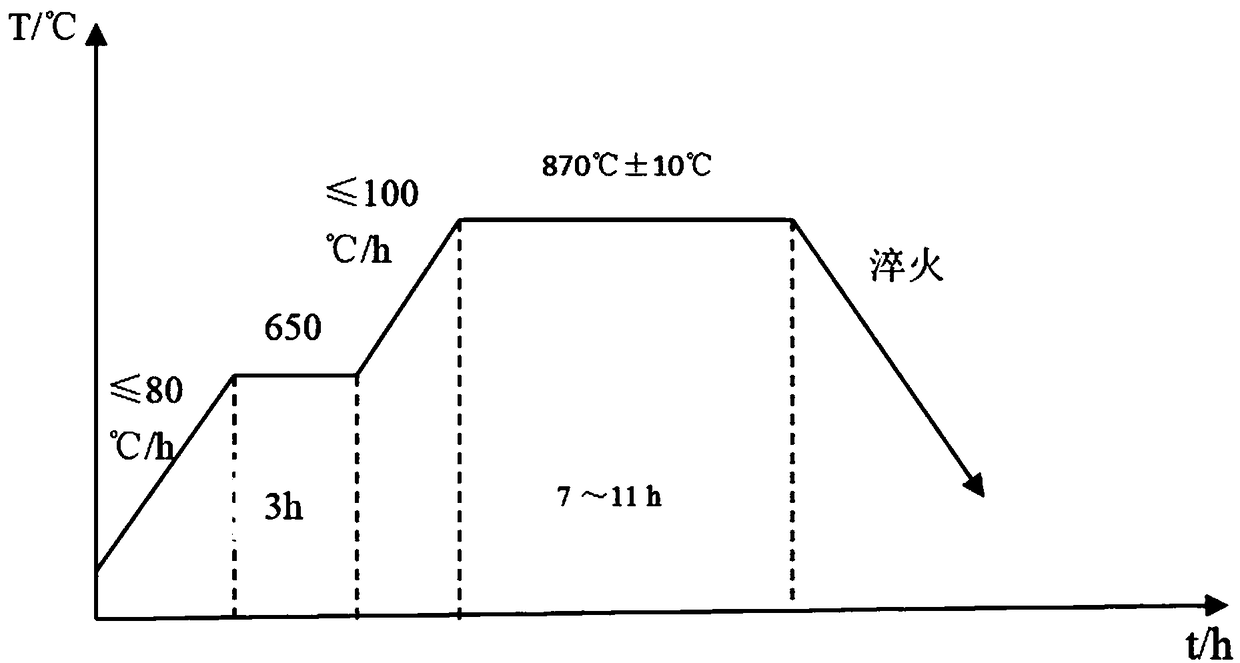

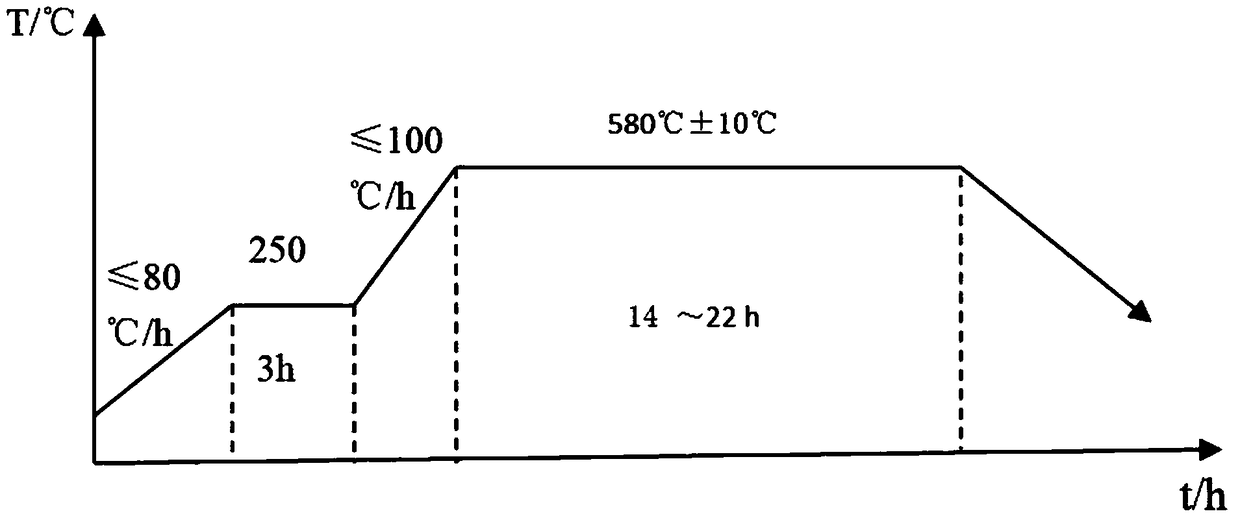

Thermal treatment process for 40CrNiMoA core rod and 40CrNiMoA core rod obtained through process

ActiveCN103849746ASufficient quenching and cooling intensityAvoid crackingMandrelsFurnace typesPearliteRejection rate

The invention belongs to the field of forging technology, and particularly relates to a thermal treatment process for a 40CrNiMoA core rod and the 40CrNiMoA core rod obtained through treatment. The thermal treatment process comprises three processes, namely normalizing treatment, quenching treatment and tempering treatment, and the 40CrNiMoA core rod is obtained through the three processes. The thermal treatment process adopts the method of normalizing and quenching; through normalizing and accelerating cooling after normalizing, the as-forged particle size can be improved and thick lamellar pearlite can be eliminated, so that quenching is ready; the water-air-water gap cooling method is adopted when quenching cooling is performed, initial water temperature and temperature rise in the process of cooling are strictly controlled; enough quenching severity of a wokpiece is guaranteed to obtain so that a martensitic structure is obtained, while the quenching stress is reduced to the maximum to avoid cracking of the workpiece due to too large stress; a fine and even tempered sorbite is obtained by virtue of high-temperature quenching; relatively high impact toughness is obtained while the high strength is guaranteed; the thermal treatment process has the advantages of being high in production efficiency and low in rejection rate, and improving the impact toughness while ensuring the high strength.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

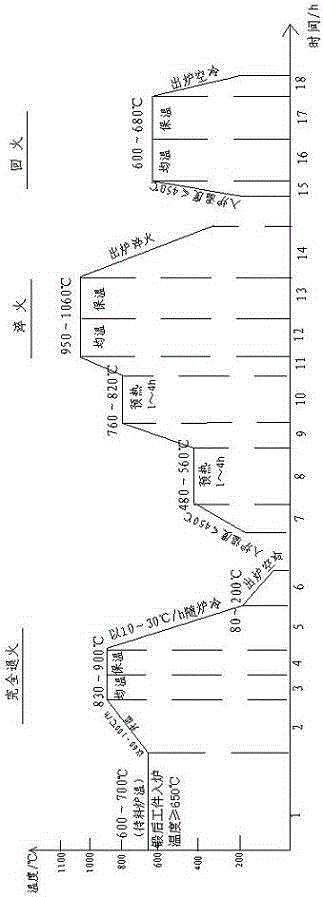

Heat treatment method of high-chromium martensitic stainless steel

ActiveCN102719627ASufficient quenching and cooling intensityAvoid crackingMartensitic stainless steelQuenching

The invention relates to a stainless-steel heat treatment technology, in particular to a heat treatment method of high-chromium martensitic stainless steel. The heat treatment method comprises the following steps of: 1) annealing; 2) preheating; 3) quenching; and 4) tempering. The heat treatment method has the following advantages that 4Cr16Mo stainless steel heat treatment process comprises the following procedures of: (1) complete annealing, controlling the furnace entering temperature after forging, the heating speed, the heating temperature, the insulating time and the furnace cooling speed; (2) quenching heating, controlling the preheating temperature, the heating speed, the heating temperature and the insulating time; (3) quenching cooling, adopting a gap-cooling mode of air-liquid-air-liquid-air-liquid, the quenching stress is furthest reduced while ensuring that a workpiece obtains enough quenching cooling severity and obtains a martensitic structure, and the cracking of the workpiece caused by excessive stress is avoided; and (4) tempering, strictly controlling the tempering furnace-entering time, tempering heating temperature and the insulating time, the structure transformation is complete, the quenching stress is eliminated, and fine and uniform tempering sorbite is obtained.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

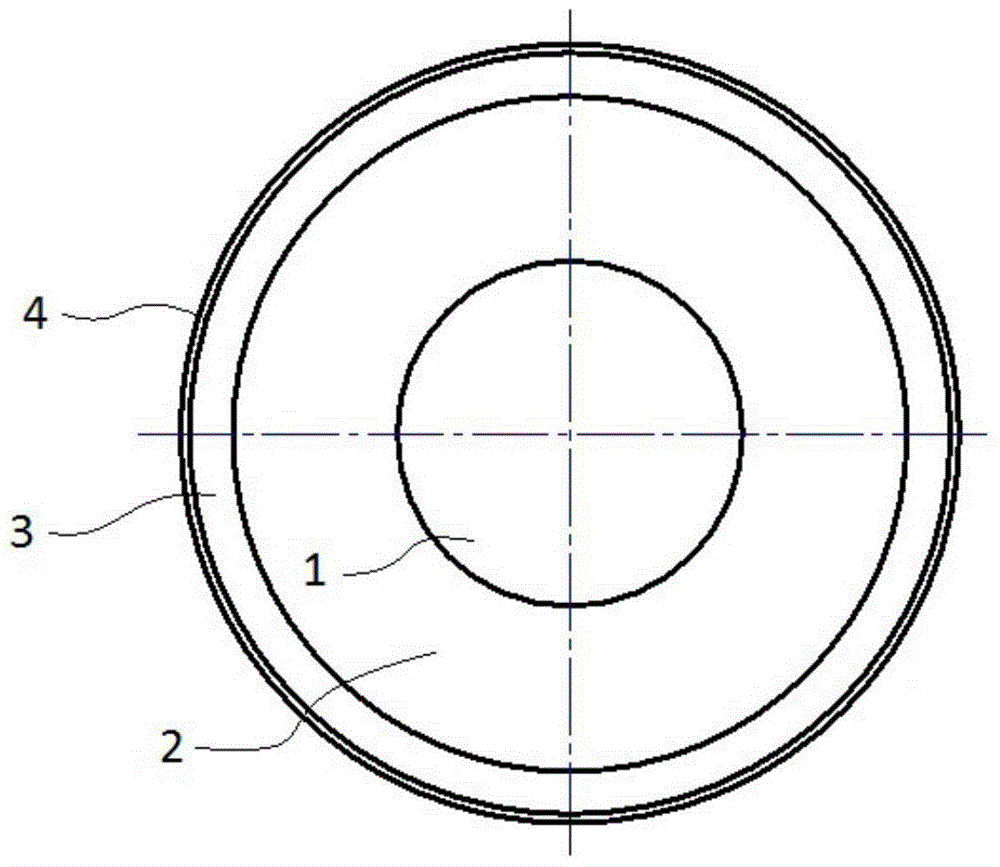

Slitting cutting disc and preparation method thereof

The invention discloses a slitting cutting disc and a preparation method thereof, which belong to the process field of cutters. The slitting cutting disc is of a circle blade, and comprises a center hole, a cutter disc and a blade, wherein the center hole is arranged in the center of the cutter disc, the blade is arranged on an outer ring of the cutter disc, a blade opening is arranged on an outer ring of the blade, and the opening angle delta ( ) of blade opening is 23-27 degrees. The opening thickness h of the blade opening is 0.24-0.26mm. The materials which are made into the slitting cutting disc comprise components with percentage by weight: carbon (C) 1.15-1.33%, nitrogen (N) 0.2-0.4%, manganese (Mn) 0.30-0.40%, silicon (Si) 0.52-1.20%, chromium (Cr) 8.50-10.50%, tungsten (W) 1.50-2.50%, vanadium (V) 0.35-0.50%, molybdenum (Mo) 0.25-0.4%, nickel (Ni) 0.30-0.40%, copper (Cu) <=0.30%, sulphur (S)<=0.020% and phosphorus (P)<=0.027%, and the allowance is ferrum (Fe). The slitting cutting disc has the advantages that the slitting cutting disc is excellent in abrasive resistance and is not easy to deform, and the blade opening resists abrasion, not easy to crack, long in service life and easy to make.

Owner:安徽华天机械股份有限公司

Machining process for large spring pieces

InactiveCN104668907AEliminate processing stressReduce thermal stressFurnace typesHeat treatment furnacesSurface stressPunching

The invention relates to processes for springs, in particular to a machining process for large spring pieces. The machining process includes the following steps of blanking of a 3mm plate, punching, finishing, rough grinding, thermal treatment, accurate grinding, oxidation treatment and packaging, wherein the step of thermal treatment includes high-temperature tempering, quenching and intermediate-temperature tempering. The large spring pieces produced by the machining process are stable in quality, free of saw blade cracking and basically free of workpiece cracking; a shaping die is adopted for tempering, so that uniformity in surface stress is realized, warping of the spring pieces is ensured to be slight, and the machining process is a mature thermal treatment process.

Owner:NANTONG HONGFENG ELECTRO MECHANIC

Thermal treatment process for spring steel PAG water-soluble quenching medium for band spring of automotive vehicle

InactiveCN101429591AReduce quenching stressRapid coolingFurnace typesQuenching agentsWater solubleMetal

The invention relates to a process for carrying out heat treatment on spring steel PAG of an automobile steel plate spring SiMn system through a water-soluble quenching medium. The process utilizes the reversibility of an aqueous solution of a PAG polymer; when hot metal is immersed and quenched in quenching liquid, a coating layer enclosed by the metal-rich PAG polymer controls the radiation speed of the surface of the metal; the aim of the process is to solve the increase of hardenability of the spring steel of the SiMn system with thick specification in quenching, thereby ensuring that large quench hardening depth is obtained in quenching while the thermal stress and the structural stress of a workpiece are smallest.

Owner:长沙胜通汽配科技股份有限公司

Forging process for forge piece

ActiveCN107282839AShort heating timeIncrease production rateHandling devicesSurface finishSurface cleaning

The invention discloses a forging process for a forge piece and aims to provide a forging process for a forge piece with high structural strength and surface smoothness. According to the technical scheme of the forging process, the forging process for the forge piece is characterized by comprising the following steps of (1) charging, (2) heating, (3) dummying, (4) die forging forming, (5) trimming , (6) heat treatment, (7) surface cleaning, (8) flaw detection and (9) inspection. The forging process is suitable for a forging machining process.

Owner:TAIZHOU YUPENG MACHINE FORGING

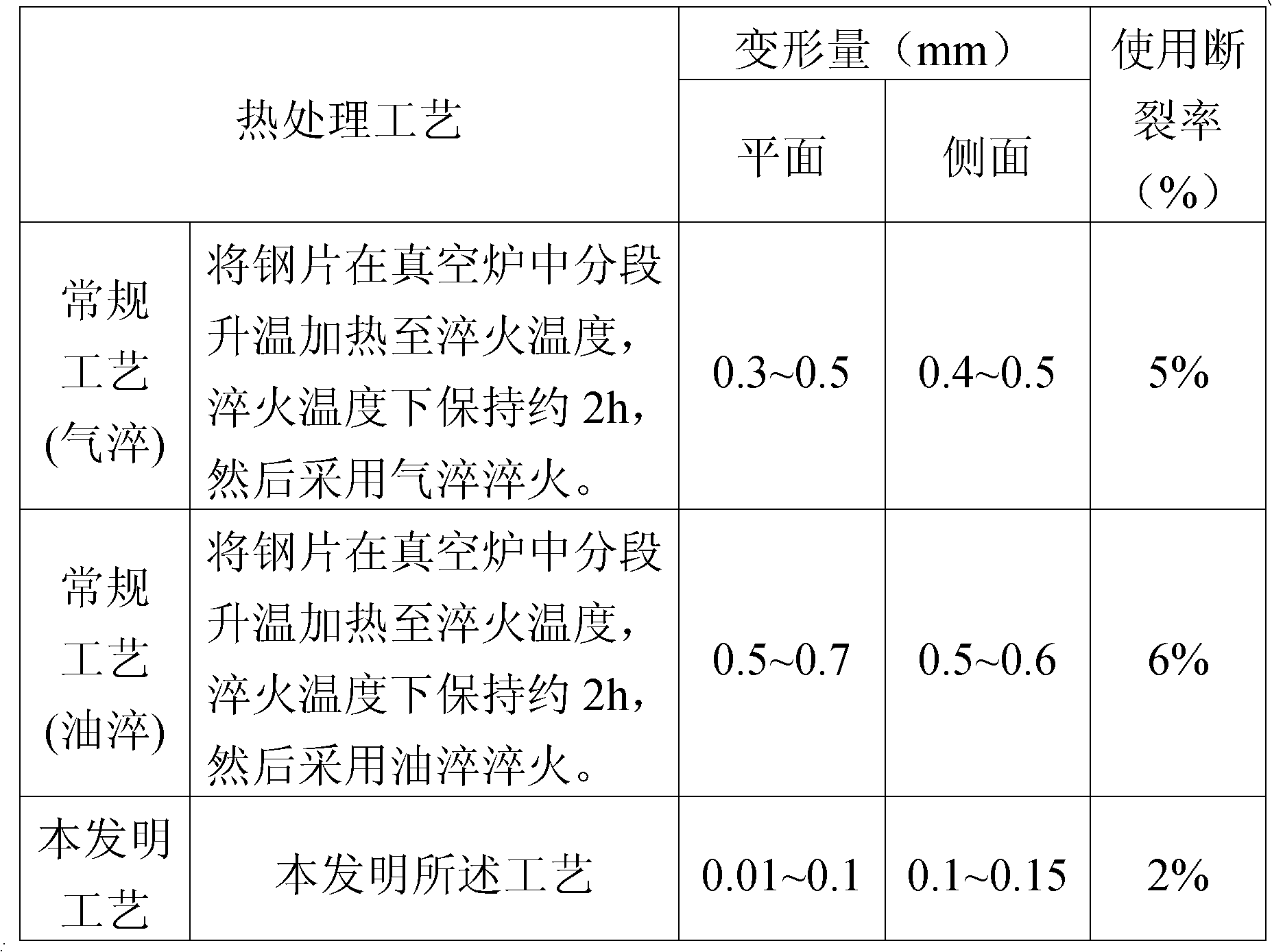

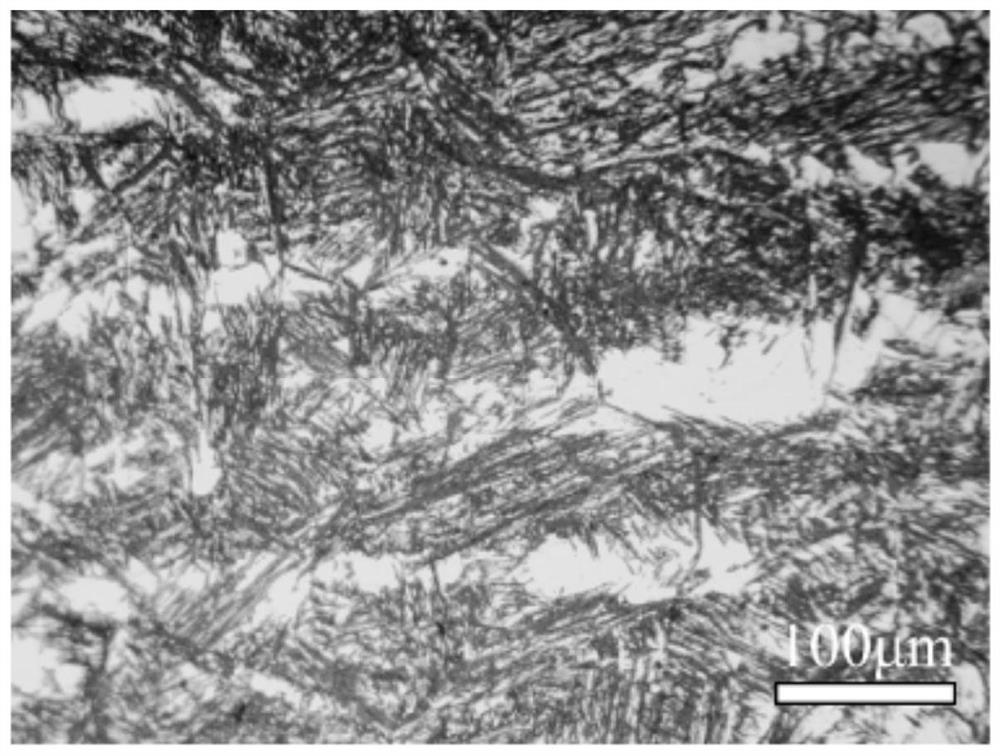

Composite carburizing and quenching heat treatment method of gear

ActiveCN105239033AReduce quenching stressSmall quenching deformationSolid state diffusion coatingFurnace typesCarburizingCorrosion

The invention relates to a composite carburizing and quenching heat treatment method of a gear, and belongs to the technical field of heat treatment. The method comprises the steps of carburization, cooling, heating, quenching and tempering. The composite carburizing and quenching heat treatment method can effectively refine grains and martensite needles, improves the gear surface hardness, further improves the wear resistance, the fatigue strength and the corrosion resistance of the gear, and improves comprehensive mechanical performance of the gear.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Quenching-tempering heat treatment method for large-scale module die steel

The invention discloses a quenching-tempering heat treatment method for large-scale module die steel. The method comprises the following steps of carrying out heating; carrying out heat preservation;carrying out water-cooling and air-cooling alternate quenching multiple times; and carrying out high-temperature tempering. The method has the advantages that a water-quenching air-cooling mode is adopted, water-lifting air-cooling is carried out multiple times, self-tempering is carried out, the surface structural transformation stress is eliminated, the cooling strength is within oil quenching and water quenching, and therefore through quenching of a large-scale module is ensured, and meanwhile, water-quenching cracking is avoided; the perlitic transformation caused by water quenching is avoided, then water lifting is carried out multiple times to decrease the cooling speed, so that the quenching stress is decreased, and therefore the cooling speed of a high-temperature section is increased, and meanwhile, quenching cracking is also prevented; and when the temperature of martensite cooled to 1.2738 begins to change temperature, air cooling is carried out, so that the forming speed ofthe martensite is decreased, and therefore the structural stress can be greatly decreased, and cracking of a low-temperature section can be avoided.

Owner:武钢集团襄阳重型装备材料有限公司

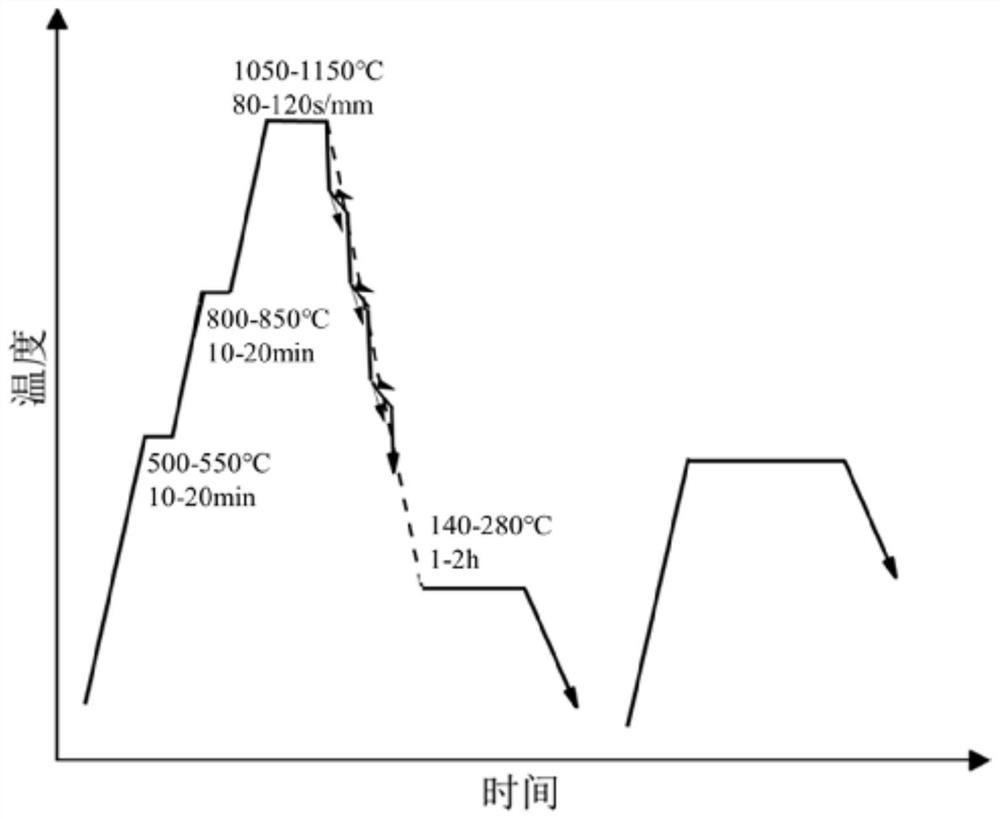

Isothermal transformation thermal treatment method for superhigh-intensity steel

ActiveCN102864299AImprove mechanical propertiesSave energyHeat treatment process controlRoom temperatureUltimate tensile strength

The invention discloses an isothermal transformation thermal treatment method for superhigh-intensity steel, which comprises the following steps of: directly quenching rolled steel material, wherein the initial quenching temperature is 850-900DEG C, and the final quenching temperature is 150-250DEG C; preserving the temperature of the quenched steel material for 0.1-0.5min / mm, wherein the mm is the unit of the thickness or the radius of the steel material; heating and tempering the steel material of which the temperature is preserved, wherein the on-line tempering temperature preservation temperature range is 200-350DEG C, the tempering temperature preservation time is 2-6min / mm, and the mm is the unit of the thickness or the radius of the steel material; and after tempering treatment, cooling the steel material to the room temperature.

Owner:LAIWU IRON & STEEL GRP

Niobium micro-alloyed wear-resisting cast steel material, application thereof and preparation method thereof

InactiveCN109457086AHigh hardnessImprove wear resistanceFurnace typesProcess efficiency improvementMetallic materialsSolid solution strengthening

The invention discloses a niobium micro-alloyed wear-resisting cast steel material, application thereof and a preparation method thereof, and the niobium micro-alloyed wear-resisting cast steel material is suitable for manufacturing a niobium alloying effect based wear-resisting cast steel part of a ball mill lining plate. The niobium micro-alloyed wear-resisting cast steel material comprises alloy components, and a thermal treatment process, and belongs to the technical field of metal material processes. The niobium micro-alloyed wear-resisting cast steel material consists of the following components in percentage by mass: 0.45-0.55% of C, 0.95-1.05% of Si, 1.5-1.6% of Mn, 4.2-4.8% of Cr, 0.75-0.80% of Mo, 0.15-0.20% of Nb, less than or equal to 0.02% of S, less than or equal to 0.03% ofP and the balance of Fe. An element niobium is added to obtain fine discontinuously-distributed niobium carbide, so that the effects of solid solution strengthening and grain boundary pinning are achieved, and therefore, hardness, impact toughness and tensile strength of the material are matched and improved very well, a wear-resisting lining plate material with stable performance is obtained under an air-cooling way, and the process is simple and environmentally friendly.

Owner:SHANGHAI UNIV

QAl9-4-4 aluminum bronze alloy heat treatment process

The invention belongs to the technical field of thermal processing of copper alloys, and in particular relates to a QAl9-4-4 aluminum bronze alloy heat treatment process. The operation steps are as follows: (1) cutting an extruded QAl9-4-4 aluminum bronze alloy pipe or bar into specified lengths, placing the QAl9-4-4 aluminum bronze alloy pipe or bar in a resistance furnace heated to a temperatureof (850 to 900) DEG C for thermal insulation for 1 to 5 hours for high temperature heat treatment, and immediately cooling the QAl9-4-4 aluminum bronze alloy pipe or bar in 50-80 DEG C warm water after discharged from the resistance furnace; (2) placing the high-temperature thermally-treated QAl9-4-4 aluminum bronze alloy pipe or bar in the resistance furnace heated to a temperature of (420-470)DEG C for thermal insulation for 3 to 8 hours for low-temperature heat treatment, and cooling by air the QAl9-4-4 aluminum bronze alloy pipe or bar after discharged from the resistance furnace; and (3) processing the low-temperature thermally-treated QAl9-4-4 aluminum bronze alloy pipe or bar into parts, placing the parts in the resistance furnace heated to a temperature of (480-550) DEG C for thermal insulation for 2 to 6 hours for heat treatment, and cooling by air the parts after discharged from the resistance furnace. The QAl9-4-4 aluminum bronze alloy pipe or bar prepared by the QAl9-4-4aluminum bronze alloy heat treatment process has a tensile strength reaching 820 MPa or more, a hardness reaching 220 HBS or more, and an elongation of 10% or more. The comprehensive mechanical properties of the QAl9-4-4 aluminum bronze alloy pipe or bar are better than commonly used QAl10-4-4 alloys, and the QAl9-4-4 aluminum bronze alloy pipe or bar is stable in structure and performance, and can be more widely used in the manufacture of various wear-resistant and corrosion-resistant parts such as bearings and bushings.

Owner:贵溪骏达特种铜材有限公司

Chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method

ActiveCN103639231AImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesManganeseChromium

The present invention discloses a chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method designed by the present invention, the prepared chromium-molybdenum low-alloy zinc-plating steel strand has characteristics of high strength, good hardenability good, cracking resistance, low relaxation degree, and smooth and uniform surface zinc plating.

Owner:TIANSHUN GROUP

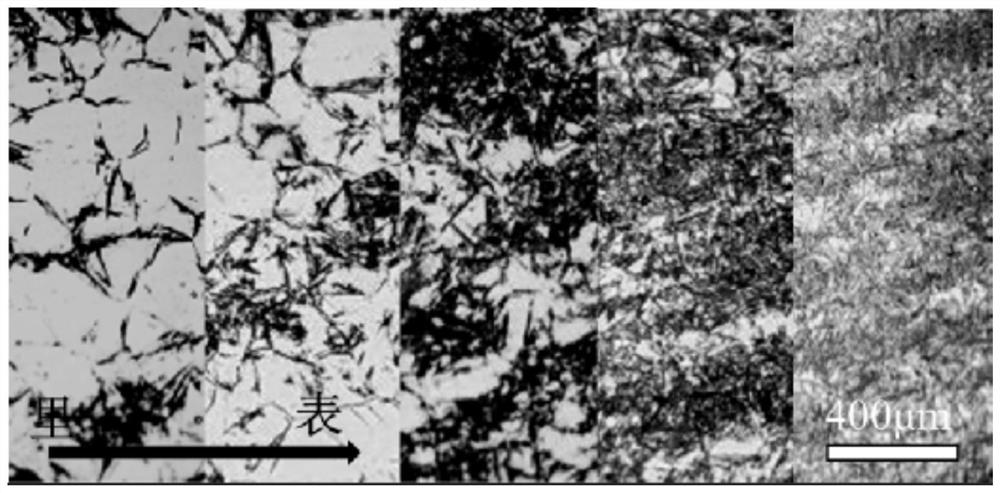

Cold rolling roller with ultra-deep hardening layer and manufacturing method of cold rolling roller

The invention discloses a cold rolling roller with an ultra-deep hardening layer and a manufacturing method of the cold rolling roller. The cold rolling roller comprises, by mass, 0.85%-0.95% of C, 0.60%-0.80% of Si, 0.60%-0.80% of Mn, 4.80%-5.80% of Cr, 0.30%-0.50% of Ni, 0.40%-0.60% of Mo, 0.05%-0.15% of V, 0-0.015% of P, 0-0.015% of S, and the balance Fe and inevitable impurities. The manufacturing method of the cold rolling roller comprises the process steps of smelting quenching and tempering, finish heat treatment and the like. The surface hardness of the manufactured cold rolling roller is 92-99 HSD, the hardening layer with the hardness being over 90 HSD is over 45 mm in depth, and the cold rolling roller is provided with the ultra-deep hardening layer.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method

ActiveCN103643146AImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesPre stressManganese

The present invention discloses a chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel is adopted as a billet material and comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method designed by the present invention, strength and toughness of the steel wire can be substantially increased, a corrosion resistance degree of the steel wire can be enhanced, and a service life can be prolonged.

Owner:TIANSHUN GROUP

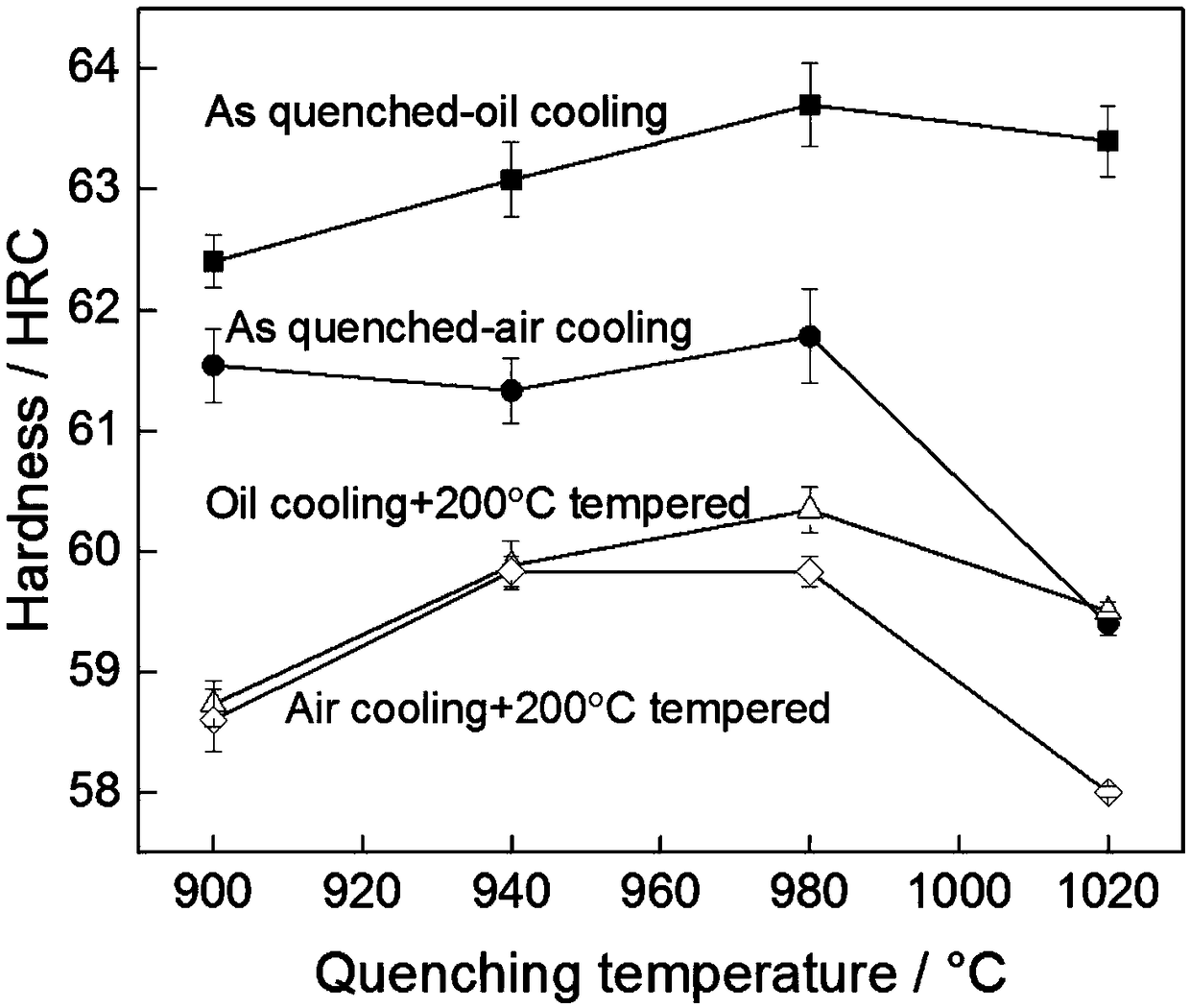

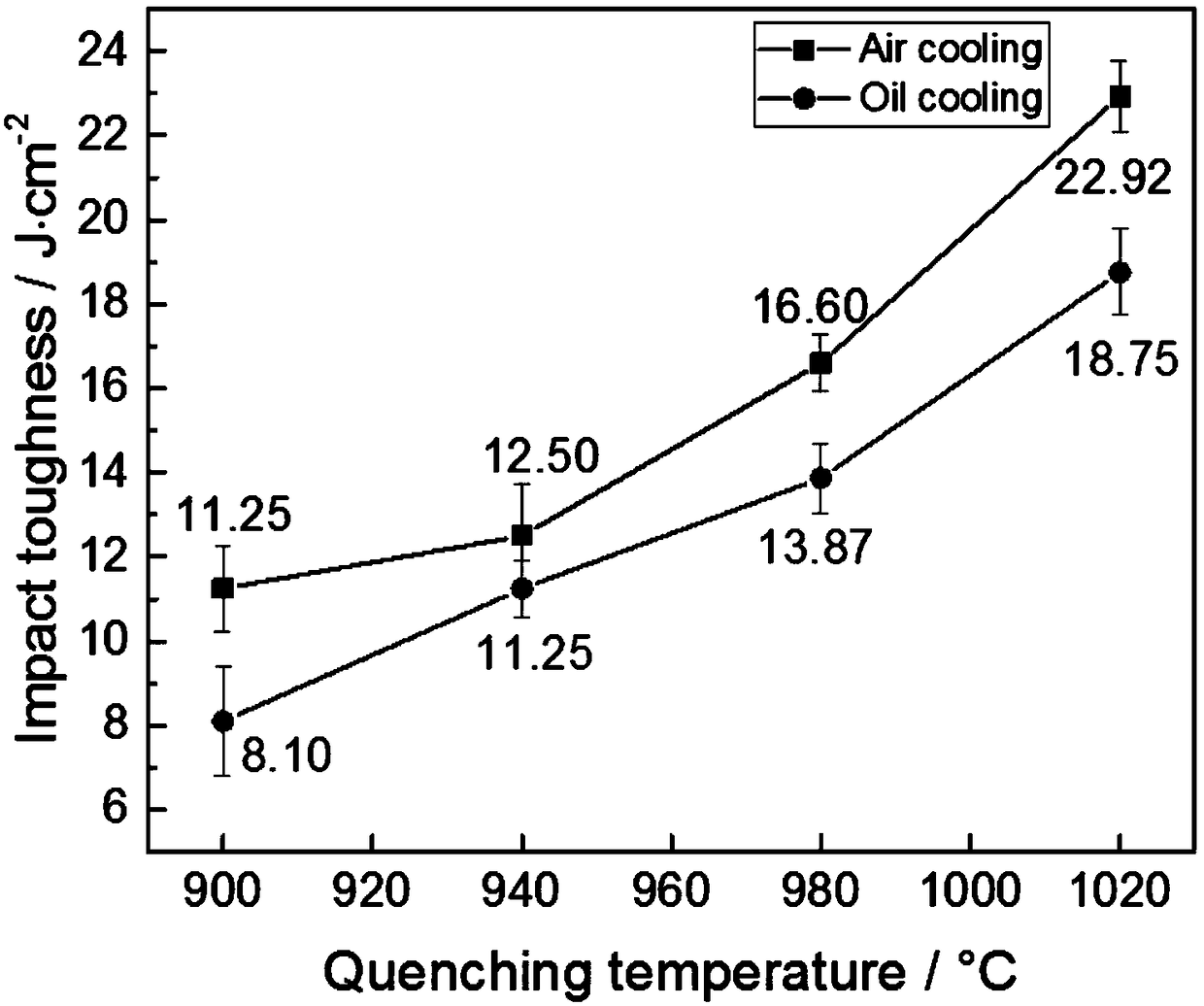

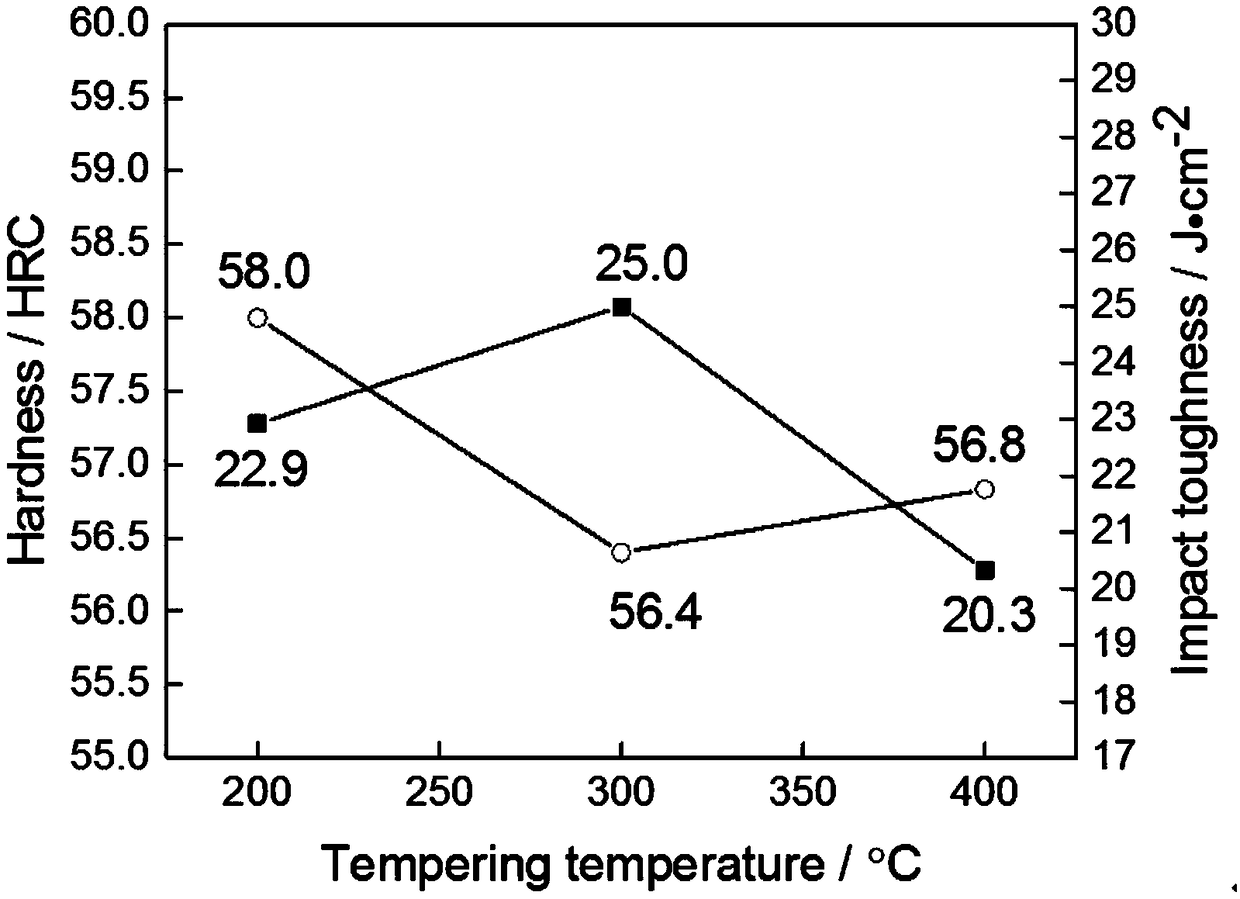

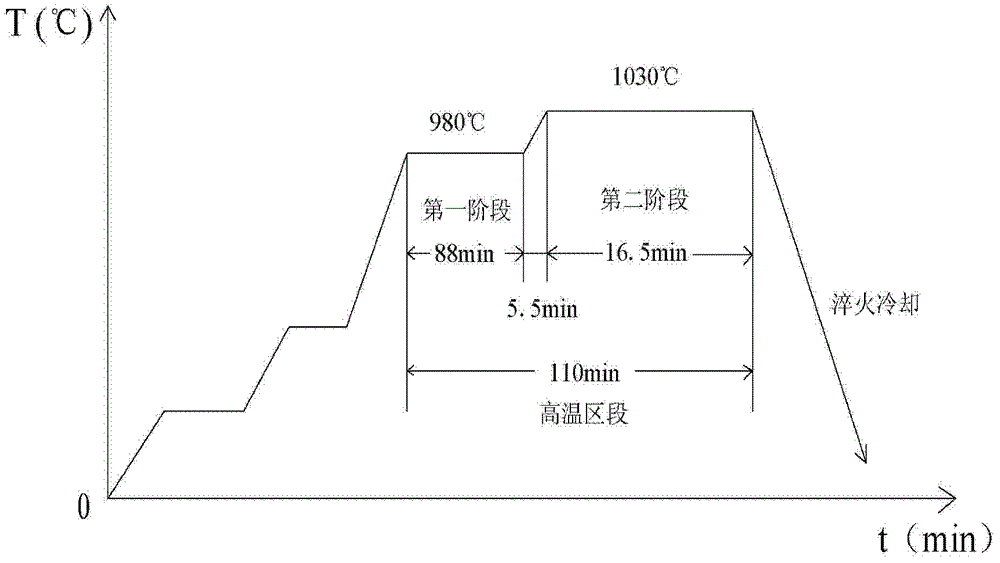

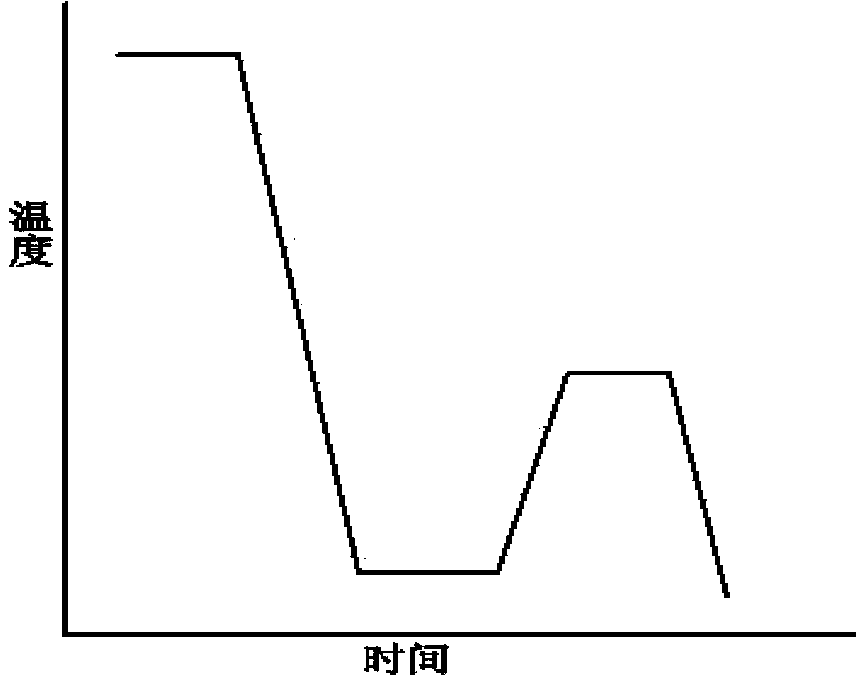

Setting method in sections of high alloy steel vacuum heat treatment high-temperature region parameters

ActiveCN103060538AReduce quenching stressReduce heat treatment distortionHeat treatment process controlHeating timeProperty value

The invention discloses a setting method in sections of high alloy steel vacuum heat treatment high-temperature region parameters. The method comprises setting of heating temperature of a high-temperature region first phase and first phase insulation time parameters, setting of heating temperature of a high-temperature region second phase and second phase insulation time parameters as well as setting of heating time parameters between the high-temperature region first phase and the high-temperature region second phase. The process method provides reasonable optimization on the heat treatment property values of the high alloy steel workpieces under the high-temperature region, the quenching stress of the high alloy steel workpiece decreases to minimum, heat treatment distortion amount of the workpiece is reduced, the performance of the material can be performed with maximum limit, so that the high red hardness and high wear resistance can be obtained, and good plasticity and toughness can be simultaneously obtained.

Owner:昆山鑫昌泰模具科技有限公司

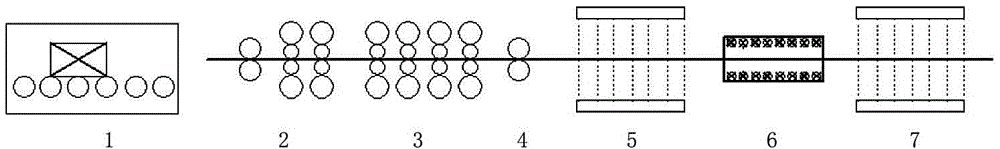

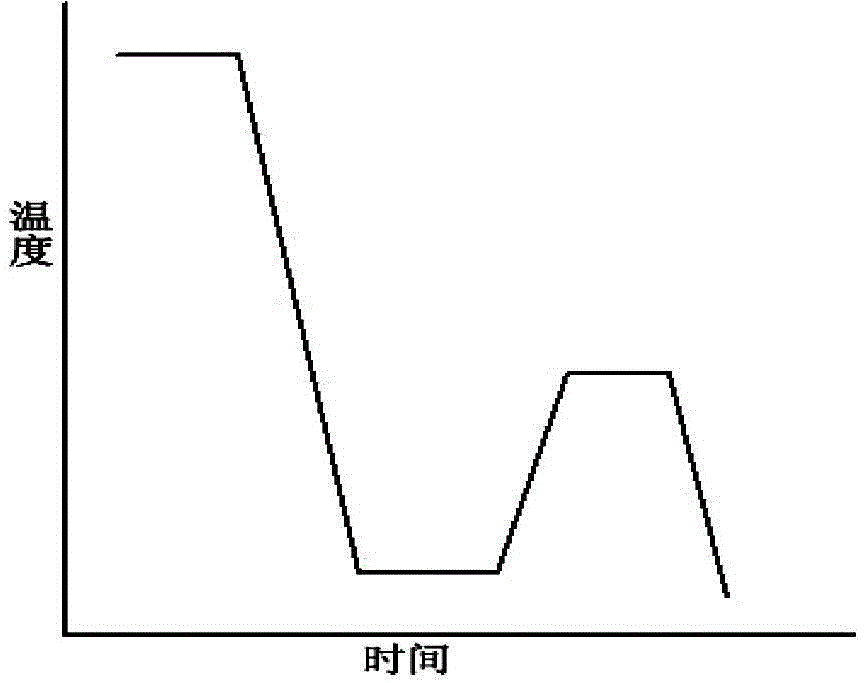

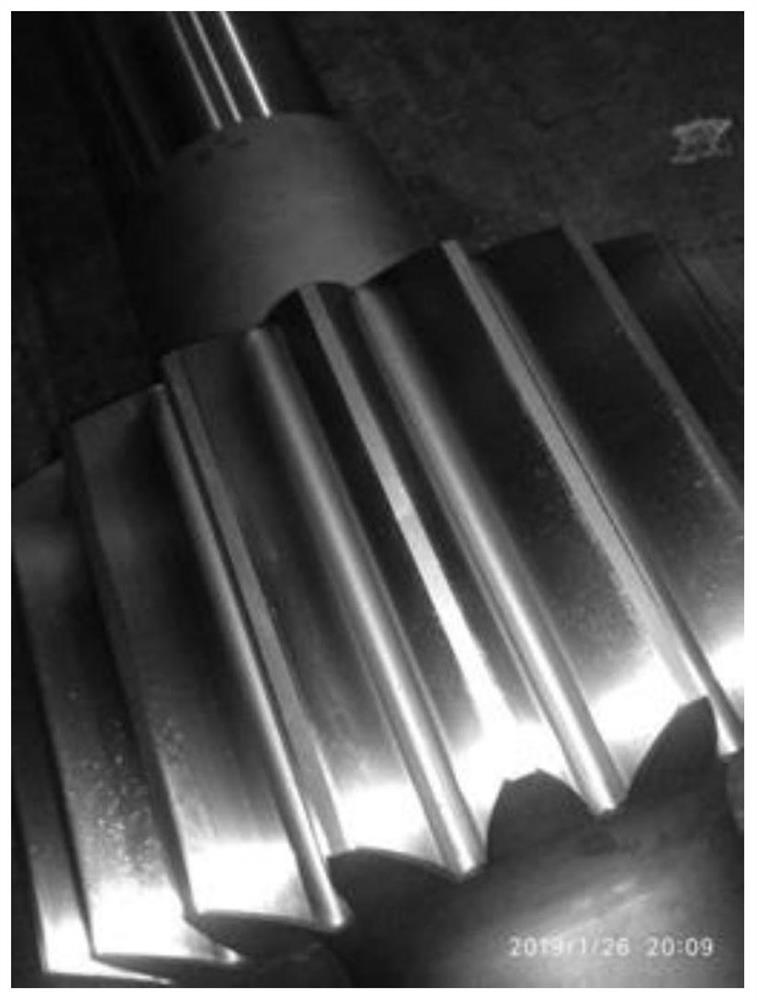

Heavy-duty gear carburizing and quenching method

ActiveCN110331260AReduce quenching stressReduce stressSolid state diffusion coatingFurnace typesWater basedThermal insulation

The invention discloses a heavy-duty gear carburizing and quenching method, and relates to the technical field of special steel making. The method comprises the following steps that a gear workpiece is subjected to carburizing treatment in a gas carburizing furnace, and then is subjected to austenitizing heating thermal insulation after getting out of furnace; then the gear workpiece is subjectedto precooling quenching; the gear workpiece is subjected to water-base medium quenching, salt bath quenching and fog cooling in sequence; and the gear workpiece is washed after fog cooling is finished, and then is subjected to tempering treatment. With the heavy-duty gear carburizing and quenching method, the problem that for a large-control-section gear made of a low-hardenability material, a quenching method in the prior art cannot achieve the purposes of making the performance of a center part and a gear root excellent and having effectively control over stress type cracking at the same time is solved, it is achieved that a heavy-duty gear is controllable in carburizing and quenching deformation without cracks, and the hardness, the texture, a hardened layer and the dynamic performanceof the heavy-duty gear all meet the technological design requirements.

Owner:CHANGZHOU TIANSHAN HEAVY IND MACHINERY

Heat treatment method of aluminum magnesium alloy

ActiveCN105839036AEvenly heatedReduce temperature differenceRoom temperatureUltimate tensile strength

The invention relates to the technical field of heat treatment of alloy, in particular to a heat treatment method of aluminum magnesium alloy. The heat treatment method comprises the following steps: placing the aluminum magnesium alloy in a vacuum heat treatment furnace at first; controlling the temperature to be 490-510 DEG C along with the temperature of the furnace in a mode of heating and then cooling; cooling after insulation is finished; placing the aluminum magnesium alloy in an environment at the temperature of 360-380 DEG C and insulating for 1-2 hours; carrying out single-pass deformation at the insulating temperature, wherein deformation is 25-45%; then carrying out cold rolling, wherein the rolling speed is 0.08-0.25 m / s, and reduction in cold rolling is 30+ / -5%; and finally cooling the aluminum magnesium alloy in air until the temperature of the aluminum magnesium alloy reaches room temperature. The heat treatment method is simple to operate and easy to implement; and the machining time is shortened. The aluminum magnesium alloy treated by the method has the characteristics of dimensional stability, corrosion resistance, mechanical property and excellent extrusion performance, and further has the advantage that the strength of the aluminum magnesium alloy is reasonably matched with plasticity.

Owner:贵州航天风华精密设备有限公司

Preparation method for automobile plate spring

ActiveCN111809034AReduce usageReduce lossSolid state diffusion coatingFurnace typesTemperingIndustrial engineering

The invention discloses a preparation method for an automobile plate spring. The preparation method is characterized in that the automobile plate spring is manufactured by adopting a spring steel blank containing molybdenum, vanadium and trace chromium and nickel elements, and the preparation method comprises the following steps that spring steel is forged to obtain a blank, the blank is hot-rolled into an automobile plate spring steel plate with variable cross-section characteristics, eye coiling is carried out, constant-temperature treatment is carried out, water-cooling quenching is carriedout, air cooling is carried out, surface accurate grinding is carried out, shot blasting treatment is carried out, gas co-permeation is carried out, overlay coating is carried out, and a finished product is obtained after drying. According to the preparation method, after a hot rolling process, waste heat is repeatedly utilized by means of a constant temperature device to complete forming and heat treatment of the plate spring, the heating time is shortened, the energy loss is greatly reduced, in the heat treatment process, water is adopted as a cooling medium, the problem of environmental pollution is reduced, tempering and surface gas co-permeation treatment are simultaneously carried out, the cost is greatly reduced, the surface quality of the plate spring is improved, and the corrosion resistance and the fatigue performance are improved.

Owner:四川丰元机械制造有限公司 +1

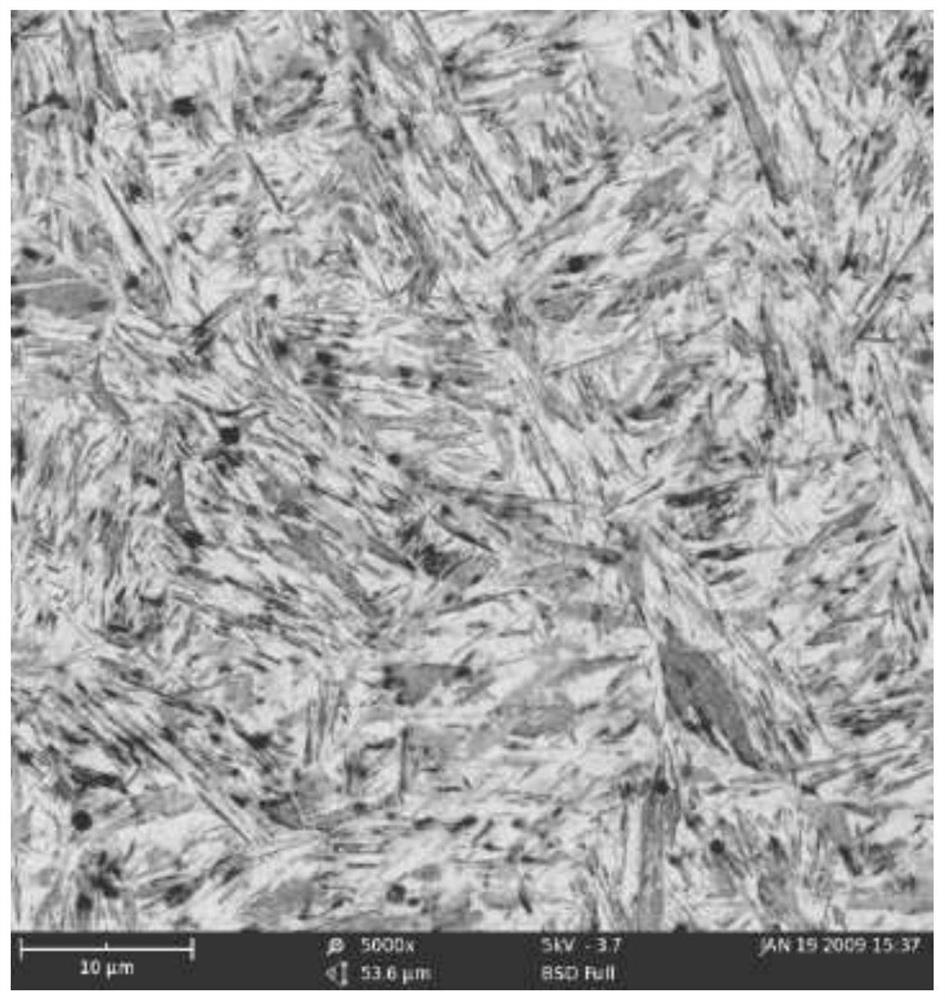

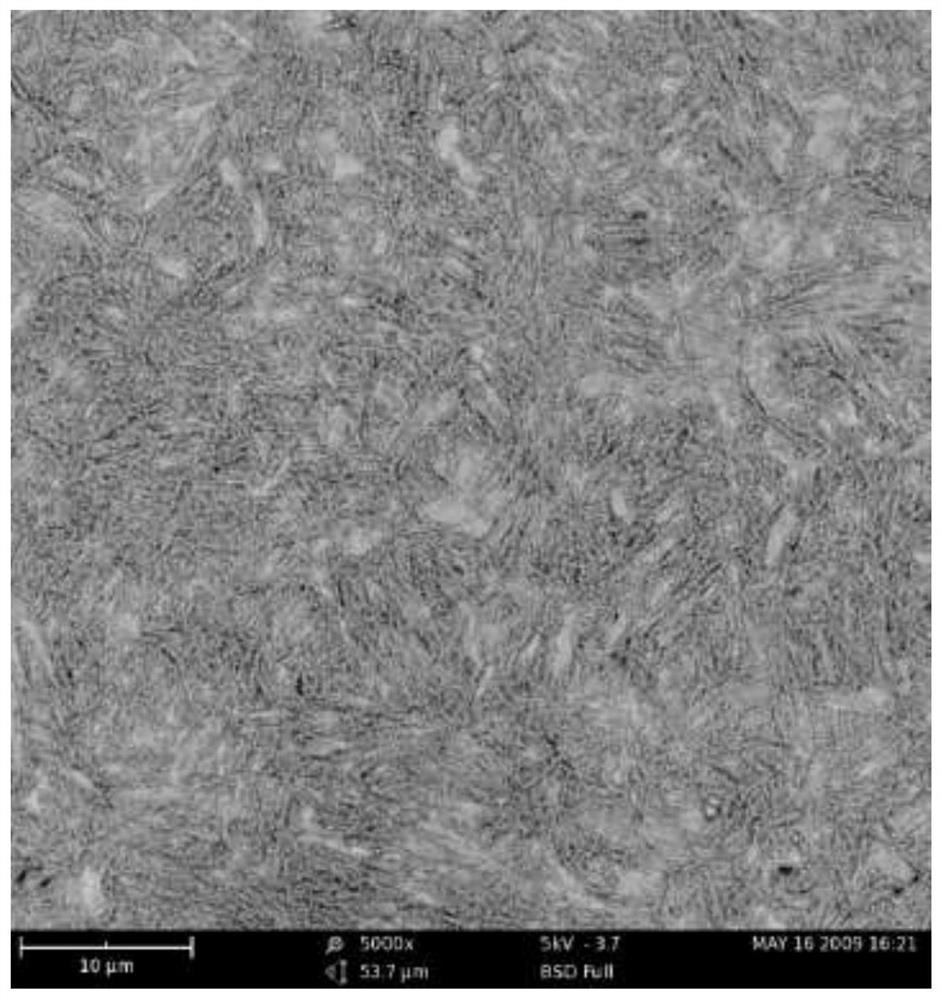

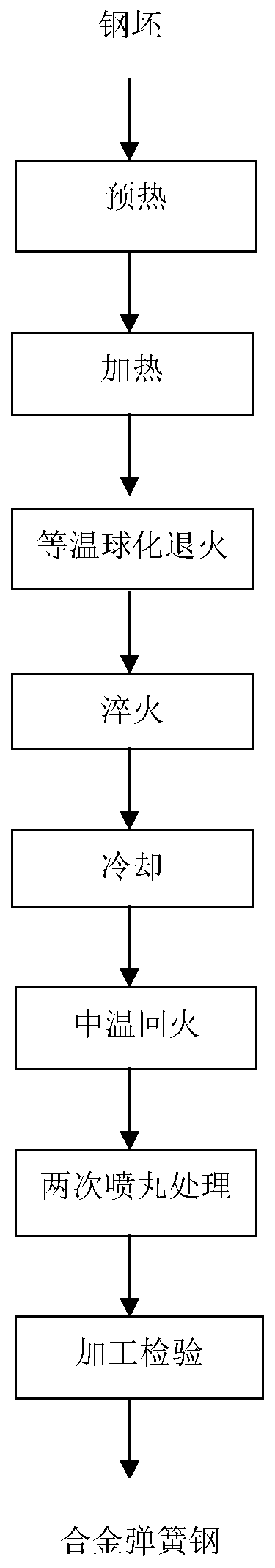

Heat treatment process of alloy spring steel

InactiveCN111593190AAvoid insufficient spheroidizationEvenly distributedFurnace typesHeat treatment furnacesTemperingCarbide

The invention provides a heat treatment process of alloy spring steel. The process comprises the steps of performing preheating, heating, isothermal spheroidizing annealing, quenching, cooling, medium-temperature tempering, two times of shot blasting treatment and processing inspecting on a steel billet. According to the method, the temperature of isothermal spheroidizing annealing is controlled to be 650-700 DEG C, and the annealing time is 2-3 hours, so that the phenomenon that part of carbide cannot be fully spheroidized is avoided, the hardness of the spring steel is reduced to 32-48 HRC,the problem that deforming or cracking is prone to occur in subsequent heat treatment is solved, the corresponding tensile strength is reduced to 1810-1930 MPa, the using stress amplitude is improvedby 10 %-15 % compared with that of spring steel prepared through a traditional technology, and the novel spring steel has higher ductility and toughness; the quenching temperature is controlled to reduce the quenching stress and reduce the deformation, so that a high yield ratio and good comprehensive mechanical properties are obtained; and the cooling mode is controlled, and the two times of shotblasting treatment is adopted, so that the surface of the spring steel is strengthened, the surface quality of the spring steel is improved, the residual compressive stress is generated on the surface, and the the spring steel is improved in fatigue strength and prolonged in service life.

Owner:江苏联峰实业有限公司

Manufacturing method of high-yield non-bonding prestress steel bar

ActiveCN103639650ASpread evenlyAvoid excessive intergranular corrosion and pitting corrosionDuctilityManufacturing engineering

The invention discloses a manufacturing method of a high-yield non-bonding prestress steel bar. The steel bar has the advantages of bringing convenience to manual construction, being low in cost, high in strength, good in ductility and high in delayed fracture and saving steel, has ideal insulation effects, and can reduce environment pollution. According to the manufacturing method, steel structure anticorrosive paint is adopted, good mechanical performance and excellent anti-corrosion performance are achieved, stability for weather, oil water mixtures and the like is good, various colors can be mixed according to needs, the steel bar can have good visual effects after the steel anticorrosive paint is used, attractiveness and elegance in decoration are achieved, and cost can also be saved due to the fact that the paint has long anti-corrosion time.

Owner:TIANSHUN GROUP

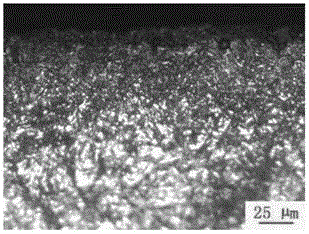

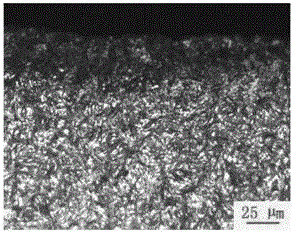

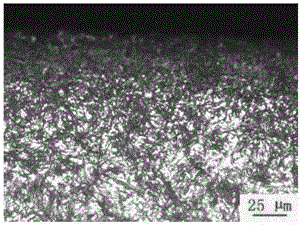

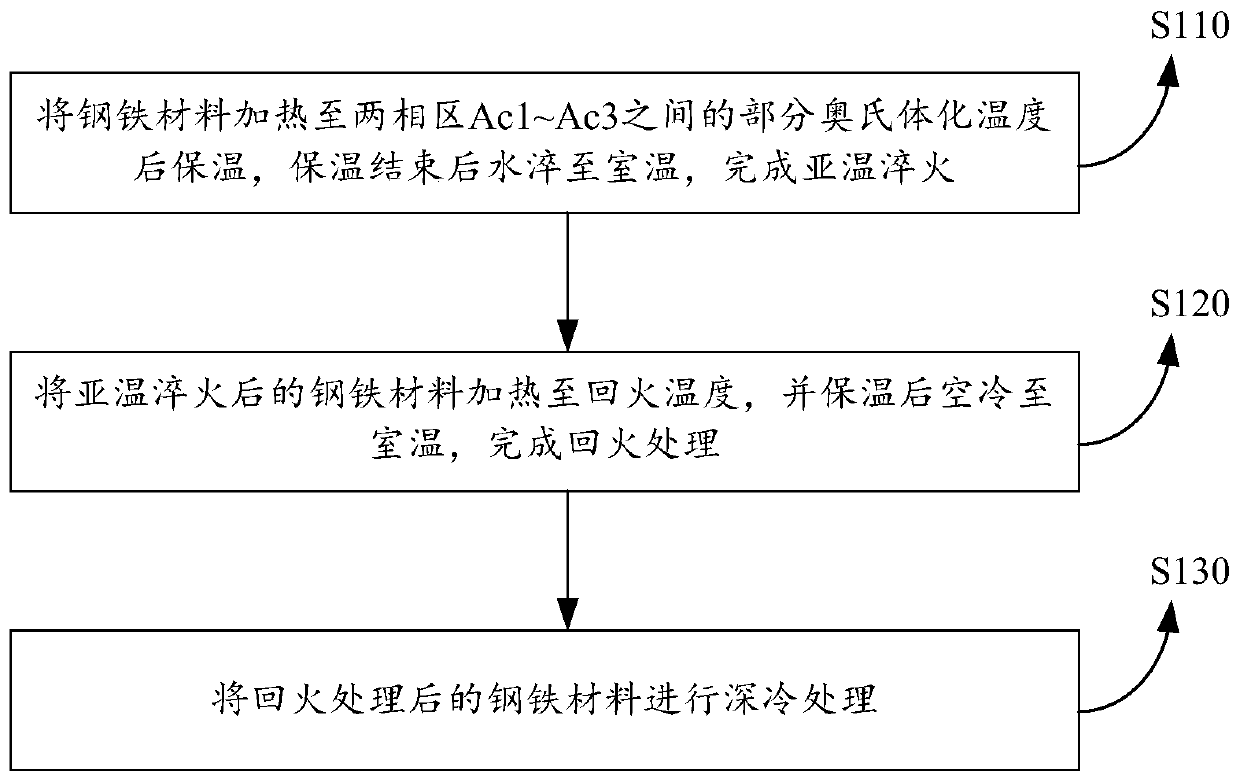

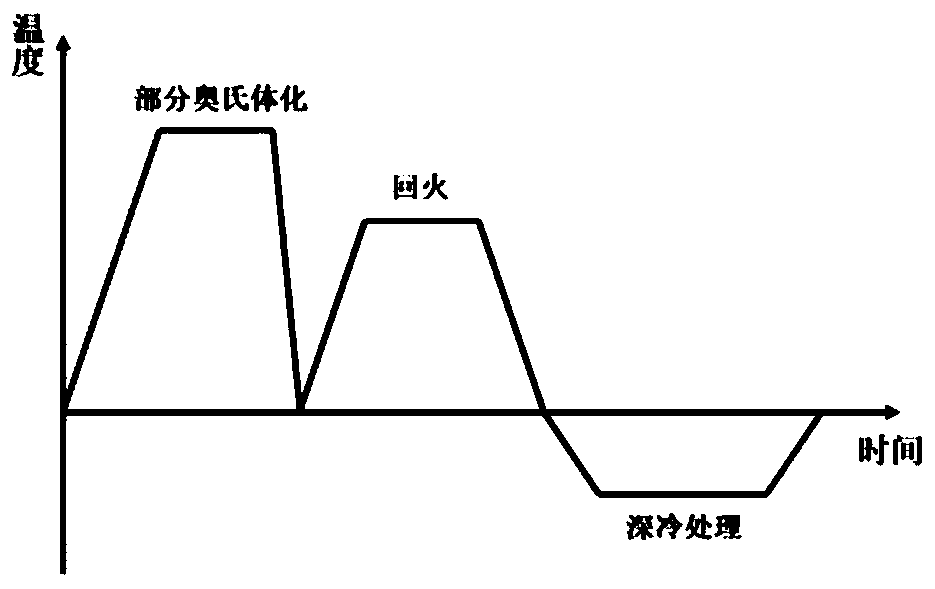

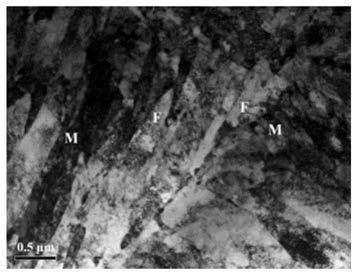

Strengthening and toughening treatment method of steel and iron material

The invention provides a strengthening and toughening treatment method of a steel and iron material. Subcritical quenching and subzero treatment are combined, the steel and iron material is subjectedto subcritical quenching treatment, a microstructure is a ferrite and martensite biphasic structure, then, tempering treatment is carried out, quenching stress can be reduced, meanwhile, the effect ofprecipitation of certain carbide can be achieved, the subzero treatment is carried out, a ferritic structure can be refined, the ferrite-martensite orientation relationship can be improved, the phenomenon that in the use process of the steel and iron material, due to a rough and uneven structure, the use property of a workpiece is reduced can be avoided, the toughness of the steel and iron material can be effectively improved, the subzero treatment is carried out after tempering, the influence of the subzero treatment on supersaturated martensite decomposition in the tempering treatment process can be avoided, meanwhile, through the shrinkage effect of crystal lattices at the low temperature, precipitation of carbide particles can be further promoted, and the strength and the hardness ofthe steel and iron material can be effectively improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

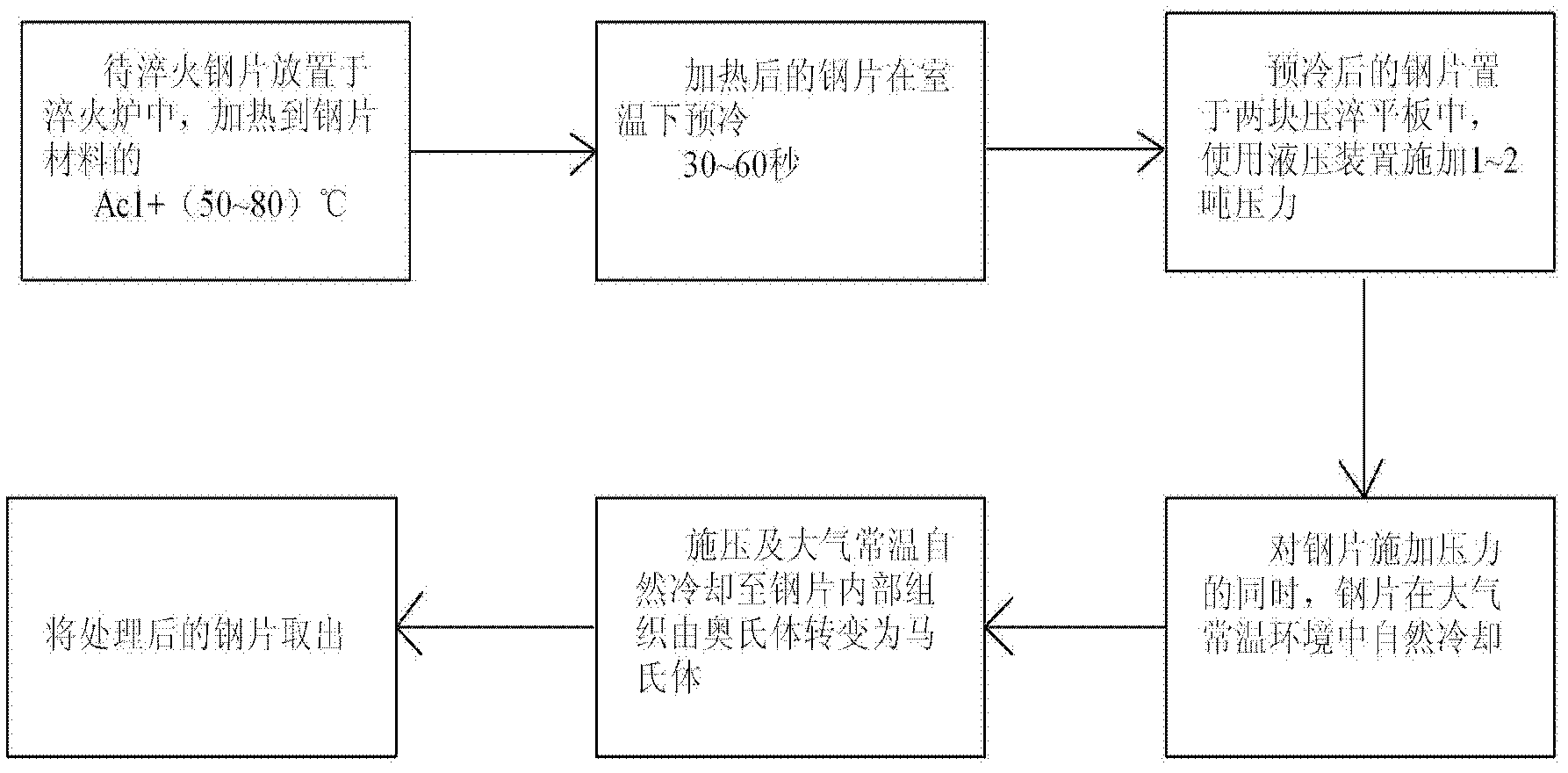

Pre-cold pressing quenching correction technology for die steel

InactiveCN103103330AEasy CalibrationReduce deformationFurnace typesHeat treatment furnacesThermal treatmentQuenching

The invention discloses a pre-cold pressing quenching correction technology for a die steel. The technology, which quits the manner of the traditional thermal treatment process that the die steel needs to be insulated for a while after heating, comprises the steps of pre-cooling the die steel part after being heated to Ac1+(50-80)DEG C of the material, and carrying out pressing quenching cooling correction on the die steel directly without heat preservation. According to the technology, the plasticity and toughness of an austenite material are fully utilized, the quenching stress of the die steel being thermally treated is lowered to the minimum, the die steel deforms slightest, and then the die steel workpiece is simple and easy to correct.

Owner:昆山鑫昌泰模具科技有限公司

600 MPa-grade-and-above high strength steel bars and reinforced concrete application method thereof

ActiveCN103643147AImprove wear resistanceIncrease resistanceConstruction materialGirdersReinforced concreteRebar

The present invention discloses 600 MPa-grade-and-above high strength steel bars and a reinforced concrete application method thereof. According to the present invention, 0.4-0.65% by weight of Mn, 0.6-0.7% by weight of Cr, 0.15-0.3% by weight of Mo, 0.5-0.65% by weight of Ni, and 0.25-0.4% by weight of V are added to the steel bar component so as to improve strength, toughness, corrosion resistance, wear resistance and impact resistance of the steel bar, make the steel bar be compact, improve hardenability of the steel, and improve atom activities of the elements such as C and N, such that deformation and cracking can be reduced; and the application method of the diameter 6 mm and diameter 22 mm 600 MPa-grade-and-above high strength steel bars in the reinforced concrete has advantages of steel bar consumption reduction, carrying capacity increase, and crack extension resistance.

Owner:江苏森林建筑新材料股份有限公司

A method for manufacturing chromium-molybdenum low-alloy prestressed aluminum-clad steel wire

ActiveCN103643146BImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesChromium nickelManganese

The present invention discloses a chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel is adopted as a billet material and comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method designed by the present invention, strength and toughness of the steel wire can be substantially increased, a corrosion resistance degree of the steel wire can be enhanced, and a service life can be prolonged.

Owner:TIANSHUN GROUP

Heat treatment deformation control method for 23Co14Ni12Cr3MoE steel large part

The invention discloses a heat treatment deformation control method for a 23Co14Ni12Cr3MoE steel large part. The heat treatment deformation control method comprises the steps of stress relief tempering, gas-cooled quenching, ice-cold treatment, low-temperature tempering, correction, final tempering and the like. According to the heat treatment deformation control method, vacuum gas-cooled quenching is adopted to replace oil-cooled quenching with a relatively high cooling speed, the hardness, tensile strength, yield strength, fracture toughness and the like of the part after heat treatment allmeet the technical standard requirements, moreover, the generation of quenching stress can be reduced, the part is basically not deformed after heat treatment, and the size precision meets the designrequirements.

Owner:SHENYANG AIRCRAFT CORP

A carburizing and quenching method for heavy-duty gears

ActiveCN110331260BReduce quenching stressReduce stressSolid state diffusion coatingFurnace typesTemperingThermal insulation

The invention discloses a heavy-duty gear carburizing and quenching method, and relates to the technical field of special steel making. The method comprises the following steps that a gear workpiece is subjected to carburizing treatment in a gas carburizing furnace, and then is subjected to austenitizing heating thermal insulation after getting out of furnace; then the gear workpiece is subjectedto precooling quenching; the gear workpiece is subjected to water-base medium quenching, salt bath quenching and fog cooling in sequence; and the gear workpiece is washed after fog cooling is finished, and then is subjected to tempering treatment. With the heavy-duty gear carburizing and quenching method, the problem that for a large-control-section gear made of a low-hardenability material, a quenching method in the prior art cannot achieve the purposes of making the performance of a center part and a gear root excellent and having effectively control over stress type cracking at the same time is solved, it is achieved that a heavy-duty gear is controllable in carburizing and quenching deformation without cracks, and the hardness, the texture, a hardened layer and the dynamic performanceof the heavy-duty gear all meet the technological design requirements.

Owner:CHANGZHOU TIANSHAN HEAVY IND MACHINERY

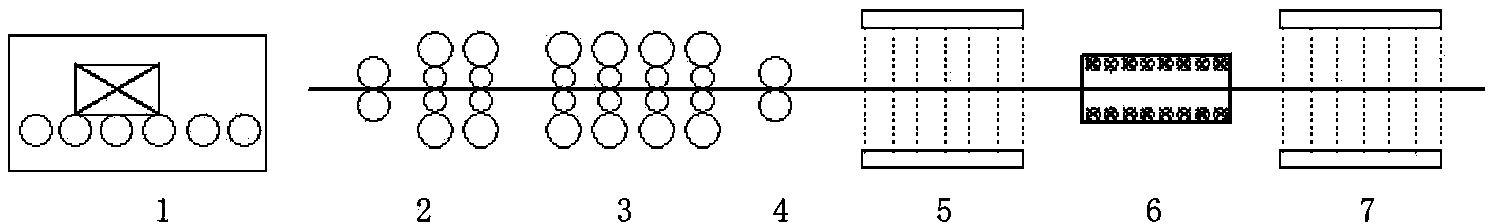

Energy-saving metal heat treatment processing equipment

InactiveCN113564313AAvoid wasteful situationsShorten heating timeFurnace typesHeat treatment furnacesHeating furnaceEnergy consumption

The invention discloses energy-saving metal heat treatment processing equipment. The energy-saving metal heat treatment processing equipment comprises a base, a heating furnace, a first fan, a connecting block, a first connecting pipe, a second fan, a three-way pipe, a filter plate, a preheating device, a low-temperature tempering device and a heat storage device; the top of the base is fixedly connected with the bottom of a heat treatment chamber; the heating furnace is mounted in the heat treatment chamber; the heating furnace is electrically connected with a controller through a wire; one side of the first fan is fixedly embedded into one side of an air inlet pipe; the other side of the first fan is fixedly embedded into one side of an air outlet pipe; the first fan is fixed to one side of the heating furnace through hexagon bolts; the other side of the air outlet pipe penetrates through the outer wall of one side of the heating furnace and extends into the heating furnace; and the other side of the air inlet pipe penetrates through one side of the inner wall of the heat treatment chamber and extends to the outer wall of the heat treatment chamber. According to the energy-saving metal heat treatment processing equipment, as the preheating device is arranged, the part heat treatment heating time is shortened through the preheating device, so that the energy consumption of the heat treatment equipment is reduced.

Owner:盐城刚达机械有限公司

Isothermal quenching heat treatment process method for third-generation bearing steel

The invention relates to an isothermal quenching heat treatment process method for third-generation bearing steel. The isothermal quenching heat treatment process method comprises the following stepsthat A, solution treatment is carried out; B, isothermal quenching is conducted, specifically, when the thickness h of a steel block is smaller than or equal to 20 mm, constant-pressure and constant-flow-speed gas quenching is adopted, specifically, the pressure is 0.2-1.5 MPa, the flow speed is 0.1-0.8m / s, the cooling time is smaller than or equal to 15 min, the cooling speed is 60-100 DEG C / min,and heat preservation is conducted for 1-2 h after the steel block is cooled to the isothermal temperature of 140-280 DEG C; then air cooling is carried out to room temperature; and when the thickness h of the steel block is larger than 20 mm and smaller than or equal to 50 mm, high-pressure high-flow-speed gas quenching and low-pressure low-flow-speed gas quenching are adopted for segmented circulating cooling. By adopting the isothermal quenching heat treatment process, the plasticity and toughness of the third-generation bearing steel can be improved, so that the structure components are uniform and environment-friendly.

Owner:BEIHANG UNIV +1

Isothermal transformation thermal treatment method for superhigh-intensity steel

ActiveCN102864299BImprove mechanical propertiesSave energyHeat treatment process controlRoom temperatureUltimate tensile strength

The invention discloses an isothermal transformation thermal treatment method for superhigh-intensity steel, which comprises the following steps of: directly quenching rolled steel material, wherein the initial quenching temperature is 850-900DEG C, and the final quenching temperature is 150-250DEG C; preserving the temperature of the quenched steel material for 0.1-0.5min / mm, wherein the mm is the unit of the thickness or the radius of the steel material; heating and tempering the steel material of which the temperature is preserved, wherein the on-line tempering temperature preservation temperature range is 200-350DEG C, the tempering temperature preservation time is 2-6min / mm, and the mm is the unit of the thickness or the radius of the steel material; and after tempering treatment, cooling the steel material to the room temperature.

Owner:LAIWU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com